Why Choosing the Right Embalming Station Matters for Your Funeral Home

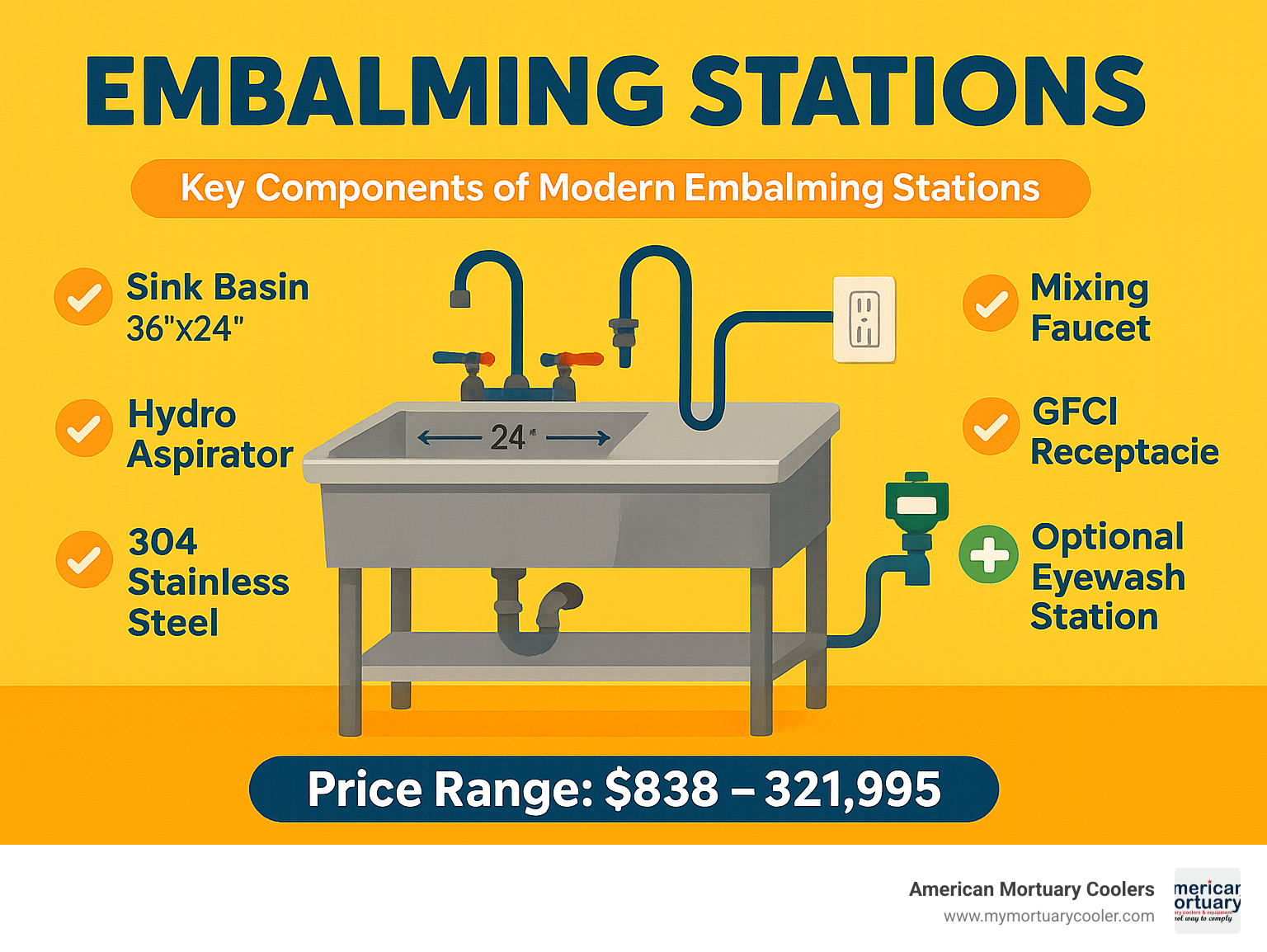

Embalming stations are specialized workstations designed for body preparation and preservation in funeral homes and mortuaries. These stainless steel units integrate essential components like sink basins, hydro aspirators, mixing faucets, and GFCI outlets to create a safe, hygienic workspace for embalming procedures.

Key Components of Modern Embalming Stations:

- Sink Basin - Large, deep basin for body washing and fluid drainage

- Hydro Aspirator - Creates suction for removing body fluids

- Mixing Faucet - Controls hot/cold water temperature for embalming solutions

- GFCI Receptacle - Electrical safety protection near water sources

- 304 Stainless Steel Construction - Corrosion-resistant, medical-grade material

- Optional Eyewash Station - Emergency safety feature for chemical exposure

The price range for embalming stations spans from $838 for basic units to $21,995 for advanced autopsy stations with center sinks. Most funeral homes invest between $5,795 and $6,995 for a standard stainless steel station with essential features.

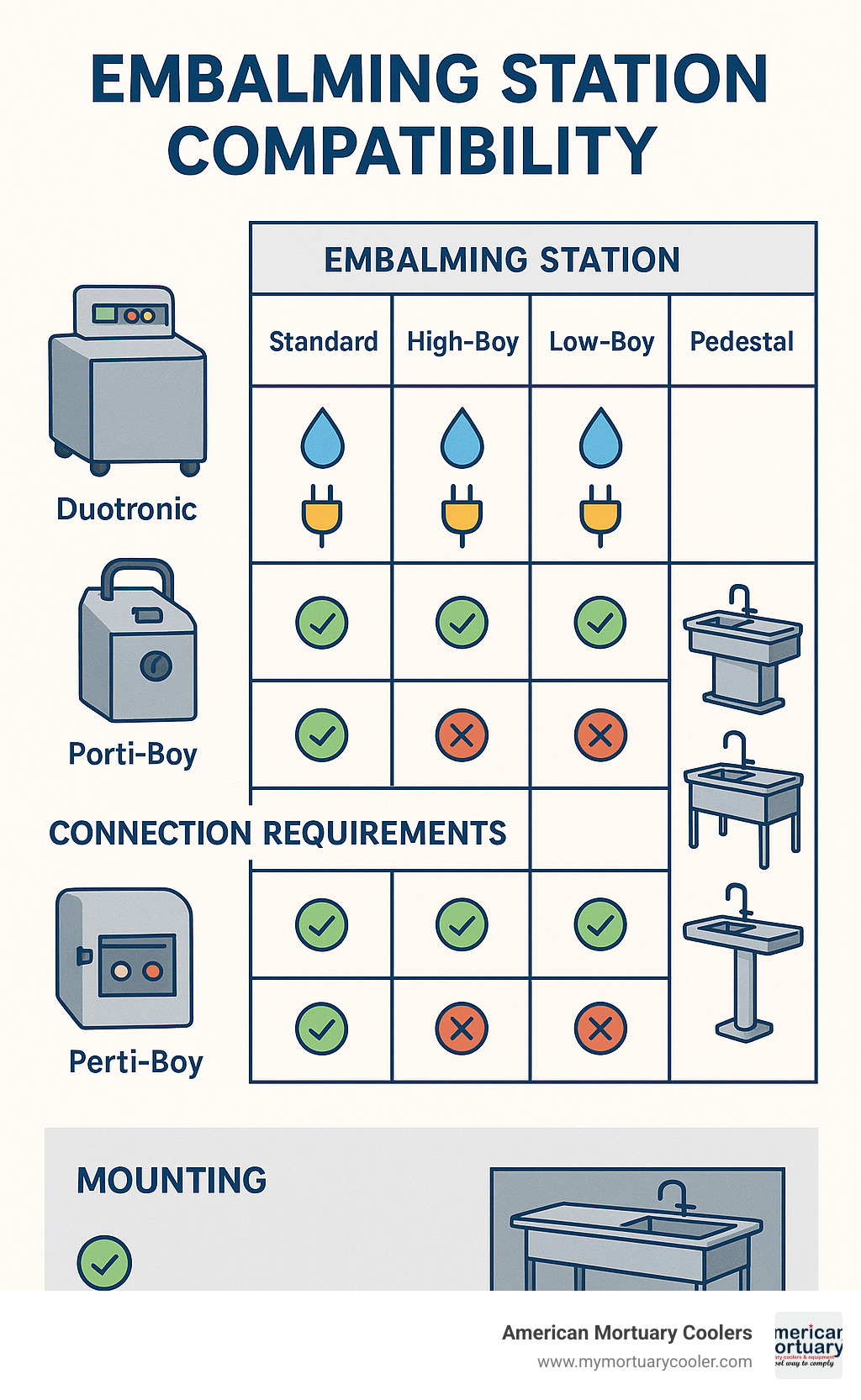

Wall-mounted stations save space in smaller prep rooms, while floor-mounted units offer easier plumbing installation and heavy-duty capacity. Modern stations are designed to integrate seamlessly with popular embalming machines like Duotronic and Porti-Boy models.

As a funeral director, you know that your prep room equipment directly impacts both staff efficiency and regulatory compliance. The wrong station can create workflow bottlenecks, safety hazards, and costly repairs down the road.

We're American Mortuary Coolers, a Tennessee-based company specializing in custom mortuary equipment with direct delivery across the contiguous 48 states. Over the years, we've seen how the right embalming station choice can transform a prep room's efficiency and safety standards.

Simple embalming stations word guide:

Understanding Embalming Stations: Purpose & Primary Functions

When you walk into any professional prep room, the embalming station immediately commands attention as the centerpiece of the entire operation. These aren't just fancy sinks—they're sophisticated workstations engineered specifically for the delicate art and science of body preservation.

Think of an embalming station as mission control for the embalming process. Every component serves a specific purpose in the careful choreography of preparing human remains with dignity and respect. The station creates a controlled environment where funeral directors can perform arterial injection procedures, introducing preservative fluids through the vascular system while maintaining the sterile conditions required by health regulations.

The aspiration function is equally critical. Modern stations use powerful hydro aspirators to remove body fluids and gases—a process that requires precise suction control and proper drainage systems. This isn't something you can accomplish with standard plumbing fixtures.

Beyond the technical aspects, these stations serve as the prep room hub where all body preparation activities converge. From initial washing and positioning to the final restoration steps, everything flows through this central workspace. The design ensures that embalmers have immediate access to temperature-controlled water, electrical connections for equipment, and proper drainage for biological waste.

Hygiene standards in modern embalming stations mirror those found in hospital operating rooms. The nonabsorbent stainless steel surfaces resist bacterial growth and allow for thorough disinfection between cases. This hospital-grade construction isn't just about cleanliness—it's about protecting both funeral home staff and the families they serve.

The regulatory role of embalming stations can't be overlooked either. OSHA requirements, state health department standards, and funeral industry best practices all influence station design. Features like eyewash stations, proper ventilation tie-ins, and electrical safety systems aren't optional extras—they're essential components that keep funeral homes compliant and staff protected.

The Heart of the Prep Room

Every prep room has a natural flow, and the embalming station sits right at the center of that primary workflow. When a case arrives, the station becomes the focal point where science meets compassion.

Body positioning on these stations requires careful engineering. The basin dimensions, drainage angles, and surface materials all work together to provide stable, respectful positioning during procedures. Unlike a standard table, embalming stations account for the fluid dynamics of the embalming process—where liquids need to flow and how to manage them safely.

The drainage system deserves special attention because it handles much more than regular wastewater. Modern stations incorporate specialized drainage that can manage embalming chemicals, body fluids, and wash water while meeting environmental regulations.

With over 2.4 million deaths annually in the United States, the reliability of these stations directly impacts how effectively funeral homes can serve grieving families.

Components, Materials & Features That Matter

When you're shopping for embalming stations, understanding what each component actually does makes choosing the right station much clearer.

The sink basin is the heart of your station—a carefully engineered workspace that handles everything from body washing to equipment cleaning. The best basins have rounded corners and proper drainage slopes that prevent fluid pooling.

The hydro aspirator is a powerful suction system that uses water pressure to remove body fluids during embalming. Modern aspirators include reverse-flow features that instantly clear clogs by providing reverse water pressure.

Your mixing faucet controls hot and cold water temperature, which is critical for proper chemical distribution while preventing thermal damage to tissues.

Safety features like GFCI receptacles with waterproof covers aren't just regulatory requirements—they're essential protection in the wet environment of embalming procedures.

Many stations now include eyewash attachments as either standard or optional features. While not always required, these emergency safety features reflect the industry's growing focus on workplace protection when handling embalming chemicals.

Why 304 Stainless Steel Dominates

Quality embalming stations are built from 304 stainless steel. This isn't just tradition—it's smart engineering.

304 stainless steel offers exceptional corrosion resistance against the harsh chemicals used in embalming, including formaldehyde-based solutions and acidic compounds. We've seen cheaper stations deteriorate quickly when exposed to these chemicals daily, creating both safety hazards and costly replacements.

The durability factor is impressive too. These stations maintain their structural integrity under heavy use and frequent cleaning cycles. They're built to hospital-grade standards, meeting the same cleanliness and safety requirements as medical facilities.

The hygiene properties of 304 stainless steel make it ideal for mortuary environments. Its non-porous surface prevents bacterial growth and allows for thorough sanitization—crucial when you're working with biological materials.

While 316 stainless steel offers even better corrosion resistance, 304 grade provides the optimal balance of performance and cost-effectiveness for most funeral homes.

Essential Safety Features Built-In

Modern embalming stations come loaded with safety features that weren't standard just a decade ago. These aren't just nice-to-have additions—they're essential protections for your staff who handle potentially hazardous materials every day.

Eyewash stations provide immediate emergency response for chemical exposure incidents. Anti-clog aspirators with reverse-flow capabilities prevent dangerous pressure buildup that could cause equipment failure or injury.

Back-flow preventers protect municipal water supplies from contamination—a regulatory requirement that also demonstrates your commitment to community safety. Ventilation tie-ins allow proper connection to exhaust systems, ensuring adequate air circulation in your prep room.

GFCI protection prevents electrical shock in wet environments, while rounded edges minimize injury risk during procedures.

More info about safety gear can help you understand the broader context of safety in embalming procedures.

Types of Embalming Stations & Configuration Choices

Choosing the right embalming stations isn't just about picking the first one you see in a catalog. Your prep room layout, available space, and daily workflow all play crucial roles in determining which configuration will serve your funeral home best.

The main types you'll encounter are wall-mounted units that save precious floor space, floor-mounted stations that offer rock-solid stability, and specialized flushing and ventilated systems that handle the more demanding aspects of waste management and air quality.

Wall-Mounted Embalming Stations

When floor space is at a premium, wall-mounted embalming stations become your best friend. These clever units attach directly to your prep room wall, giving you all the functionality you need without eating up valuable square footage.

The space-saving design provides better splash control—fluids and chemicals are contained more effectively, which means less cleanup time and better hygiene overall.

Most wall-mounted stations feature integrated sink basins with built-in aspirators and utility connections, creating a seamless workspace that looks professional and functions smoothly. The area underneath stays completely open, making it much easier to clean and sanitize your prep room floor thoroughly.

These units can run up to $13,795 for the more advanced models, but when you consider the space optimization and improved workflow they provide, many funeral directors find them well worth the investment.

Floor-Mounted Embalming Stations

Floor-mounted embalming stations are the workhorses of the mortuary world. These sturdy, freestanding units offer maximum stability and can handle whatever your busiest days throw at them.

The biggest advantage of floor-mounted stations is their easier plumbing installation. Your plumber will thank you for choosing a unit that connects directly to floor drains and water lines rather than requiring complex wall penetrations. This often translates to lower installation costs and fewer headaches during setup.

These stations excel at heavy-duty capacity work. Whether you're handling larger cases or running multiple procedures simultaneously, floor-mounted units provide the solid foundation and robust construction needed for demanding operations.

The Low-Boy Embalming Station is a perfect example of this category's capabilities. It features a powerful .75 hp waste disposal unit and comes with internal plumbing and wiring already in place. The upper deck is specifically designed to accommodate popular embalming machines like your Duotronic or Porti-Boy models.

Flushing & Ventilated Stations

Some funeral homes need more than basic sink and aspirator functionality. That's where flushing and ventilated embalming stations come into play, offering sophisticated solutions for bio-waste management and odor control.

These advanced systems shine when it comes to OSHA compliance. They're designed to meet strict regulatory requirements while creating a more pleasant working environment for your staff.

The integrated ventilation systems connect directly to your facility's exhaust setup, ensuring continuous air circulation that keeps chemical odors and airborne contaminants under control. Meanwhile, automated flushing capabilities reduce the manual cleaning workload while improving consistency in sanitation procedures.

Collection Systems & Water Control Units

At the top end of the embalming stations spectrum, you'll find collection systems and water control units that represent the most sophisticated technology available. These aren't necessary for every funeral home, but for high-volume operations or facilities with strict environmental regulations, they're game-changers.

Closed drainage systems prevent any contamination of municipal water supplies, while formalin capture technology safely collects and contains hazardous chemicals that would otherwise require special disposal procedures.

The dual-pump setups provide both redundancy and increased capacity. If one pump experiences issues, the backup system keeps operations running smoothly.

Latest research on waste disposal provides additional insights into proper waste management practices that complement these advanced collection systems.

Safety, Hygiene & Maintenance Best Practices

Proper maintenance and hygiene protocols are essential for keeping embalming stations operating safely and efficiently. Regular cleaning and maintenance not only extend equipment life but also ensure compliance with health and safety regulations.

Universal Precautions should be followed at all times when working with embalming stations. This includes treating every remains as potentially hazardous and using appropriate personal protective equipment (PPE) during all procedures.

Daily Maintenance Tasks:

- Disinfect all surfaces with appropriate sanitizers

- Clean and rinse sink basins thoroughly

- Check aspirator function and clear any blockages

- Inspect GFCI outlets for proper operation

- Wipe down all stainless steel surfaces

Weekly Maintenance:

- Deep clean aspirator systems

- Inspect plumbing connections for leaks

- Test eyewash stations (if equipped)

- Clean and sanitize storage areas

Monthly Maintenance:

- Descale water lines and mixing faucets

- Inspect and clean ventilation connections

- Check electrical connections and outlets

- Polish stainless steel surfaces

Annual Maintenance:

- Professional inspection of all systems

- Gasket and seal replacement as needed

- Calibration of pressure systems

- Comprehensive safety system testing

Cleaning Checklist & Recommended Products

Effective cleaning of embalming stations requires specific products and procedures designed for medical-grade equipment. Using the wrong cleaning agents can damage stainless steel surfaces or leave harmful residues.

Recommended Cleaning Products:

- Neutral pH Detergents - Gentle on stainless steel while effectively removing biological materials

- Stainless Steel Polish - Maintains appearance and provides protective coating

- Disinfectants - Hospital-grade sanitizers approved for mortuary use

- Descaling Agents - Remove mineral buildup from water lines and faucets

Daily Cleaning Checklist:

- Remove all equipment and supplies from station

- Rinse sink basin with hot water

- Apply neutral pH detergent and scrub all surfaces

- Rinse thoroughly with clean water

- Apply disinfectant and allow proper contact time

- Dry with clean, lint-free cloths

- Polish stainless steel surfaces

- Replace equipment and supplies

More info about equipment options provides additional guidance on maintaining mortuary equipment.

Buying Guide: Budget, Customization & Future-Proofing

Choosing the right embalming station is one of the most important equipment decisions you'll make for your funeral home. With prices spanning from $838 for basic units all the way up to $21,995 for premium autopsy stations, understanding what drives these costs helps you invest wisely.

A quality embalming station will serve your facility for decades. The difference between a $2,000 basic unit and a $15,000 advanced system isn't just about features—it's about reliability, efficiency, and peace of mind for years to come.

Basic stations in the $838 to $2,000 range offer essential functionality with minimal frills. Standard stations priced between $5,795 and $6,995 represent the sweet spot for most facilities, featuring 304 stainless steel construction and essential safety features like GFCI outlets and proper drainage systems.

Advanced wall-mounted stations running $10,000 to $15,000 make sense when space is at a premium or when you need improved splash control and integrated features. At the top end, premium collection systems and autopsy stations commanding $15,000 to $21,995 serve high-volume facilities or those with specialized requirements.

Several factors influence the final price of your embalming station. The construction materials and grade make the biggest difference—304 stainless steel costs more than basic materials but delivers superior durability and hygiene. Included safety features like eyewash attachments can add $500 to $1,500 to the base price, while mounting configuration affects both the unit cost and installation expenses.

When calculating your return on investment, consider more than just the purchase price. A quality embalming station reduces maintenance headaches, improves staff efficiency through better workflow, and helps maintain safety compliance. Over a 20-year lifespan, the difference between a basic and premium station often comes down to just a few dollars per case processed.

Lead times typically range from 2 to 12 weeks depending on customization requirements, so plan accordingly. Most manufacturers offer warranties ranging from one to five years, with service support varying significantly by company and location.

Questions to Ask Before You Buy

Before writing that check for a new embalming station, take time to thoroughly evaluate your needs. The wrong choice can create years of frustration, while the right one transforms your prep room efficiency.

Start with the basics: room size and layout constraints. Measure your prep room carefully, noting ceiling height, door width, and existing plumbing and electrical locations. A beautiful wall-mounted station won't help if your ceiling is too low or your plumbing connections are on the wrong side of the room.

Drainage capacity often gets overlooked until problems arise. Consider your peak volume days and whether your current drainage can handle increased flow. Some stations require specific drain sizing or additional ventilation connections.

Machine compatibility matters more than many realize. If you're running Duotronic or Porti-Boy machines, verify that your chosen station can accommodate them properly. Check weight limits, mounting options, and electrical requirements to avoid compatibility issues later.

Code compliance varies significantly by location. Some areas require eyewash stations, specific ventilation connections, or particular electrical configurations. Check with your local health department before finalizing your selection to avoid costly modifications later.

Don't forget about service support. Even the best equipment needs occasional maintenance or repairs. Ask about local service availability, typical response times, and parts availability.

At American Mortuary Coolers, we've helped funeral homes from Tennessee to California steer these decisions. We take time to understand your specific needs, space constraints, and budget to recommend the optimal solution. Our direct delivery across the contiguous 48 states means you get consistent service regardless of location.

Frequently Asked Questions about Embalming Stations

We get a lot of questions from funeral directors about embalming stations - and honestly, that makes perfect sense. These aren't impulse purchases, and getting the right station can make or break your prep room's efficiency for decades to come.

Here are the questions we hear most often, along with the straight answers you need to make smart decisions for your facility.

What is the average lifespan of a stainless-steel embalming station?

A well-built embalming station made from 304 stainless steel should serve your funeral home faithfully for 15 to 25 years. We've seen some units still going strong after three decades, while others needed replacement much sooner.

The difference usually comes down to a few key factors. Usage volume plays a big role - a station handling 200 cases annually will naturally wear differently than one processing 50 cases. Maintenance quality is absolutely critical. Funeral homes that stick to daily cleaning routines and monthly descaling schedules consistently get more years from their equipment.

Chemical exposure matters too. Embalming fluids are tough on equipment, but proper handling and immediate cleanup prevent the kind of chemical damage that shortens equipment life. Even your local water quality affects longevity - hard water creates mineral buildup that can cause premature corrosion and mechanical problems.

The bottom line? A quality embalming station is a long-term investment that pays dividends when you treat it right. Most funeral directors tell us their stations easily outlast two or three embalming machines during their service life.

Are eyewash attachments required by OSHA in funeral prep rooms?

This is where things get a bit complicated, and we always recommend checking with your local health department for the final word. OSHA doesn't specifically call out funeral homes for eyewash requirements, but they do require eyewash stations wherever employees might be exposed to injurious corrosive materials.

Since embalming fluids contain formaldehyde and other chemicals that can cause serious eye damage, most safety experts consider eyewash stations essential in prep rooms. Many state and local health departments have made them mandatory for funeral home licensing.

If you do need eyewash capability, OSHA has specific requirements. The station must be within 10 seconds of where chemical exposure might occur. It needs to provide 15 minutes of continuous flow at tepid temperature (60-100°F). You'll also need to test it weekly and keep maintenance records.

The good news is that adding eyewash attachments to modern embalming stations is straightforward and relatively affordable. Most funeral directors tell us the peace of mind is worth every penny, regardless of whether it's technically required in their area.

How do embalming stations integrate with Duotronic or Porti-Boy machines?

Modern embalming stations are designed with popular embalming machines in mind, and integration is usually pretty seamless. We've worked with funeral homes using everything from older Duotronic models to the latest Porti-Boy units.

Physical mounting is the first consideration. Quality stations feature upper deck surfaces specifically sized to accommodate these machines securely. The mounting points prevent vibration during operation, and there's adequate clearance for both operation and routine maintenance access.

Utility connections are equally important. The station needs properly positioned electrical outlets for easy machine connection, water supply lines for machine operation, and drainage systems that work with the machine's waste output. The Low-Boy Embalming Station we offer exemplifies this integration - it accommodates both Duotronic and Porti-Boy machines on its upper deck while providing all necessary connections.

Workflow optimization ties everything together. The machine positioning allows efficient fluid line routing without creating tangles or interference. You can access all controls comfortably during procedures, and the aspirator systems work in harmony with your embalming machine's operation.

Most funeral directors are surprised how well-designed stations make the whole prep room feel more organized and efficient. When everything works together properly, you spend less time wrestling with equipment and more time focusing on the quality work that matters.

Conclusion & Next Steps

Choosing the right embalming station is one of those decisions that'll shape how your funeral home operates for the next two decades. It's not just about buying equipment—you're investing in your staff's safety, your facility's efficiency, and your ability to serve families with dignity and professionalism.

We've covered a lot of ground here, from understanding why 304 stainless steel is the gold standard to weighing the benefits of wall-mounted versus floor-mounted configurations. The price range from $838 to $21,995 might seem overwhelming at first, but this investment pays dividends in reliability, safety, and peace of mind.

The funeral industry is evolving, and regulatory requirements continue to tighten. What might seem like an optional safety feature today—like an eyewash station or advanced ventilation tie-ins—could become mandatory tomorrow. Future-proofing your prep room with quality equipment isn't just smart business; it's essential for staying compliant and competitive.

At American Mortuary Coolers, we've been helping funeral directors across the country steer these decisions from our Tennessee headquarters. We understand that every funeral home is different. A small family operation in rural Montana has completely different needs than a high-volume facility in downtown Chicago. That's why we focus on custom solutions rather than one-size-fits-all approaches.

Our direct delivery service reaches every corner of the contiguous 48 states, from the Pacific Northwest to the Florida Keys. Whether you're planning a complete prep room renovation or simply replacing an aging station, we'll work with you to design something that fits your space, your budget, and your workflow.

The families you serve trust you during their most difficult moments. They deserve to know that behind the scenes, you have the tools and equipment necessary to honor their loved ones with the highest standards of care. A quality embalming station is fundamental to delivering that level of service consistently, safely, and professionally.

Ready to take the next step? Give us a call to discuss your specific needs. We'll help you sort through the options, understand the regulatory requirements in your area, and design an embalming station that serves your funeral home well for years to come.

More info about comparing mortuary equipment can help you make informed decisions about your entire prep room equipment suite.

Your commitment to excellence deserves equipment that matches it. Let's build something together that makes your important work a little easier and a lot safer.