Why Commercial Walk-In Coolers Matter for Your Operation

A commercial walk in cooler is a large, insulated refrigeration unit designed to store perishable goods at safe temperatures, typically between 35°F and 40°F. These walk-in units provide businesses with bulk storage capacity, reduce product spoilage, and deliver long-term cost savings compared to traditional reach-in refrigerators.

Quick Facts About Commercial Walk-In Coolers:

- Temperature Range: 35°F to 40°F (coolers) vs. 0°F or below (freezers)

- Typical Lifespan: 15-20+ years with proper maintenance

- Price Range: $9,000 to $30,000+ depending on size and features

- Common Sizes: 6x6 feet to 25x40 feet or larger

- Construction Types: Prefabricated, custom-built, or outdoor models

Walk-in coolers extend the longevity of degradable supplies for several weeks, keeping products nearly as fresh as when first delivered. The FDA recommends that coolers operate at or below 40 degrees Fahrenheit to prevent bacterial growth and ensure food safety.

Whether you run a restaurant, grocery store, hospital, or mortuary facility, walk-in coolers maximize storage efficiency while maintaining strict temperature control. They offer superior energy efficiency compared to multiple reach-in units, and their durable construction—featuring insulated panels, high-performance doors, and commercial-grade refrigeration systems—makes them a smart long-term investment.

For specialized industries like mortuary and forensic services, walk-in coolers provide OSHA-compliant cold storage solutions that meet strict regulatory requirements while offering the reliability and capacity needed for professional operations.

Commercial walk in cooler terms to know:

Understanding the Fundamentals: Core Components and Key Differences

When you're investing in cold storage, it helps to know exactly what you're getting. A commercial walk in cooler isn't just an oversized refrigerator—it's a sophisticated system built for precision, reliability, and efficiency. Let's break down how these units work and what makes them tick.

Cooler vs. Freezer: It's All About Temperature

Here's the simplest way to understand the difference between a walk-in cooler and a walk-in freezer: temperature. Both keep your products safe, but they operate in completely different thermal zones.

Walk-in coolers maintain temperatures between 35°F and 40°F. This range is perfect for storing fresh items without freezing them—think produce, dairy products, beverages, and fresh meats. The FDA actually recommends keeping coolers at or below 40°F to prevent bacterial growth and maintain proper food safety standards. For restaurants, grocery stores, and funeral homes storing floral arrangements, this temperature range is ideal.

Walk-in freezers are a different beast entirely. They operate at 0°F or below, with some specialized units dropping to -20°F or even colder for long-term frozen storage. These units are essential when you need to preserve items for extended periods or when products must remain completely frozen.

The right choice depends entirely on what you're storing. Many facilities find that a combination unit offers the flexibility they need, but understanding these temperature differences is your starting point.

The Anatomy of a Commercial Walk-In Cooler

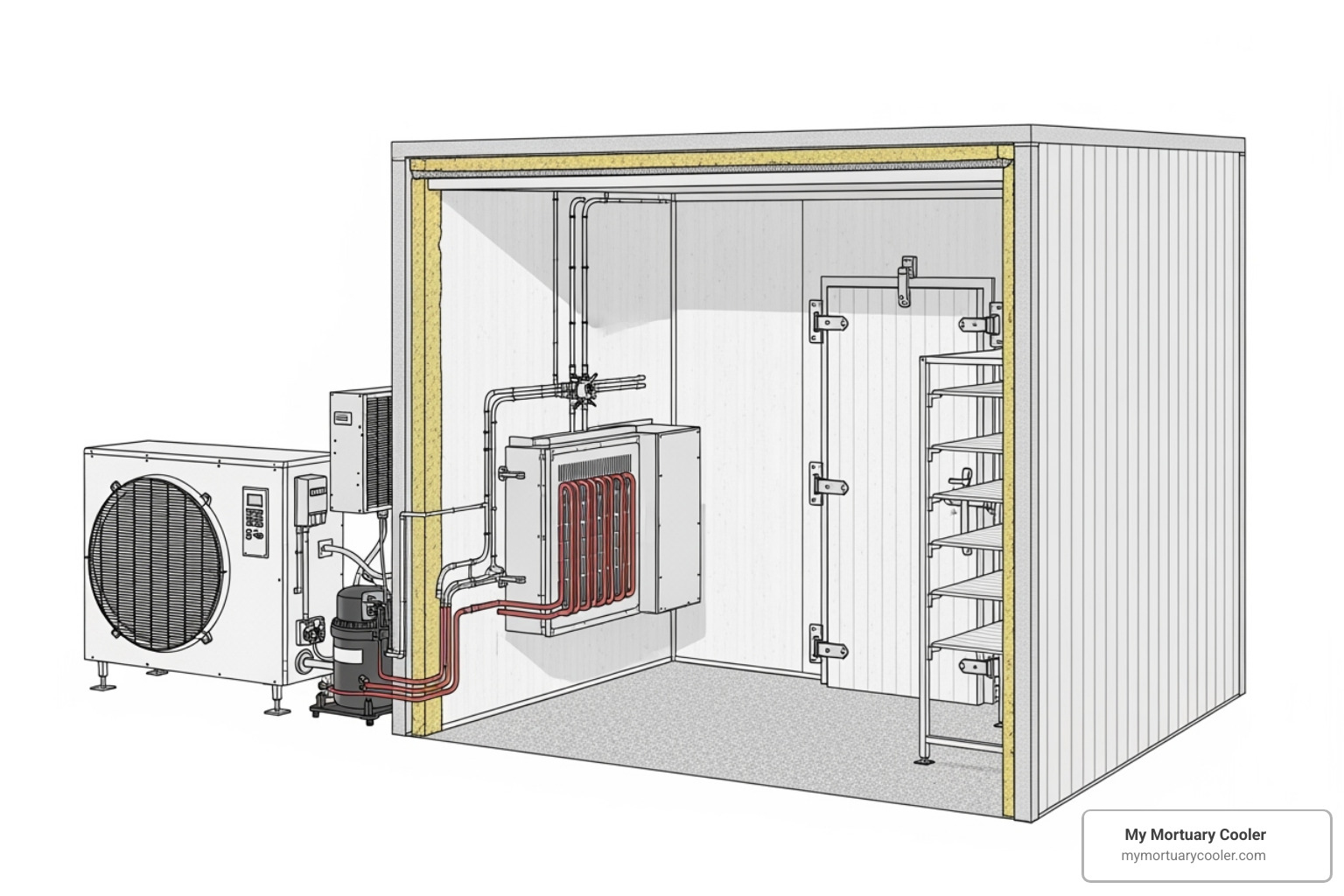

Let's peek under the hood. A commercial walk in cooler consists of several key components working together to create that perfect cold environment.

Insulated panels form the walls, ceiling, and sometimes the floor of your walk-in. These aren't just ordinary walls—they're typically 3.5 to 5 inches thick and packed with high-performance insulation like polyurethane or polyisocyanurate. The outer shell might be stainless steel, aluminum-coated steel, or aluminum, depending on your needs. The R-value of these panels determines how well they resist heat transfer, which directly impacts your energy bills. Quality panels create a vapor-tight seal that eliminates thermal bridges and keeps the cold air exactly where it belongs.

The refrigeration system is where the magic happens. Your compressor pressurizes refrigerant gas and increases its temperature—it's essentially the heart pumping life through the system. Most commercial units run on 208-230V single phase power. The hot, pressurized refrigerant then flows to the condenser coils, typically mounted outside the cooler, where it releases heat into the surrounding air. Finally, the cooled refrigerant reaches the evaporator coils inside your walk-in, where it absorbs heat from the interior and keeps everything cold. This cycle repeats continuously, maintaining your set temperature around the clock.

Doors and hardware deserve special attention because they're your main point of temperature loss. A well-designed door includes magnetic gaskets and vinyl seals that create an airtight barrier against warm air. Safety release handles are absolutely essential—they're not just a nice feature, they're a critical safety requirement that allows anyone accidentally locked inside to exit immediately. Hydraulic door closures ensure the door shuts completely every time, and many facilities add strip curtains or air curtains just inside the doorway to minimize cold air loss during frequent entries and exits.

Flooring options vary based on your needs. Some walk-ins include an integrated insulated floor, while others sit directly on your existing concrete slab. Integrated floors are crucial for freezers and recommended for many coolers to maintain consistent temperature throughout. Durable materials like aluminum diamond plate or T-rail aluminum flooring can handle heavy traffic and even forklift loads.

Modern thermostats and controls have come a long way from simple dial settings. Today's digital systems let you set precise temperatures and monitor performance continuously. Advanced controls can include defrost timers, alarm systems, and even email notifications if something goes wrong. These smart features help you catch problems early and maintain consistent temperatures that meet health department standards and NSF/ANSI Standard 7 requirements for commercial refrigeration.

Understanding these components helps you make informed decisions about what features matter most for your operation—and what you're actually paying for when you invest in a quality commercial walk in cooler.

Choosing the Right Commercial Walk In Cooler for Your Business

Finding the perfect commercial walk in cooler for your operation isn't just about picking the biggest unit or the cheapest option. It's about understanding your unique needs and matching them with the right features, size, and construction type. Think of it as finding the right partner for your business—one that will reliably serve you for years to come.

Let's walk through the key decisions you'll need to make, from calculating the right size to understanding what drives the price tag.

Sizing and Capacity: How Much Space Do You Really Need?

Here's where many businesses make their first mistake: they either overestimate or underestimate their space requirements. Both can be costly. Too small, and you're cramped from day one. Too large, and you're paying to cool empty air.

Start by looking at your inventory volume. How much product do you typically store during your busiest times? Don't just think about today—consider those peak seasons when deliveries arrive in bulk. A funeral home might need extra capacity during certain times of year, while a restaurant might see seasonal fluctuations.

The product density rule helps here: roughly 25 pounds of product fits comfortably in one cubic foot of space. This simple calculation gives you a baseline for the total volume you'll need.

Next, measure your available footprint carefully. Don't forget to account for door swings, clearance for maintenance access, and proper ventilation around the unit. A unit that technically fits might not be practical if there's no room to work around it.

Finally, think about future growth planning. Your business today might look different in five years. A slightly larger unit now could save you from an expensive upgrade later. It's like buying shoes for a growing teenager—a little room to grow makes sense.

Walk-in coolers come in sizes ranging from compact 6'x6' units perfect for small operations to massive 25'x40' installations for large-scale facilities. We've even designed custom solutions for spaces with unconventional angles and challenging layouts. For a deeper dive into sizing calculations and real-world examples, check out Everything You Need to Know About Walk-In Fridge Sizes.

Construction Types: Prefabricated, Custom, and Outdoor Models

Once you know how much space you need, it's time to decide how that cooler will be built. Commercial walk in cooler units come in three main construction types, each with its own advantages.

Prefabricated (modular) units are the workhorses of the industry. They arrive as interlocking insulated panels that get assembled on-site, like a very serious puzzle. Common sizes include 8'x10' or 8'x20' configurations. These units are cost-effective and relatively quick to install—often in just a day or two. If you ever need to move or expand your operation, they can be disassembled and relocated. The trade-off? They're less flexible for unusual spaces or very specific dimensions.

Custom-built solutions shine when standard sizes just won't work. Maybe your facility has an awkward corner that's going to waste, or you need a unit that fits perfectly between existing equipment. Custom builds maximize every inch of your available space and can integrate seamlessly into your facility's layout. We specialize in designing units for unique requirements, even those with unconventional angles. The investment is higher upfront, and lead times are longer, but the result is a perfect fit. Learn more about custom options in our guide: Everything You Need to Know About Custom Walk-In Coolers.

Outdoor walk-in coolers offer an neat solution to a common problem: limited indoor space. These weather-resistant units sit outside your facility, freeing up valuable interior real estate. They're built tough, with features like seamless fiberglass construction and robust weatherproofing to handle rain, snow, and sun. Some models arrive fully assembled and ready to operate—you just need to provide the electrical hookup. You can configure them as freestanding units or through-wall installations that connect directly to your building. The downside? They need a dedicated outdoor footprint, and the condensing unit faces more exposure to the elements, which might mean slightly more frequent maintenance.

The right construction type depends on your specific situation. Whether you're in Johnson City Tennessee, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, or anywhere across the USA and Canada, we'll help you figure out what works best for your space and budget.

Decoding Cost: What Influences the Price of a commercial walk in cooler?

Let's talk numbers. A commercial walk in cooler typically runs between $9,000 and $30,000 or more, not including installation. That's a wide range, and understanding what drives the price helps you make smarter decisions.

Unit size is the most obvious factor—larger units need more materials and more powerful refrigeration systems. An 8'x10' unit costs significantly less than a 20'x30' unit, plain and simple.

The materials and insulation quality matter more than you might think. High-grade stainless steel panels and thicker polyisocyanurate insulation cost more upfront but deliver better energy efficiency and longer lifespan. It's the classic "buy once, cry once" principle. Cheaper materials might save money today but cost you more in energy bills and repairs down the road.

Your choice of refrigeration system type makes a big difference too. Self-contained units have the condensing unit mounted right on the box, usually on top. They're simpler and less expensive to install, but they generate heat inside your facility. Remote systems locate the condensing unit away from the box—outdoors or in a mechanical room. This keeps heat and noise out of your workspace but involves higher installation costs for running refrigerant lines and electrical connections.

Here's where savvy operators can save serious money: new versus used equipment. A used 6'x8'x8H walk-in cooler might run around $9,000 CAD, while a comparable new 8'x10'x8H unit could be $16,000 CAD. Used units can be just as reliable as new ones, especially when they come with a guarantee or have been thoroughly inspected before sale. For practical strategies on finding quality affordable options, read A Comprehensive Guide to Finding an Affordable Walk-In Cooler.

Customization and special features add to the bottom line. Glass doors, advanced digital control systems, specialty shelving, or unusual configurations all increase the price. Think carefully about which features you truly need versus which are nice-to-haves.

Finally, don't forget installation fees. These can be substantial and vary widely based on the complexity of your unit, site conditions, and local labor rates. A simple prefab unit on a prepared concrete slab costs far less to install than a custom unit requiring electrical work, plumbing modifications, and structural changes.

Understanding these cost drivers helps you have realistic budget conversations and make choices that balance your immediate needs with long-term value. We believe in transparent pricing—no surprises, just straight talk about what you're paying for and why.

Installation, Energy Efficiency, and Regulatory Compliance

You've selected the perfect commercial walk in cooler for your operation. Now comes the equally critical phase: getting it installed correctly, ensuring it runs as efficiently as possible, and making certain it meets all the safety and health standards your business requires. These aren't just boxes to check—they're the foundation for years of reliable, cost-effective cold storage.

Installation Essentials and Potential Costs

Think of installation as the moment your investment either starts paying dividends or begins accumulating headaches. Proper setup isn't just about bolting panels together; it's about creating the conditions for optimal performance from day one.

The foundation matters more than most people realize. Your walk-in needs perfectly level flooring to function properly. Even slight variations can prevent panels from fitting snugly, doors from sealing correctly, and can create stress points that compromise the entire structure over time. If you're installing on an existing concrete slab, verify it's level before the installation crew arrives.

Ventilation requirements depend on your system type. Self-contained units with top-mounted condensing units generate heat that needs somewhere to go. Without adequate airflow, your refrigeration system works harder, ages faster, and costs more to operate. Remote systems are kinder to your indoor environment since the heat-producing components live outside or in a separate mechanical room.

The electrical hookup absolutely requires a licensed electrician. Walk-in coolers have specific power requirements—typically 208-230V, Single Phase for smaller units, though larger installations may need 3-phase power. Here's something many people miss: 110V supplies often require GFI (Ground Fault Interrupter) protection for safety compliance. This isn't optional, and cutting corners here creates serious liability.

Your refrigeration system constantly produces condensation that needs to go somewhere. Proper drainage prevents water from pooling around your unit or, worse, freezing inside and creating operational nightmares. For freezer applications, you'll likely need heated drain lines to prevent ice blockages. Make sure drainage is planned before installation begins, not finded as a problem afterward.

We strongly recommend professional installation services, even for prefabricated units that seem straightforward. The refrigeration system in particular demands expertise—proper refrigerant charging, correct electrical connections, and optimal component placement make the difference between a unit that lasts 20 years and one that struggles through five. Yes, professional installation adds to your upfront costs, but it's insurance against expensive problems down the road.

Maximizing Energy Efficiency to Reduce Operating Costs

A commercial walk in cooler runs 24 hours a day, 365 days a year. That's a lot of electricity. The good news? Smart efficiency choices can dramatically reduce those operating costs while actually improving performance.

It starts with high-quality insulation—those thick, high-R-value panels we discussed earlier. But insulation only works if it's continuous. The joints between panels need to form a water and vapor-tight seal, eliminating thermal bridges where heat sneaks through. Quality manufacturers use camlock systems that create truly tight connections.

Your door is the biggest vulnerability in any walk-in system. Airtight door seals are non-negotiable. Those magnetic and vinyl gaskets might seem like minor details, but gaps around doors force your refrigeration system into overdrive. We've seen businesses cut their energy bills significantly just by maintaining proper door seals and adding protective barriers.

Speaking of barriers, both strip curtains and air curtains serve the same purpose: keeping cold air where it belongs. Strip curtains are the physical, low-tech solution—vinyl strips that create a barrier while allowing easy passage. Air curtains are more sophisticated, creating a high-velocity air barrier across the doorway. Research shows air curtains can reduce compressor runtime by up to 27%, which translates directly to longer equipment life and lower energy bills. For high-traffic operations, they're worth every penny.

Inside your cooler, LED lighting is a simple upgrade that pays for itself quickly. Traditional bulbs generate heat (which your system then has to remove) and consume more power. LEDs run cool and sip electricity by comparison.

High-efficiency fan motors, particularly EC (Electronically Commutated) models, use substantially less energy than traditional AC motors. When you're running fans continuously, those savings add up month after month.

Modern smart controls do more than just maintain temperature. Advanced digital thermostats optimize defrost cycles, monitor performance in real-time, and can alert you to problems before they become emergencies. Some systems even send email notifications when temperatures drift or doors stay open too long. This isn't just about energy savings—it's about protecting your inventory and catching small issues before they become expensive failures.

Finally, automatic door closers might seem basic, but they're essential. Staff get busy, distractions happen, and doors get left open. A good automatic closer ensures every opening is brief, preserving your cold air and your energy budget.

Meeting Safety and Health Standards

Running a commercial walk in cooler means accepting responsibility for both product safety and personnel safety. The regulations exist for good reasons, and compliance isn't just about avoiding fines—it's about doing right by your customers and employees.

OSHA compliance covers the workplace safety basics. Every walk-in door must have a safety release handle that works from the inside, no exceptions. Someone accidentally locked inside needs a reliable way out. OSHA also mandates proper lighting and safe electrical installations. These aren't suggestions; they're requirements backed by serious penalties.

Local health department codes vary depending on where you operate—whether you're in Johnson City Tennessee, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, or anywhere across the USA and Canada. Most jurisdictions follow FDA guidelines recommending coolers operate at or below 40°F to prevent bacterial growth. Health departments conduct regular inspections, and non-compliance can shut down operations.

The gold standard for commercial refrigeration equipment is NSF/ANSI Standard 7. This standard establishes minimum requirements for food protection and sanitation in refrigerated equipment. It covers everything from materials and construction to cleanability and temperature control. NSF certification tells health inspectors—and your customers—that your equipment meets rigorous safety standards. Many jurisdictions actually require NSF-certified equipment, making this more than just a nice-to-have designation.

For specialized operations like mortuary and forensic services, these standards take on additional significance. OSHA-compliant cold storage isn't just about passing inspections—it's about maintaining the dignity and safety that these sensitive applications demand.

Meeting these standards protects everyone: your business from liability, your customers from contamination, your employees from hazards, and your products from spoilage. It's the responsible foundation for any operation relying on commercial refrigeration.

Ensuring Longevity: Maintenance, Troubleshooting, and Warranty

Your commercial walk in cooler represents a substantial investment in your operation's future. Like any hardworking piece of equipment, it deserves—and requires—consistent attention to perform at its best. Think of it as a partnership: you take care of it, and it takes care of your products. Let's explore how proactive maintenance, smart troubleshooting, and understanding your warranty protection can keep your cooler running efficiently for 15 to 20 years or even longer.

Proactive Maintenance for Peak Performance

Here's the truth: regular maintenance isn't about waiting for something to break. It's about preventing those breakdowns before they happen, keeping energy costs down, and ensuring your unit reaches its full lifespan potential. Neglecting this care is like ignoring a check engine light—eventually, something expensive will fail. A compressor replacement alone can cost thousands of dollars, not to mention the lost product if your cooler goes down unexpectedly.

Cleaning condenser and evaporator coils should be at the top of your maintenance priority list. Dust and debris on condenser coils force your compressor to work overtime, burning more energy and wearing out faster. For most indoor units, a quarterly cleaning works well, though outdoor units or those in dusty environments benefit from monthly attention. Turn off the power, remove visible debris with a shop vacuum, and use a proper coil cleaning solution. The evaporator coils inside your cooler also need love—vacuum away any buildup and wipe them down with a damp cloth every six to twelve months.

Your door gaskets are the unsung heroes of temperature control. These rubber or vinyl seals create that crucial barrier against warm air infiltration. Check them regularly for cracks, tears, or wear. Here's a simple test: close a thin piece of paper in the door. If it slides out easily, your seal isn't doing its job. Replace worn gaskets promptly—this small fix prevents much bigger problems.

Clearing drain lines might not sound glamorous, but blocked drains cause water backups, ice formation, and potential damage to your unit. Inspect and clean these lines regularly to keep condensation flowing freely. For freezers, make sure your drain line heaters are functioning properly to prevent freeze-ups.

Monitoring temperature logs gives you early warning of potential issues. Keep consistent records of your cooler's temperature readings. Significant fluctuations signal something's wrong before it becomes a crisis. Many modern electronic thermostats offer alarms and even email notifications for temperature deviations, giving you peace of mind even when you're not on-site.

Don't forget to inspect electrical components for frayed wires, damaged cords, or signs of burning and corrosion. Check that fan motors run smoothly and quietly, and ensure proper airflow by avoiding overpacking—products should be stored to allow full air circulation without blocking coils.

Even if you're diligent about these checks, scheduling professional service annually with a licensed technician is essential. They can check refrigerant levels, inspect the compressor, test electrical connections, and catch issues you might miss. Think of it as an insurance policy against expensive surprises.

Common Troubleshooting Tips for a commercial walk in cooler

Even with stellar maintenance, your commercial walk in cooler might occasionally throw you a curveball. Knowing how to identify and address common problems quickly can save you from product loss and expensive emergency service calls.

When your cooler isn't getting cold enough, start with the basics. Dirty condenser coils are often the culprit—they're that important. Next, check if your evaporator coils are blocked by ice or product. Inspect your door gaskets and make sure the door closes completely. If these simple fixes don't solve the problem, you might be dealing with low refrigerant (which indicates a leak) or compressor issues, both of which require a professional's expertise.

Frost and ice buildup usually points to warm, moist air sneaking into your unit. Door seal failures are the most common cause, so check those gaskets first. Your defrost cycle might also need attention—timers and heaters (especially in freezers) need to function correctly to prevent ice accumulation. In extremely humid environments, some frost is normal, but excessive buildup always signals a problem.

Water leaks can be alarming, but they're often straightforward to fix. A clogged drain line is the usual suspect—clear any blockages and the problem typically resolves itself. Also inspect your drain pan for cracks or holes. Sometimes excessive condensation can overwhelm even a properly functioning drainage system, especially during humid weather or if doors are frequently left open.

Strange noises from the compressor deserve immediate attention. Rattling or vibrating often means loose components or mounting hardware. Grinding or squealing sounds usually point to motor or bearing issues. Clicking noises can signal electrical problems or a failing relay. These compressor-related issues aren't DIY territory—call a qualified HVAC/R technician who has the specialized tools and expertise to diagnose and repair these complex systems safely.

For mortuary and funeral home applications, maintaining consistent temperature control isn't just about equipment performance—it's about dignity and regulatory compliance. Understanding these common issues helps you act quickly when problems arise.

Understanding Your Warranty

Before you invest in any commercial walk in cooler, take time to understand the warranty coverage. This protection safeguards your investment against manufacturing defects and component failures that could otherwise cost thousands to repair.

Most commercial walk-in coolers come with warranty coverage for parts and labor for a specified period. A typical structure might include one year of comprehensive parts and labor coverage, with an extended five-year warranty specifically for the compressor. Since the compressor is the heart of your refrigeration system—and one of the most expensive components to replace—this extended coverage provides valuable protection.

The key is reading the fine print carefully. Understand exactly what's covered and, just as importantly, what voids your warranty. Unauthorized repairs, improper maintenance, or incorrect installation can all invalidate your coverage. Know the process for making a warranty claim before you need it, so you're not scrambling during an emergency.

Some manufacturers and distributors offer extended warranty options beyond the standard coverage. For such a vital piece of equipment, this additional peace of mind might be worth considering, especially if your operation depends heavily on uninterrupted cold storage.

Always refer to the documentation provided with your specific unit for exact warranty terms. For example, you can review warranty details in documents like this WARRANTY & USER TERMS. Knowing your coverage means you're prepared if an unexpected issue arises, protecting both your equipment investment and your operational continuity.

Frequently Asked Questions about Commercial Walk-In Coolers

We hear a lot of questions about commercial walk in cooler units, and honestly, that's great! It means you're doing your homework. Let's tackle some of the most common ones we encounter.

What industries benefit most from walk-in coolers?

The short answer? More than you might think. Walk-in coolers are essential for restaurants, grocery stores, and hotels—in fact, the vast majority of restaurants and hotels across Canada depend on them to store bulk food supplies. But their usefulness extends far beyond the kitchen.

Commercial walk in cooler units provide safe, reliable cold storage for restaurants, grocery stores, hotels, floral shops, breweries, and medical facilities. They're critical for any business handling large volumes of perishable goods. Floral shops use them to keep delicate blooms fresh without freezing them. Breweries and wineries rely on them for proper beer and wine storage. Hospitals, clinics, and pharmacies need precise temperature control for medications, vaccines, and sensitive medical supplies.

Food processing and distribution centers depend on massive walk-in units for both raw materials and finished products. And for mortuary and forensic services—our specialty—walk-in coolers provide essential, OSHA-compliant cold storage that meets the strictest regulatory requirements while offering the reliability and capacity professional operations demand.

Basically, if your business deals with anything that spoils, degrades, or requires strict temperature control, a commercial walk in cooler is probably going to be one of your most valuable assets.

How long does a commercial walk-in cooler last?

Here's the good news: with proper installation and consistent preventative maintenance, a high-quality commercial walk in cooler can serve your business faithfully for 15 to 20 years, and sometimes even longer. We've seen well-maintained units still going strong after 30 years!

The lifespan really comes down to three main factors. First, the quality of components matters—durable construction and commercial-grade refrigeration systems are built to last. Second, usage plays a role; units in high-traffic environments naturally experience more wear and tear. Third, and most importantly, your maintenance schedule makes all the difference.

Regular cleaning of coils, inspection of door seals, and annual professional servicing aren't optional extras—they're essential. Proactive maintenance and a modest investment in cleaning supplies or occasional part replacements can prevent catastrophic failures like compressor breakdown, which could otherwise cost thousands of dollars to repair or replace.

Think of it this way: a little attention now saves you a lot of headaches (and money) later. Quality units paired with proper care deliver an exceptional return on your investment.

Can a walk-in cooler be installed outdoors?

Yes, absolutely! Installing a commercial walk in cooler outdoors is actually a brilliant solution for businesses that need to expand their refrigerated storage capacity without sacrificing valuable indoor space. We see this all the time with restaurants, event venues, and operations that simply need more room.

The key is choosing a unit specifically designed for outdoor use. These aren't just regular walk-ins sitting outside—they're engineered to handle the elements. Outdoor models feature weatherproof construction with robust materials and finishes designed to withstand rain, snow, sun, and extreme temperatures. Some units, like those with seamless fiberglass construction, prevent air and moisture from contacting insulation, ensuring both durability and energy efficiency.

They also come with extra-robust insulation to handle greater temperature differences between inside and outside. Many outdoor units arrive fully assembled and ready to operate—you simply need an electrical connection, with no on-site assembly or refrigeration work required.

Some manufacturers even offer customization options, like brick or granite finishes, so your outdoor cooler can blend seamlessly with your facility's aesthetics. It's cold storage that works hard without taking up space where you need it most.

Conclusion

Investing in a commercial walk in cooler is one of the smartest decisions you can make for your business. It's not just about storing products—it's about protecting your investment, maintaining quality, and ensuring you meet the highest standards of safety and compliance.

Throughout this guide, we've walked through everything you need to know, from understanding the fundamental differences between coolers and freezers to selecting the right size and construction type for your unique space. We've covered the essential components that keep these units running smoothly, explored how to maximize energy efficiency to keep your operating costs down, and emphasized the critical importance of proper installation and regulatory compliance.

The key to getting the most from your commercial walk in cooler lies in treating it as a long-term partner in your operation. With proactive maintenance—regular coil cleaning, door seal inspections, and professional servicing—your unit can reliably serve your business for 15 to 20 years or even longer. Understanding basic troubleshooting and knowing your warranty coverage gives you peace of mind, knowing you're prepared for whatever comes your way.

Whether you're running a busy restaurant, managing a healthcare facility, operating a grocery store, or providing mortuary services, the right cold storage solution makes all the difference. It reduces spoilage, improves workflow, and ensures you're meeting FDA and OSHA standards every single day.

At My Mortuary Cooler, we're passionate about providing professional-grade cold storage solutions that meet the demanding requirements of specialized industries. We understand that when it comes to mortuary and funeral services, reliability and compliance aren't optional—they're essential. Our fast, OSHA-compliant products are designed to deliver the performance you need when it matters most.

For those in specialized fields requiring precise temperature control for sensitive applications, we invite you to explore The Ultimate Guide to Walk-In Morgue Cooler Options for an in-depth look at our specialized solutions.

Your commercial walk in cooler is more than equipment—it's the foundation of your operation's efficiency and safety. Choose wisely, maintain it diligently, and it will serve you faithfully for decades to come.