Why Person Refrigerated Cooling Systems Are Revolutionizing Temperature Control

A person refrigerated cooling system is a portable, body-worn device that uses micro-refrigeration technology to provide localized cooling directly to the human body. Unlike traditional air conditioning that cools entire spaces, these systems target specific areas through liquid-cooled garments, ice packs, or thermoelectric modules.

Key Types of Person Refrigerated Cooling Systems:

- Wearable micro-chillers - Backpack units with vest garments

- Ice-based systems - Portable coolers with circulating cold water

- Thermoelectric devices - Solid-state cooling using Peltier effect

- Medical cooling wraps - Therapeutic temperature control for patients

- Mortuary transport coolers - Portable refrigeration for remains preservation

As personal cooling technology has evolved from its origins in astronaut suits over 60 years ago, these systems now serve critical roles across medical facilities, funeral homes, and industrial applications. The technology addresses a fundamental challenge: providing precise temperature control where traditional refrigeration systems are impractical or impossible to install.

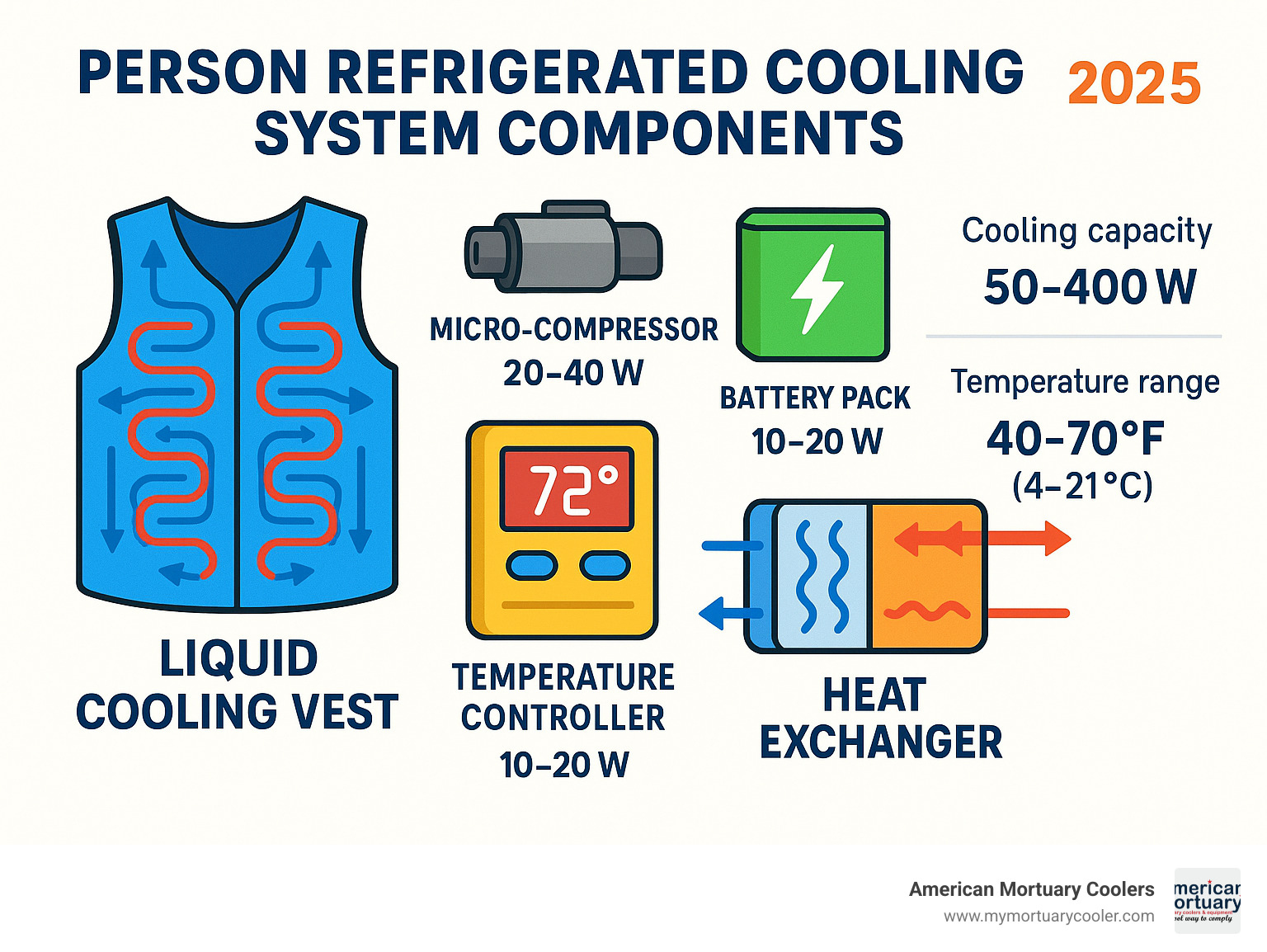

Modern person refrigerated cooling systems typically deliver 50-400 watts of cooling capacity while maintaining temperatures between 40-70°F (4-21°C). They operate on various power sources including rechargeable batteries, vehicle DC power, or standard AC outlets, making them adaptable to diverse environments from hospital operating rooms to mortuary transport vehicles.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in person refrigerated cooling system solutions for funeral homes and medical facilities. With experience in custom refrigeration equipment, I've helped hundreds of funeral directors steer the complexities of portable cooling technology to improve their service capabilities and operational efficiency.

Person refrigerated cooling system definitions:

What Is a Person Refrigerated Cooling System?

A person refrigerated cooling system is essentially a tiny, portable air conditioner designed specifically for cooling human bodies rather than entire rooms. Think of it as your personal cooling companion that follows you wherever you go.

These systems work by using micro-refrigeration technology to move heat away from your body through various cooling methods. Some use the same vapor-compression cycle you'd find in your home refrigerator, just scaled down to fit in a backpack. Others rely on thermoelectric cooling or special cooling packs that change from solid to liquid to absorb heat.

The beauty of these systems lies in their precision. While your home AC might cool 2,000 square feet, a person refrigerated cooling system focuses all its energy on cooling just you. Most systems work by circulating cooled liquid through tiny tubes woven into special garments or cooling pads. This creates direct contact between the cooling source and your skin, making heat transfer incredibly efficient. The result? You can drop your skin temperature by 15-40°F while using a fraction of the power needed for traditional air conditioning.

According to scientific research on refrigeration fundamentals, these systems operate on the same basic thermodynamic principles as larger refrigeration units, just engineered for body-centric cooling applications.

How It Differs From Traditional Refrigeration & Air Conditioning

The difference between a person refrigerated cooling system and your home AC is like comparing a precision surgical tool to a sledgehammer. Traditional refrigeration systems are built to handle massive cooling loads measured in tons. One ton of refrigeration equals 12,000 BTU per hour – enough to cool a decent-sized house. Your personal cooling system, on the other hand, typically operates with just 50-400 watts of cooling power.

The real magic happens through localized cooling rather than trying to cool all the air around you. Instead of cooling a room and hoping you feel comfortable, these systems provide direct skin contact cooling. This direct approach makes personal cooling systems about 75% more energy-efficient than cooling an equivalent space with traditional HVAC.

Plus, you can't exactly carry your central air conditioning system to a job site or wear it while riding a motorcycle. Personal cooling systems are designed for mobility, often running on battery power for 4-8 hours without needing to plug into the wall.

Evolution From Space Suits to Everyday Wearables – the person refrigerated cooling system journey

Personal cooling technology has quite the origin story. It all started over 60 years ago when NASA engineers were trying to figure out how to keep astronauts from overheating in their space suits. The solution was surprisingly simple: circulate cool water through tubes sewn into the astronauts' undergarments. Military engineers quickly saw the potential and adapted the technology for fighter pilots dealing with extreme G-forces and cockpit temperatures.

For decades, this cooling technology remained locked away in aerospace and military applications. Everything changed in the 1990s when miniaturization technology finally caught up with the cooling concept. Suddenly, engineers could build lightweight compressors, long-lasting batteries, and advanced materials that made portable cooling systems actually portable.

Today's consumer adoption has exploded across industries. Modern systems weigh as little as 2.5 kg for backpack units and can maintain temperature control within ±1°C. What started as a solution for space exploration has become an everyday tool for everyone from construction workers to medical patients.

Core Technologies & Key Components

When you peek inside a modern person refrigerated cooling system, you'll find impressive engineering packed into a surprisingly compact space. The magic happens through several key components working together. At the heart of every system, you'll find the cooling engine - either a tiny compressor or a solid-state thermoelectric module. These powerhouses can deliver 150-400 watts of cooling capacity while sipping just 100-200 watts of electrical power.

The fluid circulation system is where things get interesting. Compact pumps push coolant through networks of small tubes woven into garments or cooling pads. These pumps move about 800-1200 ml of coolant per minute while using less than 10 watts of power.

Smart control electronics act like the brain of the system, monitoring temperatures and adjusting cooling output to keep you comfortable. Meanwhile, advanced battery systems provide hours of portable operation, and the thermal interface garments ensure the cooling gets exactly where you need it most.

Vapor-Compression Micro Chillers (primary person refrigerated cooling system)

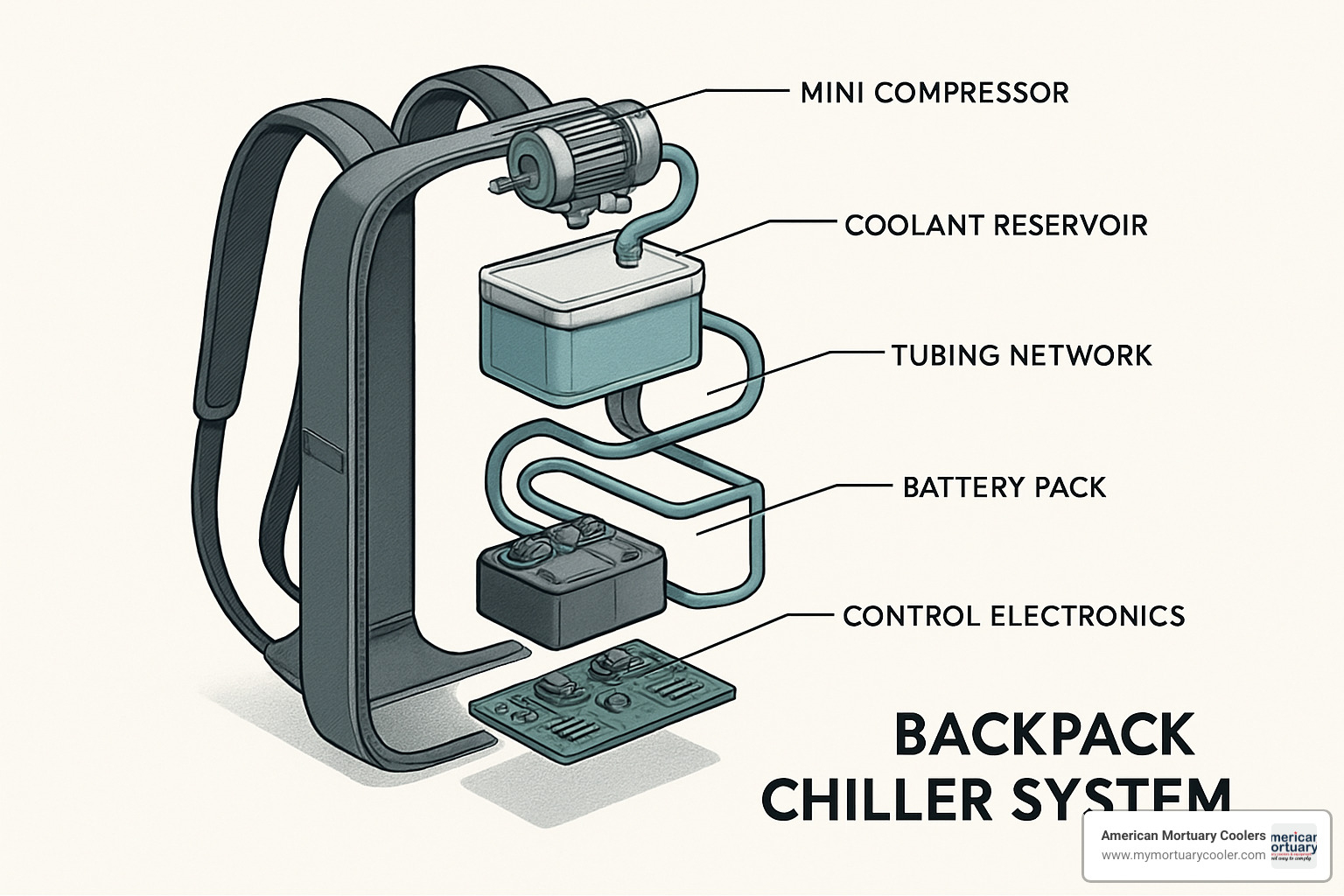

Vapor-compression systems are the heavy hitters in the person refrigerated cooling system world. They work just like your home refrigerator, but shrunk down to fit in a backpack. These systems use tiny compressors that are marvels of miniaturization.

The refrigeration cycle uses environmentally-friendly refrigerants like R-134a or newer alternatives such as R-1234yf. The system includes a micro-condenser with forced-air cooling, an expansion device (usually a simple capillary tube), and an evaporator that connects to your cooling garment through a secondary coolant loop.

What makes these systems special is their ability to reach temperatures as low as 5°C (41°F) while maintaining rock-solid temperature control within ±1°C. The entire system weighs just 2.5-4 kg in a backpack configuration, making it practical for extended wear in demanding environments.

The coefficient of performance (COP) ratings between 1.5-2.5 mean these systems are remarkably efficient - they produce more cooling than the electrical energy they consume.

Thermoelectric & Solid-State Options

Thermoelectric cooling systems take a completely different approach using the Peltier effect. When electricity flows through bismuth telluride (Bi2Te3) semiconductors, it creates a temperature difference between the hot and cold sides. No moving parts, no refrigerants, no noise - just solid-state cooling magic.

These systems are the quiet heroes of personal cooling. They deliver 50-150 watts of cooling capacity while consuming 75-200 watts of electrical power. While that's less efficient than vapor-compression systems, the trade-off comes with serious benefits: silent operation, incredible reliability, and the ability to both cool and heat.

The challenge with thermoelectric systems is managing the hot side effectively. Poor heat rejection can dramatically reduce cooling performance, so these systems work best in moderate ambient temperatures with good ventilation.

Ice-Based vs Chiller-Based Cold Sinks

Sometimes the simplest solutions are the most neat. Ice-based systems use the age-old principle of phase-change cooling - as ice melts, it absorbs heat. These systems pump cold water from insulated ice reservoirs through cooling garments, providing effective cooling with minimal complexity.

The beauty of ice-based systems lies in their simplicity and lower cost. However, they have a built-in limitation: operating duration of 4-8 hours depending on ice load and ambient conditions. As the ice melts and water temperature rises, cooling capacity gradually decreases.

Chiller-based systems use active refrigeration to maintain consistent temperatures throughout operation. While more complex and expensive, they provide unlimited operating duration when connected to external power and deliver consistent cooling performance regardless of how hot it gets outside.

| System Type | Cooling Duration | Temperature Control | Weight | Cost |

|---|---|---|---|---|

| Ice-Based | 4-8 hours | Variable (decreasing) | 3-5 kg | Low |

| Chiller-Based | Unlimited* | Precise (±1°C) | 2.5-4 kg | High |

*When connected to external power

Applications & Use Cases of Person Refrigerated Cooling Systems

When you think about cooling systems, your first thought probably isn't about wearing one. But person refrigerated cooling systems have quietly revolutionized how we handle extreme heat in some pretty amazing ways.

These portable cooling units have found their way into operating rooms where surgeons need to stay cool during lengthy procedures, onto factory floors where workers face dangerous heat levels, and into funeral homes where proper temperature control can make all the difference in providing dignified care.

The beauty of these systems lies in their flexibility. Unlike traditional air conditioning that tries to cool entire rooms, person refrigerated cooling systems go where they're needed most. From wearable medical therapy devices that help stroke patients to mortuary transport solutions that ensure proper care during difficult circumstances, these systems solve problems that seemed impossible just a few decades ago. Body cooling solutions have evolved far beyond their space suit origins to become essential tools across multiple industries.

Medical & Therapeutic Cooling

In hospitals and clinics, person refrigerated cooling systems are saving lives in ways that might surprise you. After a heart attack or stroke, doctors sometimes need to lower a patient's body temperature quickly to protect the brain from damage. These cooling systems can reduce core body temperature by 2-4°C in a controlled, safe manner.

Post-surgery cooling has become increasingly popular because it reduces inflammation and helps patients recover faster. Instead of pumping cold air into an entire operating room, surgeons can use targeted cooling systems that keep them comfortable during long procedures.

Patients with conditions like multiple sclerosis or fibromyalgia often struggle with temperature regulation. Personal cooling systems give them back some control over their comfort, allowing them to participate in activities that heat sensitivity might otherwise make impossible.

Funeral & Mortuary Operations (person refrigerated cooling system spotlight)

The funeral industry faces unique challenges when it comes to temperature control. Not every situation allows for traditional refrigeration, yet maintaining proper temperatures is both a regulatory requirement and a matter of professional dignity.

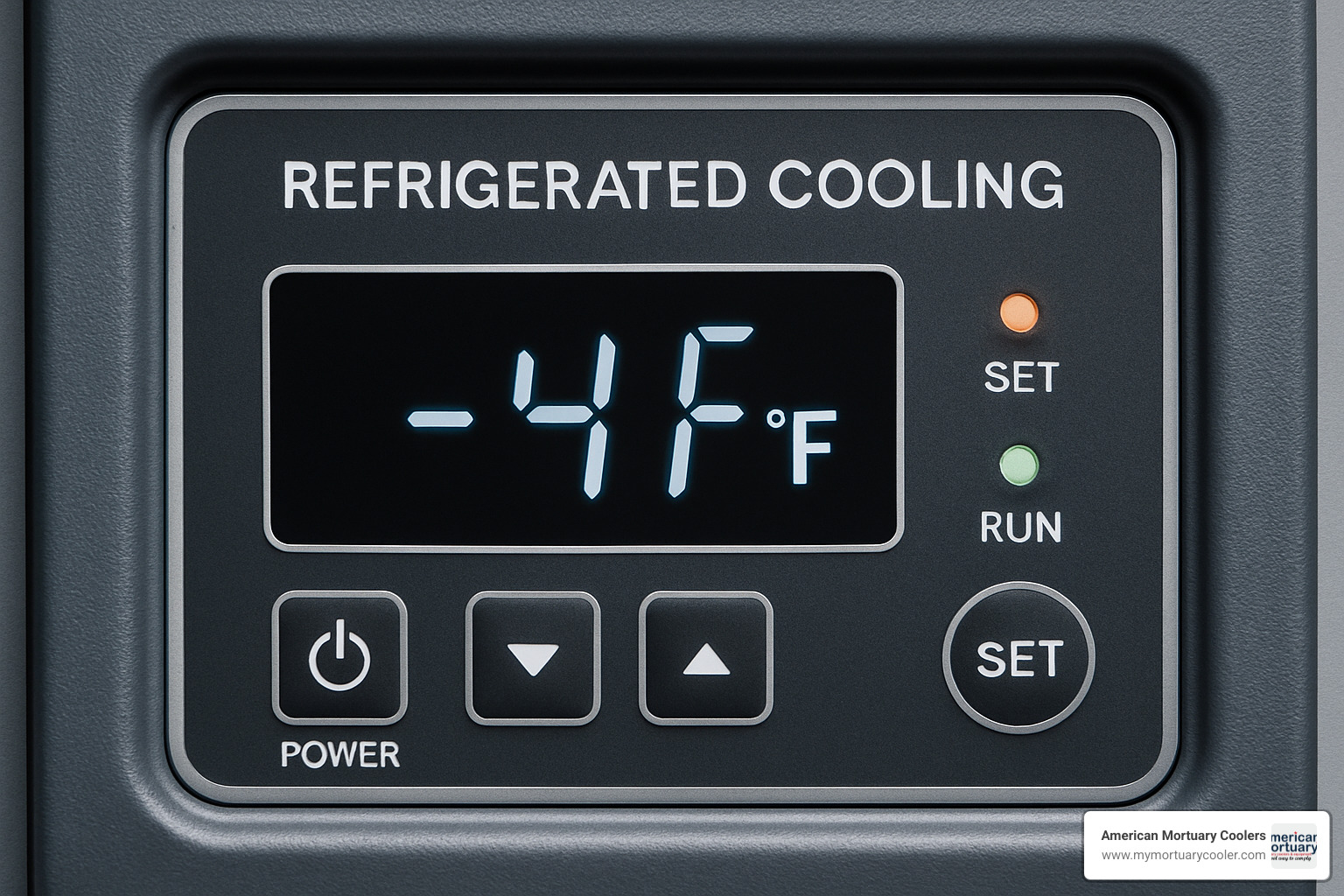

Portable gurney coolers have transformed how funeral homes handle transport and temporary storage situations. These specialized person refrigerated cooling systems maintain temperatures between 35-40°F, ensuring proper preservation whether you're transporting remains between facilities or dealing with temporary storage needs.

We've seen funeral directors struggle with situations where fixed refrigeration simply isn't available - during transport, at remote locations, or when existing equipment fails. Portable cooling systems provide the flexibility needed to maintain professional standards regardless of circumstances.

Compliance requirements from health departments demand specific temperature ranges throughout all phases of care. Modern mortuary cooling systems integrate seamlessly with existing equipment, often mounting directly to stretchers or transport gurneys for continuous temperature control.

Mobile & Wearable Comfort for Workers and Athletes

Industrial workers in extreme heat environments have found person refrigerated cooling systems to be literal lifesavers. Welding operations, foundry work, and emergency response situations often expose workers to temperatures that exceed safe limits for extended periods.

Backpack cooling units allow workers to maintain safe core body temperatures while performing demanding physical tasks. This isn't just about comfort - it's about preventing heat stroke and extending safe working duration in conditions that were previously considered too dangerous.

The sports world has acceptd this technology with enthusiasm. Race drivers dealing with cockpit temperatures over 120°F can now maintain focus and performance throughout long events. Motorcycle riders on summer road trips no longer have to choose between safety gear and heat exhaustion.

What makes these applications so successful is the mobility factor. Unlike traditional cooling systems that tie you to one location, wearable cooling systems go wherever the work or activity takes you.

Design Considerations, Performance & Environmental Impact

When you're designing a person refrigerated cooling system, it's like solving a complex puzzle where every piece needs to fit perfectly. You need enough cooling power to keep someone comfortable, but the system can't be so heavy or bulky that nobody wants to wear it. It's a delicate balancing act between performance and practicality.

The biggest challenge? Making these systems energy efficient enough to run on batteries for hours. According to the Energy Information Administration, air conditioning accounts for a huge chunk of energy consumption. That's why person refrigerated cooling systems focus on targeted cooling rather than cooling entire spaces.

Modern systems typically achieve SEER ratings between 8-12 and COP (Coefficient of Performance) ratings of 1.5-2.5. These numbers mean the system gives you more cooling than the energy it consumes - which is exactly what you want in a battery-powered device.

Environmental impact has become increasingly important in system design. Today's units use low-global-warming-potential refrigerants like R-1234yf instead of older, more harmful options.

Temperature Control & Safety Mechanisms in a Person Refrigerated Cooling System

Safety comes first when you're strapping a refrigeration system to someone's body. Modern person refrigerated cooling systems use sophisticated PID controllers - think of them as smart brains that constantly monitor temperature and make tiny adjustments to keep everything just right.

These systems typically maintain temperatures within ±1°C accuracy, which is pretty impressive for a portable device. But accuracy isn't enough - you need multiple safety layers to prevent problems. Thermal cut-offs automatically shut down the system if temperatures get too cold, while pressure relief systems in vapor-compression units prevent dangerous pressure buildup.

The really smart systems include skin temperature sensors that monitor how the user's body is responding. If your skin temperature drops too much, the system automatically reduces cooling output. Modern units often connect to smartphones through IoT integration, allowing remote monitoring and control.

Challenges: Noise, Vibration, Regulatory & Battery Life

Let's be honest - nobody wants to wear a noisy, vibrating cooling system all day. Noise control is one of the biggest design challenges, especially for vapor-compression systems with mini-compressors. Most systems target noise levels below 48 dBA, which is about as loud as a quiet library.

Engineers achieve this through vibration isolation mounts, sound dampening materials, and careful component selection. Some systems use thermoelectric cooling specifically because it's completely silent, even though it's less energy efficient.

Battery life makes or breaks the practicality of any portable cooling system. Most applications need 4-8 hours of continuous operation, which requires sophisticated battery management systems. Modern lithium-ion batteries provide this duration while keeping weight reasonable.

The regulatory landscape can be tricky to steer. Medical devices need FDA approval, while transport systems must meet UN-DOT battery shipping requirements. European markets require CE marking, and professional applications often need additional safety certifications.

Future Trends & Innovations

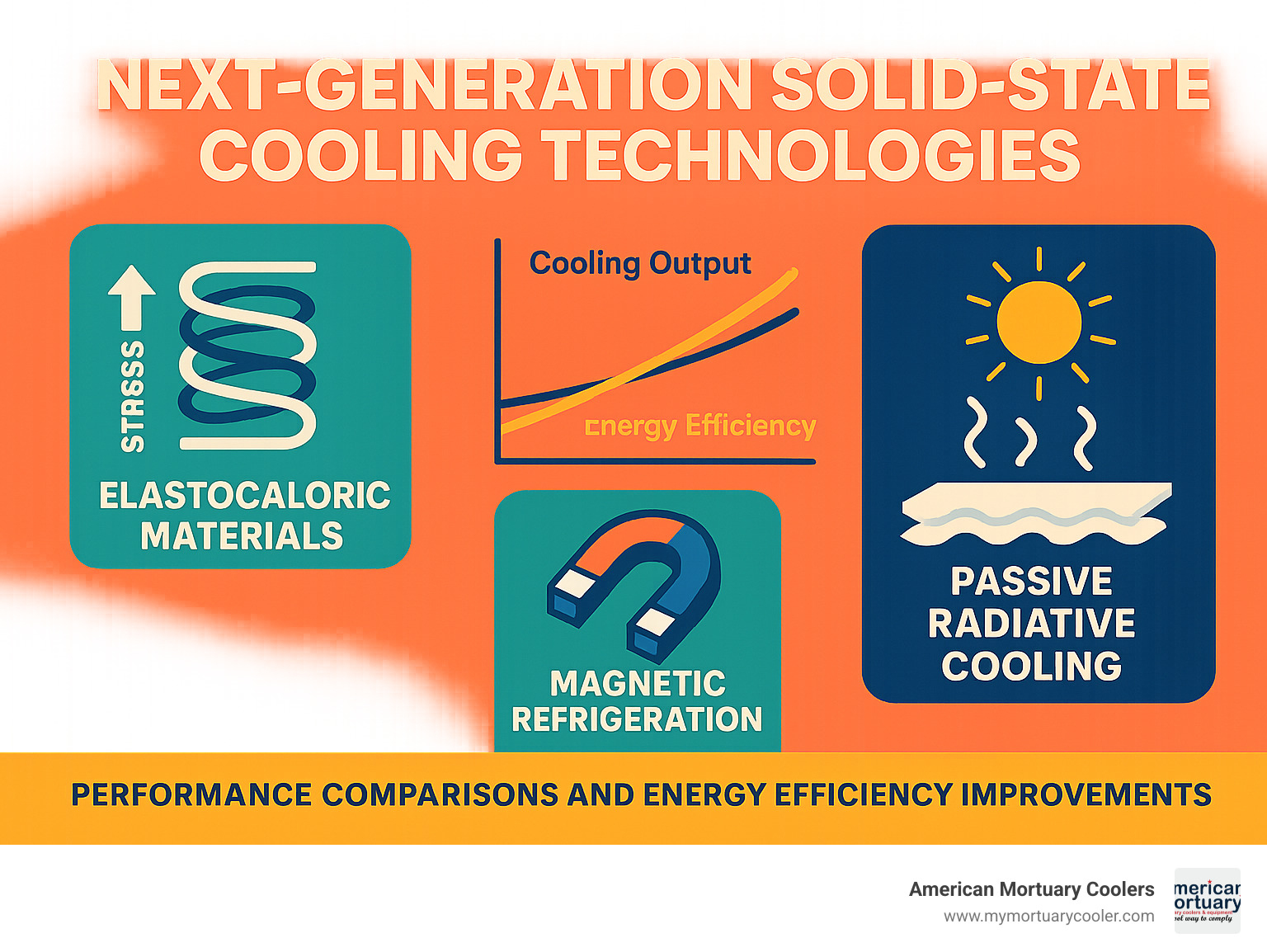

The next generation of person refrigerated cooling systems is taking shape in research labs around the world, and the innovations coming down the pipeline are pretty exciting. We're talking about technologies that could make today's systems look like old-fashioned ice boxes.

Elastocaloric cooling represents one of the most promising breakthroughs. This technology uses special shape-memory alloys that naturally absorb heat when they're stretched or twisted, then release it when they return to their original shape. The beauty of elastocaloric systems is their simplicity - no compressors, no refrigerants, and potentially much lighter weight.

Magnetic refrigeration takes a completely different approach, using materials that heat up and cool down when exposed to changing magnetic fields. While this might sound like science fiction, the technology already works in laboratory settings and could eliminate both mechanical compressors and chemical refrigerants entirely.

Passive radiative cooling fabrics offer perhaps the most neat solution of all. These engineered materials can actually radiate heat directly into space through specific wavelengths that pass right through our atmosphere. While passive radiative materials can't match the cooling power of active systems, they could work alongside traditional person refrigerated cooling systems to reduce overall power consumption and extend battery life.

IoT integration and smart controls are already changing how cooling systems operate. Future systems will learn your body's patterns, predict when you'll need cooling, and automatically adjust based on weather forecasts and your daily schedule.

Imagine a system that knows you have a long shift ahead and pre-cools your vest, or one that automatically orders replacement parts before they fail. The integration of artificial intelligence will enable systems to optimize cooling patterns for maximum efficiency while maintaining comfort.

Frequently Asked Questions about Person Refrigerated Cooling Systems

How long can a person refrigerated cooling system run on one charge?

Most person refrigerated cooling systems will keep you cool for 4-8 hours on a single battery charge. The exact time depends on how hard your system is working - if you're in blazing heat or need extra-cold temperatures, expect shorter run times.

Your battery life gets affected by several things. Setting a lower temperature makes the system work harder and drains power faster. Hot weather outside means more work for the cooling system. If you're moving around a lot, that also impacts how long your battery lasts.

Ice-based systems might seem to last longer, but here's the catch - they get less effective as the ice melts. Chiller-based systems keep the same cooling power throughout the entire battery cycle, so you get consistent comfort until the battery dies.

Need longer operation? Most professional systems can plug into your car's power outlet or wall adapter. Some even have quick-swap battery packs so you can keep going without interruption.

Are refrigerants inside these systems safe for daily wear?

Yes, modern person refrigerated cooling systems are completely safe for daily use. They use refrigerants like R-134a or R-1234yf - the same safe, environmentally-friendly chemicals found in your car's air conditioning system.

The amount of refrigerant in these personal systems is tiny - usually just 65-80 grams. That's much less than what's in your home refrigerator. Plus, these systems are built with sealed designs, so the refrigerant stays completely contained during normal use.

Safety features are built right in. Most systems have leak detection that automatically shuts everything down if there's ever a problem. Medical-grade systems go through FDA approval, and professional units carry CE safety certifications.

What maintenance is required for mortuary transport coolers?

Mortuary transport coolers need regular care to keep working reliably and meet health department standards. The good news is that maintenance is pretty straightforward if you stay on top of it.

Monthly tasks include cleaning and sanitizing all cooling surfaces that might contact remains. Check that refrigerant levels look normal and inspect electrical connections for any wear or corrosion. Replace air filters and clean the condenser coils to keep cooling efficiency high.

Your battery system needs attention too. Test the battery capacity every few months and plan to replace batteries every 2-3 years depending on how often you use the system.

Annual professional service is smart for critical applications. This includes checking the refrigerant system, testing electrical safety, and verifying that temperature controls are still accurate.

At American Mortuary Coolers, we help funeral directors set up maintenance schedules that work for their operations. Proper care keeps your cooling system reliable when you need it most and helps you stay compliant with all the regulations.

Conclusion

The journey of person refrigerated cooling systems tells a fascinating story of human ingenuity. What started as bulky space suit cooling for astronauts has transformed into sleek, powerful devices that literally save lives and improve comfort in countless situations.

These systems have come incredibly far in just a few decades. Today's micro-chillers pack serious cooling power into backpack-sized units that weigh less than a gallon of milk. The precision control that keeps temperatures steady within just one degree would have seemed impossible to those early NASA engineers.

The technology keeps getting better too. New solid-state cooling methods are on the horizon, promising even quieter operation and better efficiency. Smart controls that learn your preferences and adjust automatically are already appearing in premium models.

What really stands out is how these person refrigerated cooling systems solve problems that traditional air conditioning simply can't touch. Whether it's keeping a welder safe in extreme heat, helping a stroke patient recover faster, or ensuring proper care during mortuary transport, these systems work where nothing else will.

For funeral professionals who need reliable cooling solutions, this technology has been a game-changer. Portable systems mean you can maintain proper temperatures anywhere, from transport vehicles to temporary facilities. The peace of mind that comes with consistent, regulated cooling is invaluable when serving families during difficult times.

American Mortuary Coolers has been proud to be part of this cooling revolution, creating custom person refrigerated cooling systems specifically designed for funeral industry needs. Our Tennessee facility focuses on building equipment that funeral directors can count on, with direct shipping across all 48 contiguous states.

The future looks exciting for personal cooling technology. As materials get better and controls get smarter, these systems will become even more essential across medical, industrial, and specialized applications.