The Heart of Your Cooling System

Fridge compressors are the essential component that drives the refrigeration cycle in any cooling system. They're responsible for maintaining the temperature difference that keeps your contents cold.

Quick Facts About Fridge Compressors:

- Function: Compresses refrigerant gas, raising its pressure and temperature

- Power: Typically 1/5 to 1/3 horsepower for domestic refrigerators

- Energy Use: Accounts for up to 80% of a refrigerator's total energy consumption

- Types: Reciprocating (piston-based), rotary, and scroll compressors are most common

- Lifespan: 10-15 years with proper maintenance

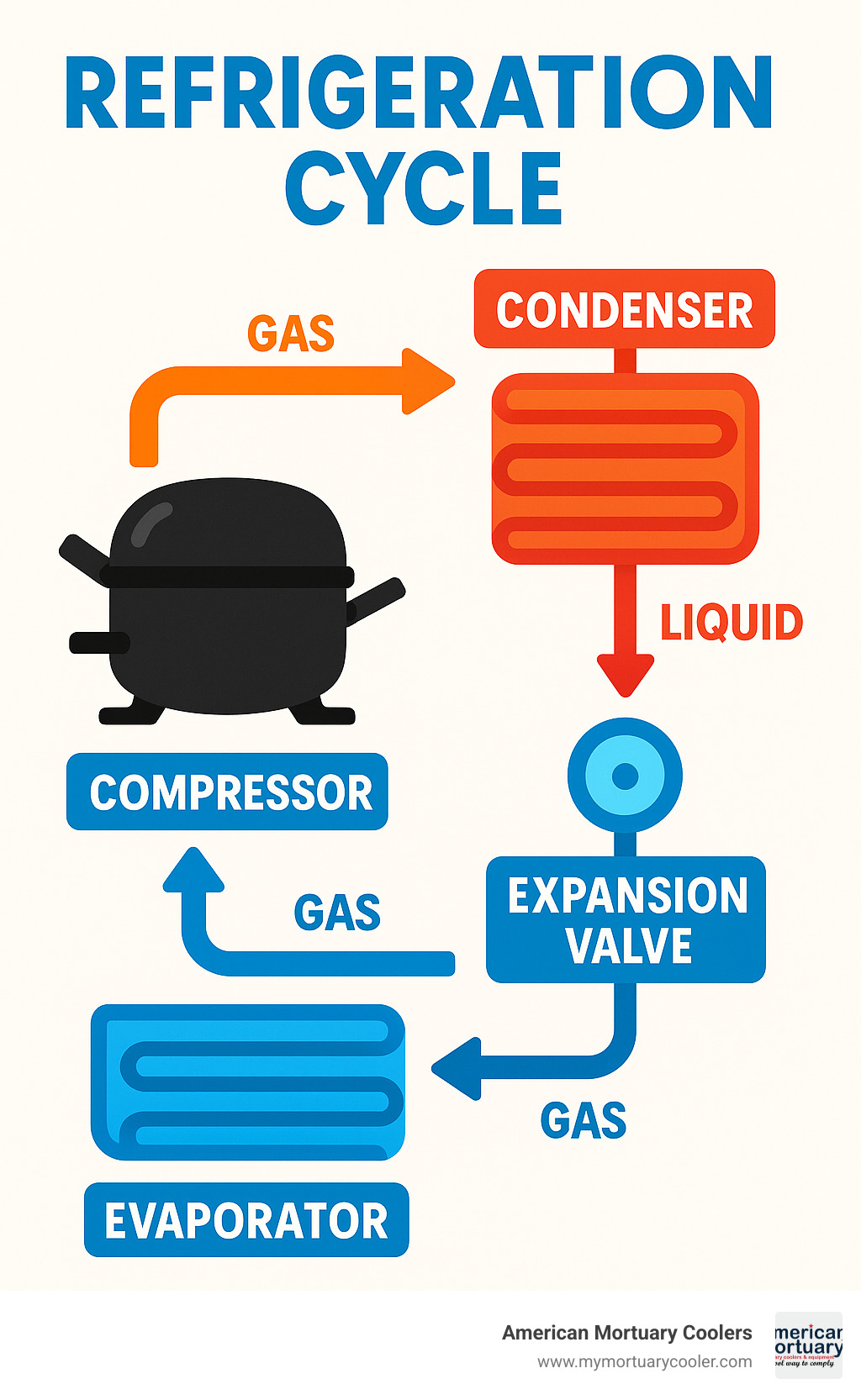

A fridge compressor works by compressing low-pressure refrigerant gas, which raises its temperature. This hot, high-pressure gas then flows to the condenser where it releases heat and condenses into a liquid. After passing through an expansion valve, the refrigerant's pressure and temperature drop dramatically before entering the evaporator, where it absorbs heat from inside the refrigerator and turns back into a gas. This continuous cycle creates the cooling effect that preserves your contents.

The process follows a simple principle known as Boyle's Law: as the volume of gas decreases, its pressure increases. Think of it like pumping a bicycle tire - as you compress the air into a smaller space, it gets hotter and higher pressure.

I'm Mortuary Cooler, a national-level supplier of mortuary cooling systems with extensive experience working with fridge compressors in commercial and specialized refrigeration applications. My expertise includes troubleshooting compressor issues, optimizing cooling efficiency, and selecting the right compressor technology for specific refrigeration needs.

Fridge compressor further reading:

How a Fridge Compressor Works

Have you ever placed your hand near the back of your refrigerator and felt that warm air? That's your fridge compressor hard at work! Think of this little powerhouse as the heart of your cooling system—it keeps the lifeblood (refrigerant) pumping through the entire refrigeration cycle.

When your fridge compressor is in action, it performs a fascinating compression stage. It pulls in cool, low-pressure refrigerant gas from the evaporator through the suction line. Once inside, something magical happens—this gas gets squeezed into a much smaller space, dramatically increasing both its pressure and temperature. This process perfectly demonstrates Boyle's Law in action: as the volume decreases, pressure rises proportionally. It's similar to what happens when you pump up a bicycle tire—the air gets hotter as you compress it!

In most traditional refrigerators, this compression happens through a clever piston-motion system. As the piston moves downward, it creates a vacuum that draws in refrigerant gas. Then, as it moves upward, it compresses the gas before sending it on its way through the discharge line. Some modern systems use rotary-motion instead, but the principle remains the same—compress the gas to create heat and pressure.

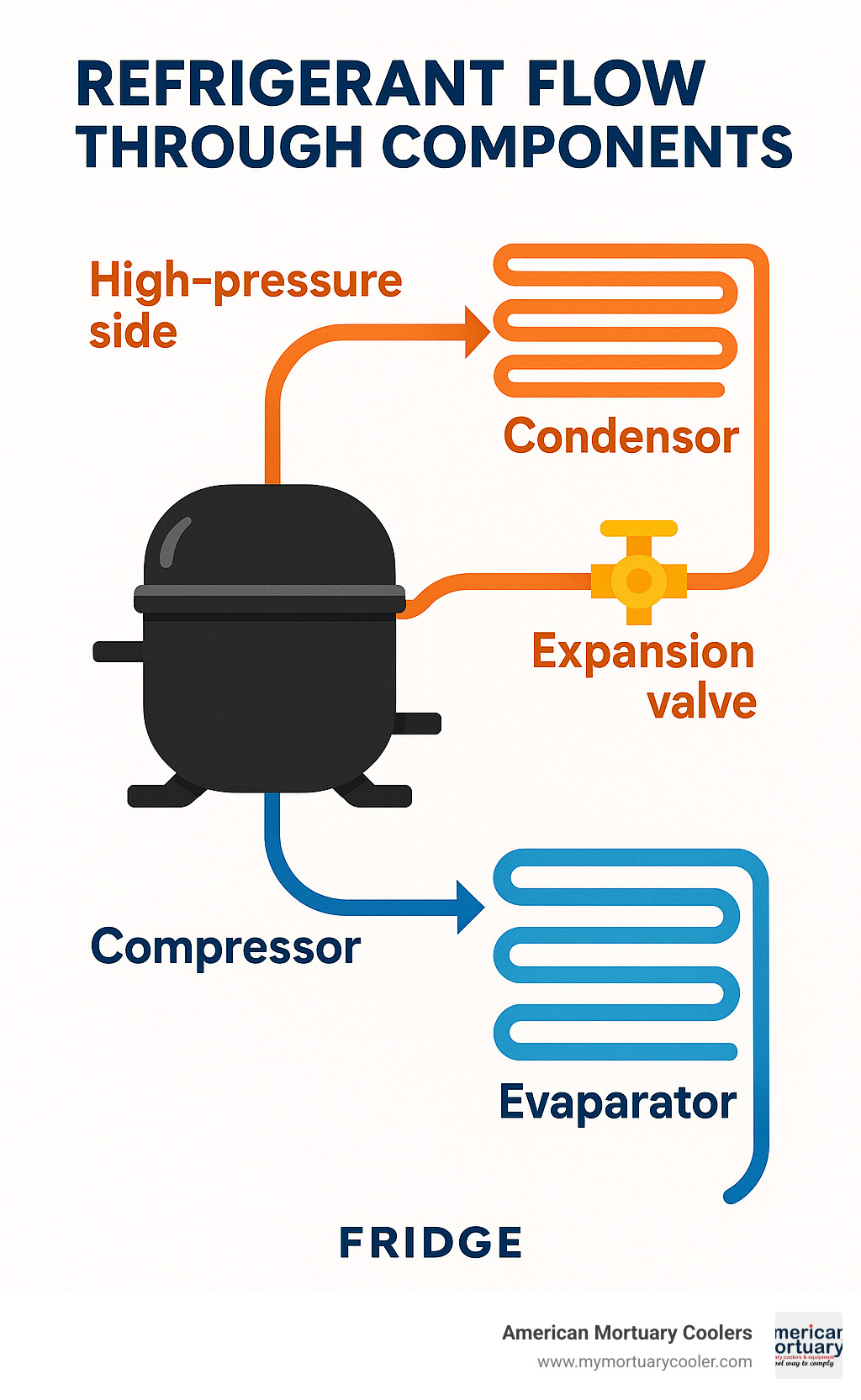

This temperature rise isn't just a side effect—it's essential! By heating the refrigerant above room temperature, we create the perfect conditions for the next step in cooling. Your fridge compressor essentially creates two distinct zones in your refrigeration system: a high-pressure side (from compressor to expansion valve) and a low-pressure side (from expansion valve back to compressor). This pressure difference is what drives the entire cooling process.

According to scientific research on compressor heat transfer, this pressure differential is the key factor that enables refrigeration to occur at all.

The Role of the Thermostat & Control Electronics

Your fridge compressor doesn't run constantly—that would waste energy and over-cool your food! Instead, it takes its cues from the thermostat, which acts like a temperature-sensitive switch.

When the temperature inside your refrigerator rises above your set point, the thermostat sends a thermostat-signal to wake up your compressor. This signal typically passes through a start-relay, which provides that initial jolt of power needed to get the motor running.

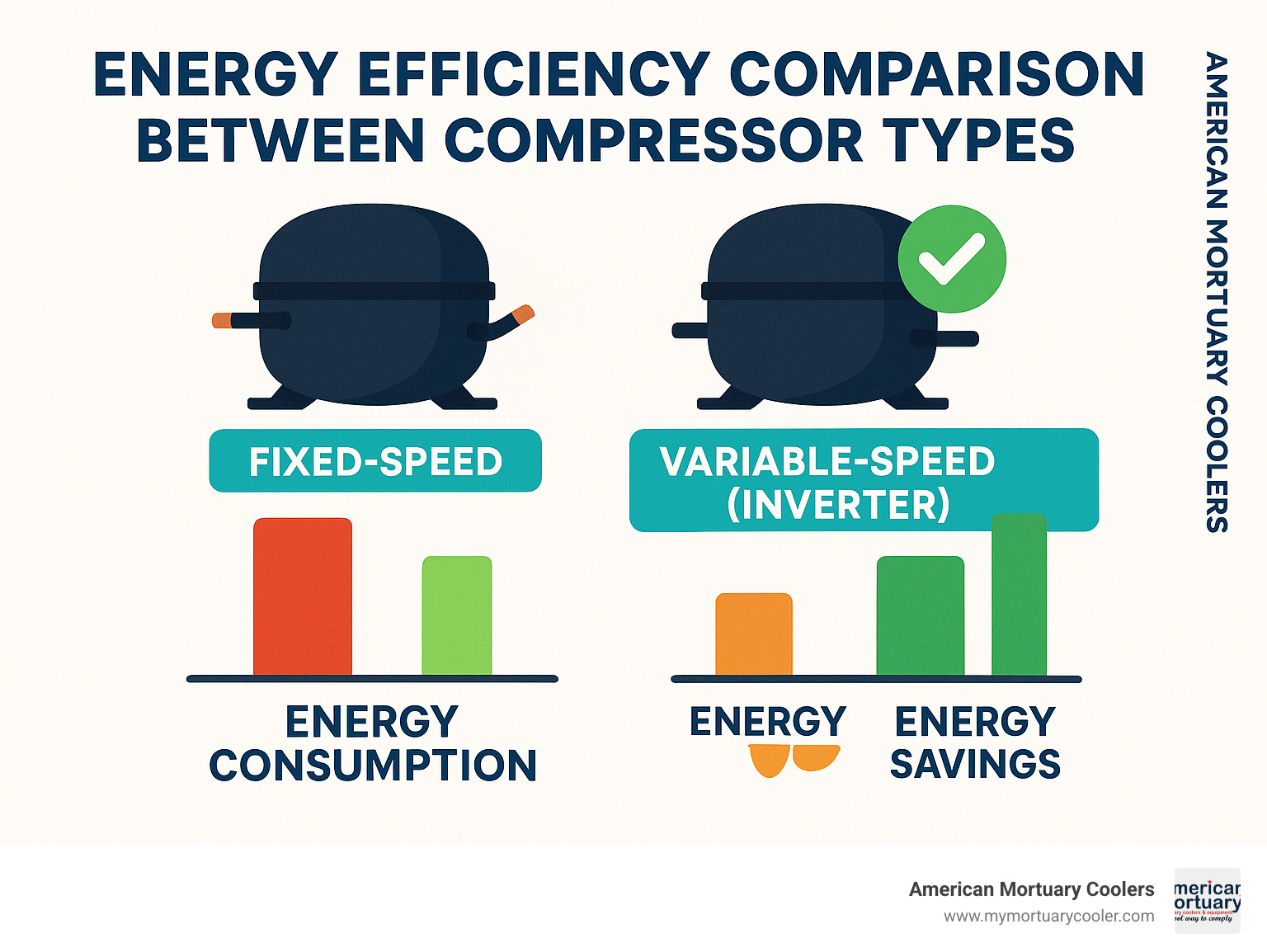

In traditional refrigerators, this operation is simple—either fully on or completely off. But modern refrigerators often feature inverter-speed technology that allows the compressor to run at variable speeds. Rather than the start-stop cycle of older models, these smart compressors can purr along at lower speeds when less cooling is needed, ramping up only when necessary. This means less noise, better energy efficiency, and more consistent temperatures!

Interaction With the Evaporator & Expansion Valve

Once your fridge compressor has done its job of pressurizing the refrigerant, this hot gas travels through the condenser coils (usually at the back or underneath your fridge), where it cools down and condenses into a high-pressure liquid.

This liquid refrigerant then travels through the liquid-line to reach the expansion valve—a critical partner to your compressor. The expansion valve creates a restriction that causes a dramatic pressure drop in the refrigerant through a process called throttling. As pressure plummets, so does the temperature—causing some of the liquid to instantly flash into gas (flash-gas).

The cold mixture then enters the evaporator coils inside your refrigerator. This is where the real magic of heat-absorption happens! As warm air from inside your fridge passes over these cold coils, the refrigerant absorbs this heat and fully evaporates into a gas. This heat transfer is what creates the cooling effect that keeps your food fresh.

The now-gaseous refrigerant returns to the fridge compressor through the suction line, and the whole beautiful cycle begins again. It's this continuous loop of compression, condensation, expansion, and evaporation that makes modern refrigeration possible.

At American Mortuary Coolers, we understand this process intimately, as we design cooling systems that must maintain precise temperatures reliably. For more information about specialized cooling components, check out our guide to walk-in cooler features.

Main Types of Fridge Compressors

When it comes to keeping things cool, not all fridge compressors are created equal. Over the years, several distinct designs have evolved, each bringing its own set of strengths to the table. Let's explore the fascinating world of compressor technology that powers everything from your home refrigerator to commercial cooling systems.

Think of fridge compressors as the hidden heroes of refrigeration. They come in several varieties, each with a personality all its own:

Reciprocating compressors are the traditional workhorses, using pistons (much like your car engine) to compress refrigerant. These are what you'll find in most home refrigerators – reliable, cost-effective, and straightforward.

Rotary-vane compressors use a spinning roller with spring-loaded vanes inside a cylinder – imagine a more sophisticated version of those spinning carnival wheels, but designed for cooling.

Rotary-scroll compressors employ two interlocking spiral-shaped scrolls that compress refrigerant in a smooth, continuous dance – they're the neat performers of the compressor world.

Centrifugal compressors are the powerhouses, using high-speed impellers to accelerate gas and convert that energy into pressure. These are typically reserved for large commercial applications where significant cooling power is needed.

Screw compressors use two meshing helical rotors (think of two screws turning against each other) to progressively compress refrigerant gas. You'll find these in larger commercial systems where reliability is paramount.

Another important distinction is between fixed-speed and variable-speed (inverter) compressors. Fixed-speed models are like light switches – either fully on or fully off. Inverter compressors, however, can adjust their speed based on cooling needs, much like a dimmer switch for your lights.

The capacity range varies widely too. Home refrigerators typically use fridge compressors with 1/5 to 1/3 horsepower, while commercial units might range from 1/2 to several horsepower. Industrial systems can scale up to hundreds of horsepower for massive cooling applications.

| Compressor Type | Efficiency | Noise Level | Cost | Best For |

|---|---|---|---|---|

| Reciprocating | Moderate | Higher | Lower | Small to medium systems, budget-conscious applications |

| Rotary-vane | Good | Moderate | Moderate | Small systems where noise is a concern |

| Rotary-scroll | Excellent | Low | Higher | Premium applications, energy efficiency priority |

| Centrifugal | Very good at high loads | Moderate to high | Highest | Large commercial/industrial systems |

| Screw | Very good | Moderate | High | Medium to large commercial systems |

Reciprocating Designs (Classic Fridge Compressor)

The reciprocating fridge compressor is the trusty pickup truck of refrigeration – nothing fancy, but it gets the job done reliably. These compressors work using pistons that move up and down inside cylinders, creating a vacuum on the downstroke that draws in refrigerant gas through a suction valve. On the upstroke, the piston compresses this gas and pushes it out through a discharge valve.

At its heart, a reciprocating compressor contains pistons and cylinders, suction and discharge valves, a crankshaft with connecting rods, and a motor to drive it all. They can have a single cylinder for smaller applications or multiple cylinders when more cooling power is needed.

What makes these compressors so popular? Their simplicity translates to lower cost and easier repairs. When something goes wrong, a technician can usually identify and fix the issue without specialized equipment.

That said, reciprocating compressors do have their quirks. They tend to be noisier – that humming sound you hear from your kitchen refrigerator is likely a reciprocating compressor hard at work. They also have more moving parts than newer designs, which means more potential wear points over time. And when it comes to energy efficiency, they're not the stars of the show.

Despite these limitations, reciprocating fridge compressors remain the go-to choice for most household refrigerators and smaller commercial applications. They're the reliable old friends of the refrigeration world – not the flashiest option, but dependable and cost-effective.

Rotary & Scroll Upgrades for Quiet Efficiency

If the reciprocating compressor is the pickup truck of refrigeration, rotary and scroll fridge compressors are the smooth-riding luxury sedans. These designs are increasingly popular in settings where you don't want to hear your refrigeration equipment working.

Rotary compressors take a different approach to compression. Instead of the back-and-forth motion of a piston, they use a rotating mechanism. The most common type features a roller that rotates eccentrically within a cylinder, with vanes that slide in and out to create compression chambers. This design is like a gentle, continuous squeeze rather than the rhythmic pumping of a reciprocating compressor.

The benefits are noticeable: smoother operation, fewer moving parts to wear out, significantly less vibration, and a more compact size that fits in tighter spaces. They're also more efficient when operating at lower capacities, making them perfect for applications where cooling needs vary throughout the day.

Scroll compressors take efficiency even further with an ingenious design using two spiral-shaped scrolls – one fixed and one orbiting. As the orbiting scroll moves, it creates pockets that trap gas between the two scrolls, progressively squeezing these pockets as they move toward the center.

The beauty of scroll technology lies in its nearly continuous compression with minimal pulsation. This translates to whisper-quiet operation with very little vibration. They're remarkably efficient across various operating conditions and tend to be more reliable thanks to having just three main moving parts. They also handle liquid refrigerant "slugging" better, which can damage other compressor types.

While these advanced designs come with a higher price tag initially, the investment often pays off through energy savings and improved performance over the equipment's lifetime. That's why you'll find these quieter, more efficient compressors in premium refrigerators and commercial cooling systems where performance justifies the upfront cost.

Mounting Options: Top vs Bottom & Remote Systems

Where you place a fridge compressor matters almost as much as which type you choose, especially in commercial settings and specialized applications like mortuary coolers. The mounting location affects everything from energy efficiency to maintenance accessibility.

Top-mounted compressors sit proudly on the roof of the refrigerated cabinet or walk-in cooler. This positioning offers natural advantages – heat from the compressor rises away from the cabinet instead of into it, dust has a harder time accumulating on components, and you don't sacrifice valuable refrigerated space to house the compressor. They typically perform more efficiently in environments that are already cool and dry.

The downside? When maintenance time comes around, technicians need to climb up to access the unit. In very hot environments, these units can struggle as they're directly exposed to high ambient temperatures.

Bottom-mounted compressors nestle beneath the refrigerated cabinet. This placement makes maintenance a breeze – no ladders required! They also tend to perform better in hot environments since they're closer to floor level where temperatures are often cooler. They require less overhead clearance during installation and often cost less initially.

However, bottom-mounted units collect dust more easily, may reduce storage space in some designs, and generate heat that naturally rises toward the refrigerated cabinet – not ideal for efficiency.

Penthouse systems offer a specialized top-mounted approach where the entire refrigeration package sits atop the walk-in cooler. These clever systems draw air from inside the cooler up to the refrigeration unit, eliminating the need for evaporator coils inside and maximizing your interior space.

Remote systems take a different approach entirely by placing the condensing unit (compressor and condenser) away from the refrigerated space, with only the evaporator inside. This strategy removes heat and noise from the refrigerated area, maximizes interior storage space, and can improve energy efficiency by rejecting heat outdoors. It also offers more flexibility in installation options.

At American Mortuary Coolers, we carefully weigh these mounting options when designing cooling solutions for funeral homes. For instance, in a busy preparation room where space is precious, a remote or penthouse system might be ideal to maximize workspace while maintaining precise temperature control.

For more details about walk-in cooler features and configurations, including compressor mounting options, check out our comprehensive guide to walk-in cooler features and prices.

Troubleshooting & Maintenance

Let's face it – even the best fridge compressors need some TLC from time to time. Think of your compressor like your car's engine – with proper care, it'll run smoothly for years, but ignore those warning signs and you might find yourself in a cooling crisis!

I've seen hundreds of compressor issues over the years, and knowing what to look for can save you from finding spoiled food (or worse). Here are the telltale signs your fridge compressor might be crying out for help:

When your compressor is overheating, you'll often notice it's unusually hot to the touch or emits that distinctive electrical burning smell – never a good sign. Short-cycling (when the compressor rapidly turns on and off) is another red flag that something's not right with the control system or refrigerant levels.

Strange noises are your compressor's way of communicating distress. Those knocks, clicks, and buzzes? They're basically your fridge compressor saying, "Help me!" If your circuit breaker trips when the cooling cycle begins, there's likely an electrical issue that needs addressing before it causes further damage.

Of course, the most obvious sign is when your refrigerator simply isn't keeping things cold despite the compressor running – or when the compressor refuses to run at all. Equally concerning is a compressor that never stops running, which wastes energy and signals an underlying problem.

Safety first, always! Before you dive into any compressor maintenance:

- Unplug the refrigerator or cut the power at the breaker

- Put on appropriate protective gear – those fins on the coils can be sharp!

- Sealed compressor units should stay sealed (they're not DIY-friendly inside)

- Be careful around refrigerant lines – these contain pressurized chemicals that require professional handling

For complex issues, especially anything involving refrigerant, it's best to call in the pros. At American Mortuary Coolers, our technicians specialize in refrigeration systems and can provide expert service throughout our coverage area.

Fridge Compressor Always Running – Causes & Fixes

Is your fridge compressor running a marathon instead of a sprint? A constantly running compressor isn't just an energy vampire – it's telling you something's wrong.

Dirty condenser coils are often the culprit behind an overworked compressor. These coils release heat from the refrigeration system, but when they're coated with dust and pet hair, heat transfer becomes inefficient. A simple cleaning every six months with a vacuum and brush attachment can work wonders for your system's efficiency.

Those rubber door gaskets might not seem important, but when they're damaged or worn, they're like leaving the refrigerator door slightly ajar all the time. Your fridge compressor compensates by running constantly to maintain temperature. Try the dollar bill test – close the door on a bill and see if it pulls out easily. If it does, it's time for new gaskets.

Location matters too! If your refrigerator sits in a hot garage or next to your oven, your poor compressor has to work overtime. The ideal environment is a cool, well-ventilated space away from heat sources and direct sunlight. Your compressor will thank you with lower energy bills and a longer lifespan.

Low refrigerant from a small leak forces your compressor to run continuously without ever reaching the target temperature. Unfortunately, this requires professional attention to locate the leak, repair it, and recharge the system with the correct amount of refrigerant.

Sometimes the issue is simply an overcrowded refrigerator. When air can't circulate properly inside, cooling becomes inefficient. The fix is simple – declutter your fridge and ensure vents aren't blocked by food items.

A faulty thermostat might be telling your fridge compressor to keep running even when the temperature is perfect. If you suspect this issue, a technician can test and replace the thermostat to restore proper cycling.

Diagnosing No-Start or Hard-Start Issues

When your fridge compressor won't start or struggles to get going, it's usually one of several components causing the trouble.

The start relay provides that initial electrical kick your compressor needs. When it fails, your compressor might sit silent or just hum without starting. A quick diagnostic trick: remove the relay and give it a gentle shake – if you hear rattling inside, it's likely failed. Replacing it is relatively straightforward if you get the exact match for your model.

Start capacitors store electrical energy like tiny batteries to help the compressor motor overcome inertia. When they fail, you might hear the compressor trying to start but unable to turn over. Look for physical signs like bulging or leaking, or test it with a multimeter. A replacement capacitor with identical specifications will often solve the problem.

The overload protector is your system's bodyguard, shutting things down if the compressor draws too much current or overheats. If it's tripping frequently, there's usually an underlying issue causing the compressor to work too hard. Replacing the protector without addressing the root cause is just a temporary fix.

Sometimes the problem lies within the compressor's motor windings. Using a multimeter to check resistance between terminals can tell you if there's an open circuit or short. Unfortunately, internal compressor failure typically means replacing either the compressor or the entire refrigerator, depending on age and cost considerations.

In newer refrigerators with electronic controls, the issue might be in the control board itself. These sophisticated systems monitor multiple parameters and may prevent the compressor from starting if they detect abnormal conditions. Look for error codes or signs of physical damage on the board.

For aging compressors that struggle to start, installing a hard-start kit can sometimes extend their useful life by providing extra starting torque. Think of it as a booster cable for your compressor's ignition system.

Preventive Care to Boost Efficiency

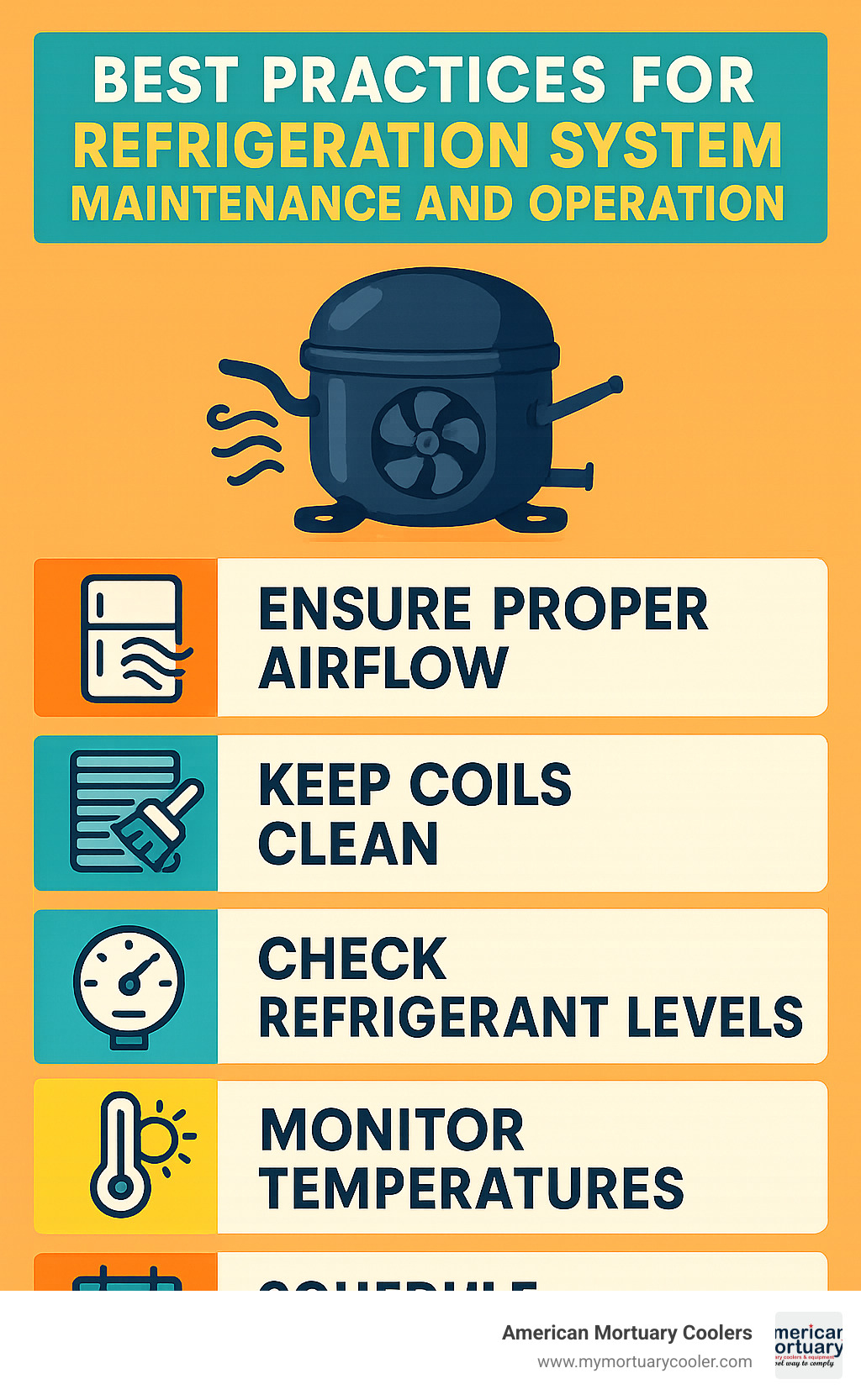

An ounce of prevention is worth a pound of cure – especially when it comes to fridge compressors. Regular maintenance not only extends your compressor's life but also keeps your energy bills in check.

Every six months, make a date with your condenser coils. These heat-dissipating components collect dust and debris that insulate them, making your compressor work harder. A thorough cleaning with a coil brush or vacuum attachment can improve efficiency dramatically. While you're there, check the compressor fan for obstructions and clean it too.

Don't forget those door gaskets! They create the seal that keeps cold air in and warm air out. Inspect them for cracks, tears, or hardening, and clean them with mild soap and water to remove food residue that can compromise the seal.

Proper airflow is crucial for compressor health. Maintain at least 2-3 inches of clearance around your refrigerator, especially near the back where most fridge compressors are located. This simple step prevents overheating and reduces energy consumption.

For commercial systems and specialized units like mortuary coolers, annual professional service is a wise investment. A trained technician can check refrigerant pressure, inspect electrical connections, and identify potential issues before they become expensive problems.

At American Mortuary Coolers, we understand that reliable refrigeration is critical for funeral homes and mortuaries. That's why we offer comprehensive maintenance plans custom to the unique needs of mortuary refrigeration systems. Our technicians are specially trained to maintain the precise temperature control these applications demand.

For more in-depth information about compressor troubleshooting and maintenance, check out our article Compressor Conundrum: American Mortuary Coolers Has You Covered.

Environmental Impact & Energy Efficiency

Let's talk about something that affects all of us – the environmental footprint of those hardworking fridge compressors humming away in our homes and businesses. This impact goes way beyond just the electricity bill; it includes the refrigerants used and what happens when the equipment eventually reaches the end of its life.

Refrigerants have come a long way over the years, and not just in terms of cooling power. We've seen quite an evolution:

The old-school CFCs like R-12 that were popular decades ago? They're completely banned now because they were punching holes in our ozone layer. Then came HCFCs like R-22, which are being phased out worldwide. Today, many systems use HFCs like R-134a, but even these have a significant environmental downside – they're powerful greenhouse gases.

That's why there's growing excitement about natural refrigerants like R-600a (isobutane). When we talk about global warming potential or GWP (how much heat a gas traps compared to carbon dioxide), the numbers tell the story: R-134a has a GWP of about 1,430, while commercial refrigerant R-404A comes in at a whopping 3,922. Compare that to isobutane's tiny GWP of just 3, and you can see why the industry is heading in this direction.

The Department of Energy isn't sitting still either. Their increasingly stringent efficiency standards are pushing manufacturers to innovate with technologies like variable-speed compressors. These smart fridge compressors adjust their running speed based on actual cooling needs rather than just turning on and off at full power. The result? Energy savings of 15-40% compared to traditional fixed-speed models – that's nothing to sneeze at!

When we're helping funeral homes choose cooling systems at American Mortuary Coolers, we always encourage thinking beyond just the price tag. The true cost includes:

- What you pay upfront

- What you'll spend on energy over 10-15 years

- Maintenance requirements

- How long the system will last

- What happens when it's time for disposal

We've made it our mission to offer mortuary cooling systems that balance performance with environmental responsibility – because we believe you shouldn't have to choose between doing right by your business and doing right by our planet.

Compressor Choice & Carbon Footprint

Did you know that your fridge compressor is the energy hog of your refrigeration system? It typically gobbles up about 80% of the total electricity used. That's why choosing the right compressor technology makes such a huge difference to both your carbon footprint and your utility bills.

The numbers are pretty eye-opening. Upgrading from an old-school fixed-speed compressor to a modern inverter model can slash energy use by 15-40%. That's like getting a partial rebate on your energy bill every month for the life of the unit! Properly sized compressors that run 14-16 hours daily (instead of 16-18 hours) operate in their efficiency sweet spot, saving energy and reducing wear and tear.

I've seen many funeral homes switch from reciprocating compressors to scroll compressors and immediately notice the difference – not just in their quieter operation but also in their energy bills, which typically drop by 10-15%.

But the story doesn't end with energy efficiency. The refrigerant inside your system matters just as much. A tiny leak of high-GWP refrigerant can wipe out all the climate benefits of an energy-efficient compressor. That's why the shift to natural refrigerants like R-600a (isobutane) or R-290 (propane) is so important – they have a climate impact that's 99% lower than conventional HFCs.

When it's time to upgrade your cooling equipment, today's fridge compressors are worlds better than those made even a decade ago. They pair beautifully with improved insulation technologies and smart controls that learn your usage patterns. For mortuary coolers, where reliability is non-negotiable but energy costs add up quickly, investing in efficient compressor technology pays dividends both financially and environmentally.

Innovations Shaping Tomorrow's Fridge Compressors

The future of cooling is looking pretty cool! Engineers and manufacturers are developing some fascinating innovations that promise to make fridge compressors even more efficient, reliable, and planet-friendly.

Micro-inverter technology is taking variable-speed compressors to the next level. Rather than making broad adjustments, these systems can fine-tune the compressor speed in tiny increments, squeezing out every last bit of efficiency across all operating conditions. It's like having a car that can adjust its engine speed by fractions of an RPM to maximize fuel economy.

Oil-free compressors are another game-changer. Traditional fridge compressors need oil for lubrication, but this oil mixes with the refrigerant and slightly reduces efficiency. By eliminating oil altogether, these new designs improve heat transfer and boost overall system performance.

Smart technology is making its way into refrigeration too. Advanced sensors and internet connectivity allow compressors to report their status in real-time, enabling predictive maintenance instead of reactive repairs. Imagine your cooler texting you: "My compressor bearings are showing early wear patterns – might want to check this out before it becomes a problem!"

Linear compressors represent a fundamental redesign of how compressors work. By using a linear motor instead of a rotary one, they eliminate the need for a crankshaft and reduce friction losses. Companies like LG have already brought this technology to market in their premium refrigerators, with impressive efficiency gains.

Perhaps most exciting is the development of magnetic refrigeration. This technology uses changing magnetic fields to create cooling effects without traditional refrigerants. While still emerging, it could eventually eliminate refrigerant-related environmental concerns completely.

For larger systems, dual and multi-stage compression splits the compression process into steps, achieving higher efficiency especially when there's a big temperature difference between the inside and outside of the cooler – exactly the situation in many mortuary applications.

At American Mortuary Coolers, we're constantly evaluating these emerging technologies to determine which ones make sense for our customers. We believe in innovation that serves a purpose – providing reliable, efficient cooling that helps funeral homes reduce both their environmental impact and operating costs. After all, the best technology is the kind that works so well you barely notice it's there.

Frequently Asked Questions about Fridge Compressors

What horsepower size does a domestic fridge compressor usually have?

Ever wondered about the little engine that keeps your food cold? Most domestic fridge compressors pack more punch than you might think, typically ranging from 1/5 to 1/3 horsepower. It's fascinating how such a relatively small motor can keep your leftovers fresh for days!

The size varies based on your refrigerator's needs. Smaller, more efficient fridges often use compressors at the lower end of this range, while that side-by-side beast with the ice maker might need something more powerful to handle the extra cooling demands.

To put this in perspective, mini-fridges in college dorms usually get by with tiny 1/8 to 1/6 HP compressors. Your standard kitchen refrigerator needs that 1/5 to 1/3 HP range we mentioned. Step into commercial territory, and you'll find beefier 1/2 HP and larger units. Our mortuary coolers, which need reliable, consistent cooling, typically use 1 HP or more depending on the size of the unit.

Remember though, horsepower isn't everything! A modern inverter fridge compressor might have a modest HP rating on paper but deliver outstanding performance through its ability to run at variable speeds. It's like having a car that can efficiently cruise at exactly the right speed for the conditions, rather than just racing or idling.

Can I replace a fridge compressor myself or should I call a technician?

I've seen this question come up a lot, and while I admire the DIY spirit, replacing a fridge compressor is one job where calling a professional really is the wisest choice. Here's why I recommend leaving this particular task to the experts:

Working with refrigerants isn't just tricky—it requires special equipment and certification. Improper handling can harm the environment and might even land you in hot water legally if you're not certified. The system needs to be properly evacuated of air and moisture after replacement, then charged with precisely the right amount of refrigerant—procedures that require specialized tools and know-how.

There's also the electrical safety factor to consider. Fridge compressors involve high-voltage connections that can be dangerous if you're not trained to handle them. Plus, what looks like a compressor failure might actually be caused by something else entirely. A technician can diagnose the true culprit, potentially saving you from an unnecessary compressor replacement.

Cost-wise, professional compressor replacement typically runs between $200-$600 for home refrigerators, depending on your model and the type of compressor needed. Commercial systems like our mortuary coolers would cost significantly more due to their specialized nature.

One last thing to consider: if your fridge is getting up there in years, sometimes replacing the entire unit makes more financial sense than investing in a new compressor for an aging refrigerator. A good technician will give you honest advice about whether repair or replacement is your better option.

How long should a modern inverter fridge compressor last?

Good news if you've invested in a modern inverter refrigerator! These clever fridge compressors typically outlast their traditional fixed-speed cousins by a significant margin. While conventional compressors generally serve faithfully for 8-12 years, today's inverter models often keep humming along for 12-20 years.

Why the impressive lifespan? Inverter compressors are like marathon runners rather than sprinters. Instead of constantly stopping and starting (which causes wear and tear), they adjust their speed to match cooling demands. This gentler operation means less stress on components, reduced heat generation, and fewer vibration issues. Many also include sophisticated protection circuitry to guard against power fluctuations.

Several factors play into how long your compressor will last. Your usage patterns matter—if your refrigerator door is constantly opening and closing (hello, hungry teenagers!), or if the unit sits in a warm garage, the compressor works harder and may wear out faster. Regular maintenance makes a huge difference too. Simply cleaning those condenser coils every six months and ensuring proper airflow around your fridge can add years to its life.

Power quality in your home affects longevity as well. Voltage fluctuations and surges can damage sensitive compressor electronics, which is why we recommend using a surge protector for your refrigerator—a small investment that can prevent costly damage.

At American Mortuary Coolers, we're particularly selective about the compressors we install. Our mortuary refrigeration systems demand unwavering reliability—after all, they're preserving something irreplaceable. That's why we choose only compressors with proven track records for dependability and longevity, often opting for premium inverter models that will provide years of quiet, efficient service.

Conclusion

The fridge compressor truly is the heart of any refrigeration system. From the smallest dorm fridge to our specialized mortuary coolers, this vital component drives the cooling cycle that keeps everything perfectly chilled. I've always thought of compressors as the unsung heroes of modern life—working quietly behind the scenes to preserve food, medicine, and in our case, provide dignity in end-of-life care.

Understanding how these mechanical marvels work isn't just interesting—it's practical knowledge that can save you money and headaches down the road. Whether you're choosing a new refrigerator for your home or selecting specialized cooling equipment for a funeral home, the compressor will largely determine how well it performs, how much energy it uses, and how long it lasts.

Throughout this guide, we've explored the inner workings of fridge compressors and finded some important truths:

Modern compressor technologies have come a long way from the noisy, inefficient models of decades past. Today's rotary, scroll, and inverter designs run quieter, use less energy, and often last years longer than their predecessors. It's like comparing an old flip phone to a modern smartphone—same basic function, but worlds apart in performance.

Maintenance doesn't need to be complicated, but it does need to be consistent. Simply keeping those condenser coils clean and ensuring good airflow around your refrigerator can add years to your compressor's life. It's those small, regular acts of care that make the biggest difference.

The environmental impact of refrigeration is something we take seriously at American Mortuary Coolers. Newer refrigerants and efficient compressor designs have dramatically reduced the carbon footprint of cooling systems. When you choose energy-efficient equipment, you're not just saving money—you're helping protect our planet.

At American Mortuary Coolers, we've built our reputation on creating custom, durable cooling solutions specifically designed for the funeral industry. We understand that in your business, refrigeration isn't just a convenience—it's absolutely essential. That's why we carefully select the right fridge compressor technology for each application, considering factors like capacity requirements, ambient conditions, energy efficiency, and noise levels.

We're not just equipment suppliers—we're partners. Our team provides expert guidance in system selection and offers ongoing maintenance support across the contiguous 48 states from our locations in Johnson City, Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, Pittsburgh, and our regional service centers.

I've personally seen how the right cooling system brings peace of mind to funeral directors. There's something deeply satisfying about knowing you've helped someone provide dignified care during life's most difficult moments.

To learn more about our mortuary coolers and how we can help with your specialized refrigeration needs, visit our mortuary coolers information page or reach out to our team. We're real people who understand your challenges and are ready to help.

Whether you're maintaining your current system or selecting new refrigeration equipment, the compressor choice will largely determine your experience for years to come. Choose wisely, maintain regularly, and you'll enjoy reliable cooling when you need it most.