Why Walk-In Freezer Shelving Requirements Matter for Safe Operations

Walk-in freezer shelving requirements are critical safety and regulatory standards that ensure proper food storage, prevent contamination, and maintain compliance with health codes. Here are the essential requirements you need to know:

Key Walk-In Freezer Shelving Requirements:

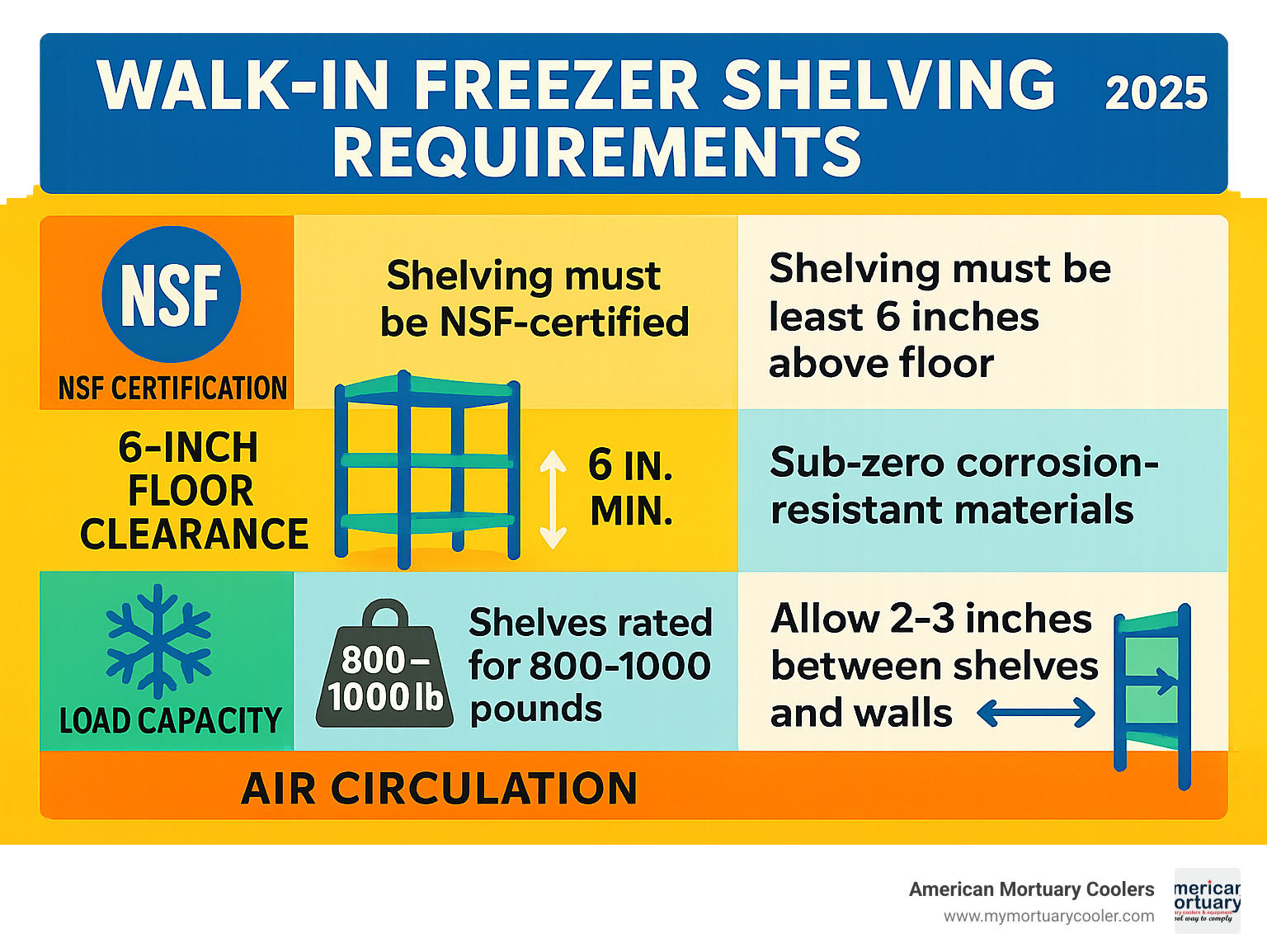

- NSF certification - All shelving must be NSF-certified for food safety

- Floor clearance - Lowest shelf must be at least 6 inches above the floor

- Material standards - Use corrosion-resistant materials like stainless steel or epoxy-coated wire

- Load capacity - Shelves must support 800-1,000 pounds per shelf safely

- Air circulation - Leave 2-3 inches between shelves and walls for proper airflow

- Temperature rating - Materials must withstand 0°F (-18°C) or lower temperatures

Whether you're setting up a new facility or upgrading existing storage, understanding these requirements protects your operation from health code violations and equipment failures. Restaurants spend approximately 30% of their budget on ingredients, making proper cold storage organization crucial to protecting your bottom line.

We're American Mortuary Coolers, a Tennessee-based company specializing in custom mortuary coolers and related equipment. While our primary focus is the funeral industry, our extensive experience with cold storage solutions gives us unique insights into walk-in freezer shelving requirements and regulatory compliance challenges.

Walk-in freezer shelving requirements terms at a glance:

Regulatory Standards You Must Know

When it comes to walk-in freezer shelving requirements, three main players set the rules: NSF/ANSI 7, DOE energy standards (10 CFR Part 431), and your local health department.

NSF/ANSI 7 handles the food safety side, making sure your shelving won't contaminate food or harbor bacteria. The DOE standards focus on energy efficiency. Your local health codes add specific requirements about floor clearances and cleaning access.

Your walk-in freezer must maintain 0°F (-18°C) or lower according to NSF standards. This temperature requirement affects everything from materials to shelving layout design. NSF certification is mandatory for commercial use - no exceptions.

NSF/ANSI 7 Points Checklist

The NSF/ANSI 7 Standard covers three critical areas for walk-in freezer materials, design, and construction.

Corrosion resistance is your first line of defense against equipment failure. Your shelving materials must handle cold, humid conditions. Galvanized materials need to be at least as tough as G90 steel. Alternative materials require NSF/ANSI 51-compliant protective coatings. For food prep areas, stainless steel surfaces are required.

Cleanable surfaces require smooth internal radii of at least 1/4 inch on corners under 135 degrees. Bacteria hide in sharp corners and crevices. Your shelving design must make cleaning easy, and everything must allow floor cleaning underneath.

Vermin-proof design blocks vermin access and eliminates hiding spots. This supports proper floor clearance requirements and pest control efforts. Sealed joints and proper gaskets prevent contamination.

Federal & Local Code Intersections

DOE energy conservation standards under 10 CFR Part 431 Subpart R affect your installation with minimum insulation requirements (R-32 for freezer walls), automatic door closers for doors ≤ 3 ft 9 in wide and ≤ 7 ft tall, and EC motor requirements for fans under 1 HP.

Your local health department typically enforces the 6-inch floor clearance rule. This prevents contamination, improves airflow, makes cleaning possible, and gives maintenance crews room to work.

Spring-hinged doors often get mandated for walk-in freezers with doors shorter than 7 ft and narrower than 3 ft 9 in. These standards overlap and reinforce each other to create comprehensive safety coverage.

Materials & Construction: Picking Shelves That Won't Fail in the Cold

Choosing the right materials for your walk-in freezer shelving means finding materials that can handle brutal cold while keeping your food safe and your business compliant. When temperatures drop to 0°F and below, not all materials are created equal.

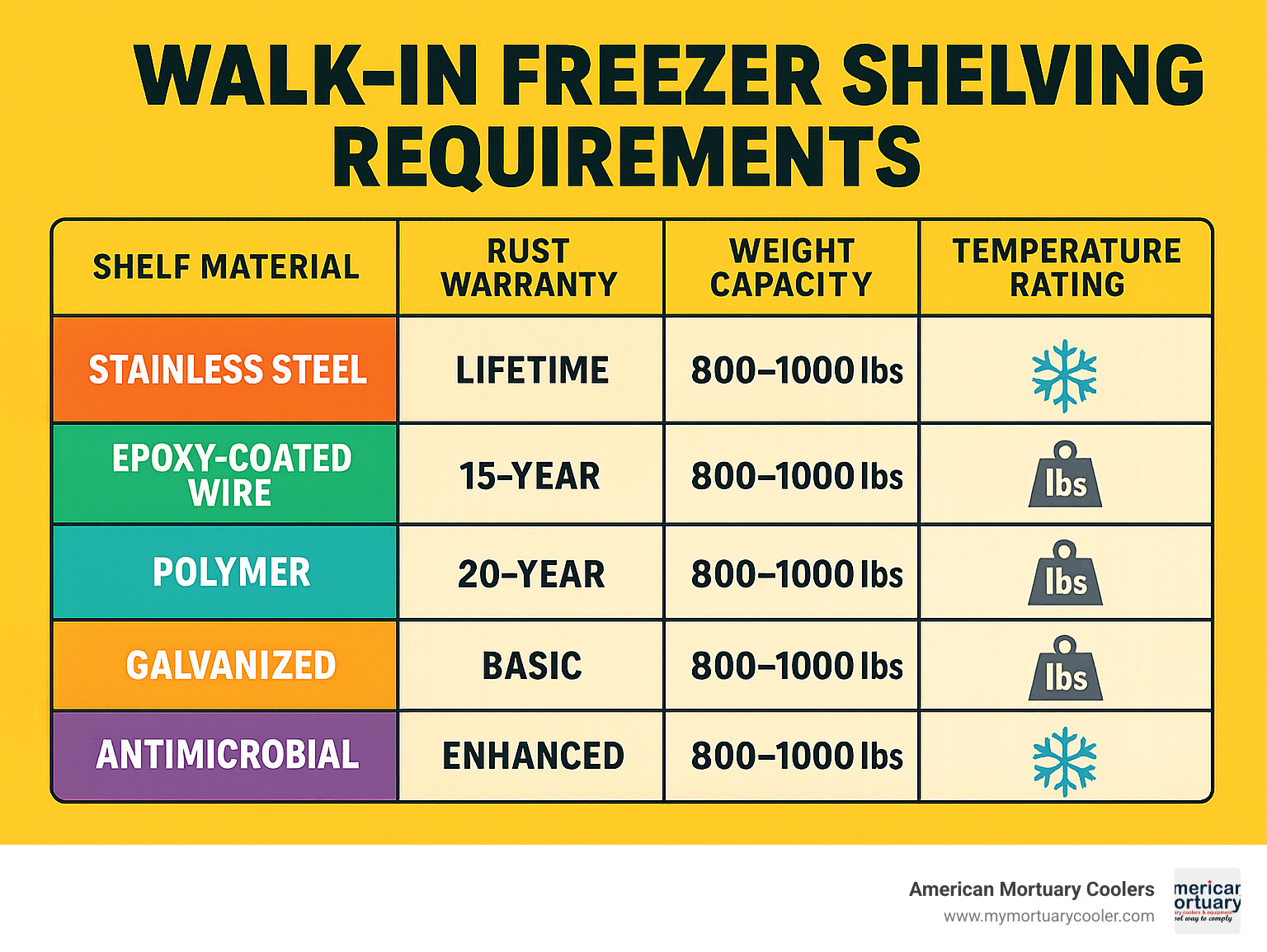

Stainless steel is the premium choice - handles extreme cold perfectly and meets NSF requirements for food prep areas. The downside is cost. If you're storing packaged goods, you might be paying for features you don't need.

Epoxy-coated wire shelving hits the sweet spot for most operations. These systems come with solid 15-year warranties and handle up to 800 pounds per shelf. The wire design lets cold air flow freely, helping your energy bill. Many include antimicrobial coatings built into the epoxy.

Polymer shelving systems offer impressive warranties - sometimes lifetime guarantees against rust and corrosion. Since they're 100% rust-proof, they're perfect for humid environments. They cost more upfront, and in freezer environments, you might not need all that rust protection.

Galvanized shelving is budget-friendly but basic galvanized steel might not meet NSF requirements for food contact areas. It works for non-food applications, but check your local codes first.

Antimicrobial shelving incorporates Microban technology for built-in contamination protection, though it adds to the cost.

Load Capacity & Strength Requirements

Walk-in freezer shelving requirements demand substantial load handling. Most NSF-certified wire shelving systems support up to 800 pounds per shelf. Premium systems like Metro's Super Erecta Pro handle 800 to 1,000 pounds per shelf thanks to their post-capture design.

The 360° post-capture design distributes weight evenly across the entire structure, preventing shelf sag. Cheaper ladder-style shelving lacks end beams and wobbles under heavy loads.

Remember: there's a difference between static loads (items sitting) and dynamic loads (when loading/unloading). A shelf rated for 800 pounds static weight might handle less during active use. Always check both ratings and distribute weight evenly across your shelving system.

Layout & Airflow: Meeting Walk-In Freezer Shelving Requirements

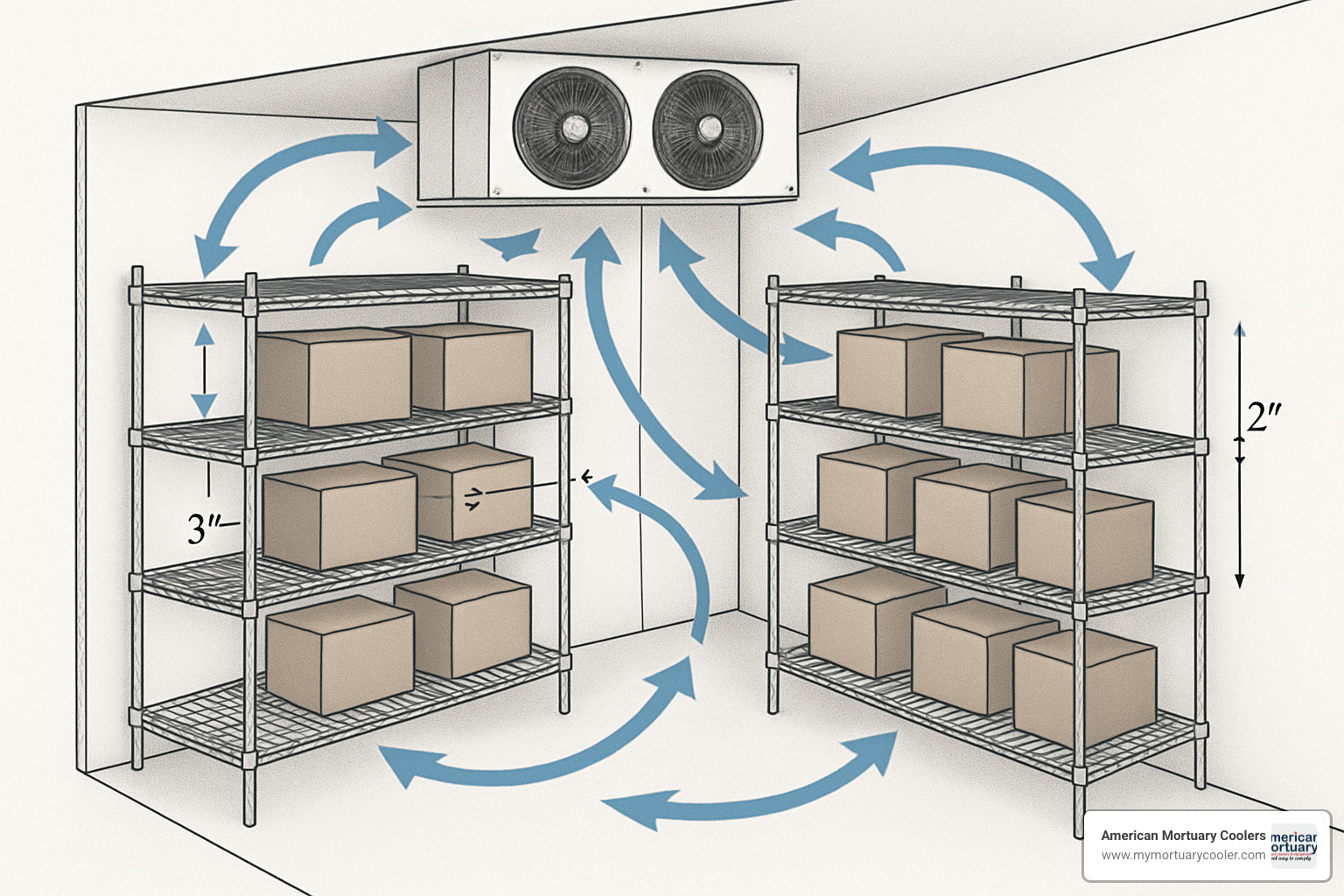

Getting your shelf layout right creates a system that keeps food safe and energy bills reasonable. Walk-in freezer shelving requirements focus heavily on airflow because without proper air circulation, you'll get frozen disasters and frustrated health inspectors.

Think of your walk-in freezer like a highway system. Cold air needs clear paths to travel around products. When you block these "air highways" with poorly spaced shelves, you create traffic jams that lead to uneven temperatures and overworked refrigeration systems.

The magic number for product spacing is 3 inches on all sides. This prevents freezer burn and temperature fluctuations. Leave at least 2 inches between shelves and walls to keep air moving freely and prevent your refrigeration system from working overtime.

Adding a fifth shelf can boost storage capacity by 25%, but cramming in extra shelves without proper spacing doesn't work well.

Shelf Height & Floor Clearance—Core Walk-In Freezer Shelving Requirements

That 6-inch floor clearance rule creates a contamination barrier that protects stored products. This clearance makes cleaning easier and serves pest control - health inspectors can see under your shelving with no hiding spots for mice and insects.

The 6-inch gap gives you sweeper access for daily cleaning and prevents ice buildup around shelf bases. Some operations use more than 6 inches, but that's the absolute minimum.

Shelf Depth, Width & Aisle Design

The 40-inch aisle width standard lets you safely maneuver standard food service carts without bumping shelves. Wide aisles prevent damage and injuries during busy periods.

The perimeter layout strategy works best - run shelving along walls and keep a clear center aisle. This maximizes storage while maintaining visibility for inventory management and stock rotation.

Match your shelf depth to your product dimensions - oversized shelves waste space, while undersized shelves create inefficient stacking and safety hazards.

Product Weight Distribution & BTU Load Impact

Even weight distribution prevents shelf collapse and maintains efficient airflow. When you concentrate heavy items in one area, you create stress points and restrict airflow, creating temperature variations.

Smart load distribution means spreading heavy items across multiple shelves and using lower shelves for heaviest products. This improves stability and makes loading safer. Proper airflow reduces your refrigeration system's workload, translating to lower energy bills and longer equipment life.

Safe Food Storage & Cross-Contamination Prevention

When it comes to walk-in freezer shelving requirements, preventing cross-contamination protects your customers and business reputation. Your shelving layout is the first line of defense against foodborne illness.

The golden rule: raw meat always goes on the bottom shelf. This prevents dangerous drips from contaminating everything below. When raw meat thaws or releases juices, gravity takes over.

Your storage hierarchy should flow from safest at the top to riskiest at the bottom. Ready-to-eat foods earn the top shelf, followed by seafood on the second level. Whole cuts of beef and pork come next, with ground meats and poultry taking the fourth position. Raw poultry gets the lowest shelf because it carries the highest contamination risk.

The 2-inch spacing rule between different food categories creates breathing room and makes it easier to spot problems quickly.

Organizing Shelves to Control Risk

Creating dedicated zones for different food categories turns chaos into order. When every food type has its designated home, staff can follow safety protocols automatically.

Allergen segregation deserves special attention. Common allergens like nuts, dairy, and shellfish need dedicated areas, completely separate from other products. Color-coding these zones helps staff identify allergen areas instantly.

Group similar products together so staff can work efficiently, but always keep raw and cooked products physically separated. Position frequently used items within easy reach, and use prime upper shelf spots for lighter, less risky foods.

Labeling & Rotation Systems that Pass Inspection

A solid labeling system is your best friend during health inspections. Every label needs the product name and description, critical dates like storage date, expiration date, lot numbers for traceability, and storage temperature requirements.

FIFO (First In, First Out) rotation becomes easier when you set up shelves correctly. New items go to the back, older items move to the front. Color-coding takes your labeling system to the next level - assign different colors to different days of the week for quick identification.

For detailed guidance on labeling strategies, check out this comprehensive resource about labeling practices. For flooring options that complement your shelving system, this guide to walk-in floor options covers everything you need to know.

Maintenance, Cleaning & Lifecycle Management

Taking care of your walk-in freezer shelving is essential for meeting walk-in freezer shelving requirements and protecting your investment. Regular attention prevents expensive breakdowns and keeps everything running smoothly.

Different shelf materials need different approaches. Smooth surfaces and minimal crevices make cleaning easier. If you're using shelf mats, removable ones are game-changers for thorough cleaning.

Your daily routine should include visual checks for damage or contamination, spot cleaning spills, checking door seals, and verifying temperatures. Weekly deep cleaning requires removing products, cleaning all surfaces thoroughly, and sanitizing with food-safe chemicals. Check that shelves are mounted securely.

Monthly inspections should cover the whole system - check mounting hardware, look for wear or rust, and review maintenance logs for patterns.

Cleaning Protocols That Protect Certification

Food-safe sanitizers are mandatory for maintaining NSF certification. Using wrong products can void your compliance status. Always verify cleaning supplies are approved for food service use.

The cleaning process: Remove all products first, use approved sanitizers at correct concentrations, and follow contact time requirements. Many sanitizers need several minutes to work properly.

Different materials need different approaches. Wire shelving requires extra attention to joints where bacteria hide. Polymer shelving handles aggressive cleaning, while stainless steel needs specific cleaners to prevent corrosion.

Keep detailed cleaning logs with dates, times, who did the work, and chemicals used. This documentation is crucial during health inspections.

Extending Shelf Life & Energy Efficiency

Regular torque checks on mounting hardware prevent loose connections that cause catastrophic shelf failures. Proper shelf alignment affects airflow efficiency, reducing refrigeration system workload and lowering energy bills.

Routine maintenance extends equipment life well beyond the typical 15-year average. With proper care, quality shelving systems serve for decades. Consider total cost of ownership rather than just upfront costs when planning replacements.

Replacement planning should happen before critical failures. Monitor shelf condition, track maintenance costs, and plan upgrades during slow periods.

Frequently Asked Questions about Walk-In Freezer Shelving Requirements

Let's tackle the most common questions we hear about walk-in freezer shelving requirements. These answers will help you make informed decisions and stay compliant with all the regulations we've covered.

What is NSF certification and why does my shelving need it?

Think of NSF certification as your shelving's "food safety passport." When you see that NSF blue label on shelving, it means the product has passed rigorous testing for food-contact safety and sanitation standards. This isn't just a nice-to-have feature - it's actually mandatory for commercial food service operations.

The NSF certification process puts shelving through its paces. Testing covers everything from material safety and cleanability to durability under normal operating conditions. They evaluate how well the shelving resists corrosion, how easy it is to clean thoroughly, and whether it maintains structural integrity over time.

Here's the bottom line: without NSF certification, your shelving legally cannot be used in commercial food storage applications. Health inspectors look for this certification, and using non-certified shelving can result in violations, fines, or even closure orders. The certification ensures your shelving won't contaminate food products or create safety hazards.

How high must the lowest shelf be off the floor?

The 6-inch floor clearance rule is one of the most straightforward yet critical walk-in freezer shelving requirements. Your lowest shelf must sit at least 6 inches above the floor - no exceptions, no negotiating with inspectors.

This requirement isn't arbitrary. That 6-inch gap serves multiple essential purposes that directly protect food safety. It prevents contamination from floor surfaces, which are always considered dirty in food safety protocols. The clearance also facilitates thorough cleaning and inspection, improves airflow circulation throughout the space, and provides access for maintenance equipment like sweepers and mops.

Some facilities choose even greater clearances based on their specific needs. If you use larger cleaning equipment or have particularly demanding sanitation requirements, you might benefit from 8 or even 10 inches of clearance. However, 6 inches is the absolute minimum that must be maintained consistently across the entire shelf length and width.

Which shelf material lasts longest in sub-zero temperatures?

When it comes to longevity in freezing temperatures, stainless steel takes the crown. It maintains its structural properties and corrosion resistance across the full temperature range you'll find in walk-in freezers. While it's the most expensive option upfront, stainless steel often pays for itself through extended service life and minimal maintenance requirements.

High-quality polymer systems run a close second, with some offering lifetime warranties against rust and corrosion. Systems like MetroMax 4 perform exceptionally well in extreme cold and provide superior chemical resistance compared to coated metal alternatives. The lifetime warranty makes these systems excellent long-term investments despite higher initial costs.

Epoxy-coated wire shelving offers solid performance with 15-year warranties, making it a popular middle-ground choice. However, coating damage from thermal cycling or physical abuse can reduce lifespan. The key is selecting materials specifically rated for freezer applications and following proper installation and maintenance procedures.

The material that lasts longest for your specific application depends on your budget, usage patterns, and maintenance capabilities. Consider the total cost of ownership over the expected lifespan rather than just the upfront purchase price.

Conclusion

Getting your walk-in freezer shelving requirements right protects your business, customers, and peace of mind. You now have the roadmap to create a cold storage system that works reliably for years.

The foundation starts with NSF certification for all shelving components and mandatory 6-inch floor clearance for cleaning access. Stainless steel gives maximum durability with premium pricing. Epoxy-coated wire shelving hits the sweet spot with solid 15-year warranties and 800-pound capacity per shelf. Polymer systems offer lifetime rust protection.

Adding a fifth shelf can boost storage capacity by 25% if you maintain proper airflow. Those 3-inch gaps between products and 2-inch clearances from walls keep your refrigeration system from working overtime and your energy bills reasonable.

At American Mortuary Coolers, we've learned that cold storage challenges are similar across industries. Whether designing custom mortuary coolers for funeral homes or helping food service operators understand shelving requirements, the principles remain the same: proper materials, correct spacing, and attention to airflow.

Our Tennessee-based team delivers custom solutions across all 48 contiguous states because every facility has unique requirements, space constraints, and operational needs. Getting the shelving right from day one prevents expensive do-overs.

Ready to make the right choice for your operation? Check out our comprehensive guide for choosing a walk-in freezer supplier to ensure you're asking the right questions and getting solutions that work.

Walk-in freezer shelving requirements protect more than food safety—they protect your reputation, bottom line, and ability to serve customers consistently. Invest in proper shelving systems now to avoid middle-of-the-night calls about equipment failures or failed health inspections.

The right shelving system becomes invisible—it just works, day after day, keeping your products safe and your operation running smoothly. That's exactly what your business deserves.