Why Operating Tables Are the Foundation of Modern Surgery

An operating table is a specialized medical platform designed to position and support patients during surgical procedures, serving as the critical foundation for safe and effective operations. These sophisticated systems have evolved from simple wooden chairs to advanced electromechanical platforms that can support patients weighing up to 1,200 pounds while providing precise positioning and imaging capabilities.

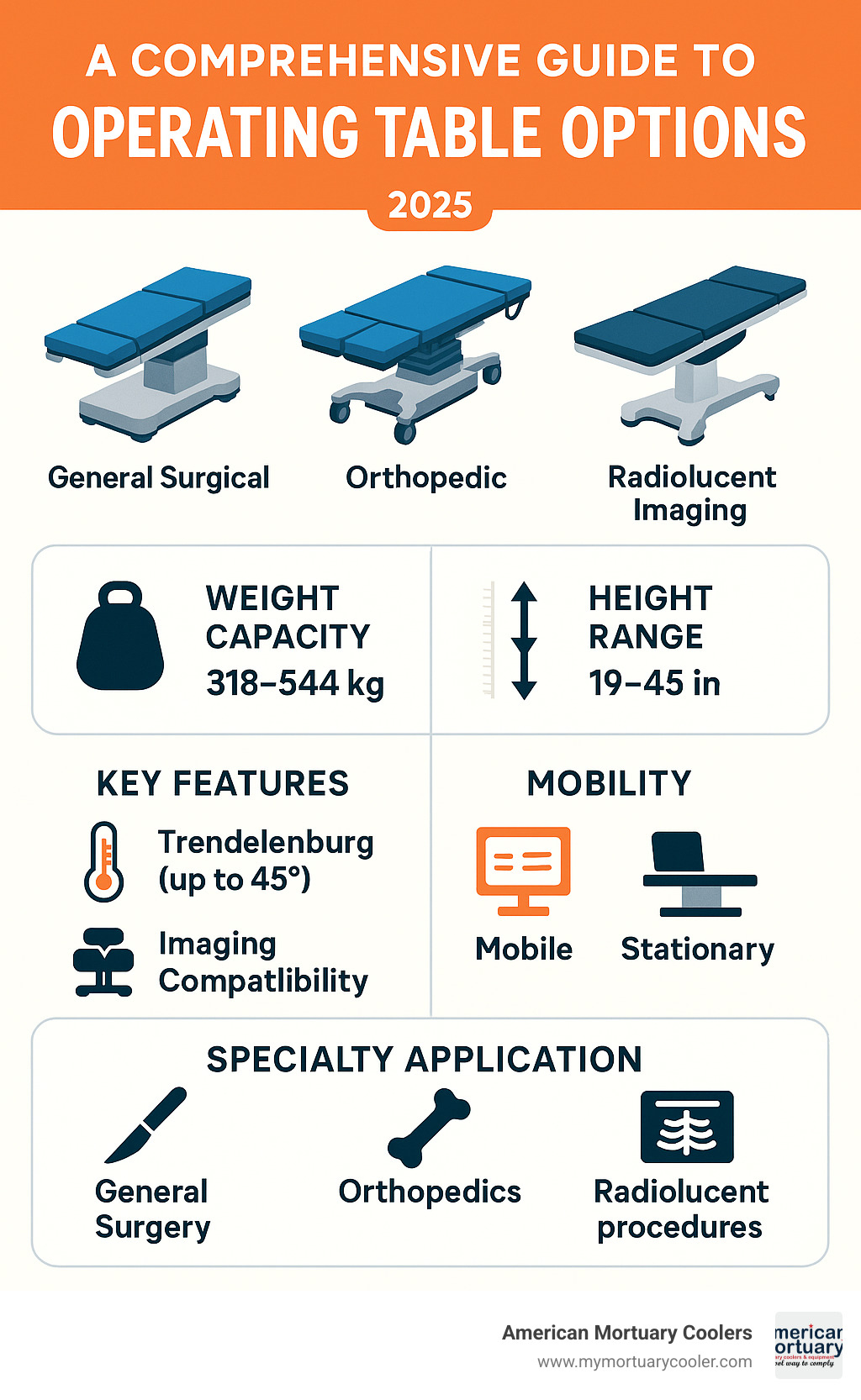

Key Operating Table Categories:

- General Surgical Tables - Versatile platforms for cardiovascular, abdominal, and general procedures

- Orthopedic Tables - Specialized for bone and joint surgeries with traction capabilities

- Radiolucent Imaging Tables - Carbon fiber tops for X-ray and C-arm compatibility

- Mobile vs Stationary - Transportable units vs fixed floor-mounted systems

The modern operating table market is projected to reach $1.7 billion by 2027, driven by advances in hybrid operating rooms and robotic surgery integration. Today's tables offer height adjustments from 19 to 45 inches, longitudinal slides up to 22 inches for imaging access, and can accommodate various surgical positions including Trendelenburg, prone, and lateral configurations.

From the early lithotomy chairs of the 18th century to today's computer-controlled systems with collision detection and battery backup, operating tables have transformed to meet the demanding requirements of modern surgical suites. Whether you're planning a new facility or upgrading existing equipment, understanding the technical specifications and options available is essential for making informed purchasing decisions.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in medical equipment procurement and facility planning. My background in healthcare equipment has given me deep insights into operating table selection criteria and the evolving needs of surgical facilities across the country.

Related content about operating tables:

What Is an Operating Table & How It Evolved

An operating table is much more than a simple platform - it's the surgical command center that holds everything together during life-saving procedures. Modern tables need to position patients with millimeter precision, work seamlessly with high-tech imaging equipment, and coordinate with robotic surgical systems.

Back in the 18th century, surgeries were performed using lithotomy chairs - basically specialized seats designed for removing bladder stones. These chairs were often suspended above the floor to prevent patients from bracing themselves when they lost consciousness during the procedure. Without anesthesia, survival rates were horrific - Paris hospitals in the 1770s lost one-third to half of their patients.

Everything changed in the 1850s when Carl Emmert developed his Paris model table. This wasn't just an upgrade - it was a complete reimagining of surgical furniture. Emmert's table could rotate a full 360 degrees, adjust up and down, change length, and even convert into a chair. This marked the real beginning of purpose-built surgical equipment designed around patient safety and surgical access.

Modern tables have come incredibly far since then. Today's radiolucent tops are made from carbon fiber that's strong enough to support heavy patients while staying invisible to X-rays and imaging equipment. The electromechanical drives provide smooth, precise movements, and the focus on ergonomics means these tables work better for both patients and surgical teams.

Early Designs to Modern Systems

The journey from those early wooden chairs to today's high-tech systems really shows how far medicine has come. Those original surgical chairs looked more like torture devices, complete with hooks and restraining straps. As surgical techniques improved and anesthesia became standard practice, the focus shifted from "hold them down" to "position them perfectly."

The introduction of hydraulic columns in the 20th century was a game-changer. Suddenly, surgeons could make smooth height adjustments and get precise positioning without the jerky, manual cranking of earlier systems.

Today's systems feature carbon-fiber tops that provide complete radiolucency - meaning X-rays and C-arms can see right through them for 360-degree imaging access. But they're also incredibly strong, maintaining the structural integrity needed to support patients safely during complex procedures.

Modern electromechanical systems like the STERIS 7080 even include collision detection technology. The table actually knows when it's about to bump into something and stops automatically.

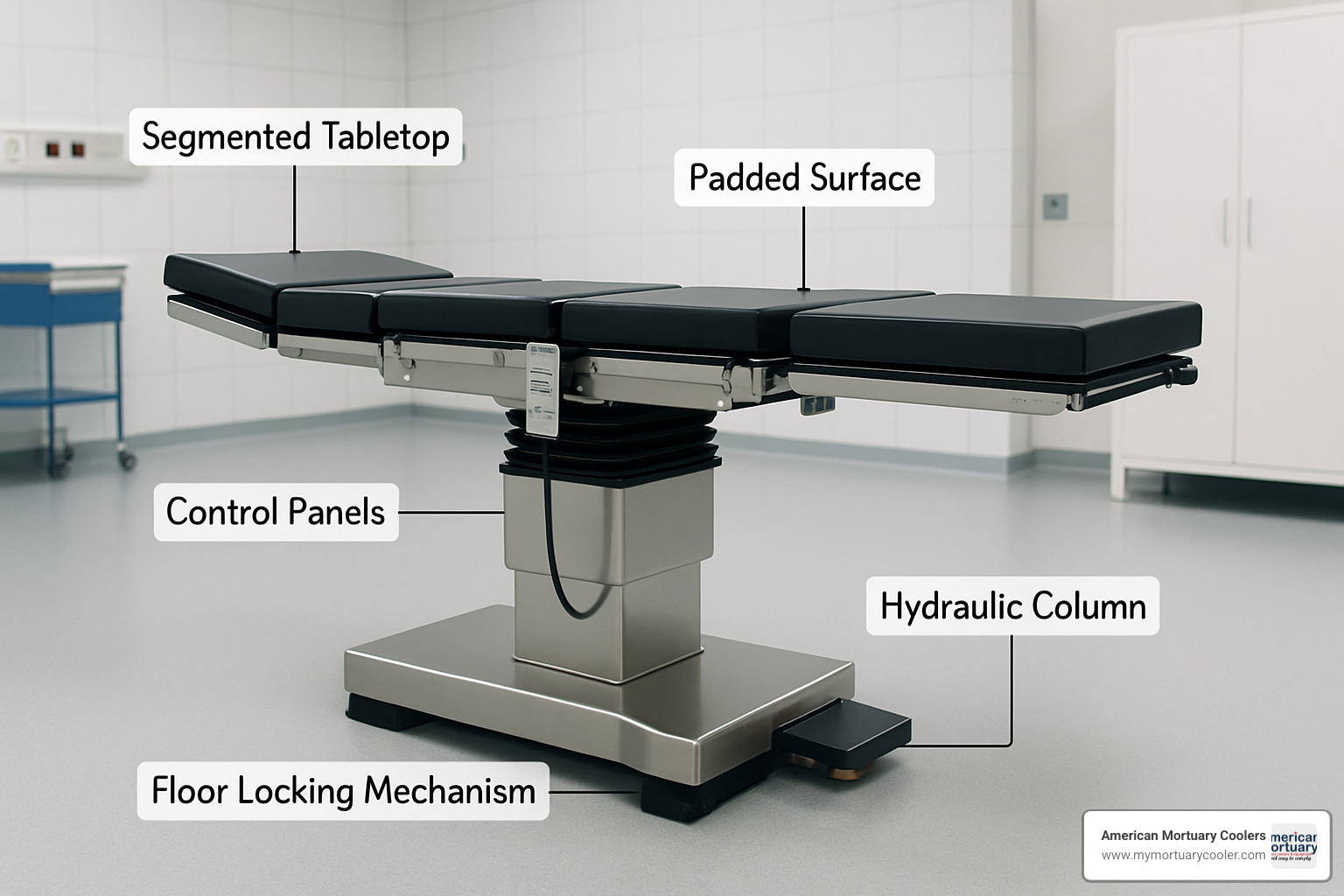

Critical Components of Today's Tables

Every modern operating table is built around several key components that work together like a well-orchestrated team.

Tabletop segments are probably the most important innovation. Instead of one solid surface, modern tables have multiple sections that can move independently. The STERIS 7080 offers adjustment ranges from +90° to -105° depending on which section you're working with. This flexibility lets surgeons position patients exactly how they need them for optimal access.

Floor locks and stability systems are absolutely critical. These tables need to stay rock-solid when supporting patients up to 1,200 pounds, even while surgeons are moving around and positioning heavy equipment.

Backup controls are the safety net that keeps everything running smoothly. If the main power fails or the primary control system has problems, redundant controls mounted on the table column can still adjust patient positioning.

Weight capacity is where modern tables really show their engineering prowess. The STERIS 7080 can support 700 pounds with full articulation capabilities, 1,000 pounds without slide functions, and up to 1,200 pounds for basic lifting operations.

Types, Positions & Accessories

Choosing the right operating table can feel overwhelming when you're faced with dozens of options. The key is understanding that each type serves specific surgical needs, and matching your requirements to the right platform makes all the difference.

General vs Specialty Platforms

Universal tables are the Swiss Army knives of the surgical world. These versatile platforms handle everything from heart surgery to appendectomies, making them perfect for facilities that perform a wide range of procedures. The STERIS 7080 General Surgical Table is a prime example - it's like having a reliable workhorse that can adapt to nearly any surgical specialty with the right accessories.

Fracture tables take a completely different approach. These specialized platforms are built for orthopedic trauma work where precise limb positioning and traction are essential. Think of complex hip replacements or spinal procedures - these tables feature integrated traction bars and electro-hydraulic shoulder plates that give surgeons the exact control they need.

When imaging is critical, radiolucent imaging tables become indispensable. The CMAX Image Guided Surgical Table features a free-floating carbon fiber design that allows unlimited C-arm positioning during procedures. Surgeons love these tables for minimally invasive vascular and orthopedic work where real-time imaging guidance is non-negotiable.

Bariatric tables address a growing reality in modern healthcare. These robust platforms support patients up to 450 kg (990 pounds) while maintaining full functionality. The Maquet ALPHAMAXX offers this maximum capacity while still providing up to 45 cm of longitudinal shift for optimal C-arm access.

Common Surgical Positions Enabled by Operating Tables

Patient positioning is where the magic happens - or where things can go terribly wrong. Modern operating table systems enable precise positioning that can make or break a surgical outcome.

The supine position is surgical positioning 101. Patient lies face-up, giving surgeons access for abdominal, cardiac, and most general procedures.

Trendelenburg positioning tilts the patient head-down up to 45 degrees, using gravity as a surgical assistant. This position moves intestines away from the surgical site and improves access to lower abdominal organs.

Reverse Trendelenburg flips the script with head-up positioning. This technique reduces bleeding in head and neck surgeries while improving upper abdominal access.

For spinal and certain neurosurgical procedures, the prone position (face-down) becomes essential. This positioning requires specialized padding and support systems to prevent pressure injuries during lengthy procedures.

Lateral positioning (side-lying) serves thoracic, kidney, and orthopedic procedures. Proper lateral positioning demands careful attention to pressure points and respiratory function.

The lithotomy position lifts and flexes the legs, primarily for gynecological, urological, and colorectal procedures. Modern stirrup systems provide adjustable support while maintaining patient safety.

Fowler's position creates a semi-upright sitting position used for certain neurosurgical and ENT procedures.

| Feature | Mobile Tables | Stationary Tables |

|---|---|---|

| Flexibility | High - can move between ORs | Limited to single location |

| Setup Time | Minimal - ready when positioned | Requires connection to utilities |

| Imaging Integration | Good with attachments | Excellent with fixed interfaces |

| Weight Capacity | Up to 450 kg typical | Up to 450 kg+ with floor support |

| Cost | Lower initial investment | Higher due to installation |

| Maintenance | Portable for service | Service performed in place |

Must-Have Accessories & Extensions

The right accessories transform a basic operating table into a specialized surgical platform. These additions aren't just nice-to-have features - they're often essential for specific procedures.

Arm boards and supports prevent nerve damage during lengthy procedures by maintaining proper arm positioning. Any procedure lasting three or more hours absolutely requires quality arm positioning systems.

Leg holders and stirrups have evolved far beyond basic positioning aids. Modern systems offer tool-free adjustment and improved safety features that make urological, gynecological, and colorectal procedures safer and more efficient.

X-ray cassette channels integrated under the tabletop provide seamless imaging access without repositioning patients. The STERIS 7080's integrated X-ray cassette channel exemplifies this essential feature.

Coupling systems might seem like a small detail, but they make a huge difference in OR efficiency. Modern intuitive coupling systems simplify attachment and removal of accessories, reducing setup time.

Head rests and positioning aids become crucial for neurosurgical and ENT procedures where millimeter-precise positioning can determine surgical success.

The development of open-source fracture tables represents an exciting innovation in making specialized surgical equipment more accessible through distributed digital fabrication and 3D printing technologies.

Key Technical Specs for Operating Table Buyers

Choosing the right operating table can feel overwhelming with so many specifications to consider. Understanding a few key technical details will help you make a smart decision that serves your facility for years to come.

Weight capacity is probably the most important spec to get right. Modern tables use a tiered system that's pretty clever. Take the STERIS 7080 - it handles 700 pounds with full functionality, including that handy slide feature. Need to support a heavier patient? It'll hold 1,000 pounds without the slide functions, and can lift up to 1,200 pounds for basic operations.

Height adjustment matters more than you might think. Most quality tables move from 19.3 inches up to 45 inches. The lower settings are perfect for minimally invasive procedures and robotic surgery, while the higher positions save your surgeons' backs during long operations.

Longitudinal slide capabilities are really interesting. Advanced tables can slide up to 22 inches, creating imaging windows that exceed 86 inches. If you're doing any C-arm work or need full-body imaging, this feature is worth its weight in gold.

Positioning ranges are crucial for different procedures. Standard Trendelenburg and reverse Trendelenburg of ±45 degrees covers most surgical needs. Add in ±30 degrees of lateral tilt, and you're ready for orthopedic and thoracic cases.

Don't overlook the power systems. Modern tables run on both battery backup and AC power, with battery level indicators that prevent those heart-stopping moments when power runs low mid-procedure.

Collision detection technology might sound fancy, but it's actually a lifesaver. These systems automatically stop movement when they detect obstacles, protecting both your expensive equipment and your staff.

Selecting an Operating Table for Specialty Procedures

Different surgical specialties have their own quirks and requirements. Robotic surgery is particularly demanding - these procedures need tables that can handle steep Trendelenburg positioning (often over 30 degrees) while staying rock-solid stable. The robotic arms need room to move, so the table design can't interfere with docking and positioning.

Spine surgery brings its own challenges. You need prone positioning capabilities, radiolucent tops for clear imaging, and specialized support accessories. The table has to stay perfectly stable even when surgeons are leaning on it.

Cardiovascular procedures can change direction quickly, so your table needs to handle rapid repositioning without losing precision. Emergency positioning features aren't just nice to have - they're essential when complications arise.

C-arm compatibility is all about access. You need 360-degree imaging capability with minimal interference from the table base and column. Slim column designs and good longitudinal slides make all the difference for interventional procedures.

Cost Breakdown of Operating Table Options

Let's talk money - because even the best operating table doesn't help if it breaks your budget. New equipment can be a significant investment. High-end surgical fracture tables can run over $200,000, while general surgical tables typically fall between $50,000 and $150,000. Those premium features like advanced imaging integration and robotic compatibility definitely add to the price tag.

Certified pre-owned tables offer a smart middle ground. You get reliable performance at a fraction of the new price. Many suppliers offer remanufacturing services that add modern upgrades to older frames, giving you advanced capabilities without the premium cost.

Financing options are worth exploring. Most facilities use equipment financing or leasing to manage cash flow better. When calculating ROI, factor in productivity improvements, reduced maintenance costs, and the expanded procedural capabilities you'll gain.

Hybrid OR investments represent the future of surgical suites. These tables cost more upfront but integrate seamlessly with advanced imaging and robotic platforms.

If budget constraints are tight, consider exploring pre-owned options. Just like with any major equipment purchase, buying used tables requires careful evaluation of condition, remaining service life, and potential for upgrades.

Maintenance, Safety & Future Innovations

Taking care of your operating table isn't just about keeping it running - it's about ensuring every patient who lies on that table receives the safest possible care. Think of it like maintaining a high-performance race car, except the stakes are much higher.

Preventative maintenance programs are your first line of defense against equipment failures. Nobody wants a table to malfunction mid-surgery, which is why professional services offer 24-hour emergency response alongside scheduled maintenance.

Modern tables must meet strict safety standards that cover everything from weight capacity certifications to electrical safety requirements. Biocompatibility standards ensure that every surface touching patients won't cause adverse reactions, while regular safety inspections protect both your facility and your patients.

Infection control actually starts with the table design itself. Modern operating table systems feature flush side rail designs that eliminate those hard-to-clean crevices where bacteria love to hide. Every exposed screw or rough surface becomes a potential problem, so manufacturers have gotten smart about creating smooth, nonporous surfaces that make thorough cleaning possible.

Cleaning Protocols & Long-Term Care

Your operating table needs thorough cleaning and disinfection after each use, but here's the catch: not all cleaning agents play nice with table materials.

Daily cleaning procedures require staff training that goes beyond "spray and wipe." Different materials like stainless steel, carbon fiber, and specialized padding each need compatible disinfectants. Use the wrong chemical on carbon fiber, and you might compromise the radiolucency that makes imaging possible.

High-volume facilities often invest in dedicated washing machines designed specifically for surgical equipment. These systems provide consistent, thorough cleaning while reducing the physical demands on staff.

Documentation requirements might seem tedious, but they serve a crucial purpose. Electronic tracking systems help ensure every table gets proper attention after every procedure. This isn't just about regulatory compliance - it's about building habits that prevent the one oversight that could lead to serious problems.

Our experience with prep-room tables has taught us valuable lessons about maintaining specialized medical equipment that applies directly to operating table care.

Emerging Tech Trends to Watch

The future of operating table technology is arriving faster than most people realize, and it's genuinely exciting. AI-guided positioning systems are being developed that will analyze the specific procedure and automatically position the table for optimal access while minimizing patient risk factors.

Sensor-based pressure mapping represents another breakthrough that addresses a persistent problem in lengthy surgeries. These advanced sensors continuously monitor pressure distribution across the patient's body and can automatically make micro-adjustments to prevent pressure injuries.

Voice control integration is moving beyond science fiction into practical reality. Surgeons will soon control table positioning through voice commands, maintaining sterile technique while having intuitive control over patient positioning.

The concept of modular top systems will revolutionize OR efficiency. Instead of having different tables for different procedures, facilities will have interchangeable tabletop modules that can be quickly swapped for optimal configuration.

3D-printed attachments open up possibilities for patient-specific positioning solutions that were previously impossible or prohibitively expensive. Complex orthopedic cases or unusual patient anatomy can be accommodated with custom-designed accessories.

Perhaps most impressively, integrated imaging platforms will eliminate the need for separate C-arm equipment in many situations. Tables with built-in imaging capabilities will streamline workflows and reduce the complexity of modern surgical suites.

Ongoing research into OR ergonomics continues driving innovations that benefit both patient outcomes and surgeon comfort during those marathon procedures.

Frequently Asked Questions about Operating Tables

People often ask us about operating table specifications and features when they're planning new surgical facilities or upgrading existing equipment. Here are the most common questions we hear, along with detailed answers based on our experience helping facilities across the country.

What is the standard weight capacity of an operating table?

There's no single "standard" weight capacity, but most modern operating table systems start at around 300 pounds as their baseline. However, today's tables are much more capable than that minimum suggests.

The reality is that weight capacity varies significantly based on how you're using the table. Take the STERIS 7080 as an example - it supports 700 pounds with full functionality, including all the positioning and slide features you'd expect. If you don't need the slide functions, that capacity jumps to 1,000 pounds. For basic lift operations only, it can handle up to 1,200 pounds.

This tiered approach makes sense when you think about it. The more complex movements and positioning you need, the more stress you're putting on the table's mechanisms. Bariatric tables push these limits even further, with some supporting patients up to 450 kg (990 pounds) while still maintaining essential positioning capabilities.

The key is matching your table's capacity to your patient population and the types of procedures you perform most often.

How do mobile and stationary tables differ in daily use?

The choice between mobile and stationary tables often comes down to how your facility operates day-to-day. Mobile tables shine in flexibility - you can wheel them between operating rooms based on your schedule, and they're ready to go as soon as you position them. There's no waiting for connections to utilities or complex setup procedures.

Stationary systems offer superior integration with your OR's infrastructure. They connect directly to imaging equipment, power systems, and other fixed components. This makes them ideal for specialized procedures that require seamless coordination between the table and other equipment.

From a cost perspective, mobile tables typically require less upfront investment since there's no installation work involved. Stationary systems cost more initially but often provide better long-term value in facilities focused on advanced procedures like hybrid OR work or complex imaging-guided surgeries.

Think about your typical day - if you're constantly moving equipment between rooms or have varying procedural schedules, mobile makes sense. If you have dedicated ORs for specific specialties, stationary systems often work better.

Which patient positions are most commonly used in robotic surgery?

Robotic surgery has really changed how we think about operating table positioning requirements. The most frequent position is steep Trendelenburg - often 25 to 45 degrees head-down - especially for pelvic procedures like prostatectomies and gynecological surgeries. This extreme angle helps move organs out of the surgical field and gives the robot better access.

Supine positioning remains common for abdominal robotic procedures, though it often requires more precise adjustments than traditional open surgery. The table needs to accommodate the robotic arms while keeping the patient perfectly positioned throughout procedures that can last several hours.

Lateral positioning comes into play for thoracic robotic procedures, where side access is essential. The challenge here is maintaining stability while the robot operates from multiple angles.

What makes robotic surgery different is that the operating table must maintain incredibly precise positioning throughout the entire procedure. Any drift or movement can throw off the robot's calibration. That's why tables designed for robotic surgery feature improved stability systems and collision detection technology to prevent any interference with the robotic components.

Conclusion

Choosing the right operating table system is one of the most important decisions you'll make for your surgical facility. Whether you need a basic mobile unit for general procedures or an advanced hybrid OR platform with robotic capabilities, today's options offer incredible functionality and safety features that would have amazed surgeons just a few decades ago.

The journey from those terrifying 18th-century lithotomy chairs to today's AI-guided positioning systems shows just how far we've come. Modern tables can support patients up to 1,200 pounds, provide precise positioning within millimeters, and integrate seamlessly with imaging equipment that gives surgeons superhuman vision during procedures.

At American Mortuary Coolers, we know what it means to build equipment that healthcare professionals depend on every single day. While our specialty is crafting custom mortuary coolers and related equipment for funeral homes across Tennessee and beyond, our experience in medical equipment gives us deep appreciation for the quality and reliability that surgical teams need.

The fundamentals never change - whether you're building mortuary coolers or operating tables, success comes down to durable construction, reliable performance, and service you can count on. Our custom solutions approach and direct delivery across the contiguous 48 states reflects the same commitment to excellence that should guide any medical equipment purchase.

As we look toward the future with voice-controlled tables, 3D-printed accessories, and sensor-based pressure mapping, one thing remains constant: the operating table will always be the foundation where life-saving surgery happens. Investing in quality equipment that can adapt and grow with advancing technology isn't just smart business - it's an investment in the countless lives that will be saved on that table.

For facilities looking at comprehensive equipment solutions, our experience with morgue tables and other specialized medical equipment demonstrates the quality standards and service approach that should guide all healthcare equipment decisions.

Your operating table choice will impact thousands of procedures over its lifetime. Choose equipment built to last, maintain it properly, and partner with suppliers who understand that in healthcare, reliability isn't just important - it's everything.