Why Understanding Refrigeration Units Matters for Your Business

What is refrigeration unit technology is the backbone of temperature-controlled storage across industries - from funeral homes to restaurants to medical facilities. At its core, a refrigeration unit is a complete mechanical system that removes heat from an enclosed space to maintain temperatures below ambient conditions.

Key Components of a Refrigeration Unit:

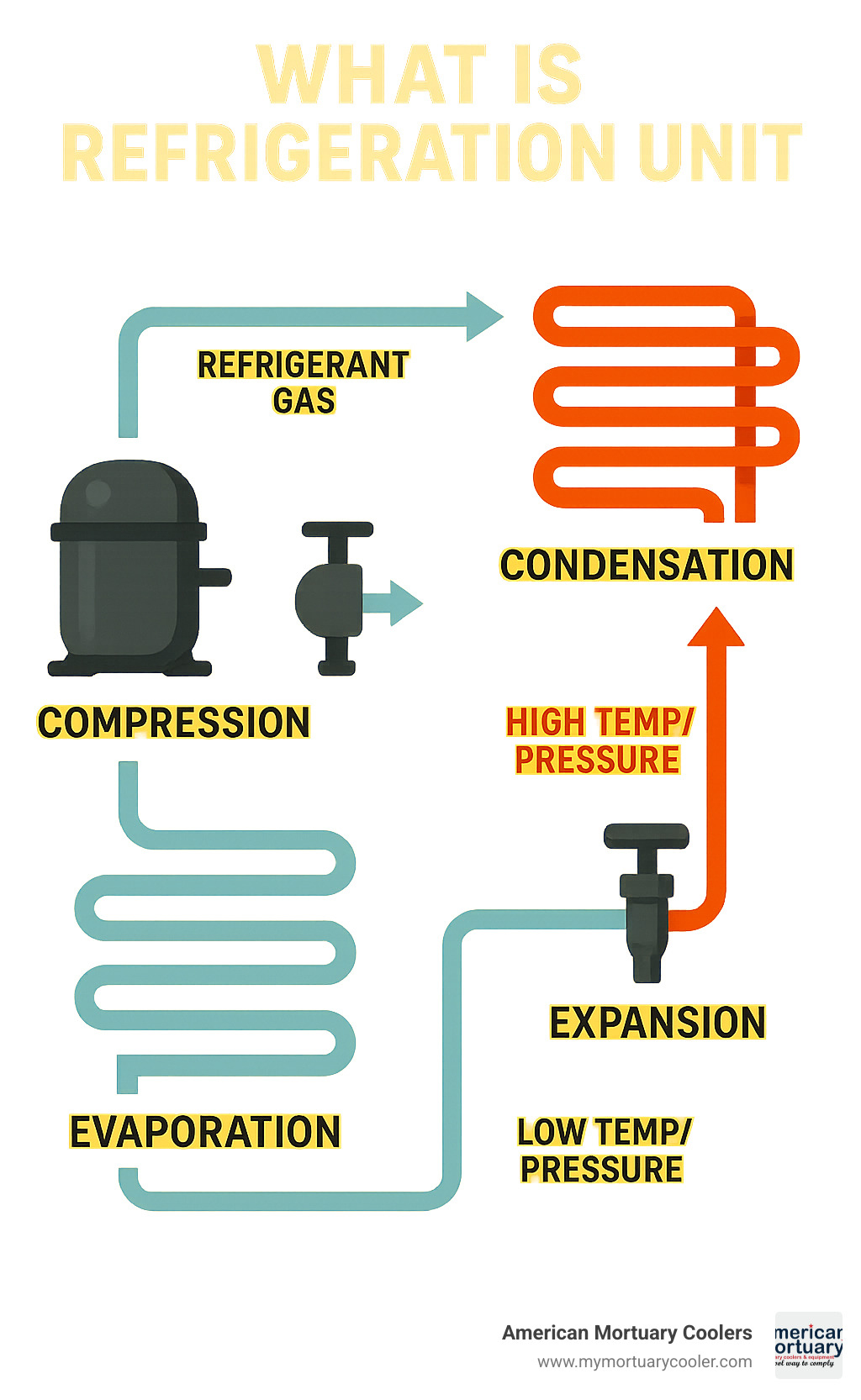

- Compressor - Pressurizes and circulates refrigerant

- Condenser - Releases heat to the environment

- Evaporator - Absorbs heat from the cooled space

- Expansion device - Controls refrigerant flow and pressure

The fundamental principle behind every refrigeration unit is heat transfer through a thermodynamic cycle. As one source explains, "you can't make cold; you only remove heat." The system works by absorbing sensible heat (temperature changes) and latent heat (phase changes) from your storage area and rejecting that heat elsewhere.

Modern refrigeration units operate primarily on the vapor-compression cycle, which has revolutionized how we preserve perishable goods. This process involves compressing refrigerant gas, condensing it to liquid form while releasing heat, then allowing it to expand and evaporate while absorbing heat from the cooled space.

Understanding the basics becomes crucial when you're responsible for maintaining product integrity - whether that's preserving food freshness, ensuring pharmaceutical stability, or maintaining proper conditions in mortuary applications where reliability is non-negotiable.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral directors understand what is refrigeration unit technology means for their specific applications.

What is refrigeration unit terms explained:

What Is a Refrigeration Unit?

When someone asks "what is refrigeration unit" technology, they're often confused about whether we're talking about a single machine or a complex network of parts. Here's the simple answer: a refrigeration unit is a complete, ready-to-use cooling system that creates and maintains cold temperatures exactly where you need them.

Think of it like the difference between buying a car versus buying an engine. A refrigeration unit is the whole car - everything packaged together and ready to drive off the lot. A refrigeration system, on the other hand, might be more like building a custom vehicle from scratch, where you're designing and connecting multiple components across a larger facility.

The power of these units gets measured in something called tons of refrigeration. Don't worry - we're not talking about how much the unit weighs! One ton of refrigeration equals 12,000 BTU per hour, which is the amount of cooling power needed to melt a literal ton of ice in 24 hours. It's an old-fashioned way to measure cooling, but it stuck around because it makes sense.

| Aspect | Refrigeration Unit | Refrigeration System |

|---|---|---|

| Definition | Complete packaged cooling solution | Broader network of cooling components |

| Complexity | Self-contained or pre-assembled | May involve multiple interconnected units |

| Installation | Plug-and-play or minimal assembly | Often requires custom design and integration |

| Applications | Walk-in coolers, display cases, transport | Large facilities, industrial processes |

Definition – what is refrigeration unit?

At its heart, what is refrigeration unit comes down to this: it's a specialized machine that moves heat from where you don't want it to where you don't mind it. These units work as low-temperature devices that follow the laws of thermodynamics - specifically, they use a repeating cycle to grab heat from inside your cooler and dump it outside.

The magic happens through what engineers call a thermodynamic cycle. The unit compresses special chemicals called refrigerants, which get really good at absorbing and releasing heat as they change from liquid to gas and back again. Modern units can maintain incredibly precise temperatures, from just below room temperature all the way down to ultra-cold storage at -70°C for specialized needs.

Understanding "what is refrigeration unit" in Everyday Context

To really understand what is refrigeration unit technology means in real life, let's look at three examples you probably encounter regularly.

Your household fridge is actually a small refrigeration unit that keeps things between 35-38°F. It uses a tiny compressor and refrigerant called R-134a to keep your milk fresh and your leftovers safe. Nothing fancy, but it does the job day after day.

Those big transport reefers you see on highways are mobile refrigeration units that can handle anything from frozen foods at -30°C to fresh produce that needs to stay around 30°C. They're basically rolling cold rooms that keep products fresh while traveling thousands of miles.

Cold rooms in restaurants, hospitals, and funeral homes represent the heavy-duty end of refrigeration units. These need rock-solid reliability because there's no room for failure when you're storing sensitive items. Whether it's keeping food safe for customers or maintaining proper conditions in mortuary applications, these units have to work perfectly every single time.

Each type serves different needs, but they all work on the same basic principle: moving heat where you want it to go, when you want it to go there.

How Does a Refrigeration Unit Work?

Think of a refrigeration unit as a heat-moving machine rather than a cold-making machine. What is refrigeration unit operation really comes down to this simple truth: you can't create cold, you can only move heat from where you don't want it to where you do.

The process happens through four main players working as a team. The compressor acts like the heart of the system, pumping refrigerant through the entire cycle. The condenser works as your heat ejector, dumping all that absorbed heat into the outside air. The evaporator serves as your heat collector, pulling warmth right out of your storage space. Finally, the expansion device controls how much refrigerant flows where and when.

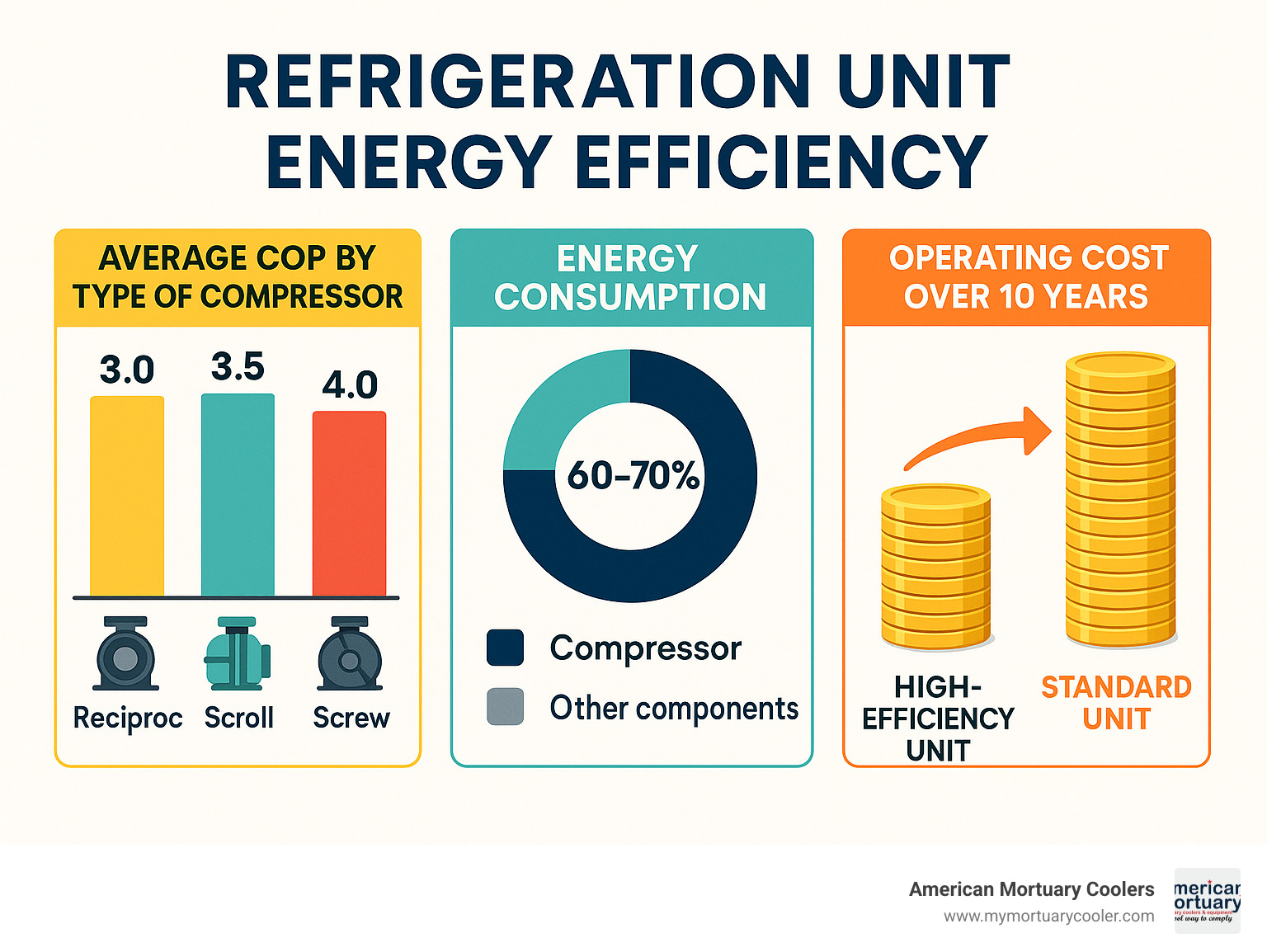

This teamwork creates what engineers call the Coefficient of Performance (COP). It's basically a measure of how much heat your unit can move compared to the electricity it uses. Most modern units achieve COP values between 2-4, meaning they move 2-4 times more heat energy than the electrical energy they consume.

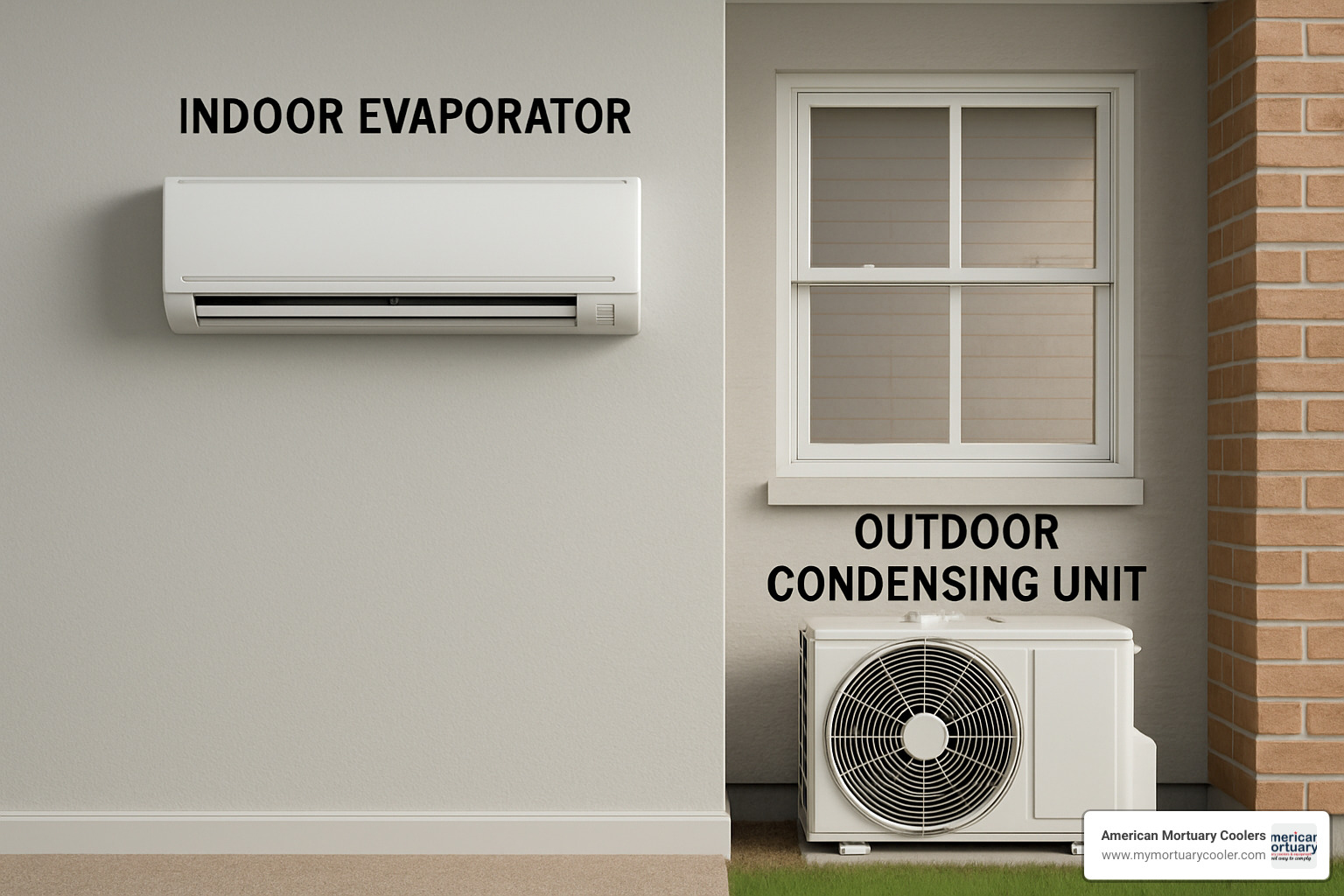

The condensing unit) handles the heavy lifting on the hot side of things, containing both the compressor and condenser components that deal with high-pressure, high-temperature refrigerant.

Vapor-Compression Step-by-Step

The vapor-compression cycle might sound complicated, but it's actually quite logical once you see how each step flows into the next.

Compression stage is where the action starts. Your compressor grabs low-pressure refrigerant vapor and squeezes it hard, dramatically boosting both pressure and temperature. This is also where most of your electrical bill comes from - compression takes serious energy.

Condensation stage comes next. That hot, high-pressure refrigerant gas flows through condenser coils where it meets cooler outside air. As it releases heat, the gas condenses back into liquid form, just like steam turning back into water.

Expansion stage is where things get interesting. The liquid refrigerant hits an expansion device - either a thermostatic expansion valve or a simple fixed opening. Pressure drops fast, and some of that liquid instantly "flashes" into vapor, cooling down the remaining liquid dramatically.

Evaporation stage completes the circle. Cold, low-pressure refrigerant enters the evaporator coils inside your cooled space. When warm air passes over these coils, the refrigerant absorbs that heat and evaporates back into vapor, ready to start the whole cycle again.

Beyond Compression: Absorption & Emerging Technologies

While vapor-compression dominates the refrigeration world, some fascinating alternatives are making waves in specific situations.

Absorption refrigeration flips the script by using heat energy instead of mechanical work to drive cooling. These systems shine when you have waste heat or cheap thermal energy available.

Thermoelectric cooling uses the Peltier effect to provide incredibly precise temperature control without any moving parts. You'll find these in applications where vibration-free operation matters more than raw efficiency.

Magnetic refrigeration exploits the magnetocaloric effect in specialized materials. It offers potential for extremely efficient cooling, but right now it's mostly confined to research labs.

The industry is also getting serious about natural refrigerants, especially CO₂, which has a Global Warming Potential (GWP) of just 1. Compare that to hundreds or thousands for synthetic refrigerants, and you can see why this matters. Scientific research on adsorption refrigeration continues pushing boundaries, exploring new ways to boost efficiency while protecting our environment.

Types of Refrigeration Units and Their Components

When you're exploring what is refrigeration unit options are available, you'll find that modern systems come in fascinating variety. Each type is designed to tackle specific cooling challenges, from keeping your morning coffee shop's pastries fresh to maintaining precise temperatures in specialized facilities.

The beauty of refrigeration technology lies in its adaptability. Single-compressor units dominate smaller applications because they're straightforward and budget-friendly. Multi-compressor systems are where things get interesting. These sophisticated units shine in larger installations like supermarkets and industrial facilities with their dynamic load management capability - individual compressors kick in and out based on actual cooling demand.

Transport refrigeration units (reefers) face unique challenges. They must keep temperatures stable while bouncing down highways, dealing with different power sources, and handling everything from desert heat to arctic cold.

Our Refrigeration Units guide dives deep into selecting the right unit for mortuary applications, where reliability isn't just important - it's absolutely critical.

Single-Compressor vs Multi-Compressor Units

Single-compressor units win hearts with their simplicity and lower upfront costs. They're perfect when your cooling needs are predictable and space is at a premium. These units typically use hermetically sealed compressors - essentially maintenance-friendly designs that keep refrigerant locked away from the outside world.

Multi-compressor systems offer something single units can't: flexibility. Imagine having separate temperature zones in the same facility - maybe you need both refrigerated and frozen sections. These systems make it possible with dual-temperature modes using separate refrigeration circuits.

The real magic happens with staging capability. Instead of one large compressor cycling completely on or off, multiple smaller compressors can step in gradually as needed. This approach delivers substantial energy savings and much more precise temperature control.

Compressor Choices & Their Pros/Cons

Reciprocating compressors are the tried-and-true workhorses of refrigeration. They operate like car engines, using pistons to compress refrigerant gas. What makes them popular is their proven reliability across different applications and their relatively straightforward service requirements.

Scroll compressors have earned their reputation for quiet operation and dependable performance, especially in high-temperature applications. The scroll design is neat in its simplicity - fewer moving parts than reciprocating units mean longer service life and less frequent maintenance calls.

Screw compressors are the heavy lifters, designed for high-capacity applications where cooling demands reach industrial levels. They excel at full load efficiency and can handle the demanding requirements that would overwhelm smaller compressor types.

Refrigerant Options & Environmental Impact

The refrigerant world is changing rapidly as environmental awareness drives new regulations. Understanding your options helps you make smart long-term decisions.

R-410A stepped in to replace R-22 in many applications, but it's facing its own phase-out due to a GWP of 2,088. R-404A is already being phased out in many regions because of its extremely high GWP of 3,922.

R-290 (propane) offers impressive thermodynamic properties with a GWP of just 3, making it environmentally attractive. The trade-off is its flammability, which requires special safety considerations.

Ammonia (NH₃) delivers zero GWP and excellent efficiency, particularly in large industrial systems. However, its toxicity demands specialized training and safety equipment.

CO₂ (R-744) systems represent the cutting edge of environmental responsibility with a GWP of 1. These systems operate at higher pressures than traditional refrigerants but offer excellent environmental credentials in transcritical applications.

Applications Across Industries

Walk-in coolers in restaurants typically maintain 35-38°F using reliable single-compressor units. Supermarkets often employ large multi-compressor systems with separate circuits for medium-temperature display cases and low-temperature frozen food sections.

Mortuary coolers require exceptional reliability and precise temperature control. At American Mortuary Coolers, we design units specifically for funeral service applications because equipment failure isn't just inconvenient - it can be catastrophic.

Pharmaceutical storage demands precise temperature control and comprehensive monitoring. Transport refrigeration faces the ultimate reliability test - maintaining temperature control while handling road vibration, varying power sources, and extreme ambient conditions.

Selecting, Maintaining, and Safely Operating Refrigeration Units

Choosing the right refrigeration unit is like picking a reliable business partner - you want something that'll work hard for years without letting you down. The process starts with understanding your actual cooling needs, not just guessing based on room size.

Load calculation forms the foundation of smart unit selection. You need to account for heat sneaking in through walls and floors, warm air rushing in when doors open, heat from products being cooled down, and internal heat sources like lighting. Miss any of these factors, and you'll end up with a unit that either struggles to keep up or wastes energy cycling on and off constantly.

Energy efficiency ratings like SEER (Seasonal Energy Efficiency Ratio) and COP (Coefficient of Performance) help you compare units fairly. A unit with better efficiency ratings might cost more upfront, but it'll save money every month on your electric bill.

Our Refrigeration System 101: Understanding the Basics guide dives deeper into the fundamentals that affect both selection and daily operation.

Key Factors When Choosing a Unit

Cooling capacity needs to match your actual heat load perfectly. An oversized unit is like having a race car for grocery shopping - it'll work, but it's inefficient and expensive to operate. The unit will short-cycle, turning on and off frequently, which creates temperature swings and wears out components faster.

Ambient conditions around your unit matter more than most people realize. Install a unit in a hot mechanical room, and it'll struggle like a marathon runner in a sauna. High ambient temperatures reduce cooling capacity and spike energy consumption.

Refrigerant regulations keep changing as environmental concerns grow. Choosing a unit with low-GWP refrigerants now saves you from costly retrofits later when older refrigerants get banned.

Service support availability can make or break your long-term experience. The best unit in the world becomes a expensive paperweight if nobody local can fix it.

Preventative Maintenance Checklist

Regular maintenance prevents most refrigeration failures - it's like changing your car's oil instead of waiting for the engine to seize up. Quarterly inspections should include checking for oil leaks, listening for unusual sounds, and making sure all fans spin freely. Coil cleaning removes the dirt and debris that acts like a blanket over your condenser, forcing it to work harder.

Semi-annual maintenance goes deeper with electrical checks and refrigeration cycle analysis. Oil analysis helps catch problems early by detecting acid formation or moisture contamination that slowly kills compressors. Superheat measurements should stay in that sweet spot between 30-45°F that manufacturers specify.

Always use a licensed technician for anything involving refrigerants. The regulations are strict, the fines are hefty, and the safety risks are real.

Safety & Sustainability Best Practices

Pressure relief valves are your unit's safety net, preventing dangerous over-pressurization that could damage equipment or hurt someone. These valves need regular testing and replacement.

Proper ventilation keeps refrigerant from building up in enclosed spaces if leaks occur. Some refrigerants can displace oxygen or create health hazards in confined areas.

Leak detection helps you catch refrigerant losses before they become expensive problems. Electronic leak detectors can pinpoint tiny leaks at joints and connections that might take months to notice otherwise.

Low-GWP refrigerants reduce your environmental footprint while often delivering better performance than older options. Energy-saving controls like variable-speed drives and smart defrost systems optimize performance automatically, cutting energy costs without requiring constant attention.

At American Mortuary Coolers, we've learned that what is refrigeration unit reliability means everything in funeral service applications. Our units are built for the long haul with components selected specifically for critical applications where failure simply isn't an option.

Frequently Asked Questions about Refrigeration Units

After helping hundreds of funeral directors understand what is refrigeration unit technology means for their operations, I've noticed the same questions come up repeatedly. These concerns usually center around getting the right size unit, keeping it running reliably, and understanding what's possible with today's technology.

Let me share the answers that matter most when you're making decisions about refrigeration equipment for your facility.

FAQ 1 – what is refrigeration unit sizing based on?

Thermal load calculation forms the backbone of proper refrigeration unit sizing, and it's measured in BTU/hr or tons of refrigeration. But here's what many people don't realize - it's not just about the size of your room.

The calculation needs to account for heat gain through insulation (walls, ceiling, and floor), air infiltration every time someone opens the door, product pull-down heat when you're cooling items from room temperature, and internal heat sources like lighting and people working in the space.

I always tell my clients to focus on peak conditions - the absolute worst-case scenario your unit will face. This might happen during a sweltering summer day when you're also receiving multiple cases that need to be cooled quickly.

Those "one ton per 100 square feet" rules you might hear? They're shortcuts that often lead to problems. A mortuary cooler serving a busy funeral home has completely different requirements than a restaurant walk-in, even if they're the same size. Professional load calculations consider your specific situation, local climate, and how you actually use the space.

FAQ 2 – How often should a refrigeration unit be serviced?

Most manufacturers recommend quarterly visual inspections and semi-annual professional service for commercial refrigeration units. But in mortuary applications, I usually suggest more frequent attention because equipment failure simply isn't an option.

Monthly inspections make sense for critical applications where reliability matters most. These don't need to be full service calls - just checking that everything looks and sounds normal, coils are clean, and temperatures are holding steady.

Units working in tough environments need extra care. If your equipment room gets dusty, greasy, or extremely hot, plan on more frequent professional service. The small investment in preventive maintenance pays huge dividends in avoiding emergency repairs and extending equipment life.

Following manufacturer guidelines keeps your warranty valid and ensures you're getting the performance you paid for. Most service contracts can be customized based on your specific needs and how critical the application is to your operation.

FAQ 3 – Can one unit handle multiple temperature zones?

Multi-compressor units excel at handling different temperature zones through dual circuits or sophisticated control systems. I've installed systems that maintain a preparation area at 35°F while keeping a separate freezer section at -10°F, all from one main unit.

The key is load management systems that automatically stage different compressors based on demand from each zone. When the prep area needs cooling, its compressor kicks in. When the freezer needs attention, its dedicated compressor handles that load. This approach delivers excellent efficiency while ensuring each area maintains its required temperature.

Single-compressor units typically serve one temperature zone effectively. However, some facilities use multiple single-compressor units with different temperature settings to serve various areas. This approach provides redundancy - if one unit has problems, the others keep running.

The choice between one multi-zone unit versus multiple single-zone units often comes down to your facility layout, budget, and how much redundancy you want built into your system.

Conclusion

Understanding what is refrigeration unit technology gives you the confidence to make smart decisions about cooling equipment that will serve your business for decades. From basic vapor-compression cycles to sophisticated multi-compressor systems using natural refrigerants, today's refrigeration units deliver reliable solutions for virtually any cooling challenge you might face.

The journey through refrigeration fundamentals - heat transfer principles, component interactions, and system types - reveals why proper selection and maintenance matter so much. When you understand how these systems work, you can spot potential problems early and ensure your equipment operates at peak efficiency.

At American Mortuary Coolers, we've seen how the right refrigeration solution transforms funeral service operations. Our Tennessee-based manufacturing facility produces custom units designed specifically for mortuary applications, because we understand that standard cooling equipment often falls short of funeral service requirements. Durability and reliability aren't luxuries in your industry - they're absolute necessities.

What excites us most about the refrigeration industry is its rapid evolution toward greater efficiency and environmental sustainability. Low-GWP refrigerants like CO₂ and propane are becoming mainstream options. Advanced control systems automatically optimize performance while reducing energy consumption.

The shift toward sustainability doesn't mean compromising performance. Today's energy-efficient units often outperform older equipment while consuming significantly less electricity. This combination of better performance and lower operating costs makes upgrading older equipment a smart financial decision.

Whether you're replacing aging equipment or planning a completely new facility, these fundamentals help ensure your refrigeration investment delivers exactly what you need. For specialized applications like mortuary cooling, partnering with experienced manufacturers who understand your unique requirements makes all the difference between adequate cooling and exceptional reliability.

Our contiguous 48-state delivery ensures you can access professional-grade mortuary cooling solutions regardless of your location. We've designed our manufacturing and logistics specifically to serve funeral service professionals who can't afford equipment failures or delays.

The future of refrigeration looks brighter than ever, with innovations in efficiency, reliability, and environmental responsibility converging to create better solutions for your business. Understanding what is refrigeration unit technology means in your specific context helps you take advantage of these improvements while avoiding costly mistakes.

More info about energy-efficient coolers provides additional details about selecting units that minimize operating costs while maximizing performance and environmental responsibility.