Understanding Walk-In Cooler Refrigeration: The Ultimate Guide

If you're looking for a refrigeration unit for walk in cooler, here's what you need to know:

| Key Consideration | What to Look For |

|---|---|

| Size & Capacity | 6,580-39,190 BTUH based on cooler dimensions |

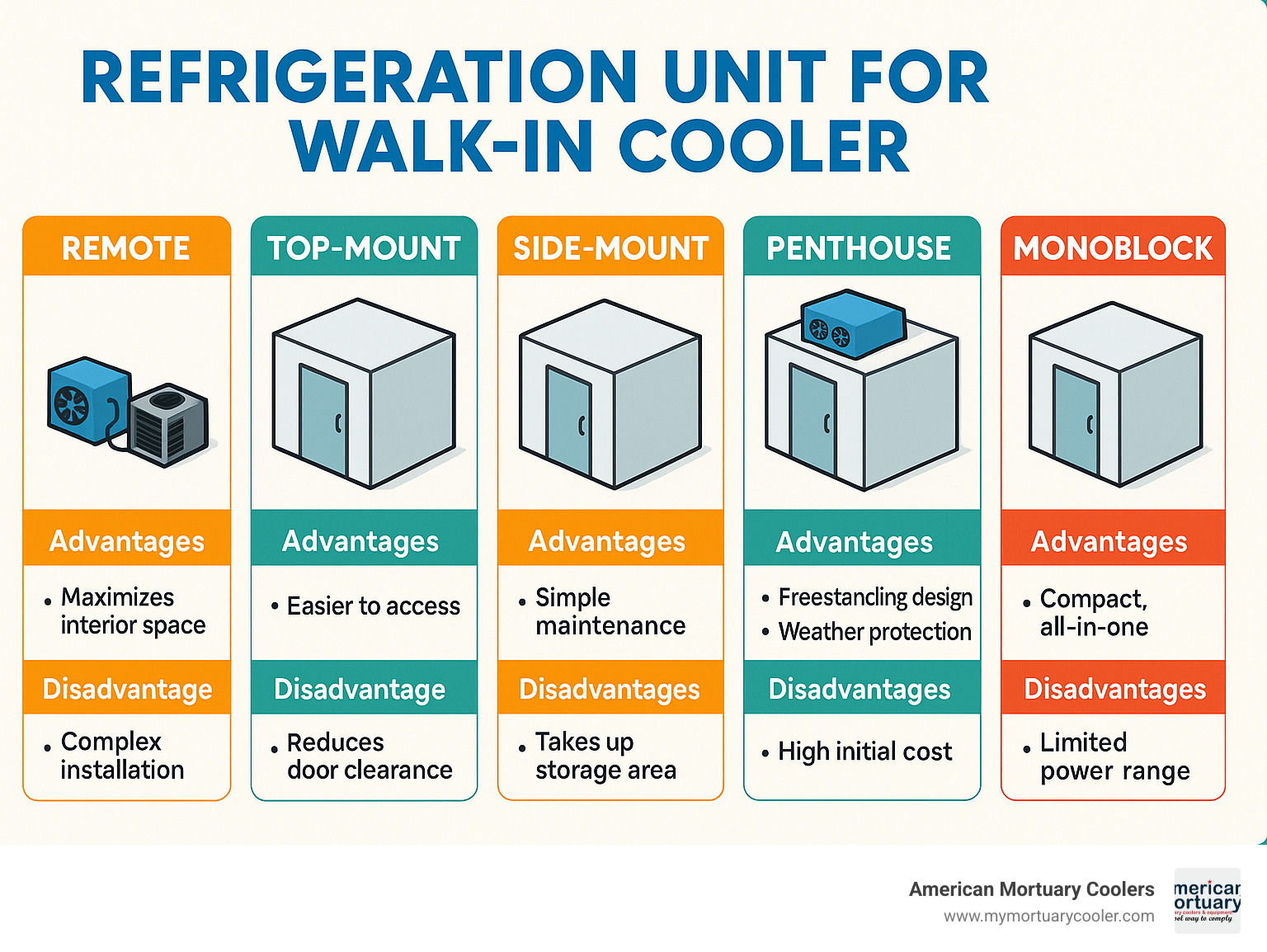

| System Type | Remote, Top-Mount, Side-Mount, Penthouse, or Monoblock |

| Temperature Range | +35°F to +45°F for standard coolers |

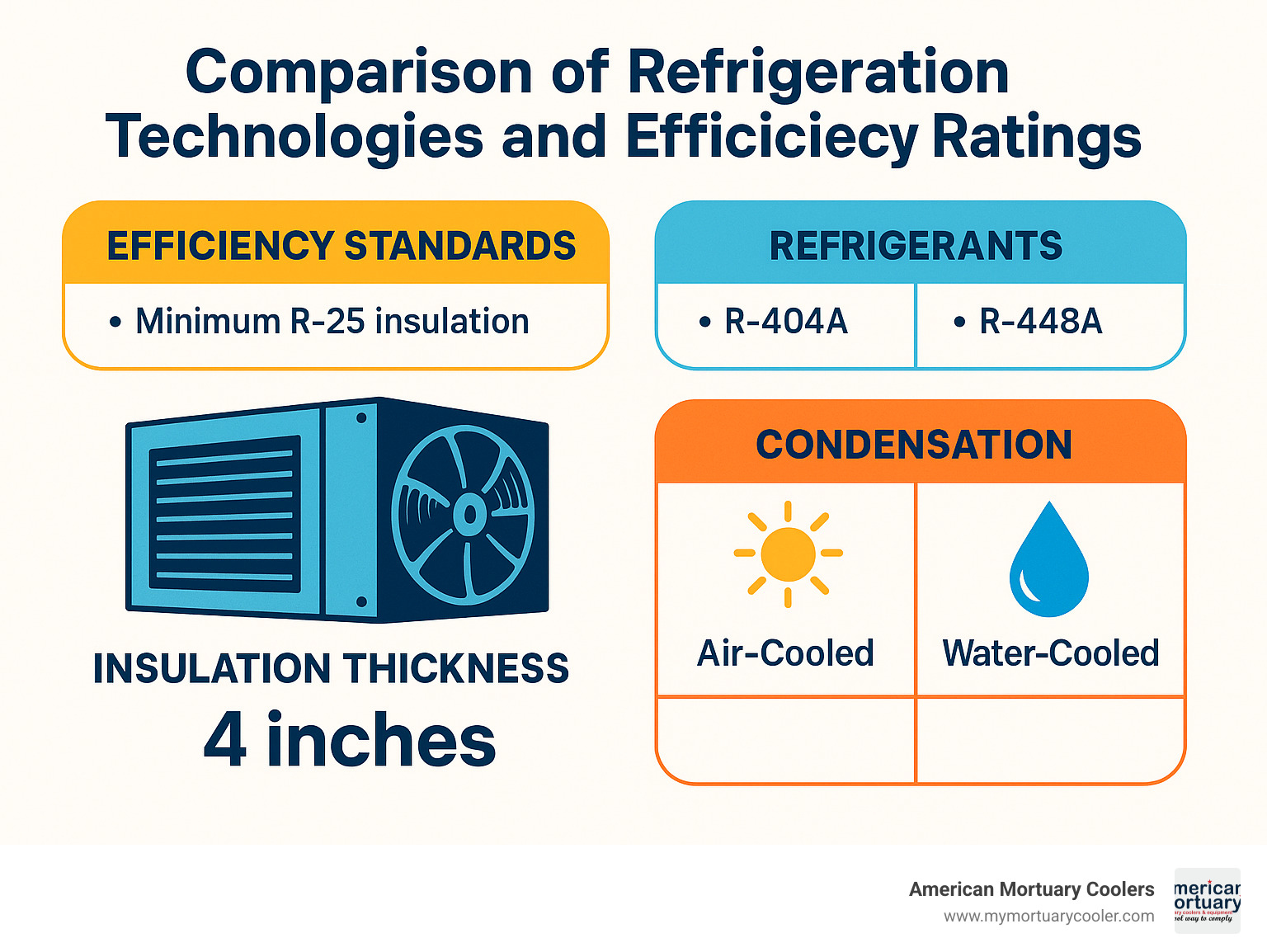

| Insulation | 4 inches of urethane (R-25) is standard |

| Installation | Licensed technician required for most systems |

A refrigeration unit for walk in cooler is the critical component that maintains proper temperature in your commercial cold storage space. Whether you're storing perishable inventory or need specialized temperature control for sensitive items, selecting the right refrigeration system is essential for operational efficiency and product preservation.

Walk-in cooler refrigeration units come in several configurations, each offering different benefits depending on your specific needs. The right unit not only maintains consistent temperatures but also impacts your energy costs, available storage space, and long-term reliability.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience providing refrigeration units for walk in coolers to funeral homes, medical facilities, and other specialized industries requiring reliable cold storage solutions. My expertise comes from years of working with US Cooler and other leading manufacturers to deliver customized refrigeration solutions that meet the exact needs of demanding environments.

Handy refrigeration unit for walk in cooler terms:

How a Refrigeration Unit Keeps Your Walk-In Cooler Cold

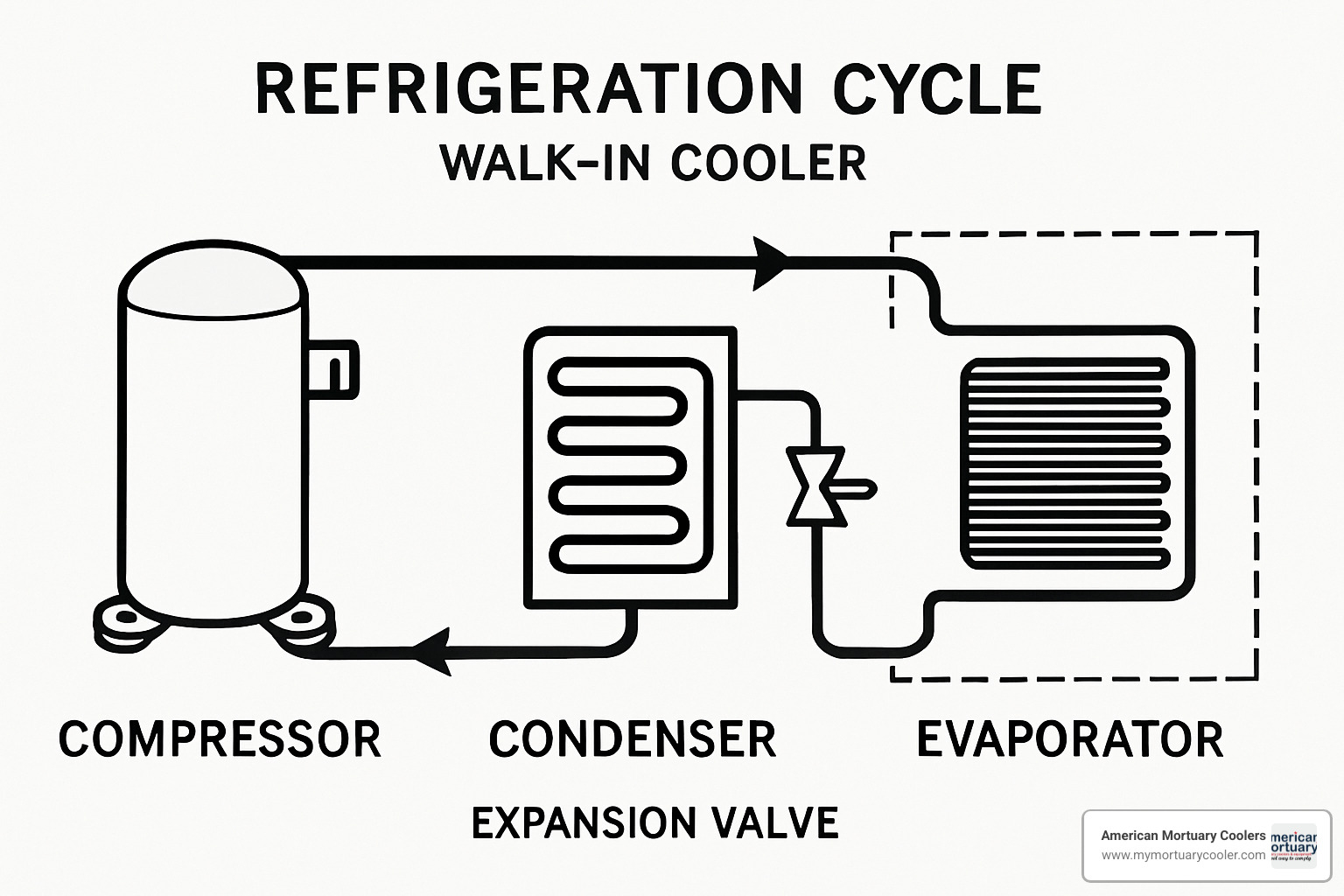

Ever wondered how your refrigeration unit for walk in cooler actually creates that chilly environment? It's a bit like magic, but with science! At its heart, refrigeration works through a clever thermodynamic cycle that moves heat from inside your cooler (where you don't want it) to the outside world (where nobody minds).

The journey begins with the compressor – think of it as the hardworking heart of your system. It squeezes refrigerant gas, heating it up while increasing its pressure. This hot, high-pressure gas then flows to the condenser, where it gives up its heat to the surrounding air and transforms into a liquid. Next, this liquid refrigerant passes through an expansion valve that acts like a pressure release – suddenly dropping both pressure and temperature. Finally, this now-cold liquid enters the evaporator inside your walk-in, where it absorbs heat from the interior air before heading back to the compressor to start the whole dance again.

Today's walk-in cooler systems typically use refrigerants like R-404A or the more eco-friendly R-448A. These specialized fluids efficiently shuttle heat while minimizing environmental impact. Just remember that your system's efficiency is significantly affected by the surrounding temperature – a unit working in a hot Texas summer has to work much harder than one in a cool Minnesota basement.

Insulation plays a huge role too. The industry standard is 4 inches of urethane insulation with an R-value of 25 (R-25). This insulation is your cooler's winter coat, keeping the cold in and the heat out, which means your refrigeration system doesn't have to work overtime.

Key Components & Their Jobs

Your refrigeration unit for walk in cooler is made up of several crucial parts working together in perfect harmony. Let's get to know them:

The compressor is truly the heart of your system. It does the heavy lifting by pressurizing refrigerant gas, and premium units often feature Copeland scroll compressors – the gold standard for reliability. Since the compressor is the biggest energy consumer in your system, its efficiency directly impacts your monthly electric bill.

Next up is the condenser, which works like your body's cooling system when you sweat. It releases heat from the refrigerant to the outside environment. You'll find these in two flavors: air-cooled versions that use fans to blow air across hot refrigerant coils, or water-cooled models that use circulating water to carry away heat.

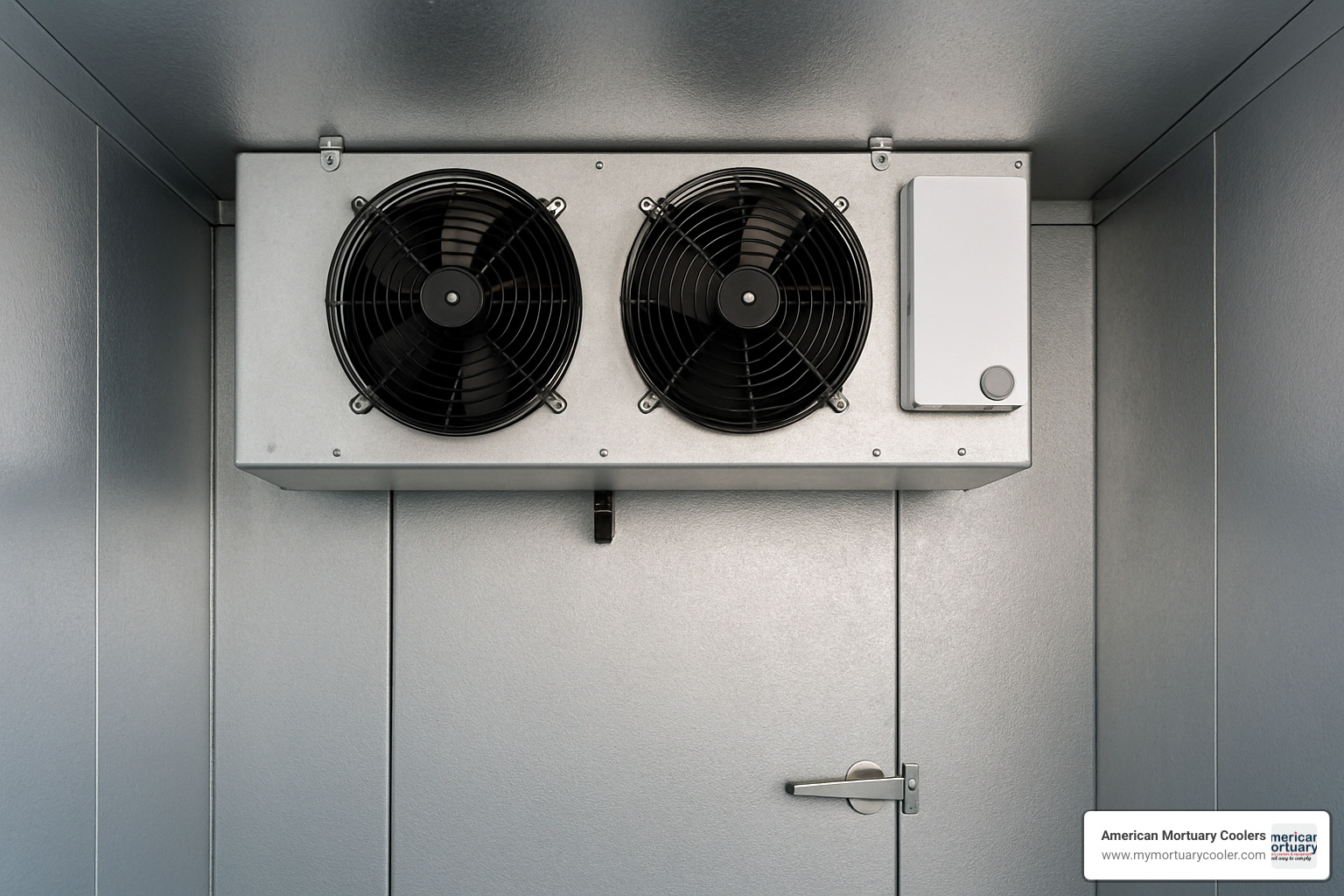

Inside your walk-in, the evaporator coil is busy absorbing heat from the interior air. As warm air passes over these chilly coils, it cools down before being returned to your storage space. If headroom is a concern, look for low-profile evaporator designs that maximize your usable space.

The expansion valve might be small, but it's mighty important. This device controls refrigerant flow into the evaporator, maintaining the perfect pressure and temperature balance. Modern systems often use thermostatic expansion valves that automatically adjust based on changing conditions inside your cooler.

Finally, the controls act as the brain of your operation. From simple thermostats to sophisticated digital systems with remote monitoring capabilities, these components regulate the refrigeration cycle to maintain your desired temperature. Advanced units even allow you to track performance and receive alerts when something needs attention – before small issues become big problems.

For optimal performance, all these components must be properly sized and matched. It's like a choir – when everyone sings in harmony, the result is beautiful. But an undersized compressor paired with an oversized evaporator is like a soprano trying to outperform a full orchestra – it just won't work well.

Main Types of Walk-In Cooler Refrigeration Systems

When you're shopping for a refrigeration unit for walk in cooler, you'll quickly find there isn't just one type that fits all situations. Each system configuration offers its own set of benefits depending on your specific needs and facility constraints.

All modern refrigeration systems today must comply with the Energy Independence and Security Act (EISA) requirements. This isn't just regulatory red tape – these standards ensure your system runs efficiently while keeping your energy bills and environmental impact as low as possible.

One of the biggest decisions you'll face is where you want all that heat to go. Refrigeration doesn't eliminate heat – it just moves it elsewhere. Will you send that heat outside your building or are you okay with it staying indoors? Your answer will significantly influence which system type works best for you.

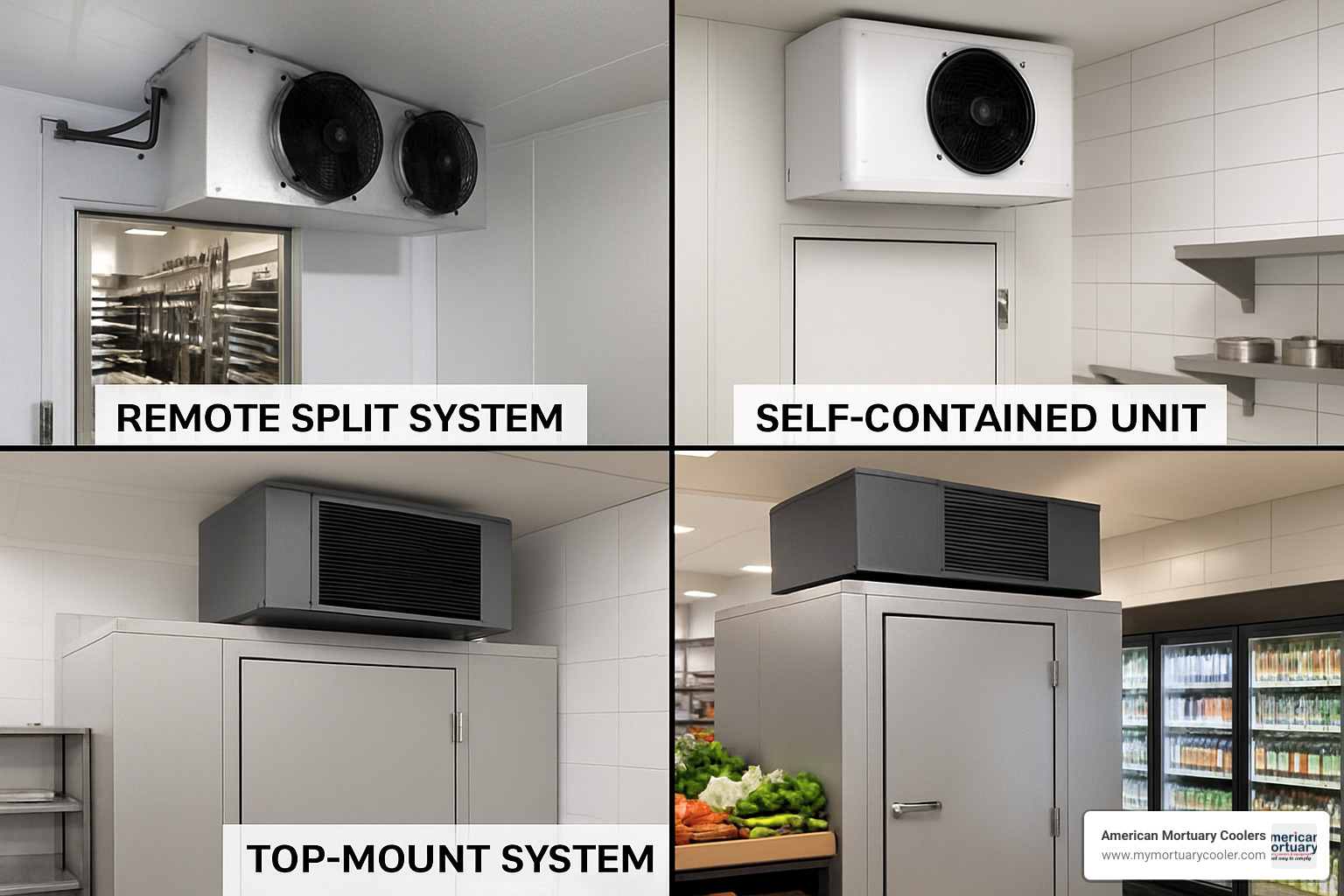

Remote Split Systems

Think of remote split systems as the "long-distance relationship" of refrigeration. The condensing unit (housing both the compressor and condenser) lives outdoors, while the evaporator stays inside your walk-in cooler. They're connected, but they don't have to be in the same place.

Remote systems shine when you don't want extra heat inside your building. They're particularly wonderful in funeral homes where maintaining a comfortable environment is essential for families and staff. Since the noisy parts live outside, your indoor space stays quieter and more peaceful. Plus, you'll enjoy every inch of your valuable cooler space since there's no bulky condensing unit taking up room inside.

The trade-off? Installation gets a bit more involved. You'll need longer refrigerant lines running between the two units, and installation requires a licensed technician to connect everything and properly charge the system with refrigerant. While the equipment itself might cost less upfront, the total installation expense can be higher unless you opt for pre-assembled systems with factory charging.

Remote systems make perfect sense when:

- You're in a warmer climate and don't want to fight additional heat indoors

- Every inch of interior cooler space matters to your operation

- Noise reduction is important for your environment

- You have appropriate outdoor space available for the condensing unit

Self-Contained Top/Side Mount

Self-contained units are the "all-in-one" solution – everything comes pre-packaged and pre-charged with refrigerant. These units mount directly on your walk-in cooler and offer a simpler installation process that's often as easy as plug-and-play.

Top-mount units sit on the ceiling of your walk-in, with evaporator coils hanging down into the interior. They're space-efficient in terms of wall space but do reduce your usable headroom a bit. These are particularly popular for smaller walk-ins where simplicity is key.

Side-mount units attach to the wall instead. While they take up some wall space, they preserve your full ceiling height. Many mortuary facilities prefer these when ceiling clearance is limited or when storing taller items.

The beauty of self-contained units is their simplicity – installation costs less initially, they're pre-charged with refrigerant, and if you ever need to relocate your cooler, they move with it easily. The downside? They discharge heat inside your building, which means your air conditioning system works harder in summer. They also create some noise inside your facility and take up space that could otherwise be used for storage.

Self-contained units work beautifully when:

- You have a smaller walk-in cooler with standard cooling needs

- You value simple, straightforward installation

- Outdoor space isn't available for a remote unit

- The additional heat load indoors isn't a concern for your facility

Penthouse & Monoblock Designs

Penthouse and monoblock designs represent innovative solutions that address limitations of traditional systems while maintaining simplicity.

Penthouse units sit proudly on top of your walk-in cooler roof. What makes them special is how they draw air up through the ceiling, eliminating the need for coils hanging down inside your cooler. This maximizes your usable interior space while providing easy service access from outside the cooler. While they might seem pricier initially, the space savings and factory assembly benefits often make them more cost-effective long-term.

Monoblock units offer perhaps the simplest installation of all. These single-piece systems install through the wall of your cooler, with some models taking as little as 20 minutes to set up. Available in sizes from 1HP to 3HP, they're perfect for quick deployment when time is of the essence. They're the "instant gratification" option of refrigeration systems.

Both designs preserve valuable interior space and come pre-charged with refrigerant from the factory. The main consideration is that they still reject heat into your building, so you'll need to account for that in your overall facility climate control.

These innovative designs particularly shine in:

- Facilities where maximizing every inch of interior cooler space is critical

- Situations requiring rapid installation with minimal disruption

- Locations with limited technical resources for complex installations

- Smaller mortuary coolers with standard cooling requirements

At American Mortuary Coolers, we help you steer these options to find the perfect refrigeration unit for walk in cooler that meets your specific needs. Whether you're prioritizing space efficiency, installation simplicity, or long-term energy costs, there's an ideal system configuration for your mortuary facility.

Best Refrigeration Unit for Walk In Cooler: 2025 Roundup

I've spent countless hours in the field evaluating what makes a refrigeration unit for walk in cooler truly stand out, and I'm excited to share our 2025 lineup with you. We've hand-selected these units based on what matters most: consistent performance, long-term reliability, energy efficiency, and overall value.

Our selections cover cooling capacities from 6,580 BTUH for smaller spaces all the way up to 39,190 BTUH for larger walk-ins. Most of our premium picks feature Copeland scroll compressors – these workhorses have earned their stellar reputation through years of reliable operation in demanding environments.

What I personally love about newer models is the EcoNet smart control technology. It's like having a technician monitoring your system 24/7, letting you check performance from your phone and alerting you before small issues become big problems. And with 5-year compressor warranties standard on quality units, you can rest easy knowing your investment is protected.

Need a solution quickly? I understand emergencies happen – that's why we offer quick-ship options that can reach your facility within 14 days or less, whether you're in the humid Southeast, the arid Southwest, the frigid Northeast, or anywhere in between.

Remote Condensing Refrigeration Unit for Walk In Cooler

The RFO series has become our go-to recommendation for remote condensing units, and for good reason. These outdoor champions deliver exceptional performance while keeping heat and noise outside your facility.

What makes these units special is their versatility. The smallest model (RFO060M4SDANT) at 6,580 BTUH works beautifully for compact coolers, while the powerhouse RFO450E4SDANT at 39,190 BTUH handles even the most demanding applications. Each comes equipped with a Copeland scroll compressor – I've seen these running smoothly after a decade of service in some installations.

The weather-resistant housing means you don't need to worry about rain, snow, or sun damage, and the included low ambient kits ensure reliable operation even when winter temperatures plummet. I especially appreciate the digital controls that allow for precise temperature management and remote monitoring.

Pricing starts around $2,251 for smaller units and reaches about $4,367 for the largest capacity models – excellent value considering their commercial-grade construction and 5-year compressor warranty.

Note: These products contain chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. For more information, visit P65Warnings.ca.gov.

Self-Contained Refrigeration Unit for Walk In Cooler

If simplicity is what you're after, our Next-Gen MiniCon series hits the sweet spot. These monoblock units install through the wall with minimal fuss – I've seen skilled technicians complete the entire installation in under 30 minutes.

Available in 1HP to 3HP configurations, these units come pre-charged and ready to run. The hot-gas defrost system is particularly impressive, efficiently clearing frost without the energy waste of traditional electric defrost systems. The low-profile evaporator design preserves valuable headroom inside your cooler, and the tool-free filter access makes routine maintenance a breeze.

What sets these units apart for mortuary applications is their precise temperature control. When you're preserving remains, temperature consistency isn't just about efficiency – it's essential for dignity and proper care. These units maintain rock-solid temperatures while offering the reliability that funeral professionals depend on daily.

Want to explore more options for your specific needs? I've put together a detailed guide on selecting the best walk-in cooler system that dives deeper into matching systems to specific applications.

Energy-Smart & Connected Units

The days of "set it and forget it" refrigeration are behind us. Today's refrigeration units for walk in coolers are smarter than ever, and I've seen how these intelligent features save both headaches and dollars.

EcoNet enabled systems have transformed how we monitor refrigeration. Instead of finding issues during a routine check (or worse, when products spoil), these systems send alerts directly to your phone. I remember one funeral director who received an alert while at a service – he was able to dispatch a technician before returning to the facility, preventing what could have been a serious situation.

The variable-speed EC fans are another game-changer. Unlike old-school fans that run at full blast or not at all, these smart motors adjust their speed based on actual cooling needs. They're whisper-quiet at lower speeds and can reduce energy consumption by up to 30%.

Smart defrost cycles are particularly valuable in mortuary settings where maintaining consistent temperatures is critical. Rather than defrosting on a rigid schedule, these systems only activate the defrost cycle when frost is actually present, minimizing temperature fluctuations.

For facilities managing multiple coolers or those with limited maintenance staff, these connected features provide invaluable peace of mind. The ability to track energy usage and receive predictive maintenance notifications helps prevent unexpected downtime and extends equipment life – something I've seen make a real difference for funeral homes and medical facilities nationwide.

Buying Guide: Sizing, Efficiency & Regulations

Choosing the right refrigeration unit for walk in cooler doesn't have to feel like rocket science, but it does require some thoughtful consideration. Let's break down what you really need to know to make a smart choice that won't leave you in the cold.

Sizing Considerations

Think of sizing like finding the right shoes – too small and you'll be uncomfortable; too large and you'll trip over yourself. An undersized cooling unit will run constantly (hello, high electric bills!) and might not even keep your cooler cold enough. On the flip side, an oversized unit will turn on and off too frequently, wearing out parts faster and wasting energy.

Here's what affects the size you'll need:

Box dimensions matter most – a bigger box needs more cooling power. Your insulation thickness plays a role too, with 4-inch urethane (R-25) being the standard we typically work with. Consider your product load – are you storing a few items or filling the space to capacity? How warm are those items when they go in?

Don't forget about door openings! Every time that door swings open, cold air escapes and warm air rushes in. If your staff is constantly going in and out, you'll need more cooling power. The ambient temperature around your cooler makes a difference too – a unit in sunny Florida works harder than one in Minnesota. And any interior equipment like lights or motors adds heat that needs to be countered.

A properly sized unit should be running about 70-80% of the time during your busiest periods. This "sweet spot" ensures efficiency without overworking the system.

Efficiency Standards

Uncle Sam has a say in your cooler efficiency through Department of Energy (DOE) regulations. These aren't just bureaucratic hoops – they actually help ensure you're not wasting energy (or money).

Current standards require minimum R-25 insulation for coolers, high-efficiency fan motors that use less electricity, improved door seals and strip curtains to keep cold air where it belongs, and efficient lighting systems that don't generate excess heat.

These requirements might seem like a pain during installation, but they're designed to save you money over the life of your system. At American Mortuary Coolers, we make sure all our systems meet or exceed these standards, so you don't have to worry about compliance.

Refrigerant Regulations

The refrigeration world is changing faster than a teenager's social media habits. Environmental concerns are driving major shifts in refrigerants:

Traditional refrigerants like R-404A are being phased down due to their environmental impact. Newer alternatives like R-448A offer similar performance with lower global warming potential. The AIM Act (American Innovation and Manufacturing Act) is pushing a steady reduction in HFC refrigerants across the board.

Looking forward, systems may start using natural refrigerants or what we call A2L refrigerants (slightly flammable but with much lower environmental impact). When you're investing in a new system, it's worth considering what refrigerant it uses and whether you'll be able to service it easily in the years ahead.

Air-Cooled vs. Water-Cooled Condensers

This choice is like deciding between an air-cooled or water-cooled engine – each has its place:

| Feature | Air-Cooled Condensers | Water-Cooled Condensers |

|---|---|---|

| Initial Cost | Lower | Higher |

| Water Usage | None | Significant |

| Efficiency | Lower in hot environments | Consistent regardless of ambient temperature |

| Maintenance | Periodic coil cleaning | Water treatment and scale prevention |

| Installation | Simpler | Requires water supply and drain |

| Best For | Most standard applications | High ambient temperatures or where noise is a concern |

Water-cooled systems shine in hot environments like kitchens or buildings without good ventilation. They maintain consistent efficiency regardless of the outside temperature, but they do require access to water and drainage. Most of our mortuary clients opt for air-cooled systems due to their simplicity and lower initial cost, but we're happy to discuss if water-cooling might be right for your situation.

Quick BTUH Load Calculation Steps

While we always recommend professional sizing (we offer this service at no charge), you can get a ballpark figure by following these steps:

First, measure your cooler dimensions to calculate the interior volume. Decide on your target temperature – most standard coolers aim for 35°F to 45°F. Then estimate your infiltration load based on how often doors open and close. Add your product load – how much warm stuff are you putting in there? Finally, don't forget to account for heat sources like lights and people working inside.

As a quick reference, here are typical loads for common cooler sizes (assuming standard 4" urethane insulation):

- 6'×6'×8' cooler at 35°F: 4,986 BTUH (typical) to 6,540 BTUH (heavy use)

- 8'×8'×8' cooler at 35°F: 6,654 BTUH (typical) to 8,990 BTUH (heavy use)

- 8'×10'×8' cooler at 35°F: 7,934 BTUH (typical) to 9,600 BTUH (heavy use)

- 10'×10'×8' cooler at 35°F: 9,213 BTUH (typical) to 11,150 BTUH (heavy use)

For mortuary applications, we typically recommend sizing toward the higher end of the range, as maintaining consistent temperature is critical, and the cost difference is minimal compared to the peace of mind.

For more detailed calculations, check out our scientific research on load sizing or just give us a call. Our team has sized hundreds of mortuary coolers across the country, and we're happy to help you get it right the first time.

Installation, Maintenance & Troubleshooting

Let's face it - even the best refrigeration unit for walk in cooler won't perform well if it's not properly installed and maintained. Think of your refrigeration system like a car - regular check-ups keep it running smoothly and help avoid those middle-of-the-night emergencies!

Installation Best Practices

Most refrigeration systems aren't DIY projects - they require a licensed technician who knows exactly what they're doing. When we install systems for our mortuary clients, we focus on these critical elements:

Proper mounting is essential - your condensing units and evaporators need to be secured according to the manufacturer's specs. Think of this as the foundation of your system. A wobbly unit is a trouble-prone unit!

Line set routing might sound technical, but it's simply about keeping refrigerant lines as short as possible with proper slopes for oil return. This is where experience really matters - poor line routing is like having kinked arteries in your system.

Before we ever charge a system with refrigerant, we perform thorough leak testing on all lines. Nothing wastes money faster than refrigerant slowly escaping into the atmosphere!

Refrigerant charging requires precision - too little or too much and your system won't perform efficiently. Your technician should be following the manufacturer's specifications exactly.

Electrical connections must comply with local codes for safety and reliability. We've seen too many systems fail due to improper wiring - it's not worth the risk.

Condensate drainage might seem minor, but proper trap installation prevents water damage and humidity issues. Water has to go somewhere, and that somewhere shouldn't be your floor!

The final system startup includes verification of proper operation, with specific measurements of superheat and subcooling. Think of this as the "test drive" before we hand over the keys.

Self-contained units are generally simpler to install, but still require professional attention to mounting, electrical connections, and drainage details.

Maintenance Schedule

Regular maintenance isn't just about preventing problems - it's about extending system life and keeping energy costs down. Here's a practical schedule we recommend to our clients:

Monthly: Check and clean those condenser coils - they're like the lungs of your system and need to breathe freely. While you're at it, inspect the evaporator coils too. Make sure condensate is draining properly (nobody wants a puddle!), and inspect door seals and strip curtains. Also keep an eye out for any ice buildup on the evaporator - that's often the first sign of trouble.

Quarterly: Have your technician check refrigerant levels and system pressures. They should also inspect fan motors and blades, check electrical connections and controls, verify your thermostat is working correctly, and test the defrost cycle operation. Think of this as your system's "wellness check."

Annually: This is the big one - a complete system inspection by a licensed technician. They should perform oil analysis to check compressor health (the heart of your system), comprehensive leak detection, control system verification, and efficiency testing. This annual check-up often catches issues before they become expensive emergencies.

Modern systems with smart diagnostics are like having a doctor constantly monitoring your health - they can alert you to potential issues before they cause system failure. For our mortuary clients, this peace of mind is invaluable.

Common Issues & Fixes

Even with perfect maintenance, problems can occur. Here's how to handle the most common issues:

Ice Buildup on Evaporator is usually caused by a defrost cycle failure, doors left open, or excessive humidity. The fix? Check your defrost timer, heater, and drain. Also verify those door seals are tight and that staff aren't propping doors open.

Short Cycling (when your unit turns on and off frequently) often means you have an oversized unit, low refrigerant, or control issues. Your technician should verify proper sizing, check refrigerant charge, and inspect controls and sensors. Short cycling wears out your compressor prematurely - it's like stop-and-go traffic for your car.

High Head Pressure typically results from dirty condenser coils, high ambient temperatures, or refrigerant overcharge. The solution is straightforward: clean those coils, improve ventilation around the unit, and verify the refrigerant charge is correct.

Oil Return Problems usually stem from improper line set routing or sizing. Your technician needs to verify proper slopes and traps in refrigerant lines. Without proper oil return, your compressor is at risk - and that's the most expensive component to replace.

Control Faults can be caused by sensor failure, wiring issues, or control board problems. Testing sensors, inspecting wiring connections, and verifying control board operation will usually identify the culprit.

Smart diagnostic systems make troubleshooting much easier by providing specific error codes that point directly to the problem. At American Mortuary Coolers, we always recommend consulting with a licensed technician for complex problems or anything involving refrigerant - it's not an area for DIY solutions.

In the mortuary industry, refrigeration reliability isn't just about convenience - your operations. That's why we focus on both quality equipment and proper installation and maintenance practices. A well-maintained refrigeration unit for walk in cooler will serve you reliably for many years, protecting your investment and ensuring peace of mind.

Frequently Asked Questions about Refrigeration Units

What size refrigeration unit do I need?

Figuring out the right size refrigeration unit for walk in cooler is kind of like buying shoes - too small and you'll be uncomfortable, too large and you'll waste money!

The perfect size depends on several key factors that work together:

First, measure your walk-in's interior dimensions - this gives us our starting point. Then consider your target temperature (are you keeping things cool or cold?), along with the ambient temperature where your cooler lives. A unit working in Phoenix has a much tougher job than one in Seattle!

Door usage makes a huge difference too. Every time that door swings open, cold air escapes and warm air rushes in. And don't forget about what you're storing - adding room-temperature products creates a significant cooling demand.

As a friendly rule of thumb, most walk-in coolers need between 70-120 BTU per cubic foot. So for an 8'×8'×8' cooler (that's 512 cubic feet), you'd likely need something between 35,840 and 61,440 BTU.

Rather than guessing, I'd recommend using our sizing calculator or giving our friendly engineering team a call. Getting this right is crucial - an undersized unit will run constantly but never reach proper temperature, while an oversized one will short-cycle, wasting energy and wearing out components prematurely.

How do air-cooled and water-cooled units differ?

When it comes to removing heat from your refrigeration unit for walk in cooler, you've got two main options - think of them as different approaches to the same problem:

Air-cooled condensers work like your car's radiator - fans blow air across metal coils to dissipate heat. They're the most common choice because they're straightforward to install (no plumbing required!), cost less upfront, and work well in most situations. The downside? On scorching summer days, they have to work harder, which reduces efficiency. They also generate more noise and need regular cleaning to prevent dust buildup.

Water-cooled condensers use circulating water to absorb heat, which makes them incredibly efficient even during heatwaves. They run whisper-quiet compared to their air-cooled cousins. The catch? They need water connections, cost more initially, and require water treatment to prevent scale buildup that could damage the system.

For most funeral homes and smaller facilities, air-cooled systems offer the best balance of cost and performance. Water-cooled systems make more sense in very hot climates, larger installations, or situations where noise would be disruptive.

How often should I service my walk-in cooler unit?

Taking care of your refrigeration unit for walk in cooler is a lot like maintaining your car - regular attention prevents breakdowns when you need it most.

I recommend this simple maintenance schedule for our mortuary customers:

Monthly, take a quick walk-around to check your coils, fans, and drainage. This five-minute visual inspection can catch small issues before they become expensive problems.

Quarterly, give those condenser and evaporator coils a good cleaning. Dust and debris act like a blanket, making your system work harder than necessary.

Twice a year, have a qualified technician perform a more thorough inspection. They'll check refrigerant levels, electrical connections, and overall system performance.

Annually, schedule a comprehensive service with a licensed refrigeration professional who can test, adjust, and verify every component of your system.

Many of our newer systems include digital monitoring that keeps an eye on things 24/7, alerting you to potential issues before they cause a failure. Think of it as having a technician constantly monitoring your system's vital signs.

Proper maintenance isn't just about preventing problems - it extends system life, reduces energy bills, and ensures your cooler maintains precise temperatures. Many of our funeral home customers find that service contracts provide peace of mind with scheduled maintenance and priority emergency service when needed.

Conclusion

Choosing the right refrigeration unit for walk in cooler isn't just a purchase decision—it's an investment in your business operations and the care you provide. At American Mortuary Coolers, we've seen how the right refrigeration solution transforms our customers' daily operations, from reducing energy bills to ensuring perfect temperature control when it matters most.

We understand that no two facilities have identical needs. That's why we've built our business around providing truly customized solutions that fit your specific situation, whether you're operating a small family-owned funeral home or managing a large medical examiner's facility.

One of the things our customers appreciate most is our nationwide reach. With service points in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA and throughout all major US regions, we're never far away when you need us. This nationwide presence means we can deliver your custom cooler solution directly to your doorstep, no matter where you're located in the contiguous 48 states.

The refrigeration units we provide are built for the long haul. With proper maintenance, many of our systems deliver 10-20 years of reliable service—something particularly important in the funeral industry where dependability isn't just convenient, it's essential. We stand behind every system we sell with comprehensive warranties and ongoing technical support from people who understand your business.

Reliability matters in your industry. When families entrust their loved ones to your care, they're counting on your facility to maintain the proper environment consistently. That's a responsibility we take seriously in every system we design and deliver.

For those interested in our mortuary-specific walk-in solutions, I encourage you to explore more information about our mortuary walk-ins. You'll find detailed specifications and examples of custom installations we've completed for clients with requirements similar to yours.

Your refrigeration system is more than equipment—it's a critical component of the care and service you provide. By selecting the right unit, ensuring proper installation, and following recommended maintenance procedures, you're setting yourself up for years of worry-free operation and optimal energy efficiency.

We're here to help you make that happen, every step of the way.