Why Proper Lighting in Walk-In Coolers Is Critical for Safety and Compliance

The lighting required in the walk in cooler isn't just about visibility - it's about meeting strict codes, ensuring safety, and controlling energy costs in challenging cold environments.

Quick Answer: Walk-In Cooler Lighting Requirements

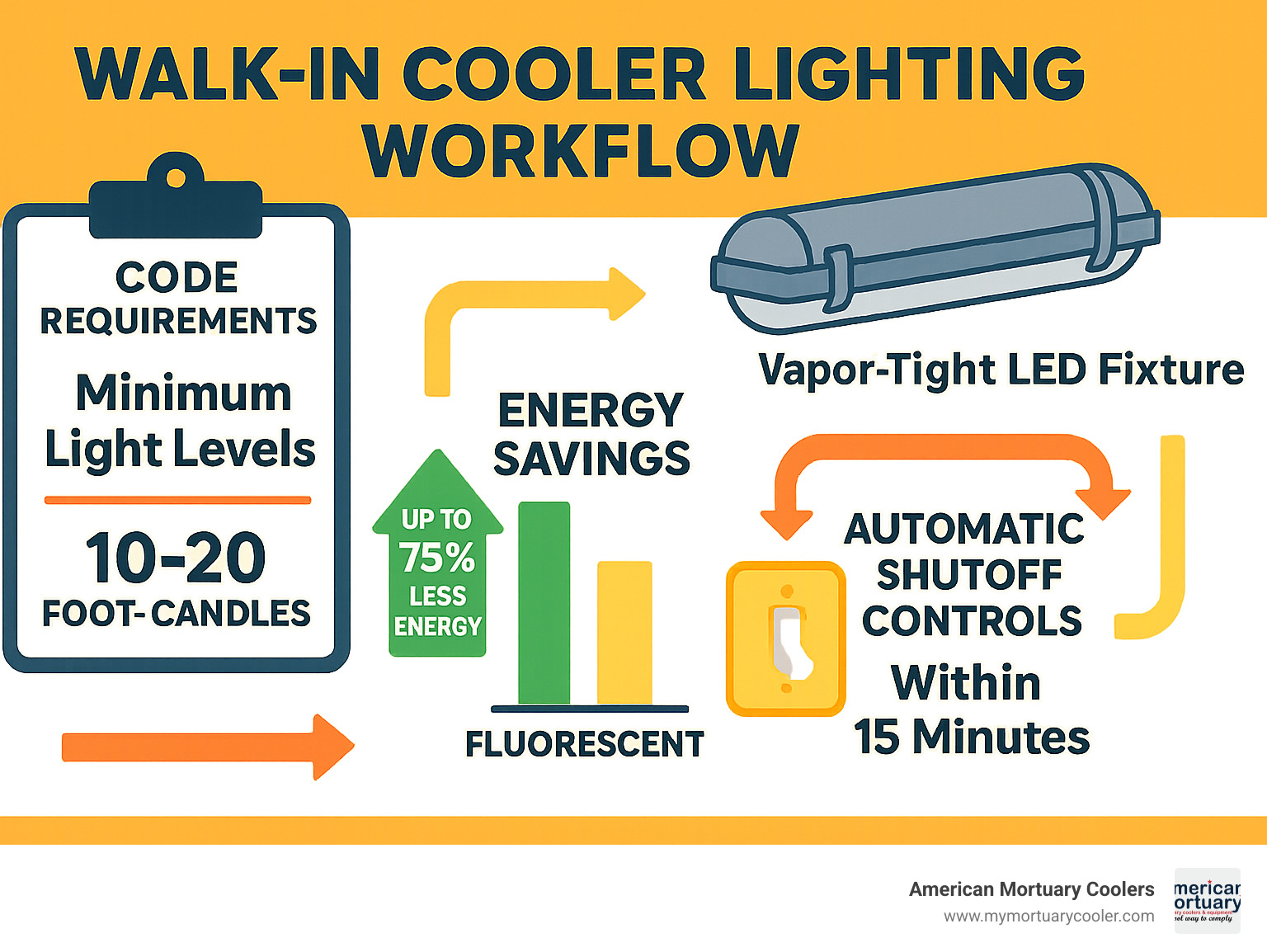

- Minimum Light Levels: 10-20 foot-candles for storage, 30-50 foot-candles for food prep areas

- Energy Efficiency: Must achieve at least 40 lumens per watt (including ballast losses)

- Automatic Controls: Lights must shut off within 15 minutes when space is unoccupied

- Fixture Requirements: Vapor-tight, NSF-rated for food areas, cold-temperature rated to -40°F

- Code Compliance: NEC 210.70(C) requires service lighting with accessible switches

Walk-in coolers present unique lighting challenges. The cold, humid environment can destroy standard fixtures. Poor lighting creates safety hazards when staff handle heavy inventory or steer tight spaces. Meanwhile, inefficient lighting adds unwanted heat load that forces your refrigeration system to work harder.

LED lights can save up to 75% on energy costs compared to traditional lighting in walk-in coolers. They also emit significantly less heat - just 3.4 BTU/hour versus 30 BTU/hour for fluorescents and 85 BTU/hour for incandescent bulbs.

ServSafe guidelines specifically require 50 foot-candles in food preparation areas within coolers. For general storage, the bare minimum sits around 10 foot-candles, though 70-80 lumens per square foot provides optimal visibility for commercial operations.

We're American Mortuary Coolers, a Tennessee-based supplier with extensive experience helping funeral homes steer the lighting required in the walk in cooler for both food storage and specialized mortuary applications.

Code & Health Regulations You Can't Ignore

When it comes to the lighting required in the walk in cooler, cutting corners isn't worth the headache of failed inspections or safety issues.

The National Electrical Code Section NEC 210.70(C) requires proper lighting outlets wherever serviceable equipment lives - including your refrigeration units. You can't just use a work light when something breaks. The code demands at least one lighting outlet with an accessible switch for technicians.

Energy efficiency rules add complexity. Florida's Energy Conservation Code C405.1.1 requires walk-in cooler lighting to hit minimum 40 lumens per watt efficiency, including ballast losses. Miss this target? You'll need occupancy controls that automatically shut lights off within 15 minutes when unoccupied.

ServSafe guidelines demand 50 foot-candles in food prep areas inside walk-in coolers. Health inspectors measure your light levels during routine visits.

Walk-in Cooler Lighting | UpCodes offers detailed references, but your local inspector gets the final say. Always check with your authority having jurisdiction before finalizing any lighting design.

Attic-Style Service Spaces Above Coolers

The space above your walk-in cooler might legally qualify as an "attic" requiring service lighting.

If you've got refrigeration equipment mounted on top of your cooler or accessible through overhead space, NEC 210.70(C) often kicks in. The code treats these areas like attic spaces, demanding proper lighting positioned near equipment that needs servicing.

The control switch must sit at the usual entry point to the space. Plan for it upfront rather than scrambling during inspection time.

Foot-Candle Minimums for Food vs Mortuary Storage

Food storage areas need at least 10 foot-candles for general storage and 30-50 foot-candles when food preparation happens in the cooler space.

For mortuary applications, we recommend similar standards - around 10-20 foot-candles for general storage areas, with higher levels of 30-50 foot-candles where detailed work occurs.

Converting to metric measurements, food storage requires approximately 150 lux while food preparation areas need 500 lux. Most commercial operations perform best with 70-80 lumens per square foot for optimal visibility throughout the space.

The Lighting Required in the Walk-In Cooler: Levels, Fixtures & Placement

Getting the lighting required in the walk in cooler right means balancing visibility, moisture resistance, cold temperatures, and energy costs.

The foundation starts with understanding your cooler's purpose. A mortuary cooler has different lighting needs than a busy restaurant kitchen. Both need proper illumination, but fixture placement, beam angles, and color rendering requirements vary significantly.

Moisture isn't optional in walk-in coolers. Moisture-resistant fixtures rated IP65 or higher are essential for preventing electrical faults and expensive replacements.

Temperature tolerance is equally critical. The lighting required in the walk in cooler must keep working reliably down to -40°F in freezer applications. LED fixtures actually perform better in cold temperatures, running more efficiently and lasting longer.

| Lighting Type | Efficacy (lm/W) | Heat Output (BTU/h) | Lifespan (hours) | Cold Performance |

|---|---|---|---|---|

| Incandescent | 10-17 | 85 | 750-2,500 | Poor |

| Fluorescent | 30-110 | 30 | 7,000-30,000 | Requires warm-up |

| LED | 50-100 | 3.4 | 35,000-70,000 | Excellent |

Minimum Foot-Candle & Lumen Standards

The lighting required in the walk in cooler must hit specific illumination targets. General storage areas need 10-20 foot-candles minimum, but for commercial operations where real work happens, design for 30-50 foot-candles in food preparation areas.

Color rendering matters more than most people realize. Specify fixtures with a Color Rendering Index (CRI) of 65 or higher for work areas, and push that over 80 for display applications.

Color temperature between 4000K and 5000K works best for most walk-in cooler applications, providing crisp, clean white light that improves visibility without feeling harsh.

Choosing Fixtures That Meet Requirements

LED fixtures designed specifically for refrigeration applications offer the best combination of performance, efficiency, and longevity. Look for fixtures rated to operate at -40°F with vapor-tight housings and non-glass diffusers.

NSF-rated fixtures are mandatory if any food preparation happens inside your cooler. These fixtures meet strict sanitation requirements with smooth, non-porous surfaces that resist bacterial growth.

LED strip lights work beautifully for general illumination along ceiling centerlines, while vapor-tight recessed cans provide targeted lighting. Polycarbonate lenses offer superior impact resistance compared to glass.

Optimal Placement & Wiring

Smart fixture placement eliminates shadows and provides uniform illumination. Position overhead fixtures along ceiling centerlines to minimize shadows cast by shelving or equipment.

Wall-mounted task lights supplement overhead lighting in areas where detailed work occurs. Pay careful attention to conduit sealing and drip loops in your electrical installation to prevent moisture problems.

Think about maintenance when planning placement. Fixtures mounted too high require ladders for bulb changes, creating safety hazards.

Controls & Energy Efficiency Inside Chilled Spaces

Smart lighting controls can slash your energy bills by 30-50% in walk-in coolers that aren't continuously occupied. But here's the catch - you can't just grab any old sensor from the hardware store and expect it to work in freezing temperatures.

The lighting required in the walk in cooler becomes much more efficient when you match the right controls to your specific usage patterns. Standard PIR occupancy sensors often fail in cold environments, either missing people entirely or triggering randomly as temperatures fluctuate. You need sensors specifically engineered for refrigeration applications.

Timer controls work beautifully for coolers with predictable schedules. Set them to automatically shut off during non-business hours, but always include manual override switches for those inevitable after-hours emergencies. Nothing's worse than fumbling around in the dark when you need to retrieve something urgently.

Daylight shut-off controls make sense if your cooler has any natural light sources, though this is less common in most installations. The real energy savings come from occupancy detection and automatic time-based shutoffs.

Lighting Options for Walk-in Coolers breaks down the various control strategies and their typical energy savings. The right combination can literally cut your lighting energy consumption in half while keeping your space safe and functional.

How Lighting Heat Affects Cooler Temperature

Every single watt of lighting becomes heat that your refrigeration system has to remove. This might not sound like much, but it adds up fast - especially with older lighting technologies.

Incandescent bulbs are energy hogs that pump out 85 BTU/hour of unwanted heat. Fluorescent fixtures aren't much better at 30 BTU/hour. Compare that to LED lights at just 3.4 BTU/hour, and you can see why the switch makes such a difference.

Here's where it gets interesting: that heat reduction affects way more than just your electric bill. Lower heat loads mean your compressor runs less, experiences less wear, and needs fewer defrost cycles. We've seen customers extend their refrigeration equipment life by years simply by upgrading to efficient lighting.

In a typical commercial cooler running 16 hours daily, switching from fluorescent to LED can reduce your refrigeration load by hundreds of BTU/hour. That's real money saved every single month, and it keeps compounding over time.

Utility Rebates & Code Triggers

Your local utility company probably wants to pay you to upgrade your lighting - seriously. Many utilities offer rebates covering 20-50% of retrofit costs for high-efficiency lighting in commercial applications.

ASHRAE 90.1 energy standards often trigger rebate eligibility, but you need to document everything properly. Take photos of your existing setup, gather fixture specifications, and calculate energy savings before you start the project. Some programs require pre-approval, so call your utility provider first.

The paperwork might seem tedious, but it's worth it. Keep detailed records for permit applications, rebate claims, and code inspections. This documentation also comes in handy for warranty claims down the road.

We've helped customers secure thousands of dollars in utility incentives just by planning ahead and filling out the right forms. The energy savings pay for themselves within two years, and the rebates make the payback even faster.

Maintenance, Safety & Food-Handling Compliance

Keeping the lighting required in the walk in cooler working properly requires understanding the unique challenges of cold, damp environments.

Your first line of defense is choosing fixtures with IP65-rated housings that seal out moisture completely. Check those rubber gaskets around the housing every few months for cracks or compression. Cold temperatures make rubber brittle, and temperature swings stress the material.

When cleaning, develop a wipe-down protocol that gets fixtures clean without damaging seals. Use food-safe cleaning solutions and avoid high-pressure washers that can force water past gaskets.

Emergency egress lighting deserves special attention in walk-in coolers. If your main lighting goes out when someone's inside, you've got a serious safety problem. Battery-backup emergency fixtures provide that critical safety net.

For food preparation areas, NSF cleaning requirements add complexity. These fixtures must handle frequent sanitizing without breaking down or creating places where bacteria can hide.

Don't overlook color rendering when choosing fixtures for inspection areas. Poor color rendering can hide spoilage or contamination that would be obvious under proper lighting.

Cold-Room Fixture Longevity Hacks

LED fixtures actually last longer in cold environments than in warm ones. We regularly see fixtures hitting 50,000 hours or more in walk-in coolers. The catch is that driver electronics don't always share that longevity.

When possible, position drivers outside the cooler or specify fixtures with drivers specifically rated for cold temperatures. This single decision can double or triple your fixture lifespan.

Even vapor-tight fixtures can develop internal condensation during temperature cycling. Look for fixtures with condensation drains or design features that prevent water accumulation.

Spare parts planning becomes critical with specialized refrigeration fixtures. Keep replacement gaskets, drivers, and LED modules on hand for important installations.

ServSafe & Mortuary Considerations

ServSafe requirements go beyond just having enough light to see. Proper lighting enables visual inspection that catches foodborne pathogens and contamination before they become health hazards.

In mortuary applications, lighting serves a different but equally important purpose. Proper illumination enables respectful handling while maintaining professional standards that grieving families deserve.

Shatter-proof covers protect against contamination if fixtures get damaged accidentally. Glass fragments in food prep areas or mortuary spaces create serious contamination risks that proper fixture selection prevents entirely.

Consider the psychological impact of lighting in mortuary coolers. Warmer color temperatures around 3500K-4000K may be more appropriate for mortuary applications while still providing needed illumination.

More info about cooler safety covers additional safety considerations that work hand-in-hand with proper lighting design.

Upgrade & Retrofit Best Practices

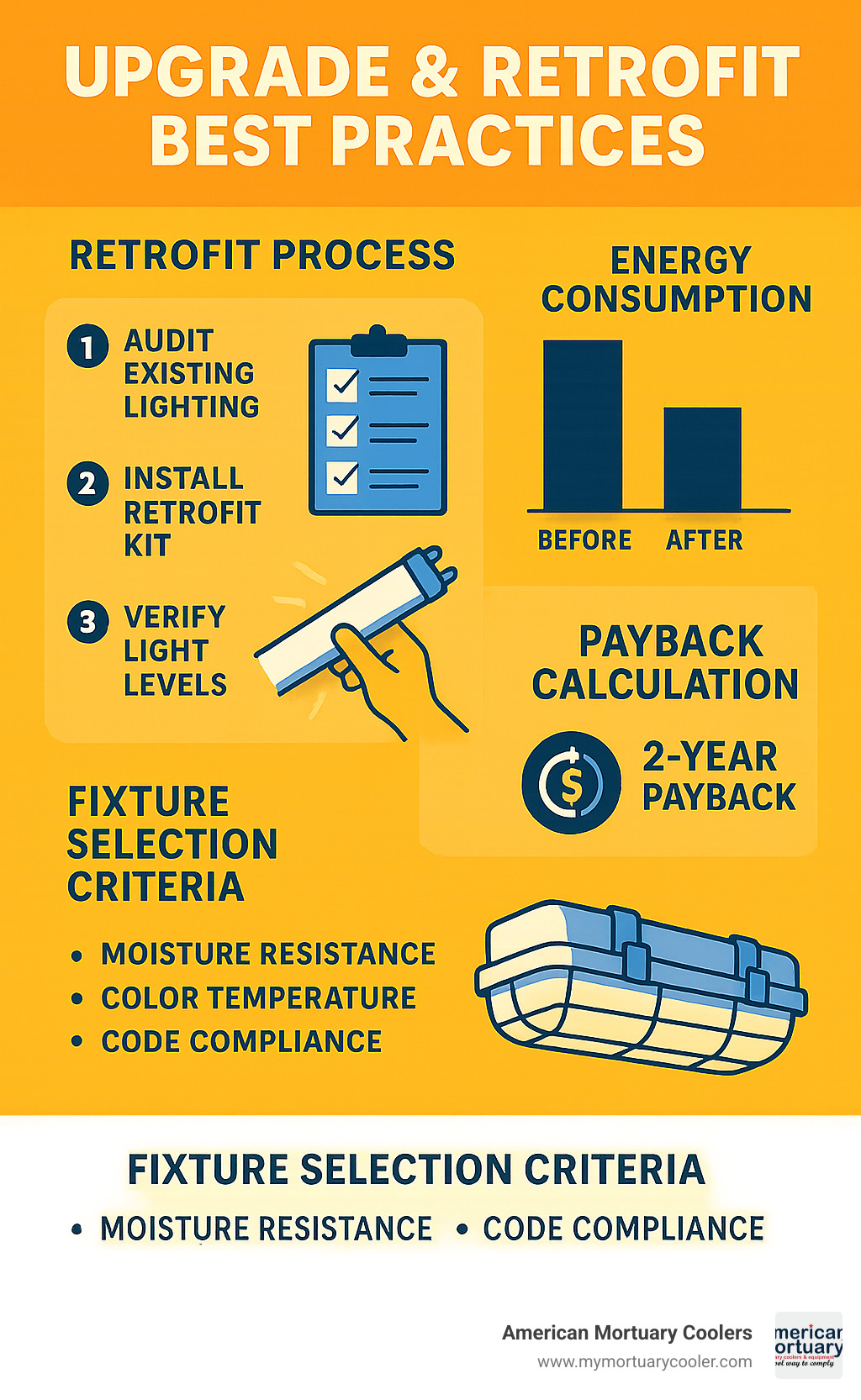

Upgrading your existing walk-in cooler lighting is one of the smartest investments you can make. The lighting required in the walk in cooler retrofits typically pay for themselves within just 2 years through energy savings alone.

Start by documenting everything - how many fixtures, what types, how they're mounted, and where electrical connections are. Measure your current light levels to establish a baseline.

Retrofit kits offer the easiest upgrade path if you've got structurally sound fluorescent fixtures. These kits let you swap out tubes and ballasts for LED modules and drivers while keeping existing housings.

Ballast-free LED tubes give you another option, but require rewiring to bypass old ballasts entirely. This works great when fixtures are in decent shape but ballasts are acting up.

For the best long-term results, complete fixture replacement is hard to beat. Yes, it costs more upfront, but you get fixtures designed from the ground up for cold, wet environments.

Need more guidance on cooler upgrades? Our Ultimate Guide to Walk-In Coolers covers everything from basic retrofits to complete system overhauls.

Calculating ROI Before You Flip the Switch

Calculating your return on investment isn't just about counting kilowatt-hours - though LED lighting typically slashes energy consumption by 50-75% compared to fluorescent fixtures.

Start with wattage reduction multiplied by annual operating hours. Don't forget that every watt of lighting heat you eliminate saves additional energy on the refrigeration side.

Demand charges are the hidden villain in many commercial electric bills, sometimes representing 30-50% of total costs. When you reduce your lighting load during peak demand periods, you're cutting those monthly demand charges too.

Factor in maintenance savings from longer LED lifespans. LED fixtures can run 50,000 hours or more - that's years of trouble-free operation. Add up the cost of replacement bulbs, ballasts, and labor for those hard-to-reach fixtures.

Selecting Vendors & Spec Sheets

UL listings are absolutely non-negotiable for commercial installations. Make sure your fixtures carry the right UL ratings for wet locations and low-temperature operation. The complete fixture assembly needs to be UL listed, not just individual parts.

Warranty length tells you everything about a manufacturer's confidence in their product. Look for fixtures with 5-10 year warranties covering both LED modules and drivers.

Temperature ratings must match your application. Cooler fixtures should handle -22°F reliably, while freezer applications need -40°F ratings minimum.

Lead times can be brutal for specialized refrigeration fixtures - we're talking 6-12 weeks or longer. Plan ahead and consider keeping spare fixtures on hand for critical applications.

Frequently Asked Questions about the Lighting Required in the Walk-In Cooler

Let's tackle the most common questions we hear from funeral directors and facility managers about the lighting required in the walk in cooler. These questions come up in nearly every consultation, so you're definitely not alone in wondering about these details.

Do walk-in coolers legally need emergency lighting?

Here's where things get a bit tricky - it depends on your local building codes and how your space is classified. Most walk-in coolers aren't legally required to have emergency lighting, but that doesn't mean you should skip it.

Think about what happens when the power goes out and someone's inside your cooler. Complete darkness in a confined space with heavy equipment or caskets creates serious safety risks. Staff could trip, get disoriented, or struggle to find the door handle.

Battery-backup emergency fixtures cost relatively little compared to the safety they provide. We've seen too many situations where a simple power outage turned dangerous because someone was trapped in darkness. The peace of mind alone makes emergency lighting worth considering, especially in larger coolers where navigation becomes more challenging.

What color temperature looks best without changing product color?

The lighting required in the walk in cooler should fall between 4000K and 5000K for the best balance of visibility and natural appearance. Most of our clients choose 5000K because it provides crisp, clean light that doesn't distort colors.

Avoid going higher than 5500K - that harsh, bluish light makes everything look unnatural and can be uncomfortable for staff working in the space. On the flip side, anything below 3500K gets too warm and yellow, making it harder to see details clearly.

Color Rendering Index (CRI) matters just as much as color temperature. Specify fixtures with CRI above 80 for mortuary applications where respectful presentation is essential. This ensures skin tones and fabric colors appear natural under your lighting.

How many fixtures do I need for a 10 × 10 ft cooler?

A typical 10 × 10 ft cooler needs 2-4 fixtures depending on what you're using the space for and how much light each fixture produces. For basic storage where you're just moving items in and out, two 4-foot LED strip fixtures usually do the job.

If you're doing any detailed work inside the cooler - like preparation tasks or thorough inspections - you'll probably want 3-4 fixtures to eliminate shadows and provide adequate working light. The goal is uniform illumination without dark corners where accidents could happen.

The height of your ceiling and the type of shelving or equipment inside also affects how many fixtures you need. Higher ceilings require more fixtures or higher-output units to achieve the same light levels at floor level.

Rather than guessing, we recommend having a lighting professional run the calculations. Proper photometric analysis ensures you get adequate light levels without wasting money on unnecessary fixtures or energy costs. It's especially important for critical applications where proper lighting affects both safety and compliance.

Conclusion

Getting the lighting required in the walk in cooler right isn't just about screwing in a few bulbs and calling it done. It's about creating a safe, compliant, and efficient environment that serves your business for years to come.

Energy savings alone make the upgrade worthwhile. Modern LED fixtures slash energy consumption by up to 75% compared to old fluorescent or incandescent lighting. When you factor in the reduced heat load on your refrigeration system, the savings compound quickly. Most businesses see their lighting investment pay for itself within two years.

But the real value goes beyond the monthly utility bill. Better lighting means safer working conditions for your team. It means easier inspections that keep health departments happy. It means equipment that actually works when you need it, even when the temperature drops to -40°F.

Compliance has to come first - there's no wiggle room when it comes to electrical codes and health regulations. The good news is that meeting these requirements doesn't have to break the bank. With proper planning and the right fixtures, you can exceed code requirements while staying within budget.

At American Mortuary Coolers, we've helped businesses across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, Pennsylvania, and beyond solve their cooler lighting challenges. Whether you're storing food products or providing dignified mortuary services, we understand that every detail matters.

Your lighting system should work as hard as you do. That means choosing fixtures that can handle the harsh environment, controls that save energy without sacrificing safety, and designs that make maintenance simple rather than a headache.

The investment you make today in proper cooler lighting will pay dividends for decades. Better visibility, lower energy costs, reduced maintenance, and most importantly - a safer environment for everyone who works in your facility.

Ready to brighten up your walk-in cooler the right way? Our team is here to help you steer everything from code compliance to fixture selection. Because when it comes to the lighting required in the walk in cooler, getting it right the first time saves you time, money, and headaches down the road.

Walk-In Coolers That Won't Freeze Your Budget offers additional guidance on optimizing your cooler investment while maintaining the highest standards of safety and compliance.