Why Deep Stainless Steel Trays Are Essential for Professional Operations

A deep stainless steel tray is a durable, corrosion-resistant container typically measuring 2-4 inches in depth, designed for food service, medical, laboratory, and mortuary applications. Here's what you need to know:

Key Features:

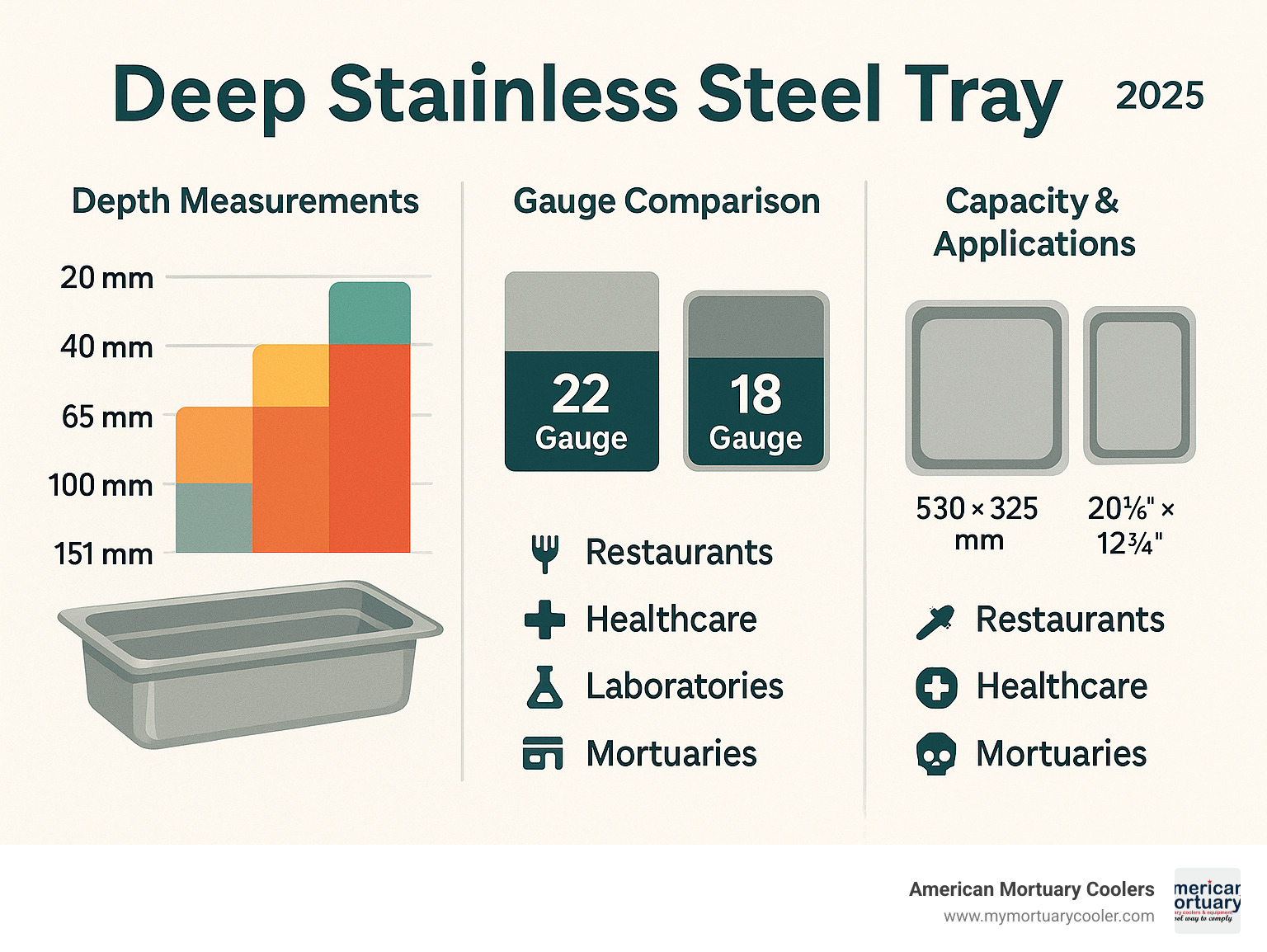

- Depth Range: 2-4 inches (up to 151mm)

- Material: 22-gauge, 300 series stainless steel

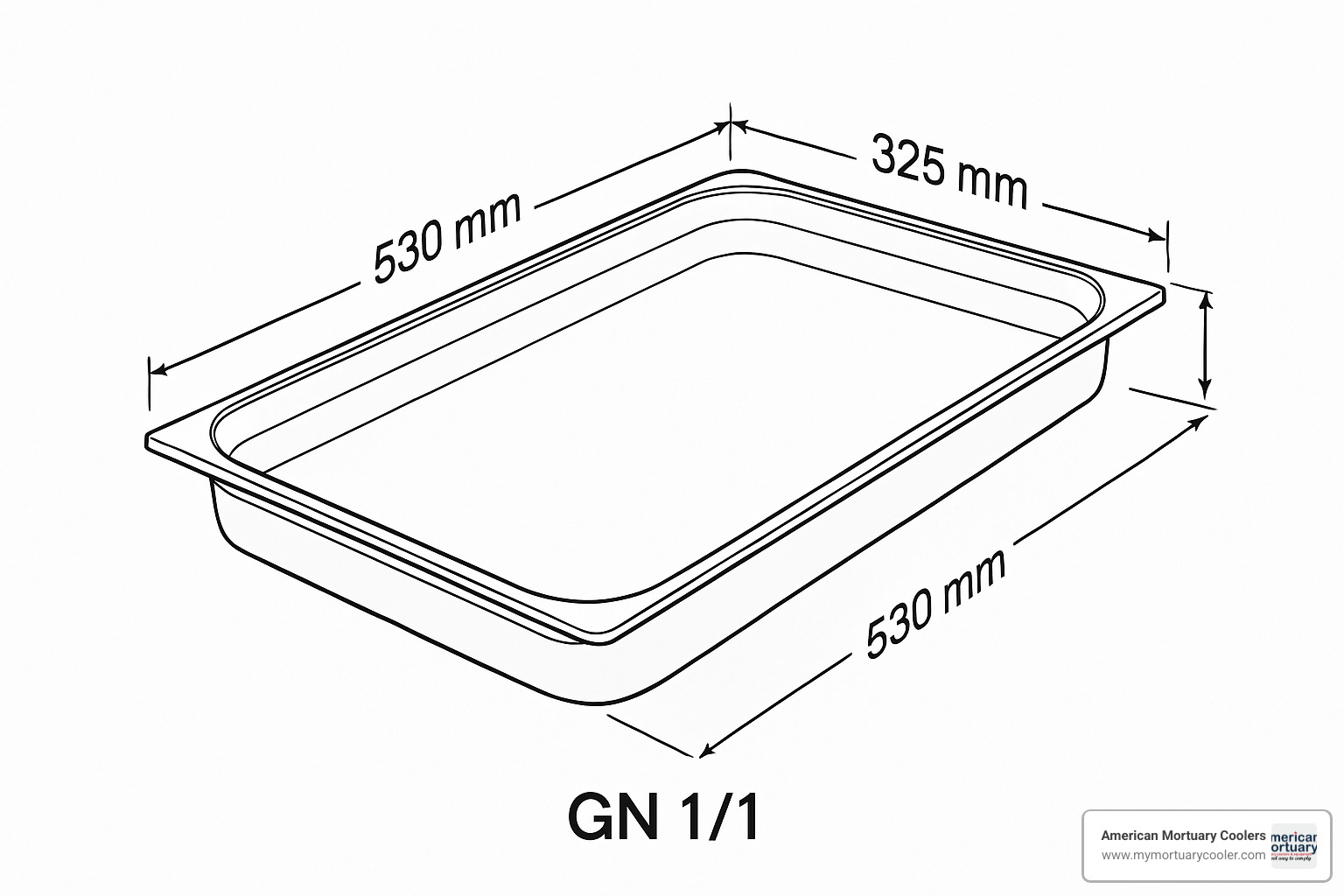

- Sizes: GN 1/1 (530 × 325 mm) or US hotel pan (20⅞" × 12¾")

- Safety: Oven-safe, freezer-safe, dishwasher-safe

- Price Range: $17.95 - $53.68

Common Applications:

- Commercial kitchen food prep and storage

- Medical instrument sterilization

- Laboratory specimen handling

- Mortuary and autopsy room use

- Industrial parts washing

The popularity of deep stainless steel trays stems from their best durability and versatility. Unlike aluminum or plastic alternatives, these trays resist dents, corrosion, and temperature extremes while maintaining food-safe and medical-grade cleanliness standards.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in selecting and specifying deep stainless steel tray systems for funeral homes and medical facilities. My background in mortuary equipment has taught me that the right tray selection can make the difference between smooth daily operations and costly equipment failures.

Understanding Deep Stainless Steel Trays

What Is a Deep Stainless Steel Tray?

A deep stainless steel tray is the workhorse of professional kitchens, labs, and medical facilities. It's a heavy-duty container made from 300 series stainless steel that ranges from 2 inches up to 4 inches deep, providing serious capacity for everything from roasting to lab specimens.

The rolled edges prevent cuts and add strength to prevent warping under heavy loads. Reinforced corners are welded smooth to eliminate crevices where bacteria hide. Most professional-grade deep stainless steel trays use 22-gauge, 300 series stainless steel with chromium and nickel that creates a self-healing oxide layer preventing rust.

Core Uses Across Settings

In food service, they're essential for steam tables, hotel pans for buffets, and prep containers for large-scale cooking. Medical facilities rely on these trays for sterilizing instruments, transporting specimens, and surgical prep work. The non-porous surface prevents bacterial contamination and handles repeated autoclave cycles.

Laboratory settings use them for chemical processing and sample prep where contamination could ruin work. In mortuary and autopsy work, deep stainless steel trays provide essential chemical resistance and easy cleaning. Industrial applications include parts washing, chemical processing, and quality control testing, benefiting from stainless steel's durability and ability to handle temperature extremes from freezer storage to high-heat processing.

Types, Sizes & Specs You'll See on the Market

The market operates on two main sizing systems. The European Gastronorm (GN) standard features the popular GN 1/1 size at 530 × 325 mm, with smaller options like GN 1/2 at 265 × 325 mm. US hotel pans use imperial measurements, with full-size at 20⅞" × 12¾", nearly identical to GN 1/1.

Depth options range from shallow 20mm for cookies up to deep 151mm for large roasts or specimens. Popular depths are 40mm (1.5"), 65mm (2.5"), and 100mm (4"). Gauge thickness ranges from 22-gauge for lighter duty up to 18-gauge for heavy applications.

| Standard | Full Size Dimensions | Common Depths | Primary Use |

|---|---|---|---|

| GN (European) | 530 × 325 mm | 20-151mm | Commercial kitchens, hospitals |

| US Hotel Pan | 20⅞" × 12¾" | 1.5"-4" | Food service, catering |

| Round | 12" diameter | 1"-2" | Serving, display |

| Custom | Variable | Variable | Specialized applications |

Deep Stainless Steel Tray vs Aluminum Pan

Aluminum wins on heat conduction - transferring heat three times faster than stainless steel, perfect for quick temperature changes. However, aluminum creates hot spots more easily, while stainless steel provides consistent temperature distribution.

Weight favors aluminum at 35% lighter, but stainless steel offers superior warp resistance and typically 2-3 times longer lifespan. Initial cost for stainless steel runs 40-60% higher, but longer lifespan often provides better value.

Perforated, Solid & Diamond Plate Variants

Solid trays handle liquids and general-purpose applications with easy cleaning. Perforated variants feature 5/32" (4mm) drain holes perfect for steaming vegetables or draining seafood, but unsuitable for liquids. Diamond plate variants provide slip-resistant texture and improved structural rigidity for industrial settings.

For specialized mortuary applications, more info about tray options provides detailed selection guidance.

Key Benefits & Industry Applications

What makes a deep stainless steel tray special? When manufacturers add chromium to steel, it creates a self-healing oxide layer that continuously repairs itself when scratched. This invisible shield provides ongoing corrosion resistance even in harsh environments.

This chromium oxide layer makes these trays incredibly hygienic with completely non-porous surfaces where bacteria can't penetrate. They handle temperature extremes from -10°F freezer storage to 500°F oven use without warping. The one-piece construction eliminates seams where bacteria hide.

These trays contain about 60% recycled content and are 100% recyclable, lasting 5-10 years in commercial settings versus 1-2 years for plastic alternatives. Check out these Stainless Steel Hot/Cold Serving Trays | Frontgate for long-lasting design examples.

Why Stainless Beats Plastic & Coated Metals

The non-toxic properties eliminate chemical leaching concerns with heated plastics. Unlike coated metals that peel or chip, stainless steel maintains integrity throughout its lifespan. The lifecycle cost savings add up - quality deep stainless steel trays serve 5-10 years versus 1-2 years for plastic, making them superior value when factoring replacement costs and contamination risks.

Sectors that Rely on Deep Stainless Steel Trays

Commercial kitchens use these workhorses from freezer to oven to serving line. Hospitals depend on them for instrument sterilization and specimen transport with autoclave compatibility. Autopsy rooms and laboratories require the chemical resistance and easy decontamination for sensitive materials.

Manufacturing facilities leverage durability for parts washing and chemical processing. Mortuaries rely on specialized deep stainless steel trays for body storage with essential corrosion resistance and sanitization capabilities. Catering operations appreciate the stackable design for prep-to-service efficiency.

Buying Guide: How to Choose the Right Deep Stainless Steel Tray

Start with your capacity needs. A 2-inch deep tray holds significantly less than a 4-inch model, but deeper trays might not fit existing equipment. Measure your equipment first.

Gauge thickness matters more than expected. 22-gauge (0.031" thick) works for light to moderate use. For busy kitchens or heavy materials, 18-gauge (0.050" thick) prevents denting and extends life dramatically.

Choose solid trays for liquids and general storage, perforated versions for steaming or draining. Anti-jam lugs prevent trays from sticking together but take slightly more storage space. Verify compatibility - GN and US hotel pan standards aren't always interchangeable.

Selecting a Deep Stainless Steel Tray for High-Heat Tasks

Quality trays handle oven temperatures up to 500°F without problems. Thermal shock from rapid temperature changes destroys cheap trays through warping or buckling. Quality construction with distributed stress points prevents these failures.

Convection ovens treat trays gently, while direct flame applications create hot spots requiring heavier gauge materials. For constant temperature extremes, invest in heavier construction.

Price Ranges & What Drives Cost

Current pricing ranges from $17.95 for basic 12-inch rounds up to $53.68 for full-size, 4-inch deep perforated versions. Brand premiums reflect quality and warranty support. Material grade creates price tiers - standard 304 stainless works for most applications, while premium 316 grade costs 30-50% more for chemical environments.

Gauge thickness adds 15-25% per step up. Bulk discounts start at 3-6 pieces for 5-10% off, with dozen quantities getting 15-20% savings.

Popular Brands & Where They Excel

Vollrath dominates commercial markets with their Super Pan 3 series featuring anti-jam lugs and reinforced construction. Winco balances quality and price for mid-range applications. Hafele brings European precision for cutlery systems. Webstaurant Store offers broad selection with house brands for entry-level pricing.

Quality manufacturers provide 1-2 year warranties. USA manufacturing offers faster delivery and better service, though at higher cost than imports.

Care, Maintenance & Safety Tips

Remove food debris immediately - the longer you wait, the harder cleaning becomes. Your commercial dishwasher's high-temperature cycles (140-160°F wash, 180°F sanitizing rinse) help maintain stainless steel's protective layer. Avoid chlorine bleach - it can cause pitting and discoloration.

For hand washing, use alkaline cleaners and clean in the direction of the grain. Rinse thoroughly and dry immediately to prevent water spots that can start corrosion. Store trays with protective padding or choose models with anti-jam lugs.

For comprehensive guidance, check out more info about maintenance for stainless steel tables.

Extending Tray Lifespan

Alkaline cleaners work beautifully without attacking the protective oxide layer. Non-abrasive cleaning pads preserve smooth surfaces - steel wool creates scratches where bacteria hide. Immediate drying prevents water spots and moisture problems. Inspect regularly for pitting or unusual wear - small issues caught early can often be fixed.

Food & Medical Safety Considerations

For saline solutions or high-chloride environments, 316-grade stainless steel provides superior protection. NSF certification ensures trays meet strict standards for materials and cleanability. Sterilization protocols vary by application, but stainless steel's compatibility with chemical sanitizers and high-temperature treatment provides flexibility for proper procedures.

Frequently Asked Questions about Deep Stainless Steel Trays

How do deep stainless steel trays perform in high-temperature ovens or freezers?

Deep stainless steel trays handle temperature extremes exceptionally well. Quality trays safely withstand temperatures up to 500°F without warping, thanks to stainless steel's low thermal expansion coefficient. Avoid sudden temperature shocks - going straight from -10°F freezer to 450°F oven can cause temporary warping.

On the cold side, these trays maintain strength and impact resistance even at sub-zero temperatures. The non-porous surface prevents ice crystal formation within the material, eliminating freeze-thaw damage that destroys other materials.

Are perforated trays safe for holding liquids?

Perforated deep stainless steel trays are specifically engineered for drainage, not liquid storage. Those 5/32" diameter holes excel when you want liquid separation - steaming vegetables, washing produce, or draining fats. For soups, sauces, or cleaning solutions, stick with solid-bottom trays for complete leak-proof performance.

What accessories should I buy with my new tray?

Compatible lids top the must-have list for storage, transport, and temperature maintenance. Wire racks provide lifted storage within trays. Steam table adapters ensure perfect fit in existing equipment. For mortuary applications, specialized accessories include body blocks, drainage fittings, and transport covers.

For complete mortuary systems, more info about cooler racks & trays provides detailed guidance on integrated solutions.

Conclusion

Deep stainless steel trays have proven essential across professional settings due to their remarkable durability and versatility. The upfront investment pays dividends through years of reliable service, eliminating the hidden costs of frequent replacements and potential contamination risks from degraded materials.

Whether you're running a restaurant kitchen, research laboratory, or medical facility, the right tray selection sets the foundation for smooth operations. The key is matching your specific needs - depth, gauge thickness, and surface configuration - with available options.

At American Mortuary Coolers, we've seen how proper equipment choices make all the difference in professional operations. Our custom mortuary cooler systems work seamlessly with rugged deep stainless steel trays to create complete storage solutions that funeral homes and medical facilities depend on. We deliver these custom systems directly across the contiguous 48 states.

When durability, hygiene, and long-term value matter most, quality stainless steel provides an best foundation your business can build on for years. More info about cooler racks & trays can help complete your setup with all the right components.