Why Working Tables Are Essential for Every Professional Workspace

A working table is a specialized surface designed for specific tasks that require durability, proper height, and functionality beyond what a regular desk can provide. Unlike standard desks, working tables are built to handle heavier loads, provide ergonomic positioning for various activities, and offer features like adjustable height and specialized surfaces.

Key differences between working tables and regular desks:

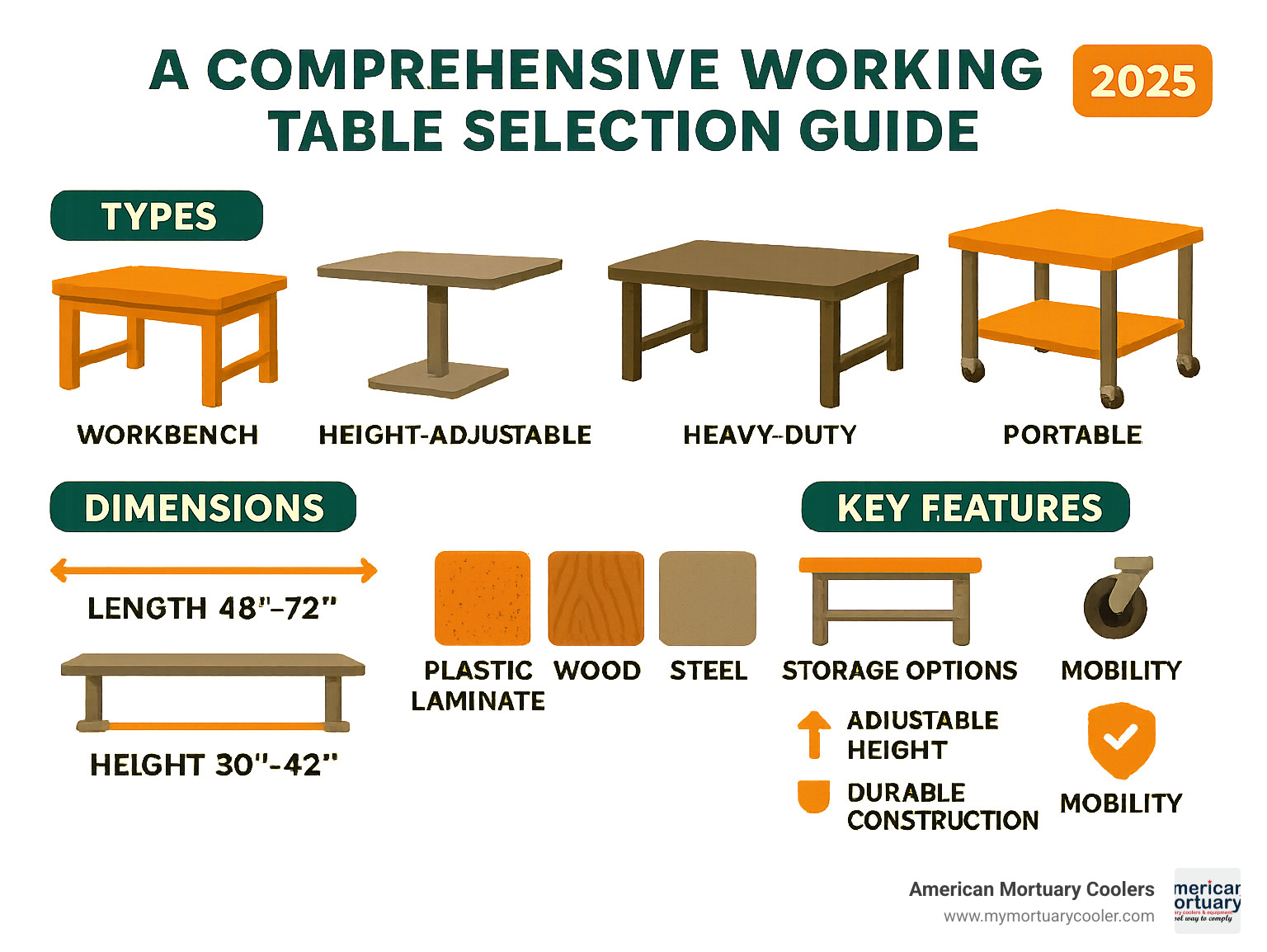

- Height: Working tables typically range from 30-42 inches (versus 28-30 inches for desks)

- Load capacity: Built to support 300+ pounds compared to 50-100 pounds for most desks

- Surface materials: Often feature durable laminate, solid wood, or specialized surfaces

- Adjustability: Many offer sit-stand functionality or manual height adjustment

- Purpose: Designed for active work like cutting, assembly, or crafting rather than just computer use

Whether you're setting up a workshop, craft room, sewing space, or professional facility, the right working table becomes the foundation of productivity and comfort. Research shows that alternating between sitting and standing throughout the day decreases body discomfort, increases blood flow, and can significantly boost productivity while reducing eye and back strain.

Modern working tables come in various configurations - from DIY wooden benches to high-tech adjustable models with built-in storage and mobility features. Standing work tables typically measure 38-42 inches in height and average 36 inches wide to accommodate multiple users or large projects on a single surface.

As specialists at American Mortuary Coolers, we've helped funeral home directors nationwide select durable working tables that meet the demanding requirements of professional mortuary environments. Our experience with heavy-duty working table solutions has shown us how the right surface can transform workflow efficiency and operator comfort.

Why This Guide Matters

Choosing the wrong working table can lead to chronic back pain, reduced productivity, and frustration with your workspace. We've seen too many professionals struggle with inadequate surfaces that don't match their work requirements or physical needs. This guide eliminates the guesswork by providing research-backed recommendations and practical insights from real-world applications.

Who Needs It

This comprehensive guide serves anyone who needs a functional work surface:

- Workshop owners and hobbyists

- Sewing and crafting enthusiasts

- Professional tradespeople

- Funeral home operators

- Artists and designers

- Small business owners setting up workspaces

How to Use This Guide

We've organized this guide to take you from basic concepts to specific purchasing decisions. Start with the fundamentals in "Working Table 101" if you're new to the topic, or jump directly to "Choosing the Perfect Working Table" if you already understand the basics. Each section builds on the previous one, culminating in actionable recommendations you can implement immediately.

Working Table 101 & Health Benefits

What Makes a Working Table Different

When you're shopping for a workspace surface, you might wonder what separates a working table from your average desk. The answer lies in how they're built and what they're meant to do.

Think of your office desk – it's designed for typing, maybe holding a monitor, and storing some paperwork. A working table? That's a whole different beast. These surfaces are engineered for real work: cutting materials, assembling projects, supporting heavy equipment, and handling whatever you throw at them.

The most obvious difference is sheer strength. While your typical desk might buckle under 100 pounds, a proper working table laughs at 300+ pounds of weight. Take the Husky Adjustable-Height Work Table – it's built with that exact 300-pound capacity in mind, whether you're sitting or standing.

The surface materials tell the story too. Instead of that thin veneer that chips if you look at it wrong, working tables feature thick solid wood, heavy-duty laminate, or even stainless steel. These surfaces shrug off scratches, dents, and chemical spills that would ruin a regular desk.

Height makes a huge difference as well. Standard desks sit at a comfortable 28-30 inches for typing, but working tables range from 30-42 inches. Standing models typically hit that sweet spot of 38-42 inches – perfect for keeping your back happy during hands-on work.

How a Working Table Boosts Productivity

Here's something interesting: the right working table doesn't just make you more comfortable – it actually makes you more productive. Research shows that switching between sitting and standing throughout your day reduces body discomfort and gets your blood flowing better, which means less eye strain, less back pain, and sharper focus.

When your work surface is at the right height, your body naturally finds better posture. No more hunching over a too-low surface or straining to reach materials. Your spine stays aligned, your shoulders relax, and you can work longer without that nagging fatigue.

The generous size of most working tables plays a big role too. Picture this: a large workshop table measuring around 120 inches long by 43 inches deep gives you enough room to spread out your entire project. No more constantly shuffling tools and materials around – everything has its place, and your workflow stays smooth.

Standing vs. Sitting: Science-Backed Benefits

Let's talk about why standing work surfaces have become so popular – and it's not just a trend. The science backs up what many of us feel intuitively: our bodies weren't designed to sit all day.

Standing working tables typically measure 38-42 inches high and average 36 inches wide – dimensions that work well for multiple people or large projects. But the real magic happens in your body when you stand.

Better blood flow is the big winner here. When you're standing, your heart doesn't have to work as hard to pump blood throughout your body. No more of that pooling that happens when you're seated for hours. Better circulation means you stay more alert and feel less drained.

Your back gets a break too. Standing with good posture engages your core muscles and keeps your spine in its natural curves. Compare that to sitting, which puts extra pressure on your spinal discs – especially if you're leaning forward over your work.

Your metabolism gets a gentle boost as well. Standing burns about 50% more calories than sitting. It's not going to replace your gym routine, but every bit helps.

Mental sharpness often improves when you're standing. There's something about the slight physical engagement that keeps your brain more alert and focused.

The key isn't to stand all day – that would be just as problematic as sitting all day. The best working table setups let you easily switch between sitting and standing as your body tells you what it needs. At American Mortuary Coolers, we've seen how the right adjustable work surface can transform the daily experience for funeral directors who spend long hours preparing for services.

Choosing the Perfect Working Table: Types, Sizes, Materials, Features

Finding the right working table can feel overwhelming with so many options available. The good news? Once you understand the main categories and what makes each one special, the choice becomes much clearer. Let's break down everything you need to know to make a smart decision.

Major Working Table Categories at a Glance

Standing tables are the workhorses of the working table world. Fixed at 38-42 inches tall, they're perfect when you need to apply downward pressure or do detailed hand work. Think of them as the reliable friend who's always there when you need them - no fuss, just solid performance.

Adjustable tables are the chameleons of workspace furniture. With manual cranks or electric motors, they let you switch between sitting and standing throughout the day. Modern versions often remember your favorite heights, making transitions smooth and effortless. They're ideal if you're still figuring out your preferred working style or share the space with others.

Traditional workbenches bring that old-school craftsmanship vibe to your workspace. Built from heavy-duty wood or steel, they often come with built-in vises, tool storage, and specialized features that woodworkers and mechanics love. These tables mean business and can handle whatever you throw at them.

Mobile workstations roll where you need them. Equipped with heavy-duty casters, they're perfect for dynamic environments where your working table needs to move between projects or areas. Just remember to get ones with good locking mechanisms - nobody wants their table rolling away mid-project!

Specialized tables are designed with specific tasks in mind. Sewing tables come with extension wings and storage cubbies. Crafting tables feature cutting mats and supply organization. Industrial tables sport chemical-resistant surfaces that can handle harsh environments.

Selecting a Working Table for Specialized Tasks

Your work determines your table needs more than anything else. Sewing and crafting enthusiasts need tables around 30 inches high for comfortable seated work, though adjustable height helps when you're cutting large pieces while standing. Wide surfaces accommodate those sprawling fabric projects, while built-in storage keeps your supplies from taking over the entire room. Light-colored surfaces are a game-changer for pattern work and photography.

Woodworking demands serious construction - we're talking solid wood tops that are 1.5-2 inches thick. Built-in tool storage, dog holes for clamps, and integrated vises turn a simple table into a complete workstation. These tables need to handle the abuse that comes with serious craftsmanship.

For electronics and precision work, stability is everything. Anti-static surfaces protect delicate components, while good lighting integration helps you see those tiny details. The height should let you work comfortably without craning your neck - your future self will thank you.

Industrial applications call for chemical-resistant surfaces that clean easily and handle heavy loads. Stainless steel tops are common in food service and medical settings, including funeral homes where hygiene and durability are non-negotiable.

Feature Checklist & Ergonomic Sizing

When evaluating any working table, start with load capacity. Look for ratings of 300+ pounds if you're doing serious workshop tasks. It's better to have too much capacity than not enough - trust us on this one.

Surface material choices each have their personality. Solid wood brings beauty and can be repaired when life happens, but it needs regular maintenance. Laminate is the practical choice - durable, easy to clean, and budget-friendly, though it can chip and can't be repaired. Stainless steel offers that professional, hygienic look that's perfect for medical or food applications, but it's cold to the touch and shows every scratch. Specialized surfaces like anti-static materials or self-healing cutting mats serve specific needs beautifully.

Adjustability comes in two flavors. Manual crank systems offer reliability and precision - they'll work for decades with minimal maintenance. Electric adjustment provides convenience for frequent height changes. Consider how often you'll actually adjust the height before paying extra for electric.

Storage integration keeps your workspace organized and efficient. Drawers, shelves, and tool organization features mean less hunting around for what you need. Mobility through heavy-duty locking casters gives you flexibility without sacrificing stability.

Look for certifications that matter. Many modern work tables, like those from Vari, carry GreenGuard and GreenGuard Gold certifications with 10-year warranties. These ensure low chemical emissions and long-term reliability - important considerations for spaces where you spend significant time.

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Solid Wood | Beautiful, repairable, traditional | Requires maintenance, can dent | Woodworking, crafting |

| Laminate | Durable, easy to clean, affordable | Can chip, not repairable | General workshop use |

| Stainless Steel | Hygienic, chemical-resistant | Cold, expensive, shows scratches | Medical, food service |

| Composite | Lightweight, moisture-resistant | Less durable, limited load capacity | Light-duty applications |

Build or Buy? DIY Guides and Top Brands Compared

Step-by-Step DIY Overview

Building your own working table can be incredibly rewarding – and surprisingly straightforward if you've got basic woodworking skills. After helping countless funeral directors set up their facilities, we've learned that sometimes the best solution is the one you build yourself.

The numbers tell the story: a custom DIY working table typically costs 40-60% less than buying comparable commercial models. Plus, you get exactly what you need, sized perfectly for your space.

For a substantial workshop table measuring 120.5" long by 43" deep by 36" high, you'll need six 4×4×8' posts for the legs, eight 2×4×8' boards for the frame, and five 2×10×12' boards for the tabletop. Don't forget six heavy-duty 5" casters if you want mobility – trust us, you'll appreciate being able to roll that table around.

The construction process is more manageable than it looks. Start by cutting all your materials according to your plan (measure twice, cut once!). Then drill pocket holes in your tabletop boards and frame pieces, spacing them about 8" apart. A Kreg Jig makes this step much easier and more accurate.

Assemble the tabletop using wood glue and pocket screws, working in sections you can handle comfortably. Build your frame with properly notched joints – this isn't the place to cut corners on strength. Attach those casters for mobility and height adjustment, then finish with stain and polyurethane for protection and good looks.

Most experienced DIYers complete this project in one to two solid days. The DIY Large Work Table guide provides detailed plans and step-by-step photos that make the whole process much clearer.

Popular Ready-Made Models & Price Tiers

Sometimes buying makes more sense than building, especially when you need a working table up and running quickly. The market breaks down into three clear categories.

Budget options ($200-500) get the job done for light-duty work. You'll typically find particle board tops with laminate surfaces and basic fixed heights. They're not glamorous, but they work for occasional projects or tight budgets.

Mid-range models ($500-1500) offer much better value for serious users. These usually feature manual crank height adjustment, solid construction, and useful extras like storage drawers. The Husky Adjustable-Height Work Table falls into this category with its 300-pound capacity and sit-stand functionality.

Premium tables ($1500 and up) bring electric height adjustment, memory settings, and commercial-grade construction. Vari stands out in this category with their GreenGuard certification and impressive 10-year warranties. These tables make sense for professional environments or heavy daily use.

We've found that most people are happiest in the mid-range category. You get real durability and useful features without paying for bells and whistles you might not need.

When to Hunt for an Antique Working Table

Here's something most people don't consider: antique working tables can be absolute gems. We're talking about pieces built when furniture was meant to last generations, not years.

Antique work tables range from delicate Victorian sewing tables with intricate inlays to massive industrial factory benches that could probably survive a direct meteor strike. Prices typically run from £230 to £6,500, depending on age, condition, and rarity.

The construction quality on these older pieces is often superior to modern alternatives. Solid wood throughout, traditional joinery techniques, and attention to detail that's hard to find today. Plus, you get a conversation starter that doubles as a functional workspace.

Consider going antique when you value unique character over modern conveniences, when your work doesn't require electrical integration, or when you enjoy restoration projects. Just remember that these beauties need regular maintenance – but that's part of their charm.

One word of caution: make sure any antique working table can handle your intended use. That neat Victorian sewing table might not be the best choice if you're planning to use power tools on it.

Maintaining, Accessorizing & Future Trends

Routine Care for Longevity

Taking care of your working table isn't complicated, but it makes all the difference in how long it serves you well. Think of it like maintaining a good friendship – a little attention goes a long way.

For wood surfaces, the key is staying ahead of wear rather than trying to fix major damage later. When your table starts looking tired, sand it progressively from coarse to fine grits, starting around 120 and finishing with 220. Apply stain in thin, even coats, working in sections you can manage comfortably. Nobody wants to rush through staining and end up with blotchy results.

The real protection comes from multiple coats of polyurethane. Sand lightly between coats – just enough to smooth things out. For day-to-day cleaning, stick with wood cleaners that won't build up over time. Your table will thank you for it.

Metal components need their own kind of attention. Keep those casters clean and lubricated so they roll smoothly instead of fighting you every time you need to move the table. Check and tighten bolts periodically, especially on adjustable models that get a workout. If you've got steel surfaces, protect them from rust before it becomes a problem.

The general maintenance routine is pretty straightforward. Inspect weight-bearing connections regularly – better to catch a loose bolt now than deal with a wobbly table later. Replace worn casters before they start damaging your floors. Keep adjustment mechanisms clean and properly lubricated so they work when you need them.

Must-Have Accessories for Any Working Table

The right accessories transform a basic working table into a productivity powerhouse. It's like the difference between a bare apartment and a real home – the details make it work for you.

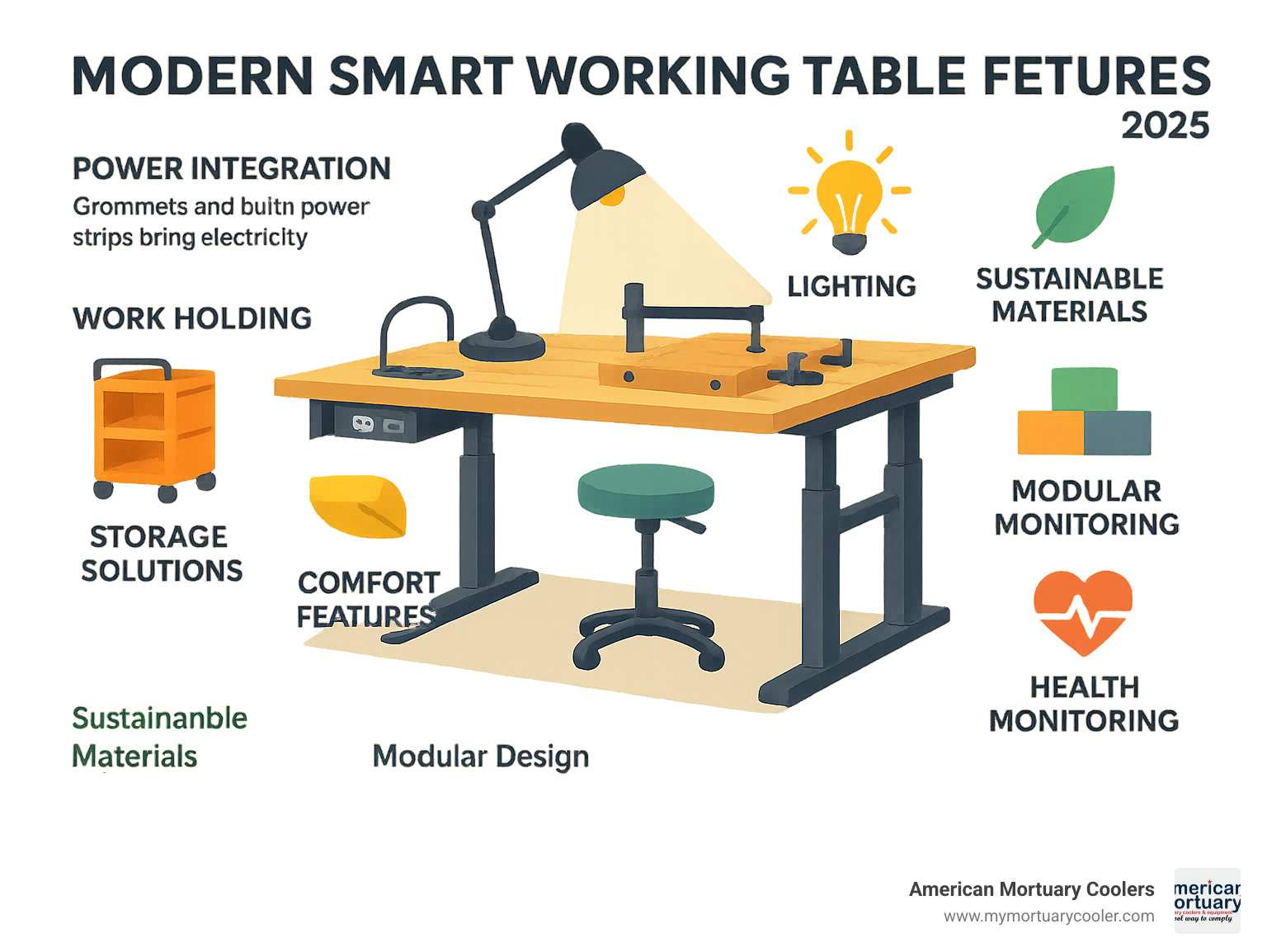

Power grommets and built-in power strips solve the eternal problem of getting electricity where you need it without turning your workspace into a spaghetti bowl of extension cords. There's something deeply satisfying about having power exactly where you need it, when you need it.

For work holding, think beyond basic clamps. Clamp rails, bench dogs, and integrated vises turn your table into a third hand that actually helps instead of getting in the way. These features secure materials during operations so you can focus on the work instead of fighting to keep things in place.

Lighting deserves special attention because good lighting reduces eye strain and improves work quality. Adjustable task lighting, LED strips under shelves, or quality desk lamps provide targeted illumination that makes detailed work actually enjoyable instead of a squinting contest.

Storage solutions keep essential items within reach while maintaining clear work surfaces. Rolling carts, pegboard systems, and magnetic tool strips mean you spend time working instead of hunting for the right tool. Organization isn't just about looking neat – it's about working efficiently.

Don't forget comfort features that support your body during long work sessions. Anti-fatigue mats for standing work, adjustable stools for sitting breaks, and ergonomic accessories help you maintain proper posture without thinking about it constantly.

Trend Watch: Smarter, Greener Workspaces

The future of working tables is getting pretty exciting, combining technology with genuine sustainability in ways that actually make sense.

Smart features are moving beyond gimmicks to genuinely useful capabilities. Height-memory settings remember your preferred positions, app-controlled adjustments let you fine-tune without interrupting your workflow, and integrated charging stations keep devices powered without cluttering your workspace.

Sustainable materials are becoming the norm rather than the exception. Manufacturers increasingly use recycled materials, low-VOC finishes, and sustainably sourced wood. It's not just about feeling good – these materials often perform better and last longer than traditional alternatives.

Modular design systems adapt to changing needs instead of forcing you to buy entirely new furniture. Systems like IKEA's MITTZON allow configurable group or individual workstations with acoustic screens that grow and change with your requirements.

Some advanced models now include health monitoring features like posture reminders and activity tracking to encourage healthy work habits. While this might sound like overkill, anyone who's dealt with chronic back pain from poor workspace ergonomics appreciates the gentle nudges.

At American Mortuary Coolers, we're seeing increased demand for sustainable, durable working tables that meet both environmental and performance standards. Our clients across Tennessee, Georgia, Illinois, and other regions are investing in equipment that supports both immediate needs and long-term sustainability goals. When you're serving families during difficult times, having reliable, well-maintained equipment isn't just about efficiency – it's about respect and professionalism.

Frequently Asked Questions about Working Tables

When we help funeral directors and workshop owners across Tennessee, Georgia, and Illinois choose the right equipment, we hear the same questions over and over. Here are the answers to the most common working table questions that will help you make the best decision for your workspace.

What is the standard height of a working table?

The "standard" height really depends on what you're planning to do at your table. We've learned from years of helping professionals that one size definitely doesn't fit all.

For seated work like detailed assembly or sewing, you'll want your table around 30 inches high. This lets you work comfortably without hunching over or straining your shoulders.

Standing work is where things get more interesting. Most standing work surfaces sit between 36-42 inches tall, but the sweet spot depends on your height and the task. For general workshop tasks, 36-38 inches works well for most people.

Here's a pro tip from our experience: if you're doing cutting tasks, position your work surface a few inches below your elbow height when standing. For precision work, you want it right at or slightly above elbow height.

The smartest choice? An adjustable model that lets you switch between sitting and standing positions throughout the day. Your back will thank you, and you'll be more productive too.

Which material lasts the longest in a garage workshop?

After helping countless workshop owners over the years, we've seen which materials hold up and which ones don't. Garage environments are tough - you've got temperature swings, humidity changes, and the occasional spilled coffee or motor oil.

Laminate surfaces over engineered substrates give you the best bang for your buck in garage settings. They laugh off temperature changes, clean up easily when you spill something, and can handle the daily abuse of workshop life without breaking the bank.

Solid wood has its charm and can last decades if you're willing to put in the work. The catch? It needs regular maintenance, and garage humidity can make it warp or crack. But here's the upside - you can sand it down and refinish it as many times as needed.

Stainless steel is the ultimate survivor. It handles everything you can throw at it and still looks professional. We use it in mortuary applications because it's so durable and easy to sanitize. The downside? It costs significantly more, and for typical garage work, it might be overkill.

For most garage workshops, we recommend starting with a quality laminate surface. You can always upgrade later if your needs change.

Can I convert my desk into a standing working table?

We get this question a lot, especially from folks trying to save money or work with what they have. The short answer is: maybe, but probably not the way you're hoping.

The main problem is that regular desks just aren't built for working table duties. Those desk legs that seem sturdy enough for your computer and paperwork? They typically can't handle the loads that real workshop tasks demand. Plus, desk surfaces are usually thin veneers or lightweight materials that won't stand up to cutting, hammering, or heavy assembly work.

Desktop risers can work for light-duty standing tasks - things like sorting parts or light assembly. But if you need to apply pressure, use power tools, or work with heavy materials, you're asking for trouble.

Here's what we tell our clients: if you're serious about having a functional working table, invest in the real thing. You'll get better durability, proper load capacity, and features designed for actual work. Your productivity will improve, and you won't be constantly worried about damaging your makeshift setup.

Sometimes the cheapest option upfront ends up costing more in the long run when you factor in frustration, reduced productivity, and the eventual need to buy the right tool for the job anyway.

Conclusion

Choosing the right working table isn't just about finding a place to work—it's about creating a foundation that supports your best efforts every single day. After decades of helping funeral directors across the country find equipment that stands up to demanding professional use, we've learned that the right work surface makes all the difference.

The decision comes down to understanding what you really need. Height matters more than most people realize—your back will thank you for taking the time to get this right. Load capacity should always exceed what you think you'll need, because projects have a way of growing. And surface materials need to match your reality, not your wishful thinking about how carefully you'll treat them.

Whether you're drawn to the satisfaction of building your own table, the convenience of a premium adjustable model, or the character of a well-crafted antique piece, the best choice is the one that fits your specific situation. Don't get caught up in what looks impressive—focus on what works for your hands, your projects, and your space.

At American Mortuary Coolers, we see how the right equipment transforms professional environments. Our clients from Tennessee to California rely on work surfaces that perform flawlessly under pressure, day after day. That same principle applies whether you're running a funeral home, crafting furniture in your garage, or setting up a sewing room.

The investment in a quality working table pays for itself in ways you might not expect. Less fatigue means better work. Better organization means faster completion. And the confidence that comes from having the right tools for the job? That's priceless.

Take your time making this decision. Measure twice, as they say. Consider how your needs might change over the next few years. And remember—a good work surface isn't just equipment, it's the foundation of everything you'll create on it.

For specialized mortuary applications or when you need equipment built to exacting professional standards, explore our comprehensive equipment options designed specifically for the demands of funeral service environments.