The Essential Guide to Luer Connectors in Medical Equipment

A luer needle is a standardized medical connector used to create leak-free connections between syringes, needles, and other medical equipment. These connectors feature a 6% tapered design that ensures a secure fit for safe fluid transfer in healthcare settings.

Quick Reference Guide to Luer Needles:

| Feature | Description |

|---|---|

| Types | Luer Lock (threaded) and Luer Slip (friction fit) |

| Standard | 6% taper defined in ISO 594 |

| Common Uses | Injections, fluid sampling, embalming, laboratory work |

| Gauge Range | 18G (large) to 31G (small) |

| Key Components | Hub, shaft, and beveled tip |

Luer needles have been the medical industry standard for over 110 years, providing healthcare professionals with reliable connections across different manufacturers' equipment. Their simple yet effective design creates a secure seal that prevents leakage during fluid transfer procedures.

The standardized nature of luer connections means that virtually any syringe with a luer tip will connect to any compatible needle, regardless of manufacturer. This universal compatibility has made luer needles essential in medical, laboratory, and mortuary settings worldwide.

I'm Mortuary Cooler, and I've worked extensively with luer needle systems in mortuary applications, helping funeral professionals select appropriate equipment for embalming procedures and other preparation room tasks. My experience has shown that understanding luer needle compatibility is crucial for maintaining sterile conditions and ensuring proper fluid delivery in mortuary science.

Understanding the Luer Needle: Anatomy & History

Let's explore luer needles - those small but mighty tools that have revolutionized medicine, laboratory work, and yes, even the mortuary sciences!

What Is a Luer Needle?

A luer needle is essentially a precision-engineered marvel: a hollow stainless-steel tube attached to a standardized connector (the "luer hub") that creates a secure, leak-free connection with compatible syringes and devices. What makes these needles special is their universal design - you can connect them to virtually any compatible device regardless of manufacturer, which is incredibly helpful when you're in the middle of an embalming procedure or working in a busy clinical setting.

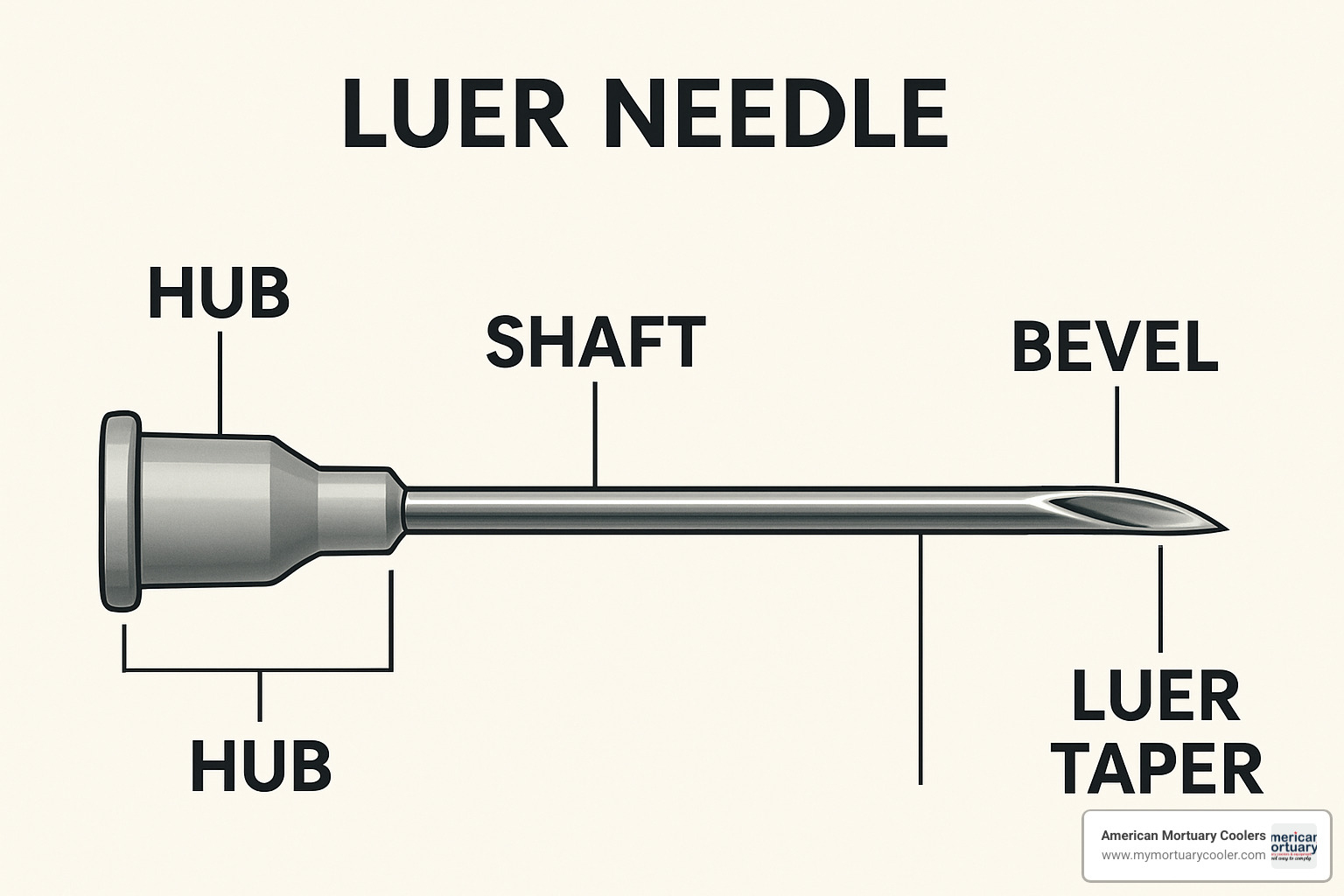

Think of the luer needle as having four key parts working together:

| Part | Function |

|---|---|

| Hub | The connector end; attaches to the syringe or tubing |

| Shaft | The long, hollow tube through which fluids flow |

| Bevel | The angled tip for piercing skin, tissue, or rubber stoppers |

| Luer Taper | The 6% conical fit ensuring a leak-free, universal connection |

The beveled tip is particularly clever in its design - depending on your needs, you might use a sharp bevel for injections or a blunt one for safely drawing fluids from vials or for laboratory work. This versatility makes luer needles indispensable across multiple industries.

Evolution at a Glance

The story of how the luer needle came to dominate medical connections worldwide is both fascinating and surprising. It's a journey spanning over a century of innovation:

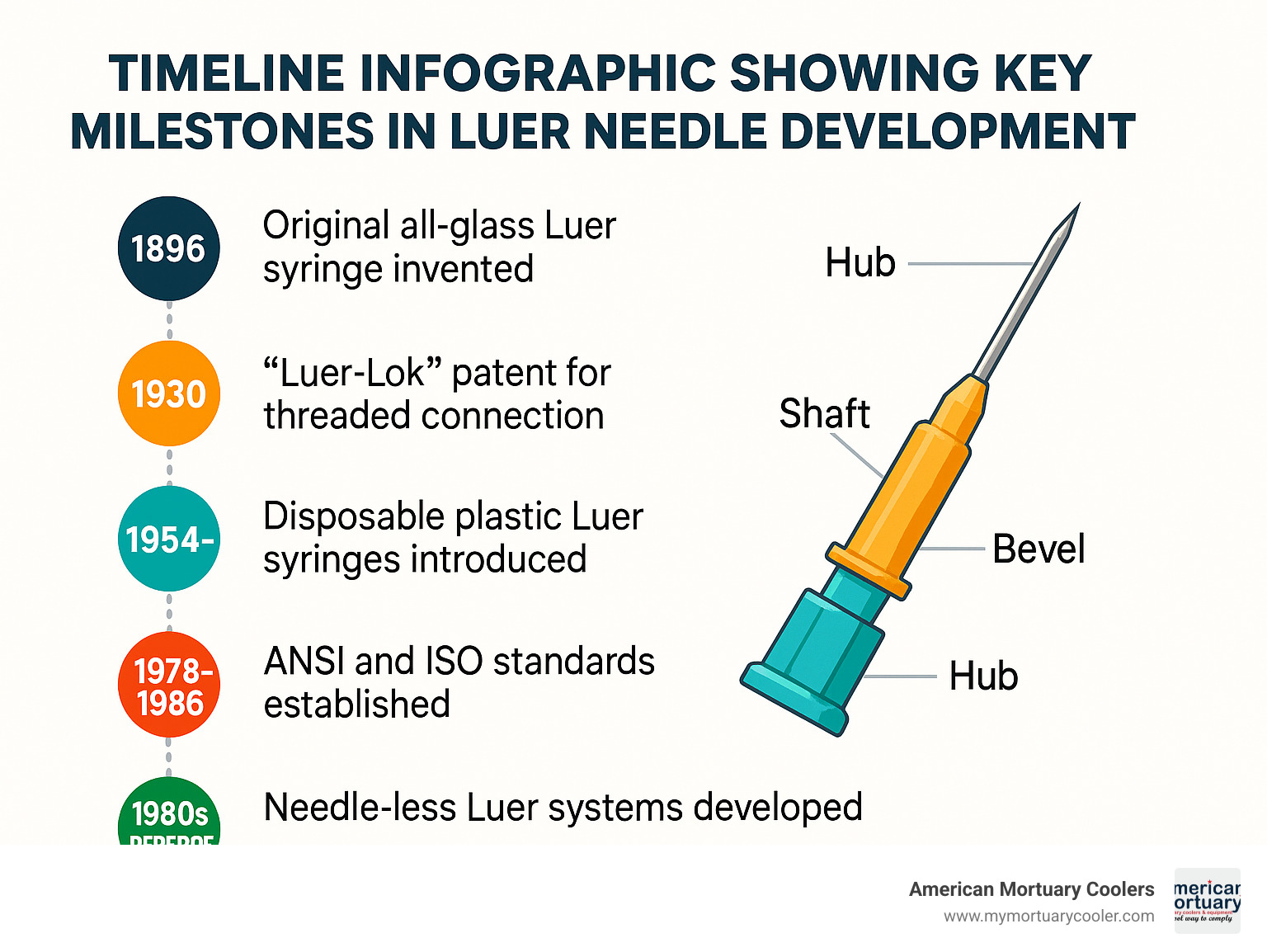

1896: Karl Schneider invented the original all-glass luer syringe - a simple but brilliant design with a glass plunger and barrel that needed no rubber seals or extra components.

1930: The game-changing "Luer-Lok" patent introduced threaded flanges that prevented needles from accidentally disconnecting under pressure. Anyone who's ever had a syringe come apart mid-procedure (yikes!) can appreciate this innovation!

1954-1961: A perfect storm of events - the massive Salk polio vaccine campaign and a hepatitis outbreak linked to reused glass syringes - created overwhelming demand for disposable options. Plastic luer syringes took the market by storm, capturing one-third of the U.S. needle market in just one year.

1978–1986: The push for standardization led to ANSI and later ISO 594 specifications for the luer connection, ensuring worldwide compatibility - a major win for healthcare professionals everywhere.

1980s–present: Growing concerns about HIV, hepatitis, and needlestick injuries have driven development of needle-less and closed-system luer technologies, along with color-coded connectors and even RFID-enabled systems for better tracking.

The reliability of luer needles was put to the ultimate test during the 1954 Salk vaccine trial, when over one million children across 44 states were vaccinated using luer syringes. That's a million connections that needed to work perfectly - and they did!

At American Mortuary Coolers, we've seen how crucial reliable connections are in mortuary science. Whether you're performing arterial embalming or cavity embalming, the security and ease of luer needle connections make a meaningful difference in your daily work.

For those interested in the broader history of tools used in mortuary science, including how luer needles fit into the evolution of embalming equipment, check out everything you need to know about embalming supplies. The scientific research behind the Luer taper design is also fascinating reading for those who appreciate the engineering behind these everyday tools.

Luer Connection Types & Compatibility

When you're working with medical equipment, few things are as reassuring as knowing your connections won't leak or come apart. That's the beauty of the luer needle system—but there's more than one way these connectors fit together! Let's explore the options and help you find your perfect match.

Luer Lock vs. Luer Slip: The Classics

Think of the difference between a screw-top bottle and a push-on cap—both work, but for different situations.

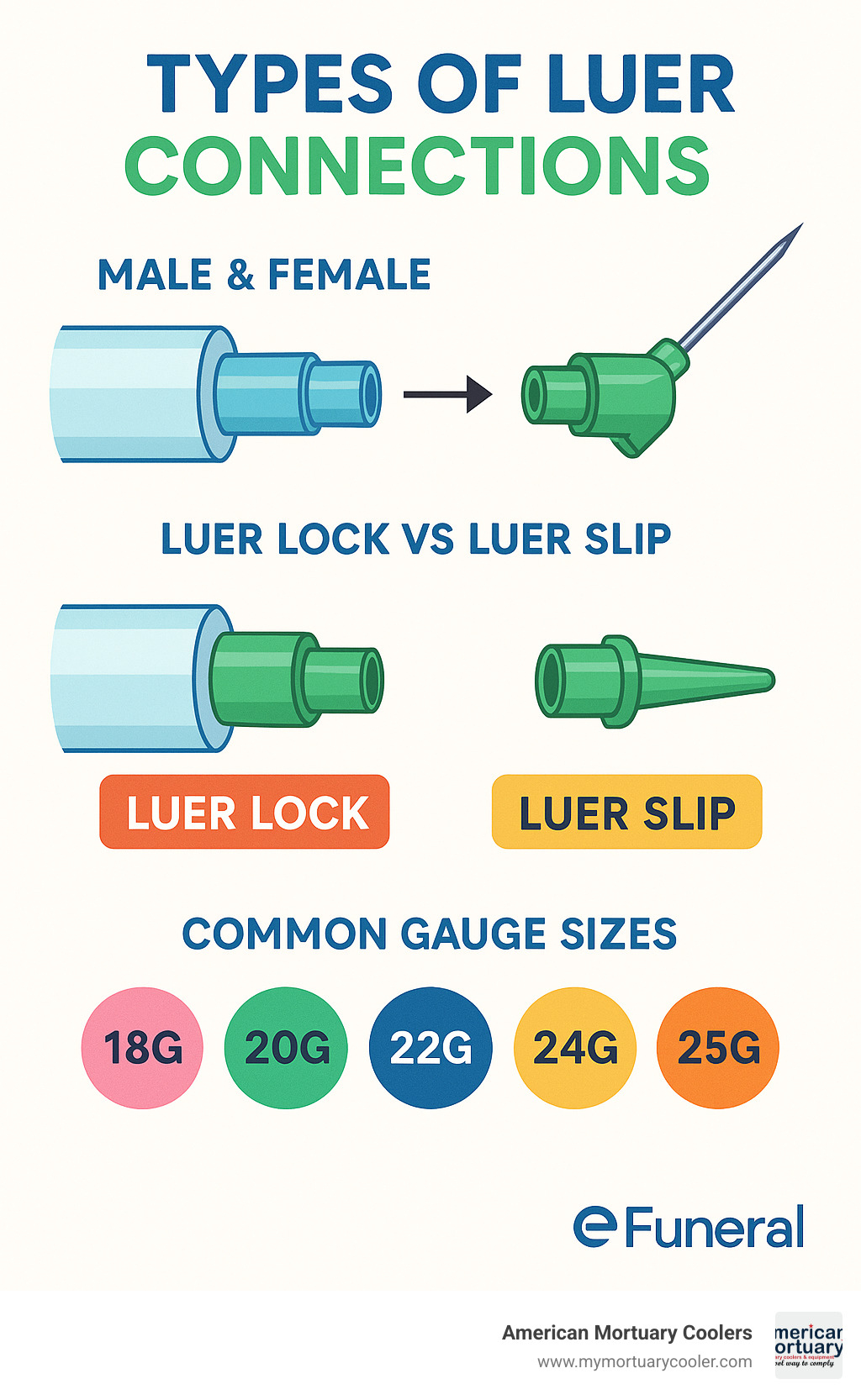

Luer Lock connectors feature a threaded collar that you twist to secure. This gives you that satisfying, confidence-inspiring connection that won't budge even under pressure. When I'm working with embalming fluids or other viscous solutions, I always reach for a luer lock—there's nothing worse than a connection failing mid-procedure!

Luer Slip connectors, on the other hand, rely simply on friction. You just push the components together for a quick connection. They're perfect when you need to make rapid changes or for lower-pressure applications. Many professionals prefer them for routine blood draws or quick saline flushes.

Male vs. Female Connectors

Every successful connection needs two compatible parts. In the luer world:

Male Luer connectors are the protruding, tapered ends typically found on syringes. Think of them as the "givers" in the relationship.

Female Luer connectors are the receiving hubs usually found on needles or tubing—the "receivers." Almost all needles have female hubs designed to accept the male end of your syringe.

Tip: Remember this simple rule: syringes are almost always male luer, while needles and adapters are female luer. They're designed to fit together perfectly!

Specialized Adapters & Color-Coded Collars

Beyond the basics, you'll find some helpful variations in the luer family. Blunt Luer Stubs let you connect tubing or draw up fluids without the risk of accidental sticks—a godsend when you're preparing solutions at the lab bench.

Many manufacturers also use color coding on luer hubs and collars for quick identification. That flash of pink or green can tell you the gauge size at a glance—incredibly helpful when you're working quickly or in dim lighting conditions.

For those wanting to dive deeper into the technical specifications, Scientific research on Luer compatibility offers fascinating insights.

Luer Needle vs. Luer Syringe Interface

The way needles and syringes connect affects your whole procedure. Threaded Fit connections (Luer Lock) prevent those heart-stopping accidental disconnects. They're essential for pressurized applications like IV infusions or embalming procedures where reliability is non-negotiable.

Push-Fit connections (Luer Slip) offer speed and convenience but come with limitations. They're best suited for low-pressure, low-risk uses like flushing lines or filling cartridges. I've learned through experience that a luer slip can disconnect if pulled or twisted under load—sometimes at the most inconvenient moment!

Choosing the Right Luer Connection for Your Task

Selecting the right connection comes down to three main factors:

Drug Viscosity matters tremendously. Thick fluids like blood products or embalming chemicals create more back-pressure, making luer lock connections the safer choice. The last thing you want is to have a connection fail when working with hard-to-clean substances.

Pressure Requirements should guide your decision. High-pressure applications practically demand luer locks, while frequent changes might make luer slips more practical despite the slightly higher risk.

Quick-Change Needs might push you toward luer slip connections. If you're constantly switching between different needles or adapters—like when priming ink cartridges or working with seed injection robotics—the time saved with push-fit connections can be substantial.

In my years working with mortuary equipment, I've found that understanding these connection types isn't just about technical specifications—it's about finding the right tool for the job to ensure safety, efficiency, and peace of mind.

Sizing, Color Codes & Materials Demystified

Ever found yourself squinting at a tiny luer needle trying to figure out what size it is? Or wondering why some have pink hubs while others are yellow? You're not alone! Let's clear up the confusion around these essential tools.

Reading Gauge on a Luer Needle

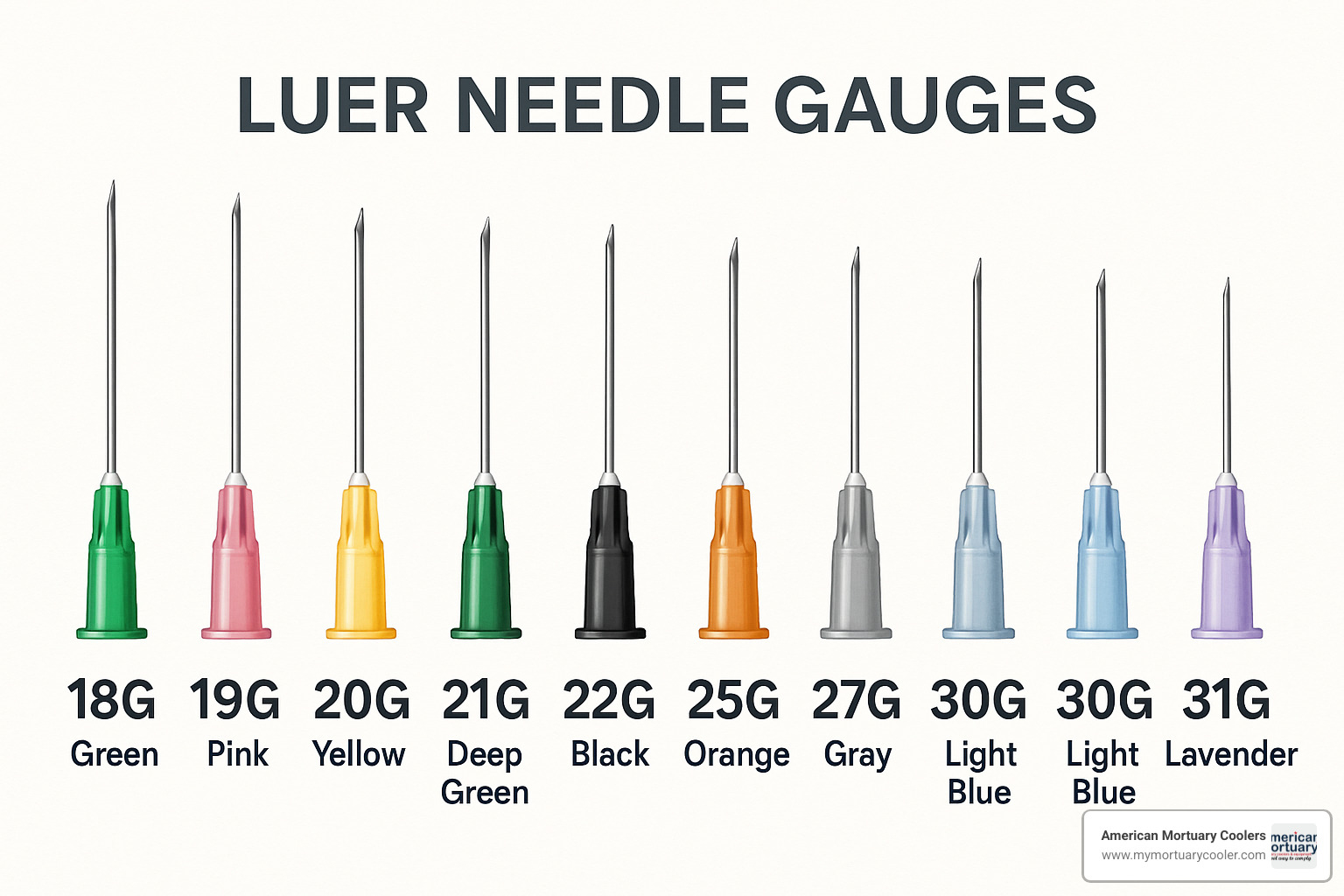

The gauge system for luer needles follows a wonderfully counterintuitive pattern that's tripped up many beginners. Here's the secret: the higher the gauge number, the thinner the needle! An 18G needle is actually much thicker than a 31G needle.

Think of it like medieval wire-drawing, where the measurement was based on how many draws it took to reach that diameter. More draws meant thinner wire—and a higher gauge number.

When you're selecting a luer needle for your procedure, you'll need to consider both the gauge (diameter) and length. Needles typically range from 1/8 inch for shallow injections up to 3 inches for deeper applications. In the mortuary setting, you'll often need those sturdier 18-22G needles that can handle thicker embalming fluids without clogging.

Color coding makes quick identification possible, though I always recommend double-checking the packaging. Most manufacturers follow a standard color scheme:

Pink hubs typically indicate 18G needles—perfect for viscous fluids. Yellow usually means 20G, while green signifies 21G. Need something more delicate? Look for orange (25G) or grey (27G) hubs. When working with extremely fine applications, light blue hubs generally mark ultra-thin 30G needles.

For those who love precision, the Needle gauge comparison chart provides exact measurements down to the millimeter.

Material Matters

The materials used in luer needles aren't just random choices—they're carefully selected for specific properties that affect everything from durability to chemical compatibility.

Most needle shafts are crafted from stainless steel—and for good reason. This remarkable metal resists corrosion from bodily fluids, chemicals, and cleaning agents while maintaining structural integrity when subjected to pressure. For mortuary professionals handling various chemicals, this corrosion resistance is particularly valuable.

The colorful hubs we just discussed? They're typically made from polypropylene or similar medical-grade plastics. These materials offer excellent chemical resistance and can be precisely molded to maintain that crucial 6% taper that defines the luer standard.

"I've found that single-piece stainless steel needles with minimal joints provide the smoothest flow for embalming applications," shared one of our longtime customers, a funeral director from Georgia.

For laboratory or mortuary applications where piercing isn't necessary, blunt-tip luer needles offer a safer alternative. These have carefully deburred tips that won't damage rubber septa or puncture skin but maintain the same precise flow characteristics.

While most clinical settings exclusively use single-use disposable needles (a practice that gained tremendous momentum in the 1960s), some industrial and research applications still employ reusable, sterilizable versions. However, even in mortuary settings, the shift toward single-use has been significant for infection control.

When working with delicate tissues or performing specialized procedures, knowing these material differences can make all the difference between smooth operation and unnecessary complications. At American Mortuary Coolers, we've seen how having the right tools—down to the appropriate luer needle—contributes to professional results in the preparation room.

Applications, Safety & Best Practices

The humble luer needle is truly the unsung hero of medical equipment, showing up everywhere from hospital rooms to seed-planting robots. But with this versatility comes responsibility—let's explore how these connectors are used and how to handle them safely.

Real-World Applications

When it comes to versatility, few medical tools can match the luer needle. In clinical settings, these connectors are the workhorses behind vaccinations, medication delivery, blood draws, and IV therapy. The standardized connection means nurses and doctors can focus on patient care rather than fiddling with equipment compatibility.

In laboratories, scientists rely on luer needles for precise fluid handling and sample transfers. The accuracy of many research findings depends on the reliable connections these needles provide.

For those of us in the mortuary science field, luer needles are essential tools in embalming procedures. They allow for controlled fluid injection, cavity treatment, and tissue preservation—all crucial processes in preparing the deceased with dignity and care.

And here's something that might surprise you—even modern agricultural robots use luer needles! Precision seed-planting systems rely on these standardized connectors for consistent, reliable performance in automated gardening setups.

"We use luer lock needles in our mortuary prep rooms for secure, leak-proof fluid delivery. Compatibility and sterility are non-negotiable," shares a funeral director from our Johnson City, TN location.

For more insights into the tools used in forensic and mortuary settings, take a look at our guide to Exploring essential forensic tools and equipment.

Safe Handling of a Luer Needle

Safety should always be your top priority when working with any needle system. Always maintain aseptic technique—keeping the hub, shaft, and bevel sterile until the moment of use. This simple practice prevents contamination and protects both you and those you're caring for.

The angle of insertion matters tremendously depending on your application. For intramuscular injections, a 90° angle provides the right depth. Subcutaneous injections work best at a 45° angle, while intradermal applications require a shallow 5-15° approach. These aren't just suggestions—proper angles ensure medications reach their intended tissue layers.

One of the most important safety rules might seem counterintuitive: never recap needles after use. Instead, dispose of them immediately in a sharps container. This simple habit dramatically reduces the risk of accidental needlestick injuries, which remain a significant occupational hazard for healthcare workers.

Modern luer needles often come with built-in safety shields that automatically cover the needle after use. These clever designs have significantly reduced workplace injuries—if they're available for your application, they're well worth the small additional cost.

"Needlestick injuries are a real risk—always use a safety-shielded needle if available, and never recap," advises the CDC.

Common Errors & How to Avoid Them

Even experienced professionals occasionally make mistakes with luer needles. The most common error is misconnection—always verify you have the proper male/female fit and the right connection type before proceeding with any procedure.

Selecting the wrong gauge is another frequent mistake. Remember to choose the appropriate size for both your fluid and application—thicker fluids need larger gauges, while delicate tissues require smaller ones.

When using luer lock connections, be careful to avoid cross-threading. Make sure the threads are properly aligned before tightening to prevent leaks and connection failures. This small detail can make the difference between a smooth procedure and a frustrating mess.

Finally, don't rely solely on color coding when selecting needles. While colors provide a helpful visual shortcut, always double-check the actual gauge markings to confirm you're using the right tool for the job. Color standards can vary between manufacturers, so verification is your best friend.

In mortuary settings, where precision and dignity go hand in hand, these safety practices aren't just good habits—they're essential components of professional care. At American Mortuary Coolers, we understand how the right tools and techniques contribute to both worker safety and respectful service for families in their time of need.

Standards, Regulations & Future Outlook

Have you ever wondered why your syringe always fits your needle, no matter where you buy them? That's the magic of standardization! The luer needle system isn't just convenient—it's carefully regulated to ensure safety and compatibility worldwide.

Key Standards & Regulations

The humble luer connector might seem simple, but it's backed by some serious international standards. The ISO 594 specifications define that perfect 6% taper that creates leak-free connections—a bit like how all light bulbs fit standard sockets regardless of manufacturer.

"I remember when we first implemented the ISO standards in our facility," shares a veteran nurse educator. "Suddenly, all the connection guesswork disappeared. Everything just worked."

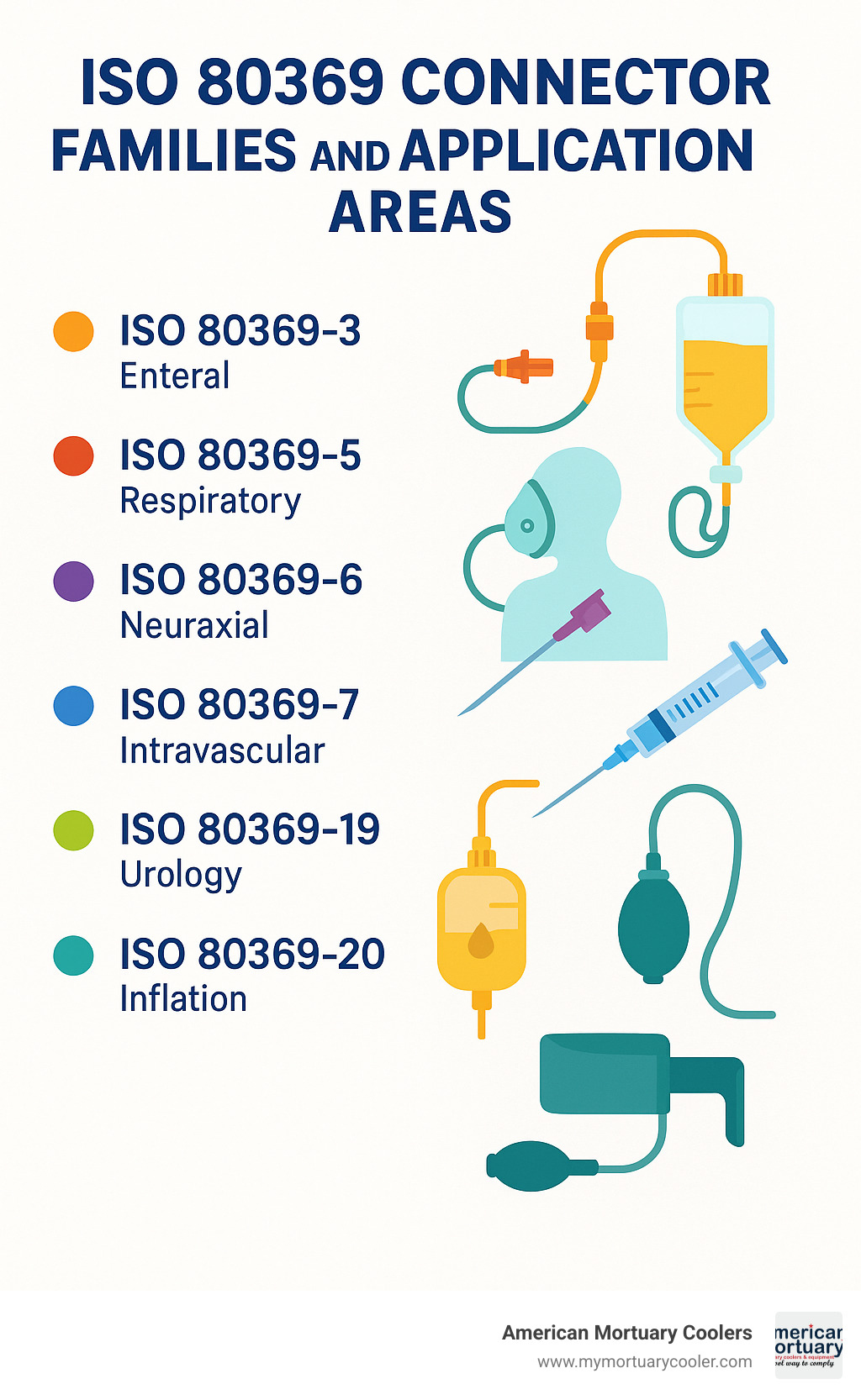

But there's been a bit of a plot twist in recent years. While the universal nature of luer connectors is convenient, it's created safety risks when, for example, a feeding tube connector accidentally fits an IV line. This led to the development of ISO 80369—a newer standard creating distinct connector families for different medical applications.

The regulatory landscape includes:

- ISO 594-1 & 594-2: The original "luer bible" that defined the 6% taper and testing requirements

- ISO 80369: The next-generation standard creating application-specific connections

- ANSI standards: The American version that works alongside international requirements

- FDA regulations: Pushing for needleless systems to reduce sharps injuries

Upcoming Innovations for the Luer Needle

The luer needle isn't going anywhere, but it is getting some exciting upgrades. Think of it like how smartphones keep the same basic function but add new features with each generation.

Color-coding is becoming more standardized globally, making it easier to quickly identify the right needle for the job. This is particularly helpful in high-pressure situations like emergency rooms or busy mortuary prep rooms.

Smart technology is entering the picture too. RFID-enabled hubs can now track usage and prevent incorrect connections—imagine a needle that "knows" what it's supposed to connect to! Some newer designs even provide an audible click when properly connected, giving users confidence in their setup.

"The most significant innovation I've seen is the closed-system design," notes a mortuary technician. "Being able to transfer fluids without exposure to air or contaminants has been a game-changer for preservation work."

In research labs, microfluidic applications are pushing the boundaries of what luer connections can do, allowing for precise handling of tiny fluid volumes for diagnostic testing and pharmaceutical development.

Frequently Asked Questions about Luer Needles

How long does a luer needle last? Most luer needles are designed for single use only, especially in medical settings. This isn't just about the needle becoming dull—it's primarily about preventing infection. In some industrial or research applications, you'll find reusable needles that can be sterilized between uses, but these are the exception rather than the rule.

How are luer needles sterilized? Manufacturers typically use ethylene oxide (EtO) gas to sterilize needles before packaging. For reusable needles, autoclaving (steam sterilization) is the most common method. Most needles arrive in tamper-evident packaging that maintains sterility until use—that little paper peel-pack is more sophisticated than it looks!

What are the disposal rules? This one's important for safety: used needles must go immediately into approved sharps containers. Never, ever recap or bend needles after use—this is when many needlestick injuries occur. In mortuary settings, proper disposal is not just good practice; it's required by OSHA and state regulations.

Can luer needles from different manufacturers connect? Yes! That's the beauty of standardization. Whether you're using products from BD, Monoject, or any other manufacturer, the luer needle connection will fit. This universal compatibility is why the system has endured for over a century.

What's the difference between a blunt and sharp luer needle? Blunt needles have rounded tips designed for drawing fluids from vials or connecting tubing—never for penetrating skin. Sharp needles have that familiar beveled tip for injections. In mortuary settings, you'll use both: sharp needles for arterial injection and blunt needles for cavity work or fluid transfers.

The future of luer needle technology balances innovation with the reliability that's made these connectors a century-long success story. While new connector families are developing for specialized applications, the classic luer design continues to evolve with safety and efficiency improvements that benefit healthcare, laboratory, and mortuary professionals alike.

Conclusion

The luer needle is a quiet hero in medical and mortuary care. Its simple, universal design keeps fluids flowing safely—whether you’re giving a vaccine, transferring a lab sample, or performing detailed embalming work. It’s easy to overlook, but choosing the right luer needle (and knowing how to use it properly) keeps your routine running smoothly, day after day.

At American Mortuary Coolers, we know that reliable tools make all the difference—especially when you’re serving families and communities in moments that matter most. That’s why we offer only dependable, compatible equipment, including a range of luer needle systems designed for every mortuary and funeral need. And of course, our specialty is crafting custom mortuary coolers that stand up to daily use—delivered directly to you, anywhere in the lower 48 states.

If you’d like to see how our products can support your work, or if you have questions about selecting the right tools, we’re always happy to help. Visit Your one-stop shop for mortuary coolers for more details about our offerings and how we support professionals nationwide.

Remember: the humble luer needle brings big value to your workflow, one secure twist or push at a time. Stay safe, stay precise, and let your equipment do the heavy lifting—so you can focus on what really matters.

This article is proudly brought to you by American Mortuary Coolers, serving the contiguous 48 states from Johnson City, TN and beyond. We’re here to keep your operations seamless, with custom solutions you can trust.