A Comprehensive Guide to Laboratory Storage Systems

Why Laboratory Storage Systems Are Critical for Modern Facilities

Laboratory storage systems are the backbone of any well-functioning scientific facility, providing organized, safe, and accessible storage for equipment, samples, chemicals, and supplies. These specialized storage solutions ensure sample integrity while maintaining strict safety protocols and regulatory compliance.

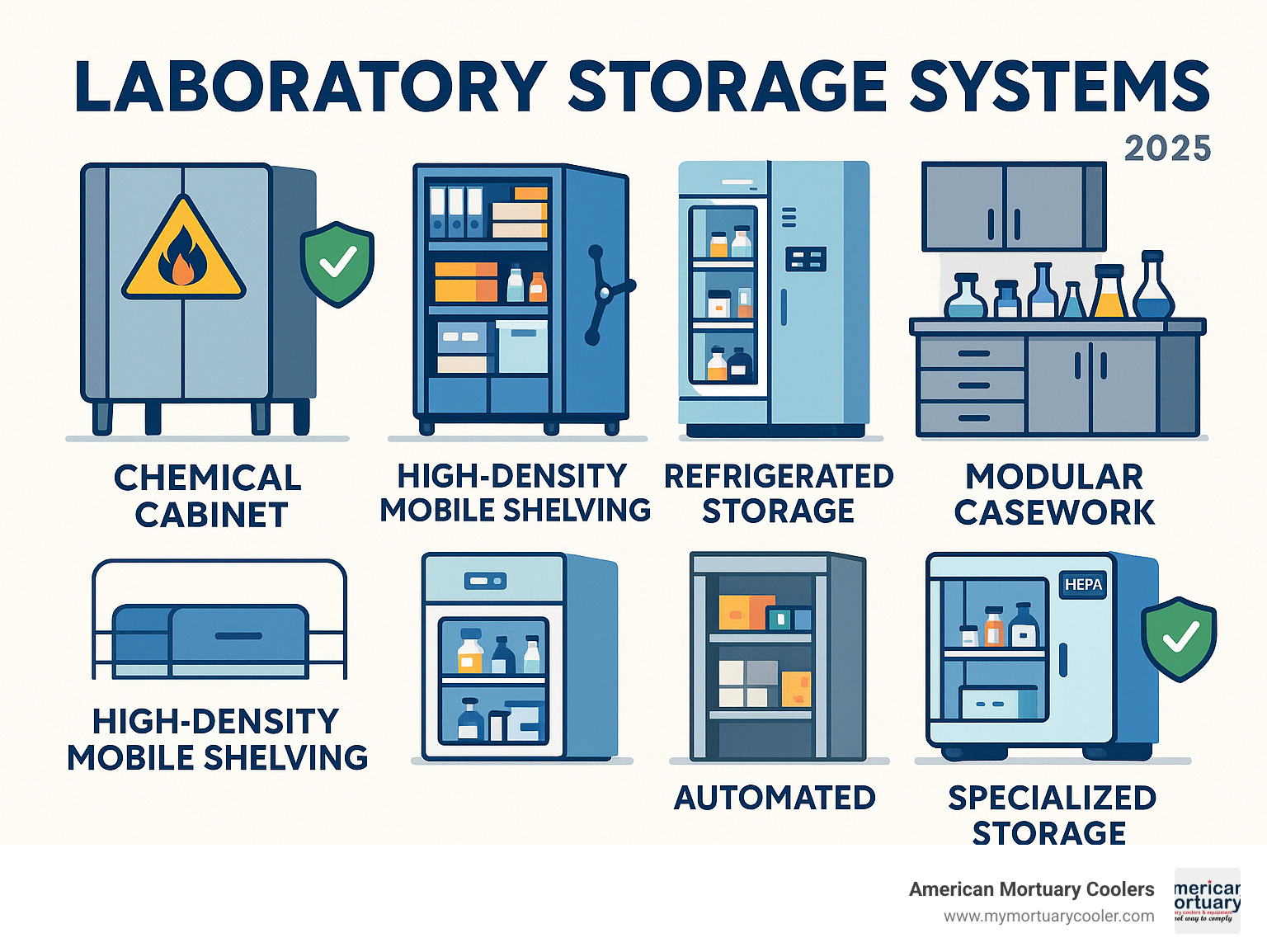

Key Types of Laboratory Storage Systems:

- Chemical Storage Cabinets - Fire-resistant, ventilated units for flammable and hazardous materials

- High-Density Mobile Systems - Space-saving solutions that can double storage capacity

- Refrigerated Storage - Temperature-controlled units for biological samples and reagents

- Modular Casework - Flexible, reconfigurable storage with chemical-resistant surfaces

- Automated Systems - Vertical carousels and robotic storage for maximum efficiency

- Specialized Units - HEPA-filtered cabinets, UV sterilization chambers, and cleanroom storage

The goal of laboratory storage systems is simple: maintain the integrity of stored items while ensuring safety and accessibility. Whether you're storing temperature-sensitive biological samples at -80°C, organizing flammable solvents in ventilated cabinets, or protecting expensive equipment from contamination, the right storage system protects both your materials and your team.

Modern labs face unique challenges including space constraints, hazardous material handling, and regulatory compliance with OSHA and NFPA standards. High-density storage systems address these issues by eliminating wasted aisle space, while specialized cabinets provide proper ventilation and spill containment for dangerous chemicals.

As American Mortuary Coolers, we've spent years helping facilities optimize their cold storage and laboratory storage systems nationwide. Our experience includes designing custom solutions that integrate seamlessly with existing laboratory workflows while meeting strict temperature and safety requirements.

Understanding the Fundamentals of Laboratory Storage

When you walk into a well-organized lab, everything just flows. Researchers move confidently between workstations, samples stay pristine, and safety protocols feel natural rather than burdensome. This seamless operation doesn't happen by accident—it's built on solid laboratory storage systems that serve three core purposes.

Sample integrity comes first, and it's more complex than it sounds. Your biological specimens need rock-solid temperature control—we've seen entire research projects derailed by a freezer that drifted just a few degrees. Chemical reagents demand proper ventilation and containment, while sensitive equipment requires protection from dust, moisture, and vibration.

At American Mortuary Coolers, we've learned this lesson through our custom installations across the Southeast. Even small environmental changes can compromise years of careful work, which is why we obsess over temperature stability and reliable monitoring systems.

User safety isn't negotiable. OSHA regulations spell out specific ventilation requirements for chemical storage, while NFPA guidelines mandate fire-resistant construction for flammable materials. These aren't suggestions—they're legal requirements that protect lives and prevent catastrophic accidents.

Efficient accessibility means more than just reaching what you need. It's about creating organized systems that support smooth workflows without creating bottlenecks or safety hazards. We've watched labs cut sample retrieval time by 60% simply through better storage organization.

Contamination control adds another layer of complexity, especially in research and medical facilities. Cross-contamination between samples can invalidate months of work, while environmental contamination creates serious health risks. Smart storage solutions include sealed compartments, HEPA filtration, and antimicrobial surfaces.

Key Challenges in Laboratory Storage

Space limitations hit virtually every lab we visit. Real estate costs force facilities to squeeze maximum value from every square foot, yet traditional storage wastes precious space with fixed aisles and inefficient layouts. High-density mobile systems solve this by eliminating static aisle space—some systems can literally double your storage capacity.

Hazardous material storage gets tricky fast. Different chemicals have incompatible needs. Acids require corrosion-resistant materials, flammables need fire-resistant construction, and some chemicals can't even be stored in the same room together.

Temperature control becomes a juggling act when you need multiple climate zones. Ultra-low freezers for biological samples, standard refrigeration for reagents, and ambient storage for equipment all require different infrastructure and monitoring.

Security requirements create their own challenges. Controlled substances need locked storage with detailed access logging, while expensive equipment requires theft protection. The challenge is balancing security with accessibility.

Future expansion planning stumps even well-designed facilities. Research directions shift, sample volumes grow unexpectedly, and new equipment arrives regularly. The smartest storage systems accommodate growth without requiring complete redesigns.

Major Types of Laboratory Storage Systems

When you walk into a modern laboratory, you'll see a carefully orchestrated symphony of laboratory storage systems working together. Each type serves a specific purpose, and when properly coordinated, the result is beautiful efficiency.

Refrigerators and freezers are the workhorses of temperature-sensitive storage. Standard lab refrigerators keep reagents and samples at 2-8°C, while ultra-low temperature freezers preserve biological materials at -80°C. These feature precise temperature control, comprehensive alarm systems, and backup power considerations.

Flammable storage cabinets provide essential fire safety through fire-resistant construction and proper ventilation, following NFPA 30 guidelines. They feature double-wall steel construction and self-closing doors for maximum protection.

Chemical-resistant casework systems handle corrosive materials with surfaces that resist laboratory chemicals. Epoxy resin countertops and phenolic resin surfaces provide durability that withstands harsh conditions.

Wire shelving systems bring versatility and visibility to general storage needs. Antimicrobial finishes make them perfect for wet environments—they're easy to clean, chemical-resistant, and stable. The open design promotes airflow while providing clear visibility.

Personal item lockers separate staff belongings from laboratory materials, preventing contamination and keeping personal items secure. Day-use lockers make shift changes smoother.

Mobile carts bridge the gap between fixed storage and point-of-use access, bringing materials directly to work areas and reducing contamination risks.

High-Density Laboratory Storage Systems

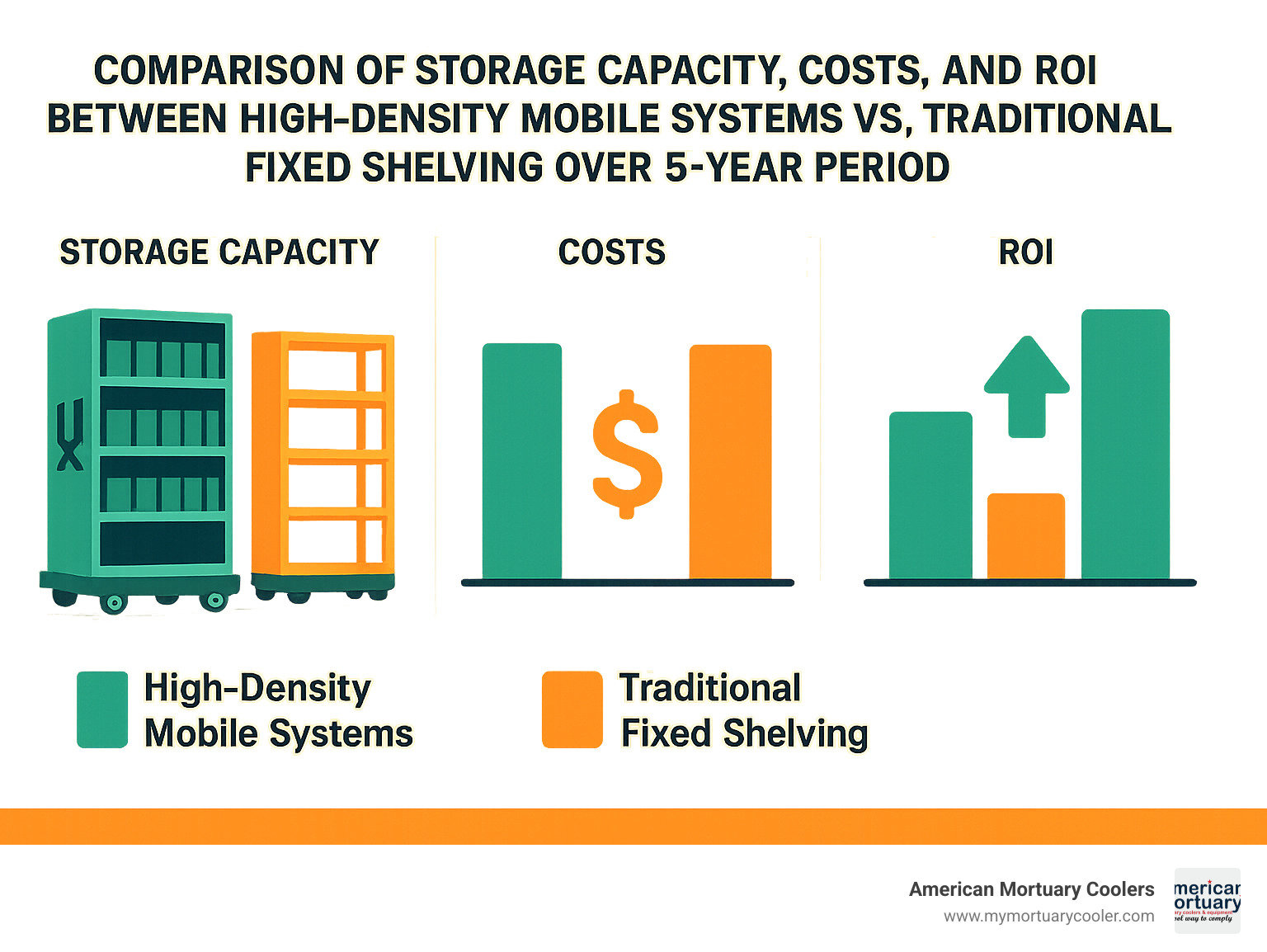

High-density mobile systems eliminate space-wasting fixed aisles by creating access paths only when needed. Instead of permanent walkways eating up 40-50% of your floor space, these systems move entire storage sections to create aisles on demand.

The space savings are remarkable—these systems can literally double your storage capacity in the same footprint. When laboratory space costs more per square foot than prime real estate, this efficiency becomes invaluable.

Modern high-density systems are surprisingly robust. Each drawer can support up to 400 pounds and comes with a lifetime warranty on rolling mechanisms. That's enough capacity for heavy equipment, massive sample collections, and bulk chemical storage.

One exciting development is cold storage integration. You can now incorporate refrigerated and freezer units directly into mobile systems, combining temperature control with space efficiency. At American Mortuary Coolers, we've designed custom installations that blend ambient and refrigerated storage in unified systems.

Safety features include anti-tip mechanisms, soft-close drawers, and integrated lighting. These systems also handle specialized storage needs like slide storage, specimen containers, and delicate equipment protection.

Automated & Vertical Laboratory Storage Systems

Automated storage represents the ultimate combination of efficiency and space utilization. Vertical storage carousels can save up to 75% of your floor space compared to traditional methods while improving accuracy and cutting retrieval time dramatically.

These systems flip the script—instead of hunting down materials, they bring items directly to you. Computer-controlled rotation presents requested items at perfect ergonomic heights, reducing physical strain and virtually eliminating retrieval errors.

Ultra-low temperature automated systems like BiOS provide -80°C storage with robotic handling. These systems maintain sample integrity while providing lightning-fast access through automated retrieval.

Inventory software integration transforms storage from passive containers into active inventory management systems. Real-time tracking, automated reordering, and usage analytics optimize inventory levels while preventing stockouts and waste.

Vertical systems shine in facilities with limited floor space but decent ceiling height, providing substantial storage capacity without expanding your facility's footprint.

Modular Casework & Adjustable Shelving

Modular casework offers exceptional flexibility. With over 120 standard sizes available, these systems can be reconfigured or relocated as your needs evolve. It's storage that grows and adapts with your research.

Chemical-resistant work surfaces include epoxy resin tops that resist most laboratory chemicals and phenolic resin surfaces that provide superior durability. These materials maintain their integrity under harsh conditions while providing safe, reliable work surfaces.

The modular approach means laboratories can adapt storage configurations as research directions shift, equipment sizes change, and workflow requirements evolve. No more ripping out entire installations when your needs change.

Lifetime warranties on rolling mechanisms and construction show manufacturer confidence in their products. For facilities making long-term investments in storage infrastructure, this assurance provides real peace of mind.

When integrating wet work areas with storage systems, consider checking out our guide on choosing lab sink cabinets for specialized applications.

Specialized Storage: Cold, Cleanroom & Personal

Ultra-low temperature (ULT) freezers maintain -80°C with precision, featuring specialized construction, comprehensive alarm systems, and reliable access mechanisms that work in extreme conditions.

HEPA-filtered cabinets create contamination-free environments for sensitive materials through positive pressure enclosures with filtered air circulation.

UV sterilization cabinets combine storage with active disinfection through integrated germicidal UV lamps, providing continuous sterilization of stored materials.

Day-use lockers address the critical need to separate personal belongings from laboratory materials, preventing contamination while providing secure storage during work shifts.

Antimicrobial wire racks resist bacterial growth in humid environments while providing excellent visibility and airflow. The open construction makes cleaning easy while preventing contamination buildup.

Designing for Safety, Efficiency, and Compliance

When it comes to laboratory storage systems, safety isn't just important—it's literally a matter of life and death. Proper design from the start saves both lives and money.

OSHA regulations form the foundation of laboratory safety requirements. These legal mandates specify everything from ventilation rates to fire protection systems. OSHA laboratory standards cover chemical storage, personal protective equipment access, and emergency procedures that every facility must follow.

NFPA 30 guidelines provide detailed construction standards specifically for flammable and combustible liquids. These standards dictate wall thickness, door specifications, and ventilation requirements for chemical storage cabinets.

Proper ventilation systems prevent dangerous vapor buildup that could create explosive conditions or poison lab workers. Chemical storage cabinets need specific air exchange rates based on stored materials.

Spill containment features turn potential disasters into manageable cleanup jobs. Secondary containment systems, leak-proof construction, and strategically placed absorbent materials contain spills before they spread.

Clear signage and labeling prevent accidents by telling people exactly what they're dealing with. Color-coded systems help staff identify hazards instantly, while detailed labels provide handling instructions.

Training protocols ensure your team knows how to use storage systems safely. Regular training updates keep everyone current on new materials, updated procedures, and changing regulations.

Best Practices for Chemicals, Biospecimens, Equipment

Chemical segregation saves lives by preventing dangerous reactions between incompatible materials. Acids need separate storage from bases, oxidizers require isolation from flammables, and each category demands specific construction materials and ventilation.

Secondary containment systems provide crucial backup protection when primary containers fail. Double-wall construction catches leaks before they become spills, while spill trays contain accidents at the source.

Comprehensive labeling systems include material identification, hazard warnings, storage dates, and expiration information. Standardized labeling protocols prevent dangerous confusion while supporting inventory management and regulatory compliance.

Temperature logging systems provide continuous monitoring that regulatory agencies demand for refrigerated storage. These systems document temperature stability for compliance audits while alerting staff to potential problems before they compromise stored materials.

LIMS integration connects storage systems directly to facility databases, enabling automated inventory tracking and usage monitoring. This integration eliminates manual record-keeping errors while providing real-time inventory visibility.

Preventive maintenance programs keep storage systems running reliably while extending equipment life. Regular inspections catch problems early, calibration procedures maintain accuracy, and scheduled component replacements prevent failures.

Planning for Growth & Future Needs

Smart facilities plan for growth from day one, because cramped storage leads to safety shortcuts and compliance problems. Scalable storage systems accommodate expansion without requiring complete replacement.

Modular add-ons enable incremental growth that matches your actual needs. Instead of buying capacity you don't need yet, modular systems let you add storage as your facility grows.

Track-based expansion systems work especially well for high-density storage. You can add mobile units to existing track systems, expanding capacity while maintaining space efficiency.

Digital tracking systems provide real-time inventory visibility that supports intelligent growth planning. Usage analytics identify trends and capacity needs, enabling proactive expansion decisions.

ROI calculations justify storage investments by quantifying space savings, efficiency improvements, and operational cost reductions. These analyses demonstrate value to decision-makers while supporting budget planning.

High-density systems typically pay for themselves within 2-3 years through space savings alone. When you factor in improved efficiency and reduced labor costs, the ROI becomes even more compelling.

Innovation & Emerging Trends in Laboratory Storage Systems

The world of laboratory storage systems is evolving rapidly, driven by sustainability concerns, technological advances, and the need for smarter operations. These changes aren't just about fancy gadgets - they're solving real problems that labs face every day.

Sustainability has become a driving force in storage system design. Manufacturers are now using recyclable materials wherever possible, creating modular designs that can be reconfigured rather than replaced, and developing energy-efficient refrigeration systems that slash operating costs. We've seen facilities reduce their energy consumption by 30% simply by upgrading to newer, more efficient refrigerated storage units.

The real game-changer, though, is smart sensor technology. Modern storage systems can monitor temperature, humidity, door openings, and even vibration levels in real-time. These IoT-connected systems send alerts directly to your phone when something goes wrong - no more weekend trips to check on critical samples because you're worried about a power outage.

Mobile apps are changing how lab staff interact with storage systems. Instead of hunting through drawers or checking paper logs, technicians can use their smartphones to locate specific samples, check inventory levels, and even reserve equipment. It's like having a personal assistant for your storage needs.

Perhaps most exciting is the emergence of AI-driven retrieval systems. These smart systems learn from usage patterns to predict what you'll need and when. They automatically reorganize storage to put frequently used items in the most accessible locations. One facility we worked with reduced sample retrieval time by 40% after implementing an AI-optimized storage layout.

3D printing is creating new possibilities for custom storage solutions. Need a specific insert to hold unusual sample containers? Print it. Want to organize equipment in a unique way? Design and print custom dividers. This technology makes it economical to create specialized storage components for even small batches of unique items.

The integration of all these technologies is creating storage systems that are more like intelligent assistants than passive containers. They track, monitor, organize, and even predict - all while maintaining the safety and compliance standards that labs require.

Frequently Asked Questions about Laboratory Storage

How do laboratory storage systems improve safety?

Laboratory storage systems transform potentially dangerous environments into well-controlled, safe workspaces through smart design and built-in safety features.

The most obvious safety benefit comes from hazard isolation. Chemical storage cabinets act like protective barriers, separating dangerous materials from daily work areas. When flammable solvents are properly contained in fire-resistant cabinets, you've eliminated a major fire risk.

Proper ventilation built into storage systems prevents the invisible danger of vapor accumulation. Quality storage cabinets include ventilation systems that continuously remove dangerous vapors, keeping air quality safe.

Perhaps the biggest safety advantage is how modern laboratory storage systems help with compliance aids. These systems come designed to meet OSHA and NFPA requirements right out of the box. Self-closing doors, proper grounding, built-in spill containment—all these features help your facility stay compliant without extra effort.

What materials are best for chemical resistance?

Choosing the right materials for chemical storage can feel overwhelming, but three materials consistently deliver excellent performance.

Epoxy resin surfaces top our recommendation list for most applications. These surfaces resist attacks from acids, bases, and solvents that would destroy ordinary materials. They're also easy to clean and maintain. For general laboratory use, epoxy provides the best balance of protection and practicality.

Stainless steel construction takes durability to the next level. Type 304 stainless steel resists corrosion while providing the sanitary properties that medical and research facilities demand. It costs more upfront, but the longevity often justifies the investment.

Polypropylene offers a lightweight, cost-effective solution that still provides excellent chemical resistance. This material works particularly well for secondary containment systems and specialized storage applications.

How can automated storage fit small labs?

Many small labs assume automated storage is only for large facilities with massive budgets, but that's not true anymore. Modern automation comes in sizes and price points that work for smaller operations.

Vertical footprint designs make automation possible even in cramped spaces. Instead of spreading across your limited floor space, these systems build upward. You get substantial storage capacity without sacrificing precious work areas.

Modular units let you start small and grow gradually. Begin with a single automated unit for your most frequently accessed materials, then add components as your needs and budget expand. This pay-as-you-grow approach spreads costs over time while providing immediate efficiency benefits.

Even benchtop automation solutions like small carousels bring automation benefits without major facility modifications. These compact units provide efficiency advantages while fitting into existing workflows and spaces.

Conclusion & Next Steps

Choosing the right laboratory storage systems is one of the most important decisions your facility will make. These systems protect valuable samples, keep your team safe, and ensure you stay compliant with regulations for years to come.

The best approach combines different storage technologies to meet your specific needs. High-density mobile systems double your storage capacity without expanding your footprint. Automated systems reduce retrieval time and human error. Specialized chemical cabinets keep dangerous materials safely contained. When these systems work together, your lab runs like a well-oiled machine.

At American Mortuary Coolers, we've been designing custom cold storage solutions for facilities across the country. While our name might suggest we only work with funeral homes, our expertise in precise temperature control and durable construction makes us valuable partners for any facility needing reliable cold storage.

Our custom coolers integrate beautifully with modern laboratory storage systems. Whether you need ultra-low freezers for biological samples, standard refrigeration for reagents, or walk-in coolers for bulk storage, we build solutions that maintain perfect temperatures while fitting seamlessly into your workflow.

We deliver directly to facilities in all 48 contiguous states, with strong presence in Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania. Our team understands that when it comes to laboratory storage, reliability isn't optional—it's absolutely critical.

Temperature-controlled storage often becomes the bottleneck in laboratory operations. Samples get compromised, research gets delayed, and costs spiral upward when cold storage fails. That's why we focus on building systems that work day after day, year after year.

Planning your storage upgrade? Start by mapping out your temperature requirements alongside your space constraints. Cold storage typically needs the most careful planning since it affects both your facility's infrastructure and your daily operations.

Ready to explore how our custom cold storage solutions can transform your laboratory? Our design team loves solving complex storage challenges. We'll work with you to create systems that protect your materials while supporting the way your team actually works.

For facilities considering walk-in cold storage options, check out our detailed guide on More info about walk-in cooler shelving options. It covers everything from maximizing space efficiency to choosing the right shelving materials for your specific storage needs.

The right storage systems don't just organize your materials—they give you peace of mind. Contact us today to discuss how we can help build that confidence into your laboratory's foundation.