The Leading Pathology Equipment Manufacturer in Michigan

Pathology Equipment Manufacturer in Oak Park is a leading manufacturer of pathology, anatomy, mortuary, and necropsy equipment located at 21750 Coolidge Highway, Oak Park, Michigan 48237. For funeral directors and medical professionals seeking reliable equipment, here's what you need to know:

| Oak Park Manufacturer Overview | |

|---|---|

| Address | 21750 Coolidge Hwy, Oak Park, MI 48237 |

| Phone | (800) 362-8491 |

| Facility Size | 60,000 square feet |

| Founded | 1992 by George Hallman and Rick Bell |

| Global Reach | Serves customers in 83 countries |

| Certifications | ISO 9001:2000 |

| Product Portfolio | 1,800+ products including grossing stations, autopsy equipment, and mortuary solutions |

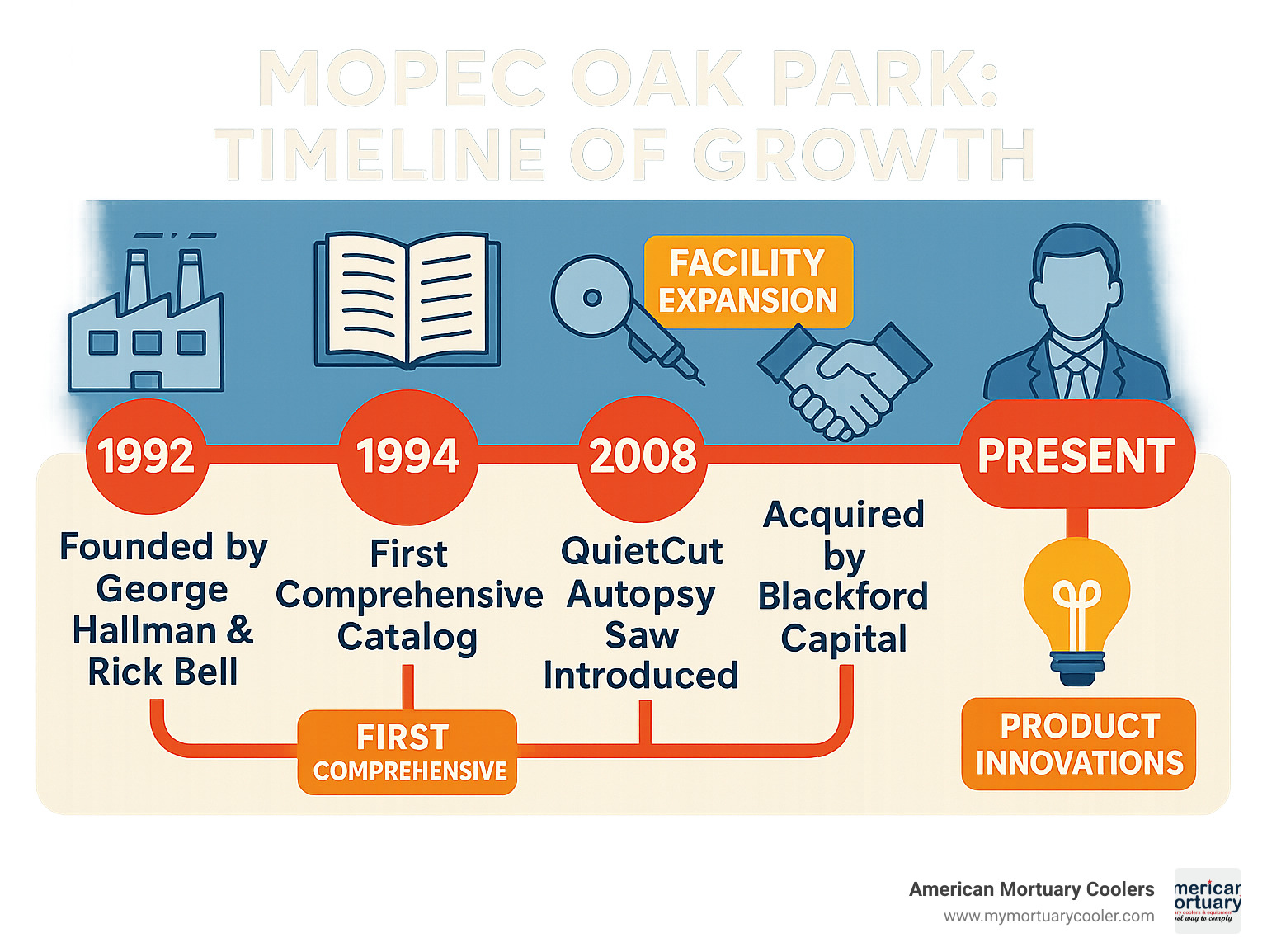

Founded in 1992, this manufacturer has grown from a small startup to become an industry leader known for high-quality, American-made equipment that prioritizes safety, efficiency, and ergonomics. Their 60,000 square foot facility in Oak Park houses a fully operational factory, warehouse, and corporate offices, serving as the hub for their global operations.

What sets this Oak Park manufacturer apart is their commitment to customization and innovation. They pioneered products like the QuietCut autopsy saw system with ergonomic design and HEPA filtration, and the touch screen grossing workstation that revolutionized pathology workflows. Their first comprehensive 220-page catalog in 1994 helped triple sales within a year, establishing them as an industry authority.

I'm from American Mortuary Coolers, a national-level supplier of mortuary cooling systems who has closely followed this Oak Park manufacturer's evolution and innovation in specialized medical equipment for over a decade. Their commitment to quality manufacturing has set industry standards that guide our own product development.

Pathology Equipment Manufacturer in Oak Park at a Glance

If you've ever driven down Coolidge Highway in Oak Park, Michigan, you might have passed by an unassuming building that's actually the beating heart of a global medical equipment powerhouse. This Oak Park pathology equipment manufacturer isn't just a manufacturing facility—it's where innovation in pathology and mortuary equipment comes to life.

Oak Park Manufacturer Location & Facility Overview

Nestled just north of Detroit, the Oak Park facility headquarters spans an impressive 60,000 square feet of American ingenuity. This isn't your typical factory—it's a complete ecosystem where designs are born, products are crafted, and solutions are shipped worldwide.

Walking through the doors at 21750 Coolidge Highway, you'd find a hive of activity. Engineers huddle over 3D models, skilled fabricators transform raw materials into precision equipment, and quality control specialists carefully inspect each finished product. The facility houses everything under one roof: manufacturing floor, warehouse operations, and corporate offices.

"We wanted a space where we could control every aspect of production," Rick Bell, co-founder, once shared during their 25th anniversary celebration. "From the first sketch to the final shipping label, everything happens right here in Oak Park."

The location itself was a strategic choice. Positioned in the Midwest with excellent access to shipping routes, this Oak Park manufacturer can efficiently distribute their specialized equipment across America and to their customers in 83 countries worldwide.

How to Contact the Oak Park Manufacturer

Reaching out to the team at this Oak Park facility is refreshingly straightforward. Whether you're a funeral director looking for specialized equipment or a pathology lab manager planning a facility upgrade, their doors (and phone lines) are always open.

Their physical address is simple: 21750 Coolidge Hwy, Oak Park, MI 48237. Need to talk directly with a human being? Their toll-free number (800) 362-8491 connects you with actual people, not endless phone trees. International callers can reach them at +1 (248) 291-2040, and for those who prefer the classic fax, it's (248) 291-2050.

In our digital age, you can also visit their comprehensive website or drop them an email at info@mopec.com. Their customer service team is available Monday through Friday from 8:00 AM to 5:00 PM Eastern Time.

What I find particularly impressive is their commitment to international customers. Despite time-zone challenges, the Oak Park team offers scheduled video consultations and maintains a network of over 40 independent representatives worldwide. They've truly built global connections from their Michigan home base.

For those lucky enough to visit in person, they welcome scheduled tours and product demonstrations. There's nothing quite like seeing their craftsmanship up close—just be sure to call ahead to arrange your visit. After all, precision equipment doesn't build itself, and the dedicated team at this Oak Park facility is usually busy creating the next innovation in pathology and mortuary solutions.

Evolution from Garage Startup to Global Leader

The story of this Oak Park manufacturer feels like the entrepreneurial dream we all secretly harbor—two people with a vision who built something extraordinary through grit, smart choices, and genuine care for their customers.

1992-2000: Founding Years & Early Innovations

Back in 1992, founders George Hallman and Rick Bell weren't content with the status quo in pathology and autopsy equipment. They rolled up their sleeves and launched a company with a simple but powerful idea: create better tools by actually listening to the people who use them.

These early days had that classic startup energy—the founders personally meeting with pathologists and mortuary professionals, asking questions, and sketching designs on notepads. They weren't just selling products; they were solving problems.

The game-changer came in 1994 when they published their first real catalog—a comprehensive 220-page showcase that replaced their humble pamphlets. The impact? Sales tripled in just twelve months.

Then came 1995's QuietCut bone-cutting instrument, a perfect example of the company's approach to innovation. They tackled two major headaches simultaneously: the jarring noise of traditional autopsy tools and the health risks of airborne particles. By adding ergonomic design and HEPA filtration, they created a signature product that professionals actually wanted to use.

As the millennium approached, the patent portfolio grew, including clever space-saving designs like a wall-mounted elevating sink—practical solutions for real workspace challenges.

2001-2013: Scaling & Private-Equity Transition

The early 2000s saw the Oak Park manufacturer hit its stride, expanding both product lines and market reach while continuously upgrading manufacturing capabilities.

A watershed moment arrived in 2013 when the founders decided it was time for the next chapter. But this wasn't a quick cash-out. As Bell explained in a Crain's Detroit Business article:

"Before selling to a private-equity firm, I made sure I did my homework first. I didn't want to sell to someone who would move manufacturing out of Michigan or disrupt the lives of our employees."

This six-month courtship with potential buyers wasn't just about the bottom line—it was about finding partners who understood what made the company special. They eventually chose Blackford Capital's Michigan Prosperity Fund for its commitment to keeping Michigan businesses in Michigan.

At this transition point, the company had grown to about 80 employees with a network of over 40 independent representatives worldwide. The reported sale price of under $20 million reflected not just current success but future potential.

2014-Present: New Leadership & Digital Expansion

With new backing came fresh perspectives. In 2016, Jay R. Troger stepped in as CEO, bringing over two decades of leadership experience across diverse industries from solar technology to environmental fuels.

Troger's outside viewpoint helped the Oak Park team accept the digital revolution. The company developed a comprehensive online catalog featuring more than 1,800 products—an impressive leap from that first paper catalog of 1994.

They didn't just digitize their offerings; they made them smarter. Interactive product-selection tools now help customers steer complex choices. Need a tissue cassette? The selection tool lets you specify everything from lid style to color, ensuring compatibility with your specific tissue printer.

Innovation continued with products like a fully submersible autopsy saw (2016) and the Maestro Encore Grossing Station with SafeDraft™ Ventilation Technology, which creates laminar airflow to protect technicians from harmful formalin exposure.

Today, that small dream from 1992 has become a global reality. The Oak Park manufacturer now serves customers in 83 countries, setting the gold standard for quality, innovation, and safety in pathology and mortuary equipment.

Product Portfolio Supporting Pathology & Mortuary Work

When you walk into the Oak Park facility, you'll immediately notice the impressive range of specialized equipment they've developed over three decades. Their product line isn't just impressive in its breadth—it's the thoughtful design behind each item that truly sets them apart.

Laboratory Workstations & Ventilation

The crown jewel of the Oak Park manufacturer's offerings has to be their laboratory workstations. The Maestro Encore Grossing Station isn't just a table—it's a carefully engineered workspace that protects the people who use it every day.

What makes these stations special? For starters, the SafeDraft™ Ventilation Technology creates a protective curtain of air that flows from front to back, whisking harmful formalin vapors away from technicians' breathing zones. This isn't just a comfort feature—it's a health essential.

The touch-screen controls make adjustments effortless, even when wearing gloves. Need to raise or lower the work surface? Just tap a button, and the height adjusts to fit whoever's using it, whether they're 5'2" or 6'4". This thoughtful ergonomic design prevents the back and shoulder strain that's all too common in laboratory work.

The lighting system deserves special mention too. Shadowless illumination means no more squinting or straining to see fine tissue details—a feature many pathologists tell us they can't imagine working without after experiencing it.

According to scientific research on laminar airflow, this ventilation approach isn't just marketing—it's based on solid principles that protect users from exposure to potentially harmful substances.

Ergonomic Tools & Safety Features

Beyond the big equipment, the Oak Park manufacturer shines in the details—the handheld tools that make a difference in daily work.

Their QuietCut Autopsy Saw System transformed a traditionally noisy, messy process into something remarkably civilized. The name doesn't lie—it really is quiet, sparing everyone in the room from the harsh mechanical whine of traditional saws. The built-in HEPA filtration captures bone dust and potential pathogens, addressing a significant safety concern that many facilities overlooked for years.

The Lumohs Lighted Scalpel Handles showcase the kind of innovation that comes from really listening to customers. By placing illumination right at the incision site, they've eliminated shadows that can obscure critical details during delicate procedures. It's a simple idea with profound impact on precision work.

For tissue marking, their Harmony dyes solved a frustrating inconsistency problem. All nine colors maintain the same viscosity—something that sounds minor until you've struggled with runny blue dye and thick green dye in the same procedure.

Their formalin-management solutions reflect a deep understanding of the daily challenges in pathology work. From prefilled containers to bulk-dispensing systems and neutralization products, they've created a comprehensive approach to handling this necessary but hazardous substance.

Digital Catalog & Selection Tools

Finding the right equipment shouldn't require a detective's license. The Oak Park manufacturer has developed intuitive digital tools that make navigating their extensive catalog (now over 1,800 products!) much simpler.

Their online Tissue Cassette Selection Tool is particularly helpful—just select your preferred lid style, cassette type, packaging, and color, and it matches options to your specific tissue printer. No more ordering the wrong cassettes and finding the mismatch when you're in the middle of processing.

Equipment-configuration tools let you visualize customized workstations before ordering, eliminating surprises during installation. Their resource libraries provide instant access to technical specs, safety data, and user manuals—information that used to require phone calls and faxed requests.

As one lab manager in Tennessee told us: "The digital tools get me 90% of the way there, but what I really appreciate is that there's always a knowledgeable human at the Oak Park manufacturer I can call when I need advice on a unique situation." That balance of digital convenience and human expertise perfectly captures their approach to customer service.

Safety, Customization & Community Impact

At the heart of the Oak Park manufacturer lies something more meaningful than just producing equipment. Their approach weaves together safety, customization, and community involvement in a way that transforms them from a simple vendor into a trusted partner for the industries they serve.

Ventilation, Ergonomics & User Protection

When you work in pathology or mortuary settings, safety isn't optional—it's essential. Chemical exposure, physical strain, and biological materials create real risks that the Oak Park manufacturer addresses through thoughtful design choices.

Formaldehyde exposure represents one of the biggest concerns in pathology labs. That's why their ventilation systems create laminar airflow patterns that gently push vapors away from where you breathe. Backdraft ventilation captures these vapors right at the source, while HEPA and carbon filtration systems clean the air thoroughly. If something goes wrong with the airflow or filters become saturated, monitoring systems alert you immediately.

"The ventilation in our station changed everything," shared one lab manager. "Staff complaints about formalin exposure dropped dramatically from day one."

Physical comfort matters too. The company tackles repetitive strain injuries with workstations you can adjust to your height, tools designed to minimize wrist strain, and thoughtfully placed controls that reduce reaching and bending. Some customers even opt for anti-fatigue flooring—a small touch that makes a big difference during long procedures.

Even noise protection gets careful attention. Their QuietCut technology significantly reduces the harsh sounds of bone-cutting procedures, protecting your hearing while making it easier to communicate with colleagues during procedures. And unlike some equipment manufacturers, this team designs with PPE in mind, ensuring face shields, gloves, and protective clothing work comfortably with their equipment.

Bespoke Projects & Community Partnerships

What truly sets the Oak Park manufacturer apart is their willingness to tackle unique, custom projects that showcase both their manufacturing skills and their genuine community spirit.

The Detroit Zoo partnership perfectly illustrates this approach. When the zoo developed its $30 million Polk Penguin Conservation Center—the world's largest penguin facility with a massive 326,000-gallon aquatic area—they faced a unique challenge: how to examine 82 penguins safely and efficiently.

The Oak Park manufacturer didn't just offer standard tables with penguin-themed decorations. Instead, they designed and donated two completely custom examination tables built directly into the walls to maximize space in the examination rooms. Every detail was custom to penguin physiology and the veterinary team's workflow.

"The custom tables have made a tremendous difference," noted a zoo representative. "They truly understood what we needed and delivered a solution perfect for our unique requirements."

This same creative problem-solving appears in other custom projects:

- Forensic anthropology labs with specialized dissection tables

- Disaster-response teams equipped with mobile autopsy stations

- Medical schools featuring teaching stations with built-in audio-visual capabilities

- Facilities with space constraints requiring custom-sized morgue coolers

A pathology-department director summed it up perfectly: "They didn't just sell us equipment—they partnered with us to understand our workflow and design solutions that addressed our specific challenges."

Global Reach, Certifications & Future Vision

From the busy factory floor in Oak Park, this manufacturer has built something remarkable—a global presence that touches 83 countries across six continents. This isn't just a company that ships boxes overseas; it's become a trusted name in pathology and mortuary equipment worldwide, backed by serious quality standards and an exciting vision for what comes next.

Quality Standards & Compliance

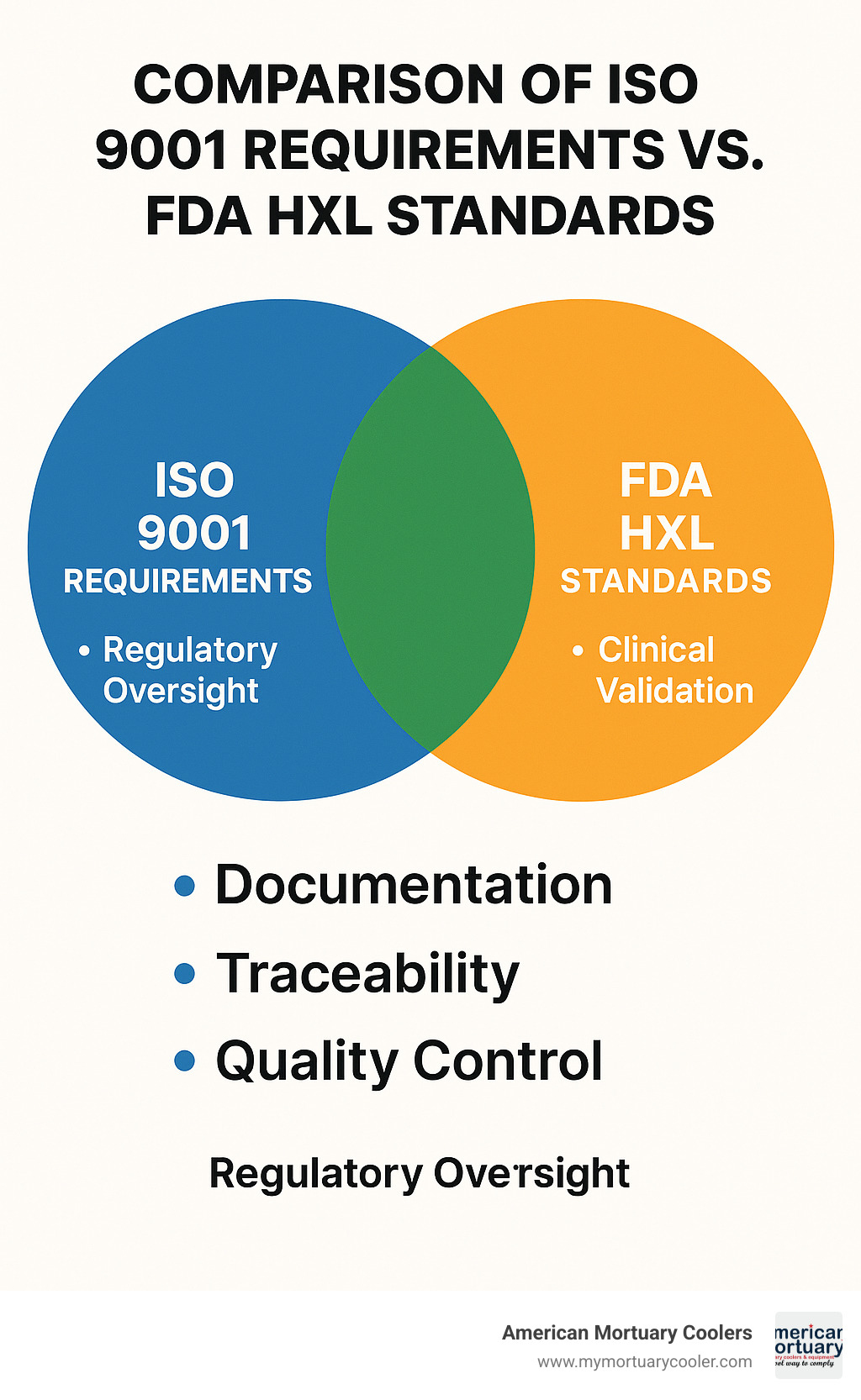

When you're making equipment that medical professionals rely on daily, quality isn't optional. That's why the Oak Park manufacturer maintains ISO 9001:2000 certification—a formal acknowledgment that their quality-management system meets rigorous international standards. But what does this actually mean in practice?

It means documented procedures that everyone follows, regular audits (both internal and from outside experts) to catch any issues, a culture of "how can we make this better?" rather than "good enough," complete traceability so they know exactly where every component came from, and systems to capture and act on customer feedback.

Beyond ISO certification, many of the company's products fall under FDA Code HXL / 878.4800, which covers manual surgical instruments for general use. This classification defines their products as "non-powered, hand-held or hand-manipulated devices … intended to perform various surgical procedures."

The quality journey starts with choosing the right materials—high-grade stainless steel that won't corrode, surfaces that resist harsh chemicals, and components built to last. Prototypes get put through their paces in real-world simulations before a design is approved. During production, there are multiple inspection checkpoints, followed by comprehensive testing before anything ships. Even after delivery, the team verifies proper installation and remains available for ongoing support.

As one pathology director who's been using their equipment for years told us: "We have equipment that's been in daily use for over 15 years and still performs like new. Their attention to quality is evident in everything they make."

Strategic Roadmap for 2025 & Beyond

The team isn't content to rest on past success. They've mapped out an ambitious vision for the future that builds on three decades of experience while embracing new possibilities.

Technology integration is a major focus. They're exploring smart features like IoT sensors that can monitor equipment performance and flag maintenance needs before problems occur, digital imaging systems that seamlessly connect with grossing stations, documentation systems that reduce paperwork, and remote-diagnostic capabilities so technicians can troubleshoot equipment without lengthy site visits.

Being good stewards of the environment matters too. The company is implementing more energy-efficient manufacturing processes, finding ways to use less water in production, switching to recyclable packaging materials, and designing equipment that minimizes chemical waste—important steps for a company that aims to be here for generations to come.

While already serving customers in 83 countries, global expansion continues. Regional distribution centers are being established to speed up delivery times, support materials now come in multiple languages, and products are being adapted to meet regional requirements—because a lab in Tokyo might have different needs than one in Toronto.

The R&D team is buzzing with activity, focusing on several exciting areas: advanced filtration technologies that capture more chemicals more effectively; improved ergonomics based on the latest biomechanical research; modular designs that can adapt as laboratory needs change; and better integration with the growing field of digital pathology.

Frequently Asked Questions about the Oak Park Manufacturer

What primary industries does the Oak Park manufacturer serve?

When folks ask me about this Michigan-based company, I always explain that they're the trusted specialists for four key industries that most of us don't think about daily—but are absolutely essential.

First, they're deeply connected to the pathology world, providing the workstations and equipment that pathologists use every day. Think about those grossing stations where tissue samples are examined, specialized processing equipment, and even the furniture that makes a pathology lab functional.

They're also a cornerstone in anatomy education. Medical students across the country learn on their dissection tables, and their preservation systems help make anatomy education possible. I've visited medical schools where students gather around these tables, getting hands-on experience that simply can't be replaced by textbooks.

In the mortuary industry (which is close to my heart at American Mortuary Coolers), the Oak Park manufacturer creates the reliable coolers, embalming stations, and transportation equipment that funeral directors depend on daily. Their attention to detail makes a real difference in this sensitive work.

Finally, they serve the necropsy and animal science community with specialized equipment for veterinary schools and zoos. I still smile thinking about those custom penguin exam tables they created for the Detroit Zoo!

What impresses me most is their reach—from small-town funeral homes to major research universities across 83 countries. That's the mark of equipment that truly works for real-world needs.

How does the Oak Park manufacturer ensure product safety and compliance?

Safety isn't just a checkbox for this team—it's woven into everything they create. As someone who works with funeral professionals, I appreciate their comprehensive approach.

Their design process starts with safety in mind. Their ventilation systems don't just meet OSHA requirements for chemical exposure—they exceed them. Those ergonomic features aren't just comfortable; they prevent the kinds of repetitive-strain injuries that can end careers. And they select materials specifically to withstand the harsh cleaning chemicals used in pathology and mortuary environments.

Behind the scenes, their ISO 9001:2000 certification isn't just a plaque on the wall. It means every product goes through multiple quality inspections during production and gets tested under conditions that simulate real-world use. I've toured manufacturing facilities that follow similar protocols, and the difference is immediately obvious in the final product.

On the regulatory front, they steer the complex world of FDA classifications (specifically FDA Code HXL / 878.4800 for their instruments), electrical-safety standards, and chemical-handling guidelines. This attention to compliance gives peace of mind to facilities where safety audits are a regular occurrence.

What I find particularly thoughtful is their approach to user training. Even the safest equipment needs proper operation, so the Oak Park manufacturer provides detailed manuals, training opportunities, and ongoing technical support. This commitment to the human side of safety makes a real difference in day-to-day operations.

Can the Oak Park manufacturer create fully customized equipment for unique applications?

Custom solutions are where this company truly shines. In my years working with mortuary equipment, I've seen how important customization can be when standard products just won't work for a unique space or specialized need.

Their approach to custom work feels more like a partnership than a transaction. It starts with genuine consultation—their engineers actually listen to understand the specific challenges and constraints. I remember one funeral director telling me how surprised he was when the team spent hours measuring and photographing his unusual space before even discussing solutions.

From there, they develop concept designs with 3D renderings that help clients visualize the final product. What follows is a truly collaborative refinement process where client feedback shapes the design. For complex projects, they'll even create prototypes to test concepts before final production.

The manufacturing happens right there in their Oak Park facility, giving them complete control over quality. Many customers have mentioned how valuable the installation and training support is—especially for one-of-a-kind equipment.

My favorite example is still those penguin exam tables they created for the Detroit Zoo. They also excel at forensic-anthropology workstations and custom-configured morgue coolers for challenging spaces.

As one funeral director put it to me: "When our historic building presented challenges no standard cooler could address, the Oak Park manufacturer designed a solution that preserved the building's integrity while meeting all our functional needs." That kind of problem-solving is increasingly rare in today's world of standardized products.

Conclusion

This Oak Park pathology equipment manufacturer represents the gold standard in American manufacturing excellence, especially in the specialized world of pathology and mortuary equipment. What began as a two-person operation in 1992 has blossomed into a global powerhouse serving professionals in 83 countries—all while keeping its heart and soul in Michigan.

Their impressive 60,000 square foot Oak Park facility isn't just where products are made—it's where innovation happens. Under one roof, engineers collaborate with production teams, customer feedback transforms into design improvements, and quality control ensures every product meets exacting standards. This integrated approach gives this Oak Park manufacturer a unique advantage in responding quickly to industry needs.

When I reflect on what makes them truly special, a few things stand out:

Their innovation consistently addresses real problems that pathologists and mortuary professionals face daily. The QuietCut autopsy saw didn't just make a procedure quieter—it made it safer with HEPA filtration. Their Maestro Encore grossing stations with SafeDraft™ Ventilation Technology protect technicians from harmful formalin exposure while improving workflow efficiency.

The company's commitment to quality isn't just marketing talk—it's validated by their ISO 9001:2000 certification and evident in products that customers report using daily for 15+ years without issues. In an industry where reliability is non-negotiable, this Oak Park manufacturer delivers peace of mind.

Perhaps most impressive is their willingness to tackle unique challenges. Those custom penguin exam tables for the Detroit Zoo? That project showcases their problem-solving creativity and community spirit. When standard solutions don't fit, their team rolls up their sleeves and designs something that does.

Throughout their product line, user safety takes center stage. From ventilation systems that exceed OSHA requirements to ergonomic designs that prevent repetitive strain injuries, their equipment protects the people who use it—something we at American Mortuary Coolers deeply value in our own product development.

While serving a global market, this Oak Park manufacturer maintains its Michigan manufacturing base, supporting local jobs and ensuring hands-on quality oversight. This balance of global reach with local roots resonates with our own approach at American Mortuary Coolers.

Looking toward the future, they're embracing technological integration, sustainability initiatives, and expanded global distribution. Their roadmap includes IoT-enabled equipment, energy-efficient manufacturing, and designs that complement digital pathology workflows—ensuring they'll remain industry leaders for decades to come.

For those interested in exploring quality mortuary equipment options, American Mortuary Coolers provides custom solutions custom to your specific needs.

Here at American Mortuary Coolers, we tip our hats to companies who share our values of quality craftsmanship, thoughtful innovation, and genuine customer care. Their three-decade journey from garage startup to global leader inspires our own commitment to excellence in the funeral and mortuary sector.