Lifting the Standard: The Mortuary Lift Advantage

The Cedar Rapids–based manufacturer highlighted below has been supplying high-quality mortuary lifting equipment for more than 50 years. Their complete range of body-handling solutions supports funeral homes, morgues, hospitals and universities that demand safety, durability and ergonomic performance.

| Quick Facts About the Iowa Lift Manufacturer |

|---|

| • Founded: 1987 (50+ years combined experience) |

| • Location: Cedar Rapids, Iowa |

| • Main Products: Ultimate 1000 Lift, Stepper, Tug-Along Winch, Body Coolers |

| • Notable Features: All-in-One Lifting™ system, custom track systems |

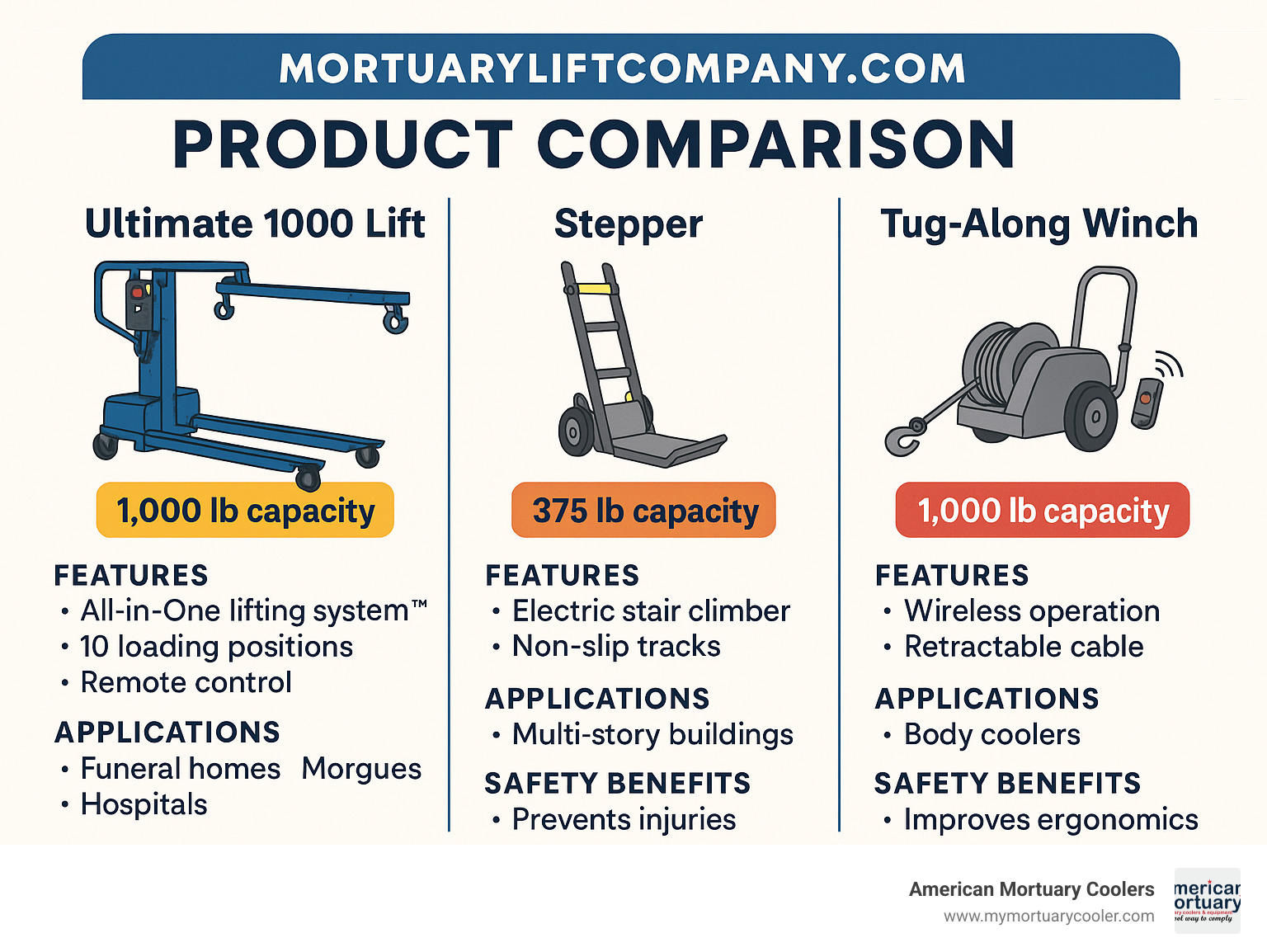

The flagship ULTIMATE 1000 LIFT™ remains one of the best-selling casket lifts in the funeral industry. Rated for 1,000 pounds, this heavy-duty workhorse is engineered for reliability and versatility.

Beyond their premier lift, the company offers innovative tools such as:

- The Stepper™ – an electric stair-climbing system with 375-pound capacity

- The Tug-Along® – a patent-pending wireless remote winch (1,000-pound capacity)

- Custom Track Systems – monorail and ceiling-less gantry options

- Body Coolers – standard and fully customizable configurations

What truly sets these products apart is the focus on ergonomics and safety. Every piece of equipment is designed to reduce back strain, prevent workplace injuries and improve operational efficiency—concerns that matter deeply to funeral directors managing daily transfers.

I'm with American Mortuary Coolers, a national-level mortuary cooler supplier with extensive experience working with various lifting products alongside our own cooling solutions. Having installed and maintained dozens of lift systems, we've seen how quality equipment transforms funeral-home operations.

Further reading on related topics:

Company Snapshot & Legacy

The Cedar Rapids manufacturer discussed in this guide was officially incorporated in 1987, yet its roots in mortuary equipment stretch back more than five decades. Despite a modest team of 2–10 dedicated employees, their lifts and coolers have earned the trust of funeral homes, morgues, universities and hospitals around the world. This focused approach allows them to maintain exceptional quality control while tailoring solutions to a very specific niche.

A Douglas County Coroner shared in a testimonial:

“After implementing the Ultimate 1000 Lift, we've eliminated virtually all manual lifting injuries in our facility. It's become an essential tool we simply couldn't operate without.”

At American Mortuary Coolers, we've had the pleasure of integrating these lift products on numerous projects throughout our service regions. From Johnson City to Atlanta, Chicago to San Francisco, quality lifting equipment consistently complements our custom mortuary coolers, creating seamless solutions for our clients.

Timeline of Growth and Innovation

- 1987: Current manufacturing entity officially takes root in Cedar Rapids

- Early 1990s: Ultimate 1000 Lift debuts, quickly becoming a flagship product

- Mid-2000s: Custom track systems and gantry options expand installation possibilities

- Early 2010s: Stepper™ electric stair-climbing system addresses a critical safety gap

- Late 2010s: Patent-pending Tug-Along® winch systems revolutionize vehicle loading

- Ongoing: Continuous research focused on ergonomics, safety and operational efficiency

Industry Reputation

Their equipment’s reputation stands on several solid foundations:

• Consistent presence at major funeral-industry conventions lets directors experience the products firsthand.

• Safety-conscious design aligns with OSHA guidelines, reflecting the growing focus on workplace safety.

• Word-of-mouth remains powerful in our close-knit industry; long-term customer loyalty speaks volumes.

In our experience installing equipment nationwide, facilities that adopt comprehensive lifting solutions report happier staff and fewer workplace injuries—the true measure of equipment that delivers on its promises.

Flagship Equipment Line-Up & Key Features

What strikes me about this manufacturer’s equipment isn’t just the impressive specs (though 1,000-pound capacities certainly get your attention). It’s their thoughtful “All-in-One Lifting™” philosophy. Instead of selling separate devices for different tasks, they create versatile equipment that serves multiple functions—saving both money and valuable space in often-cramped preparation areas.

| Product | Capacity | Primary Application | Key Differentiator |

|---|---|---|---|

| Ultimate 1000 Lift | 1,000 lbs | Prep-room casket & body handling | All-in-One Lifting™ system |

| Stepper™ | 375 lbs | Stair navigation with deceased | Acts as a “second attendant” |

| Tug-Along® Winch | 1,000 lbs | Vehicle loading/unloading | Wireless remote operation |

| Track Systems | 1,000+ lbs | Multi-room body transport | Custom configurations |

| Ceiling-less Gantries | 1,000+ lbs | Facilities without suitable ceiling structure | Free-standing design |

| Body Coolers | Various | Temperature-controlled storage | Custom sizing options |

The Ultimate 1000™ Lift: Why It’s a Best-Seller

There’s a reason the Ultimate 1000™ has been the go-to casket lift for over five decades. This workhorse isn’t just powerful—it’s thoughtfully designed for real-world funeral-home challenges.

With its impressive 1,000-pound capacity, it easily handles bariatric cases and heavy caskets without breaking a sweat. Funeral directors particularly appreciate the multi-directional versatility—it lifts, lowers and transports in multiple directions with smooth hydraulic power that gives full control even with maximum loads.

Perhaps most importantly, it’s engineered for single-operator use, allowing one person to safely handle tasks that traditionally required two or three staff members. Whether you prefer a stationary unit or a track-mounted configuration, the Ultimate 1000 adapts to your prep-room layout.

When we install our custom coolers alongside an Ultimate 1000 Lift, funeral homes immediately notice the workflow improvement. Suddenly, a single staff member can safely transfer remains from cooler to preparation table to casket without calling for backup. For more guidance on selecting the right lift, check out our detailed lift selection guide.

Stepper™ Electric Stair-Climbing System

Anyone who has carried a stretcher down a narrow staircase knows exactly why the Stepper™ was invented. This brilliant device functions like an electric second attendant, dramatically reducing the physical strain of navigating stairs during removals.

With a 375-pound capacity, it handles standard removals with room to spare. The rechargeable battery operation means no tripping over cords, while folding handles allow for compact storage when not in use. But what really makes this system special is how it transforms one of the most physically demanding—and potentially dangerous—aspects of funeral service.

I’ve seen the relief on directors’ faces when they first use a Stepper™—especially those with years of service whose backs and knees have taken a beating. Suddenly, those daunting three-story walk-ups without elevators aren’t so intimidating.

Tug-Along® Casket & Gurney Winch (Patent Pending)

The patent-pending Tug-Along® solves one of the oldest problems in funeral service—the physical strain of loading and unloading removal vehicles.

This clever device features wireless remote operation allowing complete control of the loading process from anywhere around the vehicle. Its universal vehicle integration means it works with virtually any removal vehicle or hearse, while maintaining that impressive 1,000-pound capacity for challenging removals.

What makes it particularly practical is its lightweight portability and quick-attach system—you can rapidly deploy it at a removal location, then easily transfer it between vehicles when needed.

The impact on workplace safety can’t be overstated. Scientific research on injury reduction consistently shows that mechanical assistance during vehicle loading/unloading dramatically reduces back injuries—the most common and costly workplace injury in funeral service.

Custom Track & Gantry Solutions

For funeral homes seeking a comprehensive solution, the manufacturer’s track and gantry systems extend the utility of their lifting equipment throughout an entire facility.

Their monorail track systems allow transport of remains throughout preparation areas without repeated lifting—a game-changer for staff safety. For existing buildings, they offer ceiling retrofit options that require minimal structural modification, while their free-standing gantry designs provide solutions where ceiling mounting isn’t possible.

I’m particularly impressed with their space-saving configurations that maximize operational flow in tight quarters. The modular component design also allows for future expansion or reconfiguration as needs change.

We’ve worked closely with their engineers to create integrated solutions where our coolers connect directly to these track systems, creating seamless workflows. For more details on track options, visit our track systems page.

Mortuary Body Coolers & Accessories

Although best known for lifting equipment, this Midwest manufacturer also offers quality mortuary coolers that integrate perfectly with their handling systems.

Their lineup includes standard 2-door models that ship quickly for typical funeral-home needs, as well as bariatric options with expanded width for larger cases. The stainless-steel construction provides durability and easy cleaning, while energy-efficient compressors keep operational costs down while maintaining proper temperature.

As specialists in mortuary cooling ourselves, we appreciate quality when we see it. While we might technically compete in this category, we recognize these coolers as well-designed, reliable units that pair seamlessly with their lifting systems.

For funeral homes seeking a complete solution from a single vendor, combining their lifting and cooling offerings provides a cohesive approach to mortuary operations that eliminates compatibility headaches.

Safety, Efficiency & ROI Benefits

When we visit funeral homes across the country, directors often ask, “Is this equipment really worth the investment?” After seeing these products in action at hundreds of facilities, our answer is a resounding yes. The systems deliver benefits far beyond their basic functions, creating measurable improvements that impact both your team and your bottom line.

Think about it—how much is a staff member’s health worth? How valuable is the time saved when you can move remains efficiently? These questions reveal the true value proposition of quality lifting equipment.

How the Equipment Protects Your Team

The science supporting this manufacturer’s approach to safety isn’t just marketing talk—it’s grounded in real occupational-health research. Funeral-service professionals experience back injuries at significantly higher rates than most workers. We’ve seen this when installing coolers in facilities that haven’t yet upgraded their lifting equipment.

Their lifting systems directly address these risks through thoughtful design. Every piece incorporates multiple redundant securing systems to prevent accidental drops during transport—something that brings peace of mind during challenging removals.

Emergency-stop features on all powered equipment allow immediate shutdown if needed, while CE/UL-compliant components ensure reliable operation even under demanding conditions. It’s this attention to safety details that makes the difference.

One funeral director in Illinois told us, “After twenty years of lifting, my back was nearly finished. The Ultimate 1000 literally saved my career.” We hear stories like this regularly when installing our coolers alongside their handling equipment.

From our installations across the country, we’ve observed that funeral homes implementing comprehensive lifting solutions typically see workplace injuries decrease by 60–80 percent within the first year. That’s not just good for your team—it dramatically impacts insurance premiums and workers’ compensation costs.

For more details on safety improvements, explore our safety lift guide.

Efficiency Gains for Funeral Homes, Hospitals & Universities

Beyond protecting your staff, the operational-efficiency improvements create tangible business benefits. Tasks that traditionally required two to four staff members can often be safely performed by a single operator. This isn’t about cutting staff—it’s about allowing your team to focus on the compassionate aspects of funeral service rather than physical labor.

Multi-room coverage through track systems enables smooth transport throughout preparation areas without repeated lifting. Quick-swap attachments mean the same lifting equipment serves multiple functions, reducing both equipment costs and storage needs in often cramped spaces.

The ROI timeline is surprisingly quick. Most facilities report full return on investment within 12 months through combined savings on labor, injury costs and operational efficiency. One medium-sized funeral home in Washington calculated savings of over $32,000 in the first year alone after installing an Ultimate 1000 and track system.

For university anatomy labs and hospital morgues, these efficiency gains are particularly valuable. These facilities often operate with limited specialized staff, making the ability to safely handle remains with minimal personnel not just a convenience but a necessity.

During a recent installation in Chicago, a hospital-morgue supervisor put it perfectly: “This equipment doesn’t just save our backs—it saves time, money and dignity for the deceased. That’s the complete package.”

When we pair our custom cooling solutions with this manufacturer’s handling equipment, the result is a streamlined workflow that maximizes both safety and operational throughput. It’s a partnership that simply makes sense for modern funeral service.

Purchasing, Customization & Support Roadmap

For funeral homes, morgues, universities and hospitals considering the equipment highlighted in this guide, understanding the purchasing process helps ensure you select the right solutions for your specific needs.

When you’re ready to explore your options, the journey begins with reaching out to the manufacturer directly. Their friendly team will take the time to understand your facility’s unique challenges and requirements—no cookie-cutter solutions here. For many facilities, particularly those with complex layouts, they’ll recommend a virtual tour or in-person site assessment to ensure the equipment will integrate seamlessly with your existing space.

Based on the conversation, you’ll receive a detailed quote that outlines recommended equipment, installation considerations and transparent pricing. We’ve found these quotes to be refreshingly straightforward—no hidden fees or surprises down the road.

I remember working with a small family-owned funeral home in rural Illinois that was concerned about the upfront investment. The manufacturer’s team walked them through several financing options, including a 0 percent down-payment plan that made the purchase manageable within their budget constraints. This kind of flexibility has helped countless funeral homes access equipment they might otherwise consider out of reach.

Once your order is confirmed, it enters the production queue. Lead times vary depending on the complexity of your order and any customizations, but the team keeps you updated throughout the process. They’ll work with you to schedule installation at a time that minimizes disruption—something particularly important for busy funeral homes.

For those who prefer a more streamlined approach for standard products, many items are available through convenient online stores. For more detailed information about custom cooler quotes, you can explore our cooler quoting guide.

Custom-Built Solutions & Options

What truly sets quality mortuary equipment apart is the willingness to tailor products to your specific needs. The engineers understand that no two funeral homes or morgues are identical, and their customization options reflect this reality.

Need a body cooler with a unique door configuration to fit an awkward corner? No problem. Want your equipment finished in a specific color to match your facility’s aesthetic? They’ve got you covered. From custom track layouts that steer around architectural features to non-standard cooler dimensions that maximize available space, this team approaches each project with a problem-solving mindset.

I’ve been particularly impressed with vehicle-specific Tug-Along® winch kits. Rather than offering a one-size-fits-all solution, these systems are configured to work optimally with your specific vehicle make and model, ensuring seamless integration and operation.

At American Mortuary Coolers, we share this philosophy of customization over standardization. Our collaborative projects with the Iowa manufacturer have consistently demonstrated that taking the time to create truly custom solutions results in better long-term outcomes for our clients.

Warranty, Parts & Lifetime Service

Investing in quality equipment is just the beginning—ongoing support is where this company truly shines. Standard warranties typically include one-year parts and labor coverage for manufacturing defects, with extended options available for those seeking longer-term protection.

What happens when a strap wears out after years of use? Replacement-parts programs ensure that common wear items are readily available for quick shipment. Many newer models even include remote-diagnostic capabilities, allowing technicians to troubleshoot issues without an on-site visit—saving you time and minimizing downtime.

I recall a situation with a university anatomy lab in Washington that experienced an unexpected issue with their Ultimate 1000 Lift just before a major teaching session. The support team shipped a replacement part overnight and walked the facilities manager through the simple installation process over video chat. This kind of responsive service is why the equipment enjoys such a loyal following.

Rapid-ship spare-parts inventory means critical components are maintained and ready for dispatch when needed—a commitment that reflects an understanding of how essential this equipment is to your daily operations.

Ordering Checklist

Before making that initial contact, gathering some key information will help streamline your consultation and ensure you receive the most accurate recommendations:

- Budget parameters —helps focus the conversation on solutions that make financial sense.

- Maximum weight capacity needed, including any bariatric considerations.

- Room measurements, including ceiling height and doorway clearances.

- Available electrical service (voltage, phase, amperage).

- Timeline requirements—when you need the equipment operational.

- Existing equipment that needs to integrate with new purchases.

- Special architectural considerations such as beams or ductwork that may impact installation.

Having worked with funeral homes across the country, from Johnson City to Los Angeles, I’ve seen how this preparation can make the difference between a smooth, efficient equipment upgrade and one plagued by unexpected complications. A little homework upfront saves significant headaches down the road.

For more information about mortuary coolers specifically, you can explore our comprehensive guide.

What Sets This Manufacturer Apart

In a specialized industry where details matter, this Iowa-based manufacturer has carved out a unique position that keeps funeral professionals coming back decade after decade. What makes them special isn’t just what they build, but how they build it—and why.

When you look at their equipment next to many competitors’ products (as shown above), the differences become immediately clear. While others have moved toward lighter materials to cut costs, this team remains committed to solid, all-steel construction that stands up to decades of daily use. It’s the difference between equipment that lasts a few years versus equipment that becomes a reliable workshop partner for a generation.

Their innovation approach sets them apart too. Instead of simply making small tweaks to existing products, they regularly introduce truly novel solutions like their patent-pending Tug-Along® wireless winch. This commitment to solving real problems rather than just selling products has built tremendous loyalty among funeral professionals.

Perhaps most impressive is their 50-year track record in an industry where companies come and go. When you invest in their equipment, you’re partnering with a business that has likely been supporting funeral homes since before many current directors were born. That kind of stability brings peace of mind that your investment will be supported for years to come.

Their laser-focused dedication to mortuary handling equipment—rather than branching into unrelated products—means they understand the unique challenges funeral professionals face daily. Their engineers aren’t designing garden equipment on Monday and mortuary lifts on Tuesday; they eat, sleep and breathe mortuary operations.

At American Mortuary Coolers, we appreciate these qualities in our business partners. While we focus on custom cooling solutions from coast to coast, we recognize the complementary expertise this manufacturer brings to complete mortuary solutions. Their equipment pairs perfectly with our coolers to create seamless workflows that protect both staff and dignity.

Customer Success Stories

Real-world results tell the true story of any equipment’s value. Let me share how these products have transformed operations for three very different clients.

A five-location funeral-home group in Illinois was watching their workers’ compensation claims climb higher each year due to lifting injuries. After installing Ultimate 1000 Lifts and Steppers throughout their locations, the change was remarkable. Within just 18 months, lifting-related injury claims dropped by 83 percent. They found they needed one fewer staff member per removal, which alone created significant savings. The investment paid for itself in just 11 months through combined savings—a return that exceeded even their optimistic projections.

In Washington state, a major teaching hospital’s morgue struggled with efficient body handling between their cooler, autopsy suite and release area. After implementing a comprehensive track system with an Ultimate 1000 Lift, their efficiency soared. Body-handling time decreased by 40 percent, infection control improved through reduced manual contact and staff found themselves free to focus on teaching rather than struggling with manual transfers.

A Midwest university anatomy laboratory faced the unique challenge of needing to safely handle donor bodies while maintaining an appropriate educational environment. The manufacturer designed a custom solution that included a specialized track system spanning both preparation and teaching areas, along with a modified Ultimate 1000 Lift featuring attachments designed specifically for their requirements.

The system connected directly to our American Mortuary Coolers custom storage units, creating a seamless workflow from storage to preparation to instruction. The entire installation and training were completed during a three-week semester break, allowing classes to resume without missing a beat.

These success stories highlight why this equipment has become the gold standard across funeral homes, hospitals and educational institutions nationwide. The lifts don’t just move bodies—they lift entire operations.

Frequently Asked Questions

What is the load-capacity range offered by these products?

When funeral directors ask us about equipment capacities, we’re always impressed by how thoughtfully the product line addresses different needs.

The flagship Ultimate 1000 Lift lives up to its name with a robust 1,000-pound capacity that handles everything from standard cases to bariatric situations with confidence.

The Tug-Along Winch matches this 1,000-pound capacity, creating a seamless handling system from removal vehicle to prep room. There’s something reassuring about having consistent capacity throughout your entire workflow.

For stair navigation, the Stepper offers a 375-pound capacity, which covers the vast majority of removals while remaining maneuverable on challenging staircases.

The track systems typically mirror the 1,000-pound rating of the Ultimate lift, ensuring you never encounter a weak link in your body-handling process.

I’ve noticed during our installations that these ratings include generous safety margins—something that brings peace of mind when you’re handling precious cargo.

How long does installation take and who performs it?

“How soon can we be up and running?” This is one of the most common questions we hear when coordinating lift equipment with our cooler installations.

For most funeral homes, you can expect factory-trained technicians to be on-site for about one to two days when installing standalone units like the Ultimate 1000 Lift in its stationary configuration.

More complex setups such as track systems typically require two to four days, depending on your facility’s layout and any structural considerations. When we’ve partnered on complete solutions that include both our coolers and their handling systems, the total installation usually spans one to two weeks.

What I particularly appreciate is how the manufacturer provides a detailed virtual prep guide before installation begins. This helps ensure all electrical connections, structural supports and space requirements are addressed ahead of time, making the actual installation process smooth and predictable.

Are customization and financing available for small funeral homes?

Absolutely. The company understands the unique challenges of smaller operations.

Their modular, scalable systems are perfect for growing businesses—you can start with essential components and expand as your needs evolve. For tight spaces (and we’ve seen some truly challenging prep rooms!), they offer space-efficient designs that maximize functionality without requiring architectural changes.

Flexible financing options, including 0 percent down payment for qualified buyers, can be a game-changer for cash-flow management. Lease-to-own arrangements and extended payment terms make premium equipment accessible without a large upfront investment.

Their quick-quote portal streamlines the financing approval process, often providing answers within hours rather than days.

What we find most compelling is that the operational efficiencies created by this equipment frequently improve a small funeral home’s bottom line. When one person can safely do what previously required two, the equipment essentially pays for itself through staffing flexibility alone.

Across our service regions—from Tennessee to California—we’ve helped countless smaller funeral homes pair our custom coolers with appropriately scaled handling equipment, creating complete solutions that respect both operational needs and budget realities.

Conclusion & Next Steps

As we’ve journeyed through this guide together, it’s clear that the Iowa-based lift manufacturer featured here offers something truly special in the funeral industry—a rare blend of deep expertise, innovative products and rock-solid reliability that has kept these solutions at the forefront of mortuary handling equipment for over half a century.

From the workhorse Ultimate 1000 Lift to clever innovations like the Stepper stair climber and the ingenious patent-pending Tug-Along winch, these products tackle the real-world challenges funeral professionals face every day. These aren’t just products—they’re solutions to the problems that keep funeral directors up at night.

Here at American Mortuary Coolers, we’ve seen how these solutions transform funeral homes across the country. From small-town operations in Johnson City to busy urban facilities in Chicago, the marriage of our custom coolers with quality handling equipment creates a workflow that’s both safer and smarter.

Ready to take the next step? Here’s how to move forward:

- Identify your biggest pain points. Is it that tricky staircase at the side entrance? The strain of vehicle loading? Or maybe it’s the daily transfer from cooler to prep table that’s causing staff complaints.

- Reach out directly to the manufacturer through their website or phone. Their team doesn’t just sell equipment—they solve problems.

- Consider how everything will work together. The magic often happens when high-quality handling systems integrate seamlessly with custom cooling solutions from American Mortuary Coolers, creating a complete workflow that’s greater than the sum of its parts.

- Ask about virtual demonstrations if you’d like to see the systems in action without leaving your facility.

- Working with budget constraints? Many funeral homes find success with a phased approach—addressing the most critical needs first and expanding over time.

For more details about the cooling side of the equation, take a peek at our mortuary coolers guide to see how our solutions complement premium handling equipment.

With our ability to deliver custom solutions across all 48 contiguous states and dedicated support throughout the Midwest, Northeast, Rocky Mountain, Southeast, Southwest and Pacific regions, American Mortuary Coolers is your natural partner in creating a complete solution alongside top-tier mortuary lifting equipment.

Together, we can help you build a safer, more efficient and more durable operation—one that will serve your staff, your families and your community reliably for decades to come.