Why Heavy Duty Lift Tables Are Essential for Modern Operations

A heavy duty lift table is a powerful hydraulic or electric scissor lift designed to handle loads from 1,000 to 10,000 pounds while providing precise height adjustment for ergonomic material handling. These industrial workhorses differ from standard lift tables through reinforced construction, oversized hydraulic cylinders, and improved duty cycles that support continuous operation in demanding environments.

Key specifications for heavy duty lift tables:

- Capacity Range: 1,000 - 10,000 lbs (vs. 500-2,000 lbs for standard models)

- Platform Sizes: 24"×36" up to 96"×120"

- Lift Heights: Up to 60 inches raised, 7 inches collapsed

- Power Options: Hydraulic, electric, pneumatic, or manual

- Duty Cycles: 30,000+ operations vs. 10,000 for light-duty models

- Construction: Reinforced scissor arms with oversized pins and bushings

Heavy duty lift tables serve multiple industries including manufacturing, automotive, warehousing, and specialized applications like mortuary facilities where precise positioning of heavy loads is critical. They reduce workplace injuries by up to 40% while boosting productivity through faster, safer material handling.

Quick heavy duty lift table terms:

Why This Guide Stands Out

This comprehensive guide addresses 14 key questions that industrial buyers ask when selecting heavy duty lift tables, from capacity requirements to customization options. We cover everything from basic specifications to advanced integration strategies, ensuring you have the complete picture before making your investment decision.

What Is a Heavy Duty Lift Table and How Does It Differ From Standard Models?

The difference between a standard lift table and a heavy duty lift table becomes clear when you're dealing with serious industrial loads. Standard lift tables handle 500-2,000 pounds, while heavy duty lift tables start at 1,000 pounds and reach up to 10,000 pounds capacity.

The scissor mechanism gets a complete overhaul in heavy duty models with thicker, reinforced steel construction and oversized pivot pins. Hydraulic cylinders are typically 50% larger in diameter than standard counterparts, providing consistent power for substantial loads through 30,000+ annual cycles versus 10,000 for standard models.

Platform sizes scale from 24"×36" for compact applications up to 96"×120" for oversized materials, with platform thickness increasing to 1/4" or thicker to prevent flex under load.

Key Specifications That Make a "Heavy Duty" Lift Table

A true heavy duty lift table meets specific engineering criteria including 10,000-pound maximum rating with reinforced scissor arms manufactured from high-tensile steel. Oversized pins and bushings use 1.5-inch or larger pins with bronze bushings for durability.

High-pressure pumps generate 2,000-3,000 PSI compared to 1,500 PSI in standard units, enabling faster lifting speeds at maximum capacity. The duty cycle rating of 30,000+ operations annually considers hydraulic system performance under continuous operation without overheating or degradation.

Typical Capacities & Dimensions for Heavy Duty Lift Tables

Heavy duty lift tables range from 1,000 to 10,000 pounds capacity, with popular ratings at 2,000, 3,000, 4,000, 5,000, 6,000, and 8,000 pounds. Platform dimensions scale from 24"×36" up to 96"×120", with vertical travel of 24-60 inches while maintaining stability. Collapsed height around 7 inches provides excellent loading access, with low-profile models reaching 3 inches (limited to 3,000 pounds capacity).

Types of Heavy Duty Lift Tables: Hydraulic, Pneumatic, Electric & Manual

Power source selection dramatically impacts performance, maintenance requirements, and operational characteristics of heavy duty lift tables. Each type offers distinct advantages for specific applications and environments.

Hydraulic Heavy Duty Lift Table

Hydraulic heavy duty lift tables represent the gold standard for industrial lifting, combining exceptional capacity with precise control. These systems use pressurized hydraulic fluid to power cylinders, allowing small pumps to generate enormous lifting forces - a 2-horsepower pump can lift 10,000 pounds.

Foot-pump systems offer portability without electrical requirements, ideal for mobile applications up to 3,000 pounds. Power-unit systems employ electric motor-driven pumps for consistent pressure and faster cycle times in high-volume applications.

Overload bypass valves protect operators and equipment by preventing dangerous overloading. Hydraulic Lift Tables - Portable, Durable, and Ergonomic systems incorporate multiple safety features for demanding applications.

Electric Heavy Duty Lift Table

Electric heavy duty lift tables use AC motors with mechanical actuators for precise, repeatable lifting. These systems excel in applications requiring exact positioning and integration with automated controls. Modern systems employ 0.75-2.2 kW motors driving precision ball screws through gear reducers.

Push-button pendant controls offer variable speed capabilities with programmable positioning for repetitive operations. Lift speeds range from 15-30 mm/s under full load, providing consistent movement ideal for assembly operations.

Pneumatic & Air-Bag Lift Tables

Pneumatic heavy duty lift tables use compressed air for spark-free operation in hazardous environments. Clean room applications benefit from contamination-free air leaks, while explosive atmospheres require spark-free operation. These systems typically require 80-120 CFM at 90-120 PSI.

Manual & Mobile Configurations

Manual heavy duty lift tables provide maximum versatility through foot-pump operation requiring no external power. These systems handle loads up to 3,300 pounds with unlimited duty cycles. Mobile configurations incorporate heavy-duty casters and floor locks for multi-station use throughout facilities.

Choosing the Right Heavy Duty Lift Table: Capacity, Platform, Lift Height & Custom Options

Selecting the optimal heavy duty lift table requires careful analysis of load requirements, application needs, and return on investment. The selection process should begin with detailed load analysis including maximum weight, dimensions, and lifting frequency.

Critical Selection Factors

Capacity margin represents the most critical safety factor. Industry best practice recommends maintaining at least 25% capacity margin above your heaviest anticipated load. This accounts for load variations, dynamic forces, and potential future requirements.

Platform footprint must accommodate your largest loads while fitting available floor space. Consider load dimensions plus operator access requirements and safety clearances. Vertical travel requirements typically benefit from 36-48 inches for ergonomic working heights.

Duty cycle specifications must match operational requirements. Light-duty applications might need 5,000 annual cycles, while production environments could demand 50,000+ cycles. Environmental hazards like moisture, chemicals, or extreme temperatures require special materials and protective features.

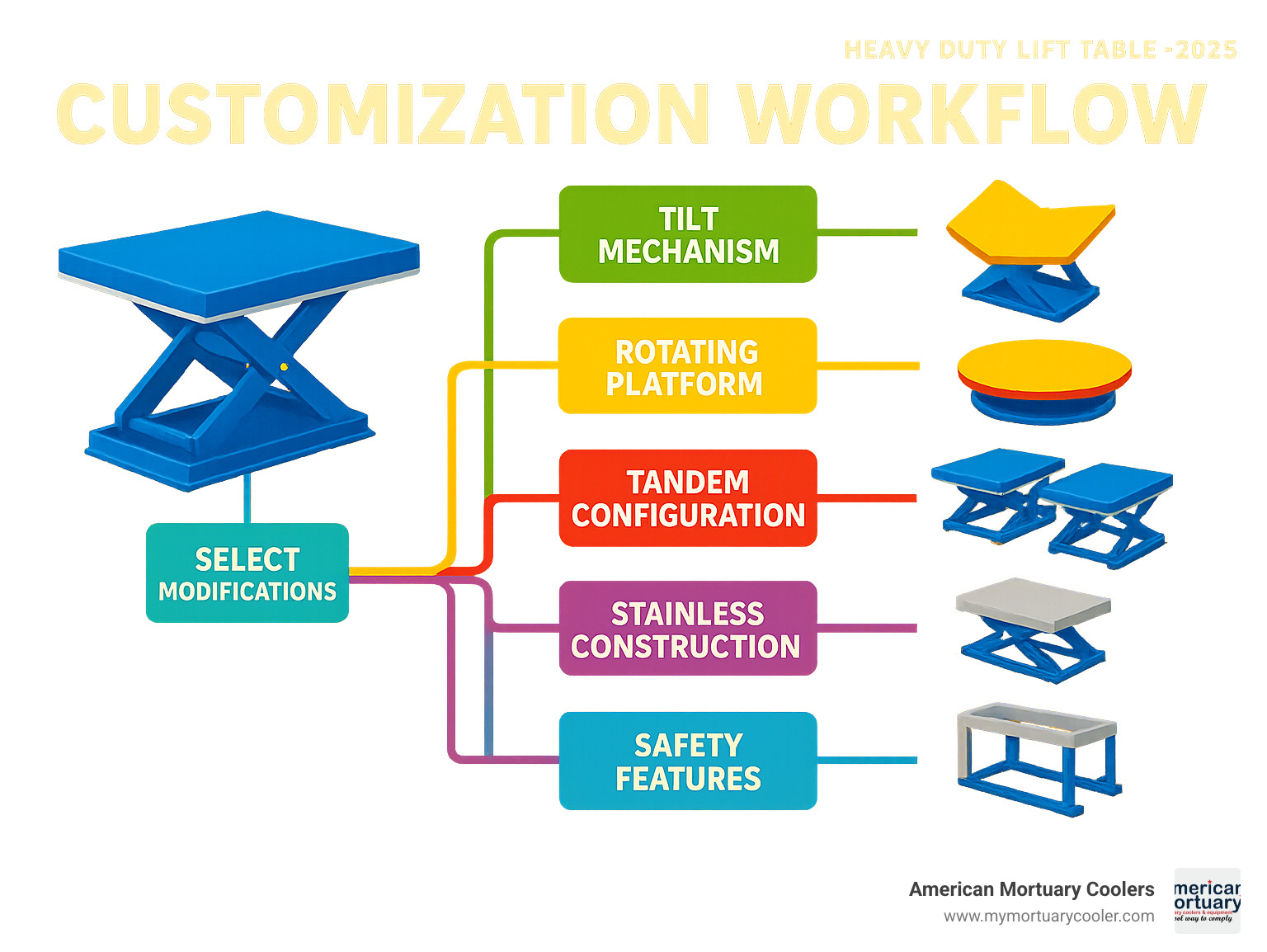

Customization Options That Pay Off

Tilt-top platforms rotating up to 45 degrees reduce operator bending and stretching, particularly benefiting assembly operations and parts handling. Rotating decks providing 360-degree rotation eliminate walking around large loads, ideal for welding and inspection procedures.

Tandem scissor configurations combine two tables for extremely long or heavy loads exceeding single-table capabilities, handling up to 20,000 pounds. Stainless steel construction provides corrosion resistance for food processing and pharmaceutical applications.

Floor-level U-shaped platforms enable forklift access without ramps, allowing wheeled equipment to drive directly onto the platform for lifting.

Cost & ROI Analysis

Initial purchase price represents only a fraction of total ownership costs. Labor savings provide the most significant ROI through 40-60% reduction in handling time and improved ergonomics. Injury reduction saves an average of $15,000 per prevented incident.

Productivity improvements of 15-25% occur through faster, more consistent material handling. Payback periods typically range from 12-24 months depending on utilization and labor costs. The Ultimate Guide to Choosing the Best Hydraulic Lift Cart provides additional ROI insights.

Safety, Ergonomics & Maintenance Best Practices

Heavy duty lift tables transform workplaces when operators understand proper use and maintenance. Operator training should cover load limits, positioning, and emergency procedures. ANSI MH29.1 standards provide guidelines for safe operation and equipment specifications.

Pinch-point guards protect operators from moving parts, while mechanical locks provide backup protection if hydraulic systems fail. Daily inspections should check for fluid leaks, unusual noises, or jerky movements.

How Heavy Duty Lift Tables Improve Workplace Safety

Heavy duty lift tables eliminate back-breaking work through reduced bending and improved load stability. Controlled descent prevents dangerous rapid lowering, while emergency stop systems immediately halt operation while maintaining load support.

Maintenance Checklist for Long Service Life

Weekly lubrication of pivot points and pins keeps everything moving smoothly. Hydraulic oil changes every 2,000 hours maintain system performance - clean oil prevents component wear and ensures smooth operation.

Hose inspection should check for cracks, bulges, or wear areas. Limit switch testing ensures safety systems function properly. Scissor pin wear checks help catch problems before expensive failures occur.

Manual Post Lift Tables | Square | Lange Lift Company offers excellent maintenance guidance for extending equipment service life.

Comparing Heavy Duty Lift Tables to Forklifts, Cranes & Pallet Jacks

| Feature | Heavy Duty Lift Tables | Forklifts | Cranes | Pallet Jacks |

|---|---|---|---|---|

| Initial Cost | $3,000-$15,000 | $20,000-$50,000 | $50,000-$200,000 | $200-$2,000 |

| Floor Space | 4×6 to 8×12 feet | 8×12 feet + aisles | Overhead or 20×20 feet | 2×5 feet |

| Operator Training | 2-4 hours | 40+ hours + certification | 80+ hours + certification | 1 hour |

| Precision Positioning | Excellent (±1mm) | Good (±25mm) | Fair (±50mm) | Poor (±100mm) |

| Load Capacity | 1,000-10,000 lbs | 3,000-15,000 lbs | 5,000-50,000+ lbs | 4,000-6,000 lbs |

Heavy duty lift tables excel where precision and ergonomics matter most, offering ±1mm positioning accuracy that forklifts can't match. Training time takes hours rather than weeks of certification.

When a Heavy Duty Lift Table Is the Superior Choice

Assembly line operations benefit from surgical precision in tight spaces. Packaging cells eliminate constant bending by maintaining optimal working height. Die handling operations demand rock-solid stability for precision tooling positioning.

Dock-level loading operations bridge truck beds and facility floors without ramps. Pallet build-up operations maintain ergonomic working height as pallets grow taller.

Integrating Lift Tables Into Existing Material-Handling Systems

Conveyor interfaces connect different level conveyors without complex transitions. Robotic cell integration optimizes robot performance by adjusting work surface height for optimal reach parameters.

Safety interlocks ensure integrated systems work together safely, preventing conveyor operation when tables are raised. More info about mortuary lift systems provides integration insights for specialized industries.

Frequently Asked Questions about Heavy Duty Lift Tables

What certifications should I look for?

ANSI MH29.1 certification represents the gold standard for lift table safety and performance, covering structural design to safety systems. CE marking indicates higher safety standards, while UL listing ensures electrical safety compliance. ISO 9001 certification indicates manufacturer quality management systems.

How often does a hydraulic unit need servicing?

Most heavy duty lift tables need service every 2,000 operating hours, typically annual maintenance for most operations. Operating environment affects intervals - dusty or extreme conditions may require service every 1,000-1,500 hours. Oil analysis can optimize service intervals by monitoring fluid condition.

Can I retrofit safety skirts or limit switches later?

Yes, most heavy duty lift tables accommodate modular safety additions. Bellows skirting, limit switches, and safety barriers can typically be added through bolt-on systems without compromising structural integrity.

Conclusion

Choosing the right heavy duty lift table transforms your workplace from daily strain into efficient, safe operations. Whether handling 1,000-pound components or 10,000-pound industrial loads, proper equipment selection makes the difference between struggling and thriving.

Capacity margins of 25% protect workers and equipment, while proper platform sizing ensures safe load handling. Choose hydraulic power for maximum strength, electric precision for automation, or pneumatic operation for hazardous environments based on your specific needs.

Customization options like tilt-top platforms and rotating decks often pay for themselves through improved productivity and reduced worker fatigue. These investments in your team's well-being directly impact your bottom line.

At American Mortuary Coolers, we've learned that the right lift table transforms how people work. Based in Tennessee with delivery across all 48 contiguous states, we've seen proper equipment selection turn struggling operations into smooth, efficient workplaces.

Our mortuary industry experience taught us that when precision matters and reliability isn't optional, standard solutions often fall short. That's why we focus on custom durability - building equipment that handles your specific challenges while maintaining safety standards.

The numbers speak clearly: labor savings of 40-60%, injury reduction preventing costly claims, and productivity improvements of 15-25% typically deliver payback within 12-24 months. Beyond financial returns, there's deep satisfaction watching your team work without daily strain.

Your next step is simple: evaluate your heaviest, most frequent lifting tasks. Calculate time spent positioning loads manually. Consider near-misses that could become major problems. Then imagine those operations flowing smoothly with the right heavy duty lift table.

For applications demanding custom solutions, we're here to help. Our engineering team creates equipment solving your specific problems while meeting rigorous safety standards. Maximize Safety with American Mortuary's Durable Crematory and Mortuary Lift Solutions showcases our custom engineering capabilities.

Ready to transform your material handling? Contact us today to discuss your heavy duty lift table requirements. Our nationwide delivery network ensures quick delivery of custom solutions. You're not just buying equipment - you're investing in years of reliable, safe, productive operation.