Understanding the Basics of Minimum Orders

What is the minimum order? It's the smallest quantity or dollar amount a supplier will accept for a single purchase transaction. This threshold ensures the seller can cover production costs and maintain profitability while providing products at reasonable prices.

Here's what you need to know about minimum orders:

| Type | Definition | Example |

|---|---|---|

| Minimum Order Quantity (MOQ) | The smallest number of units a supplier will sell in a single order | 500 units of embalming fluid |

| Minimum Order Value (MOV) | The minimum dollar amount required for a purchase | $50 wholesale order threshold |

| Free Shipping Threshold | Minimum purchase amount to qualify for free shipping | $30 ecommerce purchase |

Minimum orders exist because suppliers need to balance their operational costs with customer needs. For manufacturers, producing very small batches isn't cost-effective due to setup costs, materials purchasing, and administrative overhead. For wholesalers and retailers, processing tiny orders can cost more in handling than the profit they generate.

When suppliers set minimum orders, they're protecting their bottom line while ensuring customers receive consistent quality and pricing. However, these requirements can create challenges for businesses with limited storage space, tight cash flow, or unpredictable demand.

"If you've ever thrown an extra item in your cart to qualify for free shipping, you already understand the concept of a minimum order," as one industry expert puts it.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes steer what is the minimum order requirements while ensuring they get precisely what they need for their facilities.

What is the minimum order vocab to learn:

What is the minimum order?

In plain terms, the minimum order is the smallest purchase size a supplier accepts before an order is worth processing. It usually appears in two forms:

- Minimum Order Quantity (MOQ) – a specific unit count, e.g., a parts maker might require 50 door gaskets per order.

- Minimum Order Value (MOV) – a dollar threshold, e.g., “orders must total at least $500.”

Why set a floor at all? Every order carries fixed costs: paperwork, packaging, machine set-ups, and freight coordination. If you only bought one unit, the supplier could lose money once those costs are added in. Meeting the threshold spreads those expenses across more items so pricing stays reasonable for everyone.

Retail & wholesale examples

In ecommerce you’ve seen MOVs phrased as “Spend $35 for free shipping.” That nudge lifts the average basket size just enough to offset fulfilment costs. Wholesalers use a similar logic: a new customer might face a $500 first order, while reorders drop to $250 once the account is set up.

Manufacturing supply chains

On factory floors, minimums are often dictated by equipment realities. A metal panel line may be tuned to run 100 pieces before it needs cleaning and reset. Ordering ten panels would force the same change-over, so the factory insists on the full batch. Upstream suppliers do the same, creating a chain of nested MOQs that ripple all the way to the finished product.

At American Mortuary Coolers we optimise these production runs so funeral homes can still order custom equipment without being burdened by unnecessarily high minimums.

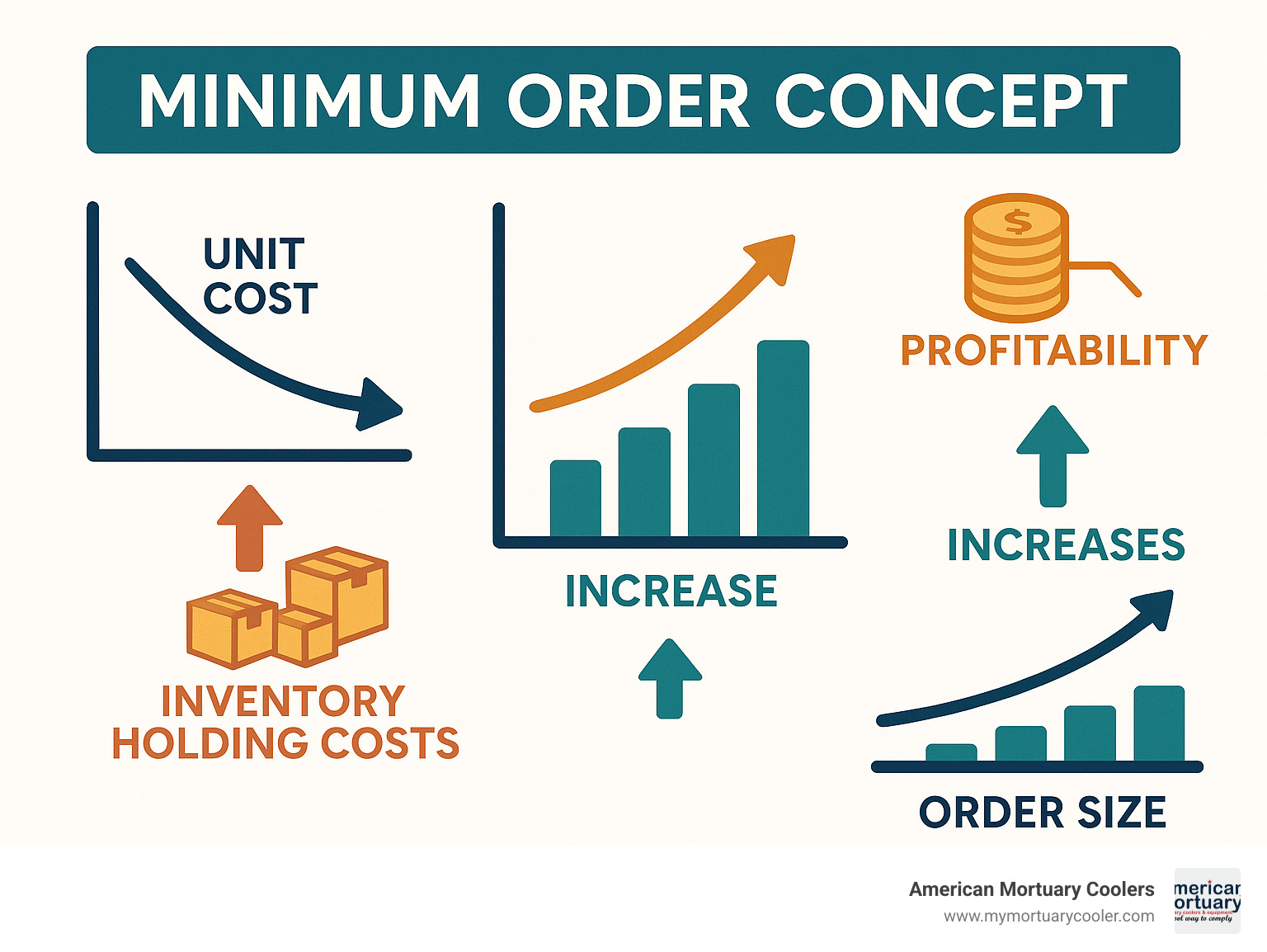

Why Minimum Orders & MOQs Matter

Minimums protect thin margins and keep supply chains running smoothly. Here’s the short version of why they exist and what they offer:

- Cover fixed overhead – the admin cost of processing an order barely changes with quantity.

- Preserve profit margins – many manufacturers operate on 2-4 % profit; small orders can wipe that out.

- Enable bulk purchasing – larger runs let suppliers secure raw-material discounts they can share with buyers.

- Stabilise inventory for buyers – predictable reorder sizes help prevent stock-outs.

| Concept | Purpose | Set by |

|---|---|---|

| MOQ | Profit per transaction | Supplier |

| MOV | Revenue per transaction | Supplier |

| EOQ | Lowest total cost for the buyer | Buyer |

Upsides for each party

Suppliers gain lower unit costs, cleaner production schedules, and steadier cash-flow.

Buyers open up volume discounts, consistent quality, and fewer purchase orders to manage.

Scientific work on inventory optimisation (see this research summary) shows that well-calculated minimums can cut total supply-chain costs dramatically.

Potential downsides

High MOQs can tie up cash, crowd storage, and create deadstock for buyers. For sellers, overly strict thresholds may scare off smaller but promising accounts. The sweet spot lies between operational efficiency and market accessibility—a balance we continually reassess at American Mortuary Coolers.

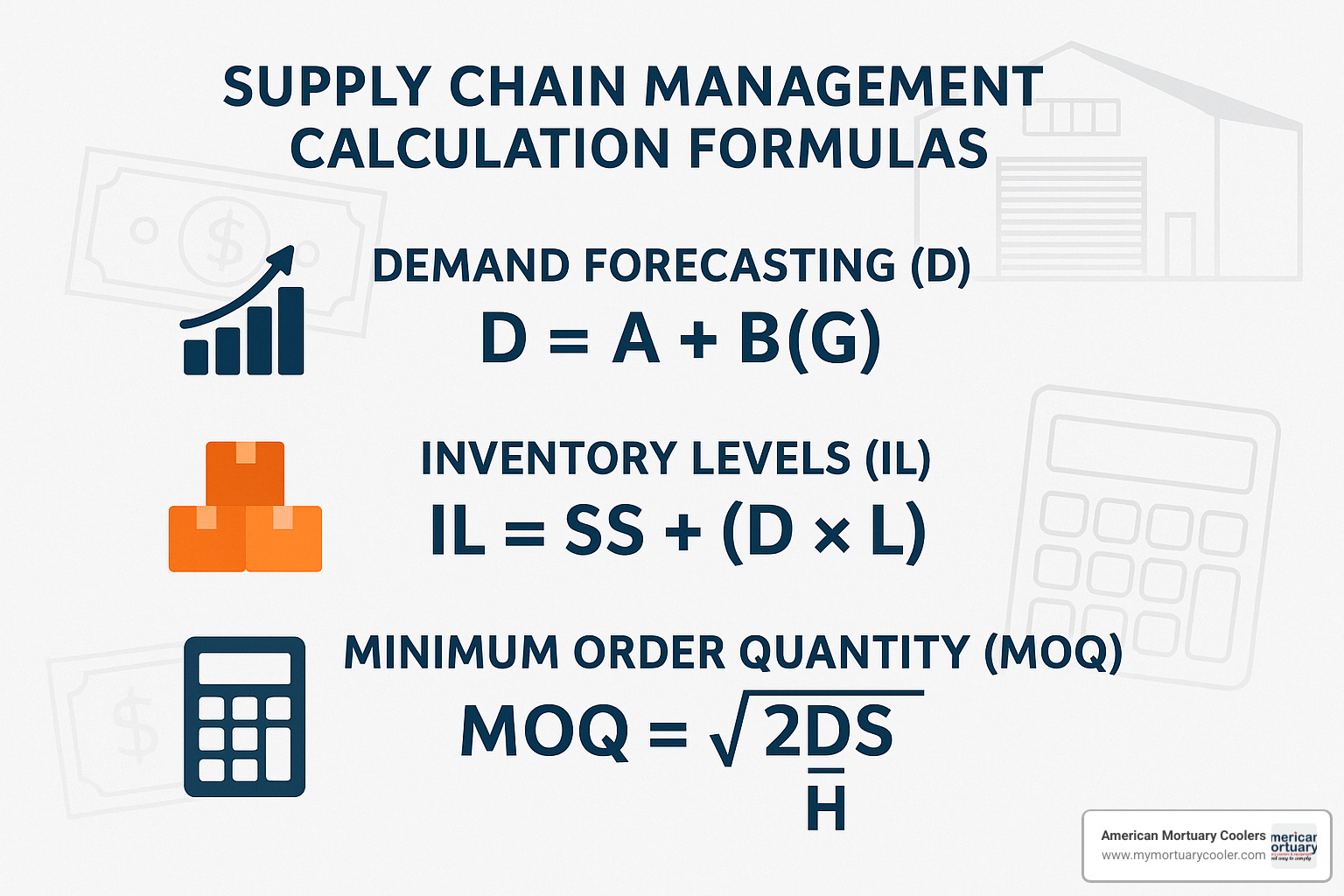

Calculating and Optimizing Your MOQ

You don’t need advanced software to set a sensible MOQ—just a few core numbers and common sense.

- Estimate demand – look at 6–12 months of sales, seasonality, and realistic growth.

- Add up fixed order costs – machine set-up, paperwork, inspection.

- Know your variable cost per unit.

- Find break-even quantity:

Break-even units = Fixed order cost ÷ (Selling price – Variable cost)

- Layer in holding cost (rent, insurance, shrinkage) to be sure keeping extra stock still makes sense.

- Cross-check cash flow – can the business comfortably fund that many units?

The result is the minimum that keeps the transaction in the black. Tweak it whenever costs, demand, or lead times shift.

Practical ways to hit a high MOQ

- Split the shipment dates to spread storage and payment.

- Mix SKUs that share components (e.g., different cooler models using the same panels).

- Team up with neighbouring funeral homes to place one combined order.

- Offer a slightly higher unit price in exchange for a lower quantity.

These tactics let buyers stay within budget while suppliers keep their lines running efficiently—exactly the balance we aim for at American Mortuary Coolers.

Managing Minimum Orders in Practice

Implementing and managing minimum order policies doesn't have to be a headache. Whether you're setting MOQs as a supplier or navigating them as a buyer, having practical systems and clear communication makes all the difference.

When we talk to funeral homes about their ordering needs at American Mortuary Coolers, we've learned that transparency and flexibility go a long way. Let's explore how to make what is the minimum order work in real-world situations.

Negotiating or lowering supplier MOQs

Finding yourself facing a minimum order that seems impossible to meet? Don't worry – there's almost always room for discussion:

Present your MOQ bid rather than simply accepting what's stated. Come to the table with your own proposal, backed by data about your projected future orders. Being honest about your business constraints often opens doors to compromise.

Pay a higher unit price if quantity is your main concern. Suppliers need to cover their fixed costs, so offering a premium per unit might make economic sense for both parties. As one negotiation expert points out, "There's no harm in negotiating MOQ terms or mix-and-match orders." However, they wisely caution that "negotiating MOQ and price simultaneously is usually a bad business move."

Standardize materials wherever possible to leverage existing supplier inventory. Using standard colors, sizes, and materials often allows suppliers to lower their minimums since they're not creating something completely custom.

Forecast future volume to demonstrate your long-term value as a customer. Sharing realistic growth projections and considering longer-term agreements can help suppliers see beyond the initial smaller order.

Leverage competition respectfully as negotiation leverage. Researching alternative suppliers' MOQs gives you information to request matching terms from preferred suppliers.

Here at American Mortuary Coolers, we understand that funeral homes come in all sizes with varying needs. While we maintain certain minimum requirements to ensure quality, our teams across Chicago, Dallas, New York and beyond work with clients to find solutions that make sense for everyone.

Communicating minimum order policies to customers

Clear communication about what is the minimum order helps set expectations and reduces friction with customers. When we implement these policies, we've found these approaches work best:

Website banners should display minimum order information prominently, with clear, concise language that leaves no room for confusion. Update these seasonally if your requirements change with inventory or demand fluctuations.

Checkout alerts provide real-time feedback that customers appreciate. Showing how much more they need to meet minimums and suggesting items that could help them reach thresholds creates a helpful experience rather than a frustrating one.

FAQ pages dedicated to explaining your minimum order policies answer common questions before they become support tickets. Update these regularly based on customer inquiries to keep them relevant.

Email nudges for abandoned carts that didn't meet minimums can be surprisingly effective. A gentle reminder with suggestions to help customers reach thresholds often converts what would have been a lost sale.

Service fees for sub-threshold orders should be clearly communicated if you choose to implement them. As one ecommerce expert recommends: "Provide a clear notice of the MOV threshold to customers" and "customize error messaging for orders below the MOV."

What happens when customers can't meet the minimum?

Having thoughtful policies for handling orders that fall below minimum requirements helps maintain customer relationships while protecting your bottom line:

Add-on incentives make reaching minimums feel like a win rather than an obligation. Suggesting complementary products or offering bundle discounts encourages additional purchases that benefit both parties.

Surcharge option implementation can work well when done transparently. "Charging a small fee to cover shipping and handling costs when customers order below the MOV" is a common approach that customers generally understand when explained properly.

Partial fulfillment during slow periods can be a smart use of excess inventory or production capacity. Prioritizing long-term customers or strategic accounts for these exceptions builds loyalty.

Exception handling workflow gives your team clear guidelines on when to make exceptions. Establishing criteria and tracking exception frequency helps inform future policy adjustments.

As one retail expert notes, "Customers will be satisfied when they can still get their products even if they don't meet the MOV (via a fee)."

At American Mortuary Coolers, we understand that funeral homes have varying needs. While we maintain minimum order requirements to ensure quality and efficiency, our teams across the Midwest, Northeast, and Southeast work with each client individually. We believe in finding solutions that accommodate specific situations while maintaining the high standards our mortuary equipment is known for.

Frequently Asked Questions about Minimum Orders

How does MOQ impact inventory management and cash flow?

When it comes to minimum order quantities, the ripple effects on your inventory and wallet can be significant.

Inventory management is directly shaped by your MOQ requirements. With higher MOQs, you'll typically find yourself with fuller shelves and warehouses—sometimes holding as much as 20 weeks' worth of inventory! While this abundance provides a comfortable buffer against running out of stock, it also means more of your valuable space is occupied and you're paying more in holding costs.

On the flip side, lower MOQs let you order in smaller, more frequent batches. This approach keeps your inventory levels leaner and reduces holding costs, but you might find yourself placing orders more often and occasionally scrambling when demand spikes unexpectedly.

As for your cash flow, the difference is just as noticeable. Those high MOQs require bigger upfront investments—imagine writing a check for $13,500 to cover a 900-piece order at $15 per unit. That's a significant chunk of money that won't be available for other business needs until those products sell.

With lower MOQs, your cash isn't tied up in inventory to the same degree. You can spread your purchasing power across different needs, though you might pay a premium per unit without the volume discount.

"MOQ is not a fixed formula but a strategic decision influenced by multiple cost factors and relationship dynamics," as one inventory expert puts it—and they're absolutely right.

Here at American Mortuary Coolers, we've seen how these dynamics affect funeral homes of all sizes. That's why we work closely with our clients to find the sweet spot that keeps their facilities properly equipped without straining their financial resources.

How often should businesses review and update minimum orders?

Minimum order policies aren't "set it and forget it" decisions—they need regular attention to stay relevant and effective.

For most businesses, quarterly reviews make sense if you're in a fast-moving market or dealing with seasonal fluctuations. If your business environment is more stable, semi-annual reviews might be sufficient. At the very minimum, every business should review their MOQ policies annually—no exceptions!

Several situations should trigger an immediate review of your minimum order requirements:

When you notice significant shifts in customer demand patterns, it's time to reassess. Similarly, if your suppliers change their policies or if your production processes evolve, your minimum orders should adapt accordingly. Pay attention when your inventory metrics start drifting from your targets, and always take customer feedback seriously, especially complaints about order minimums.

"MOQs can vary depending on supplier capacity, market conditions, and product demand; they should be reviewed and updated regularly," notes one inventory management specialist.

During these reviews, take a holistic look at your business data: examine your historical orders and fulfillment costs, check how quickly different product categories are moving through your inventory, review feedback from customers, see what your competitors are doing, and honestly assess your cash position.

At American Mortuary Coolers, we regularly review our minimum order requirements to ensure they reflect our current production realities while remaining reasonable for funeral homes across all regions—from the Rocky Mountains to the Pacific coast. This balanced approach helps us maintain quality while meeting our clients' needs.

Are MOQs and free-shipping thresholds the same thing?

While they might seem similar at first glance, MOQs and free-shipping thresholds serve different purposes and operate in distinct ways.

Minimum Order Quantities (MOQs) are primarily the domain of manufacturers and wholesalers. They're focused on making production efficient and profitable, and they're typically expressed as a specific number of units. When a manufacturer sets an MOQ, they're essentially saying, "We need to make at least this many units for it to be worth our while." These requirements are usually firm, though there may be room for negotiation in some cases. The key point is that orders below the MOQ generally don't get fulfilled at all.

Free-shipping thresholds, on the other hand, are retail and ecommerce tools. They're all about encouraging customers to add a bit more to their cart while offsetting shipping costs. These are always expressed as dollar amounts rather than quantities. As one ecommerce expert explains, "A minimum order value of $30 where a $20 basket prompts a $10 increase for free shipping" is a common strategy. Unlike MOQs, orders below the threshold still get fulfilled—they just come with shipping charges.

The fundamental difference is in how they handle orders below the minimum: MOQs typically prevent those orders entirely, while free-shipping thresholds simply add costs to smaller orders. Both strategies effectively encourage larger purchases, just through different mechanisms.

At American Mortuary Coolers, we've thoughtfully established our minimum order requirements to balance production efficiency with customer service. This approach ensures we can efficiently manufacture and deliver high-quality mortuary equipment to funeral homes throughout the contiguous 48 states, without compromising on the custom solutions our clients need.

Conclusion

Understanding what is the minimum order isn't just business jargon—it's a critical concept that affects everyone in the supply chain. Whether you're setting these requirements as a manufacturer or working within them as a buyer, these policies shape how businesses operate, make money, and build relationships with their partners and customers.

After diving deep into this topic, here's what really matters:

Minimum orders exist for good reason. They ensure businesses can cover their costs, operate efficiently, and deliver consistent quality. When a supplier asks for a minimum purchase, they're not just being difficult—they're making sure the transaction makes financial sense for everyone involved.

There's no one-size-fits-all approach. MOQs, MOVs, and free-shipping thresholds each serve different purposes and work best in different contexts. What works for a large manufacturer won't necessarily work for a small online retailer.

The best minimum orders come from real data, not gut feelings. Smart businesses calculate their thresholds based on actual break-even points, realistic demand forecasts, and true operational costs. When you base these decisions on solid numbers, everyone benefits.

Flexibility goes a long way. The most successful businesses know when to stick to their requirements and when to find creative solutions. Sometimes that means negotiating with suppliers, combining orders with other buyers, or offering customers alternatives when they can't meet minimums.

Things change, and so should your minimum orders. What made sense last year might not work today. Market conditions shift, costs fluctuate, and customer expectations evolve. Regular reviews keep your policies relevant and effective.

At American Mortuary Coolers, we've seen how important these principles are in the funeral industry. Our minimum order requirements strike a careful balance between our production needs and the practical realities faced by funeral homes of all sizes. From our Tennessee headquarters to our service areas nationwide, we're committed to providing high-quality, customized coolers with ordering policies that make sense.

When approached thoughtfully, minimum orders aren't obstacles—they're opportunities to build more efficient operations, save money, and develop stronger business relationships.

For more information about our mortuary coolers and how we handle ordering requirements, reach out to our team today. We're here to help you steer the specifics of equipment procurement with clarity and confidence.

We are your one-stop shop for mortuary coolers, dedicated to supporting funeral homes with solutions that respect both your business needs and your bottom line.