Why Walk-In Cooler Shelving Makes or Breaks Your Cold Storage Success

Walk in cooler shelving is the backbone of any efficient cold storage operation, determining everything from product safety to operational costs. The right shelving system can support up to 1,000 pounds per shelf while maintaining proper airflow, preventing contamination, and meeting strict health codes.

Quick Answer for Walk-In Cooler Shelving:

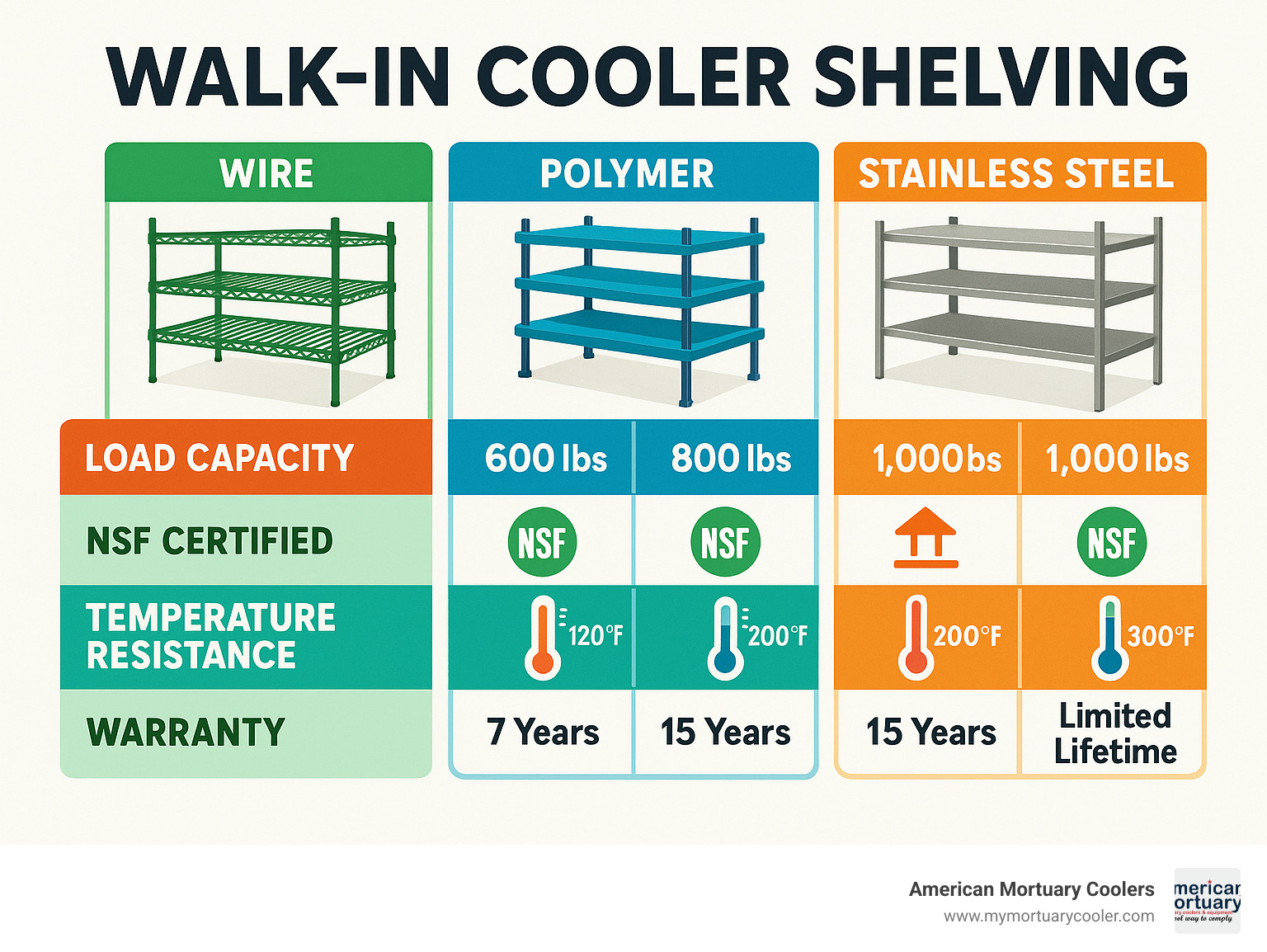

- Materials: Wire (budget-friendly), polymer (rust-proof), stainless steel (premium)

- Load capacity: 600-1,000 lbs per shelf depending on material

- Key features: NSF certification, adjustable height, corrosion resistance

- Compliance: Lowest shelf must be 6 inches above floor for health codes

- Popular options: Epoxy-coated wire (7-year rust warranty), cantilever systems (no floor supports)

Whether you're storing perishable food, medical supplies, or specialized mortuary products, your shelving choice directly impacts product quality, staff efficiency, and regulatory compliance. Poor shelving leads to blocked airflow, contamination risks, and costly product loss.

Cold, humid environments are particularly harsh on standard shelving materials. As one industry professional noted: "They've been outstanding. Incredibly sturdy, resist rust, and are easy to wipe down." This feedback highlights why specialized cooler shelving isn't just an option - it's essential.

I'm Mortuary Cooler, and as a national level mortuary cooler supplier, I've helped countless funeral homes optimize their cold storage with the right walk in cooler shelving solutions. My experience working directly with funeral directors has shown me that proper shelving selection can make the difference between smooth operations and costly compliance issues.

Terms related to walk in cooler shelving:

What Is Walk-In Cooler Shelving & Why It Matters

Walk in cooler shelving is far more than just metal racks in a cold room. It's the foundation that keeps your entire cold storage operation running smoothly, safely, and profitably. These specialized storage systems are engineered to handle the unique challenges of refrigerated environments - constant moisture, temperature swings, and heavy loads.

Regular shelving in a walk-in cooler is like wearing a cotton t-shirt in a snowstorm. The cold, humid environment inside coolers is brutal on standard materials. Rust prevention becomes critical when moisture is constantly present, and without proper coatings or rust-resistant materials, you'll watch your investment crumble.

The load capacity requirements are serious. A single shelf might need to support 800 to 1,000 pounds of product while maintaining structural integrity in freezing temperatures. When that shelf is holding expensive inventory or critical supplies, failure isn't an option.

Quality walk in cooler shelving works with your cooling equipment, not against it. Poor shelving choices can block airflow, create hot spots, and force your refrigeration system to work overtime - adding hundreds of dollars to your monthly energy bills.

How Shelving Protects Product Quality

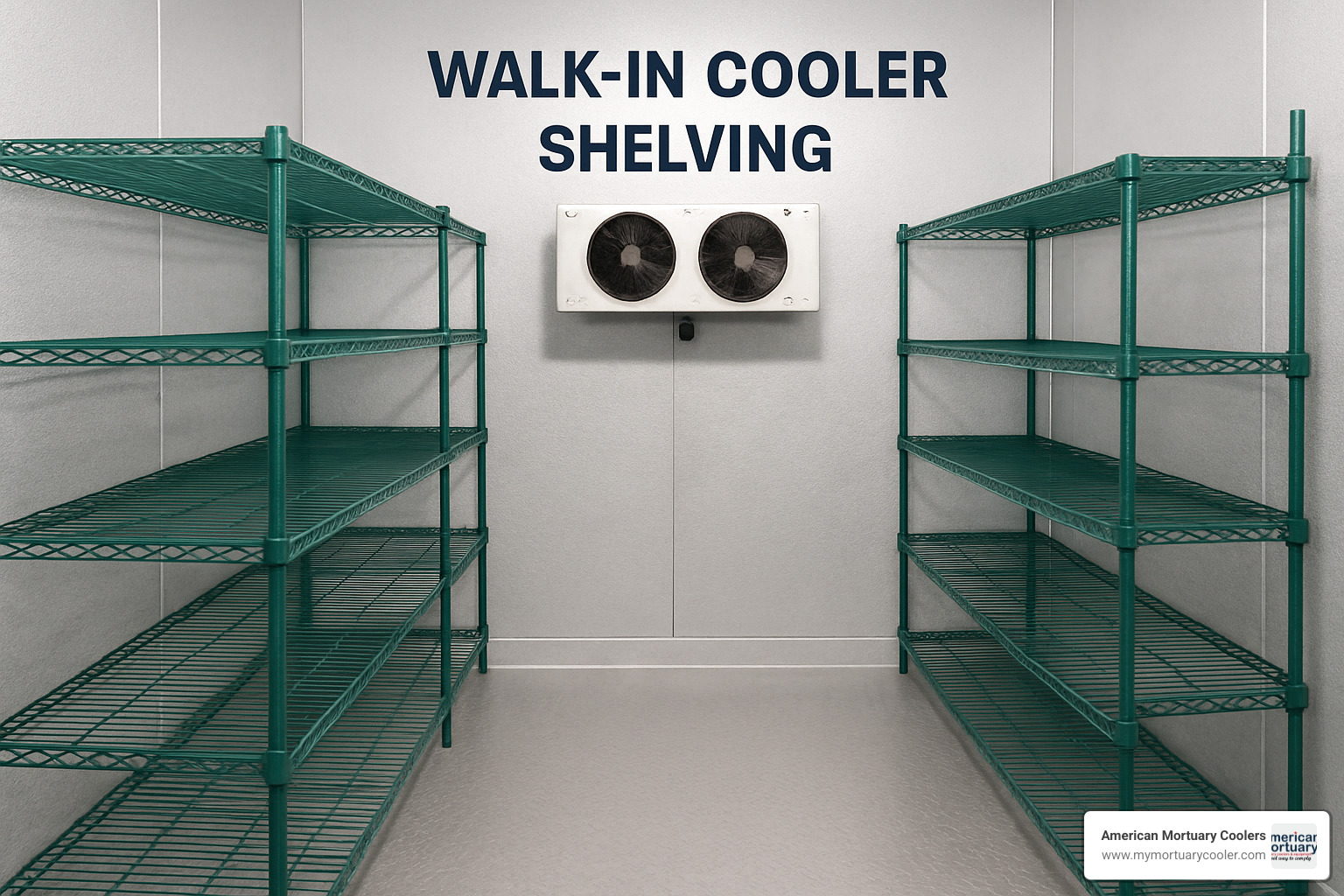

Air circulation isn't just a nice-to-have feature - it's what keeps your products fresh and your operation compliant. Wire shelving designs maximize airflow by allowing cold air to move freely around stored items. This prevents cold spots where some products freeze while others spoil.

Proper shelf spacing creates air channels that maintain consistent temperatures throughout your cooler. When you leave that crucial 2-inch gap between shelves and walls, you're creating pathways for air to circulate naturally. This simple spacing prevents humidity buildup that leads to condensation, mold, and product deterioration.

Spoilage reduction becomes automatic when air moves properly. Products stay at consistent temperatures, moisture doesn't accumulate in corners, and you avoid expensive surprises when you find ruined inventory.

Impact on Health & Safety Compliance

HACCP standards aren't suggestions - they're requirements that inspectors take seriously. Every surface that might contact your stored products, including shelving, must meet strict cleanliness and safety standards. NSF certification is your proof that your shelving system passes these tests.

That 6-inch floor clearance rule serves real purposes that protect your operation. This spacing allows thorough cleaning underneath shelves, eliminates hiding spots for pests, and ensures proper airflow at floor level. Health inspectors know exactly what to look for, and falling short can result in costly violations or shutdowns.

For funeral homes, compliance goes beyond standard food safety. Your shelving must handle the specific requirements of mortuary operations - materials that can be thoroughly sanitized, surfaces that won't absorb fluids or odors, and construction that maintains dignity while meeting safety standards.

Comparing Shelving Materials & Designs

Choosing the right material for your walk in cooler shelving is like picking the foundation for your house - get it wrong, and everything else suffers.

Wire shelving is the reliable workhorse of the industry. It's budget-friendly and excels at airflow. Epoxy-coated wire shelving gives you rust protection for at least 7 years, and each shelf can handle up to 800 pounds when the weight is spread evenly.

Polymer shelving is the premium choice that many facilities are switching to. MetroMax systems come with 20-year rust warranties, while some all-polymer systems offer lifetime guarantees against rust and corrosion. These systems can support 800-1000 pounds per shelf with their clever 360° corner design.

Stainless steel is the gold standard when you need ultimate durability and the highest sanitation levels. Yes, it costs more upfront, but it's practically indestructible and handles chemical cleaning agents without breaking a sweat.

If you want to dive deeper into specific options, this Coolroom Shelving external guide covers various material specifications in detail.

Wire vs Polymer: The Classic Debate

Wire shelving is the ventilation champion - its open design lets air flow exactly where it needs to go. Green epoxy-coated wire shelving comes with a 7-year rust guarantee and supports up to 800 pounds per shelf.

But wire has its quirks. That coating can chip over time, especially in busy areas. Once the coating gets damaged, rust can spread quickly in the humid cooler environment.

Polymer shelving solves many of these headaches. MetroMax Q systems combine wire frames with polymer shelf mats, giving you great airflow plus easy-to-clean surfaces. All-polymer systems like MetroMax 4 eliminate rust worries completely with lifetime warranties.

The catch? Polymer systems typically cost 30-50% more than wire alternatives. But when you factor in extended warranties and reduced maintenance, polymer often comes out ahead in the long run.

Cantilever & Gravity-Feed Systems

Cantilever shelving is a game-changer for maximizing your cooler space. These wall-mounted systems don't need any floor supports, which means more room to move around and much easier cleaning.

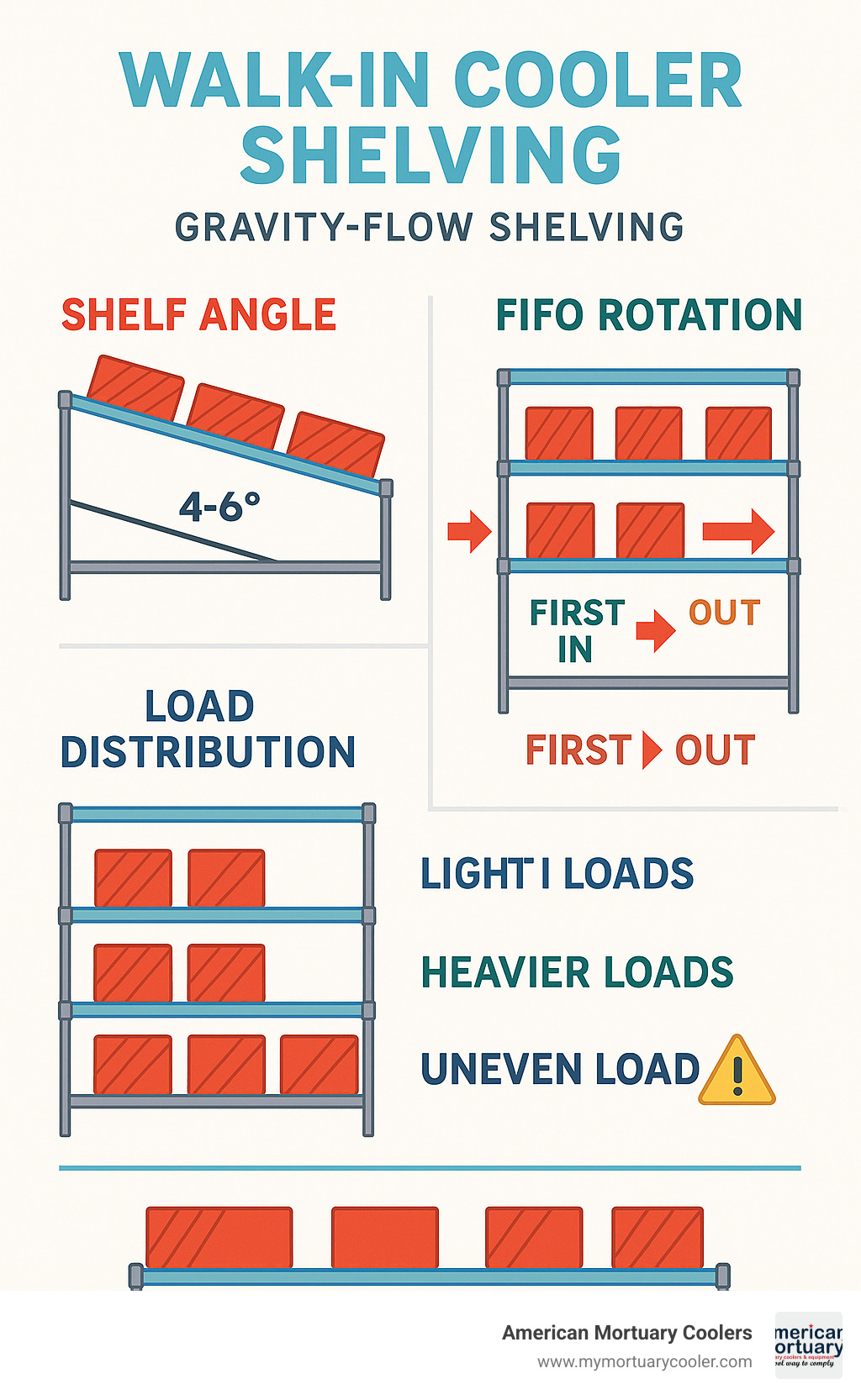

Gravity-feed systems are particularly brilliant for retail setups like beer caves. They automatically handle FIFO (First-In, First-Out) rotation without any extra work from your staff. You load products from the back, and they roll forward for easy customer access.

The ADCO Beer Cave Shelving system can store up to 2,700 pounds total (900 pounds per shelf). It includes 31 crossbars per foot, preventing bottles from tipping and keeping everything stable. The system has earned NSF's highest cold-storage rating.

Load Ratings & Warranties You Can Expect

Most quality walk in cooler shelving systems handle 600-1000 pounds per shelf when you distribute the weight evenly. Metro's Super Erecta Pro shelving safely stores 800-1000 pounds per shelf thanks to their smart 360° corner design.

Warranty terms tell you a lot about what you're buying. Epoxy-coated wire typically comes with 7-15 years of rust protection. MetroMax Q polymer systems offer 20-year rust warranties, while MetroMax 4 all-polymer systems provide lifetime warranties against rust and corrosion.

How to Choose the Right Walk-In Cooler Shelving for Your Business

Choosing the perfect walk in cooler shelving for your business isn't just about finding something that fits - it's about finding a system that works seamlessly with your daily operations while keeping you compliant with regulations.

A restaurant kitchen moves at lightning speed, with staff constantly grabbing ingredients and restocking supplies. Compare that to a medical facility where precision and cleanliness matter more than speed, or a funeral home where dignity and reliability are paramount. Each situation calls for a completely different approach to shelving.

For comprehensive shelving options across different industries, the Industrial Catalog reference offers detailed comparisons of various systems and manufacturers.

Sizing Up Your Space & Workflow

Before you fall in love with any shelving system, grab a tape measure and really understand your space. Door swing patterns matter more than most people realize. Cart traffic is another big consideration - most operations need aisles that are 36 to 42 inches wide for smooth traffic flow.

Wall-mounted cantilever systems are fantastic when floor space is tight. They attach directly to your cooler walls without any floor supports, leaving maximum room for cleaning and movement. Floor-standing units offer more flexibility since you can move them around as your needs change.

Put your high-turnover items at eye level in easily accessible spots. Heavy items belong on lower shelves for safety and to save your staff's backs.

Matching Shelving to Industry Needs

Foodservice operations thrive with adjustable shelving that can adapt to changing inventory. Beer cave merchandising uses specialized gravity-feed systems that keep products rotating automatically and maintain that fully-stocked appearance.

Medical and pharmaceutical storage demands the highest hygiene standards. You'll want stainless steel or high-grade polymer shelving with antimicrobial properties.

Mortuary applications require shelving that handles substantial weight while maintaining impeccable sanitation standards. Cantilever systems work exceptionally well because they eliminate floor supports that can harbor contaminants while providing the structural integrity needed for heavy loads.

For deeper insights on optimizing your entire cooler setup, our guide on design tips covers layout strategies that work across various applications.

Budget & ROI Considerations

The cheapest shelving option today might end up costing you significantly more over time through maintenance, energy waste, and compliance issues.

Energy savings represent one of the biggest ROI factors. Proper shelving that maintains good airflow can reduce your energy costs by 15 to 20% compared to systems that block air circulation. Over ten years, these savings can actually exceed the initial cost difference between basic and premium shelving systems.

Waste reduction is another area where quality shelving pays dividends. Systems that maintain proper product quality and enable effective rotation can reduce spoilage by 10 to 15%. In high-volume operations, this waste reduction alone can justify premium shelving costs within the first year.

Installation, Organization & Maintenance Best Practices

Getting your walk in cooler shelving installed correctly sets you up for years of trouble-free operation. The magic numbers you need to remember are simple: 2 inches from walls, 6 inches from the floor. That 2-inch gap keeps air flowing freely, preventing cold spots. The 6-inch floor clearance makes cleaning easier and keeps pests from setting up shop under your shelves.

Proper Setup of Walk In Cooler Shelving

Before you even unpack your new shelving, check your cooler floor. An uneven floor will cause your shelving to wobble and bind. Those adjustable leveling feet that come with quality systems are essential for compensating for floor irregularities.

For wall-mounted systems, don't assume your cooler panels can handle the load without checking first. Most modern coolers are built to support shelving, but older installations might need reinforcement.

Load distribution is where many people go wrong. Even if your shelves are rated for 1,000 pounds, spread weight evenly across the shelf surface. When storing particularly heavy items, consider using multiple shelves rather than maxing out a single one.

Smart Organization Strategies

Organization isn't just about making things look neat - it's about creating a system that protects your products and keeps your staff safe. The fundamental rule is simple: heavy items go low, light items go high.

FIFO rotation becomes second nature once you establish the system. New inventory goes behind older stock, and everything gets labeled with clear, waterproof tags.

Think about contamination prevention when organizing your space. Raw materials belong on bottom shelves to prevent any drips from affecting other products. Sensitive items stay in the middle zones where temperature remains most stable.

Effective labeling makes everyone's job easier: waterproof, freezer-safe labels, clear date coding, color-coded systems for different product categories, and consistent placement so staff always know where to look.

Cleaning & Preventive Maintenance Schedule

Daily attention means wiping down surfaces with mild soap and water, cleaning spills immediately, and doing a quick visual check for any obvious problems.

Weekly deep cleaning gives you a chance to inspect everything more thoroughly. Check that shelves are properly aligned and stable, look for early signs of wear or corrosion.

Quarterly inspections are your chance to catch problems before they become expensive failures. Test load capacity, examine all connection points, and document everything for your compliance records.

For shelving with antimicrobial coatings, choose cleaning products that won't interfere with these protective properties. Many modern systems include dishwasher-safe components that can be removed for thorough sanitization.

Future Trends, Innovations & Common Mistakes to Avoid

The world of walk in cooler shelving is changing fast, and staying ahead of these trends can save you money while keeping your operation running smoothly. New technologies are making shelves smarter, cleaner, and easier to maintain than ever before.

Antimicrobial coatings have become a game-changer, especially for funeral homes and medical facilities. These aren't just surface treatments that wash off - they're built right into the shelf material during manufacturing.

Tool-free adjustability is becoming the new standard. Premium systems now let you adjust shelf heights with simple cam-action locks or snap-in mechanisms.

Latest Technologies in Walk-In Cooler Shelving

Microban antimicrobial technology represents the biggest leap forward in shelf hygiene. Unlike spray-on treatments that wear off over time, Microban is embedded directly into the shelf material. This means it keeps working to prevent bacterial growth for the life of the shelf.

Rolling bottom shelves solve one of the oldest problems in cooler management - reaching items stored way in the back. These systems let the entire bottom shelf roll out on smooth-running wheels, making restocking easier and reducing back strain.

Snap-in glide sheets for gravity-feed systems eliminate the maintenance headaches that come with traditional roller systems. No moving parts means nothing to oil, adjust, or replace.

For detailed information about these cutting-edge options, check out Walk-In Cooler Shelving Systems to see what's available for your specific needs.

Mistakes That Hurt Performance & Compliance

Using galvanized shelving in wet zones is probably the most expensive mistake you can make. Galvanized coating works great in dry environments, but the constant humidity in walk-in coolers causes it to fail surprisingly quickly.

Blocking airflow with solid shelves might seem like a good idea for stability, but it's actually counterproductive. Your refrigeration system works by moving air around constantly. When solid shelves block this airflow, you get hot spots, cold spots, and an overworked compressor.

Ignoring warranty requirements is like throwing money away. Most manufacturers offer generous warranties, but they come with specific maintenance requirements. Using the wrong cleaning products or skipping recommended maintenance procedures can void your warranty completely.

At American Mortuary Coolers, we've seen how the right shelving choices make funeral homes more efficient and compliant. Poor shelving decisions create ongoing headaches that distract from your primary mission of serving families with dignity and care.

Frequently Asked Questions about Walk-In Cooler Shelving

When it comes to walk in cooler shelving, the same questions come up again and again. I've helped hundreds of funeral homes and commercial operations steer these decisions, so let me share the answers that matter most to your success.

What load capacity do I really need per shelf?

Here's the honest truth about load capacity: most people underestimate what they actually need. While 600-800 lbs per shelf handles typical foodservice needs, that changes quickly when you're dealing with heavy cases of beverages, large containers, or specialized equipment.

For mortuary applications, I always recommend systems rated for at least 800-1000 lbs per shelf. Why? Because caskets, preparation equipment, and related supplies create substantial weight loads that lighter-duty shelving simply can't handle safely.

But here's the catch - those load ratings assume even weight distribution. Stack all your weight in one corner, and even a 1000-lb rated shelf can fail catastrophically. The forces created when you're actively loading and unloading (what engineers call "dynamic loading") can actually exceed the static weight of your stored products.

Think of it this way: if you're storing 400 lbs of product, choose shelving rated for 800 lbs. That safety margin isn't overkill - it's smart business.

How high should the lowest shelf be to meet health codes?

The magic number is 6 inches above the floor - that's your minimum clearance to meet most health codes. But this isn't just some arbitrary rule dreamed up by bureaucrats. This spacing serves three critical purposes that directly impact your operation.

First, it allows proper cleaning underneath your shelves. Try mopping around shelves that sit directly on the floor, and you'll quickly understand why inspectors care about this clearance. Second, it prevents pest harborage by eliminating dark, inaccessible spaces where problems can hide.

Third, and perhaps most importantly for your energy bills, this clearance ensures adequate airflow at floor level. Block that airflow, and your refrigeration system works harder while creating temperature inconsistencies throughout your cooler.

Some jurisdictions have different requirements, so always check with your local health department. In mortuary applications, I often recommend going higher than the minimum - 8-10 inches can make cleaning and maintenance much easier, though you'll sacrifice some storage space.

Can existing coolers be retrofitted with cantilever shelving?

The short answer is yes, most existing coolers can be retrofitted with cantilever systems. The longer answer depends on your cooler's construction and current condition.

Modern coolers with structural panels typically have plenty of strength to support wall-mounted walk in cooler shelving. These systems were designed with shelving loads in mind, so retrofitting is usually straightforward.

Older coolers tell a different story. If your cooler is more than 15-20 years old, or if you notice any panel damage or sagging, you'll want a professional evaluation before installation. Sometimes a little reinforcement is all that's needed, but it's better to know upfront than find structural issues after installation.

The beauty of cantilever retrofits is the change they create. You can dramatically improve storage capacity and cleaning efficiency without major cooler modifications. Most manufacturers offer free design services to work around existing drain lines, conduit, and other obstacles.

At American Mortuary Coolers, we've retrofitted hundreds of existing facilities with cantilever systems. The improvement in workflow and cleaning efficiency always impresses our clients. Plus, eliminating floor supports means you can finally get that floor properly clean - something every inspector appreciates.

Conclusion

Your journey to finding the perfect walk in cooler shelving doesn't have to be complicated, but it does require careful thought. The choices you make today will impact your daily operations for years to come - from the energy bills you pay each month to how smoothly your staff can do their jobs.

Think about what we've covered: wire shelving that maximizes airflow but needs replacement every 7-10 years, polymer systems that cost more upfront but practically last forever, and cantilever designs that free up floor space for easier cleaning. Each option serves different needs, and the "best" choice is the one that fits your specific situation.

The numbers don't lie - quality shelving systems can cut your energy costs by 15-20% while reducing product spoilage. When you factor in the time your staff saves with properly organized, easy-to-clean systems, the return on investment becomes even clearer.

In mortuary work, these decisions carry extra weight. Families trust you during their most difficult moments, and that trust extends to every aspect of your operation. The right shelving system helps ensure you can maintain the highest standards of care and dignity while keeping your business running smoothly.

At American Mortuary Coolers, we've seen how the right combination of cooler design and shelving transforms funeral home operations. Our Tennessee-based team works directly with funeral directors across all 48 contiguous states to create custom solutions that integrate perfectly with whatever shelving approach makes sense for your facility.

Here's the bottom line: don't treat shelving as an afterthought. Whether you choose budget-friendly epoxy-coated wire or invest in lifetime-warranty polymer systems, make sure your selection supports proper airflow, meets health codes, and can handle your daily workload without constant maintenance headaches.

The funeral industry is challenging enough without worrying about equipment failures or compliance issues. Invest in shelving that works as hard as you do, and you'll have one less thing to worry about when families need you most.

For more detailed information about how cooler features and shelving work together in a complete system, check out our comprehensive guide on walk-in cooler features & prices. Your future self - and your staff - will thank you for making the right choice today.