Why Mobile Cremation Machines Are Essential for Modern Death Care

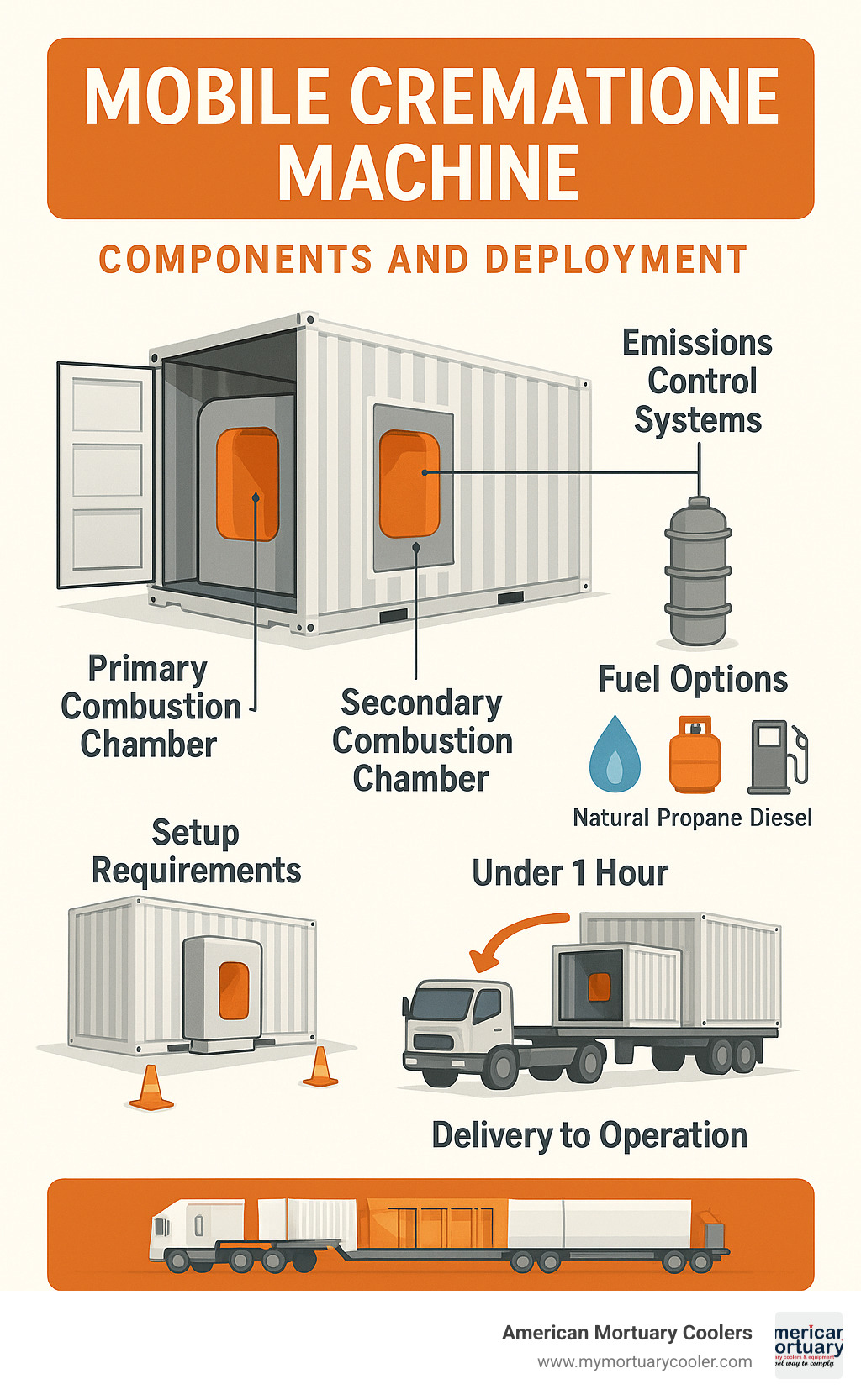

A mobile cremation machine is a complete cremation system housed in a transportable container or trailer that can be rapidly deployed wherever cremation services are needed. These self-contained units can process human remains in 35-90 minutes per cycle and be fully operational in under one hour.

Key features of mobile cremation machines:

- Container size: 20-foot or 40-foot high-cube containers

- Cycle time: 35-90 minutes per cremation

- Setup time: Less than 1 hour to full operation

- Temperature: Up to 1600°C operating temperature

- Fuel options: Natural gas, propane, or diesel

- Capacity: Primary chamber volume typically 4.2 m³

- Emissions: Multi-stage post-combustion chambers for clean operation

Recent global events have highlighted the critical need for flexible cremation capacity. The COVID-19 pandemic, natural disasters, and surge situations have pushed traditional funeral infrastructure beyond its limits. Mobile cremation machines offer funeral homes, governments, and emergency response teams the ability to provide dignified cremation services exactly where and when they're needed most.

Unlike fixed crematories that require months of construction and permanent installations, mobile units arrive ready to operate. They're being deployed everywhere from remote communities lacking cremation infrastructure to major metropolitan areas managing overflow during crisis situations.

I'm Mortuary Cooler from American Mortuary Coolers, and I've helped funeral professionals nationwide understand the technical requirements and deployment strategies for mobile cremation machine installations. My experience with mortuary equipment logistics has shown me how these portable systems are revolutionizing death care delivery across diverse operational scenarios.

Quick mobile cremation machine terms:

What Is a Mobile Cremation Machine?

Think of a mobile cremation machine as a complete funeral home crematory that's been expertly engineered to fit inside a shipping container. These aren't scaled-down versions of traditional crematories – they're full-featured cremation systems that happen to be portable.

The magic is in the containerized design. Everything you'd find in a permanent crematory gets packed into a 20-foot or 40-foot container: the primary combustion chamber, secondary treatment systems, emissions controls, fuel systems, and electrical panels. Most manufacturers use a hot-hearth design with multiple combustion stages to ensure the same quality and completeness you'd expect from any fixed installation.

What makes these units special is their independence. Traditional crematories need months of construction, permanent foundations, and complex utility hookups. A mobile cremation machine shows up ready to work – you just need a level surface and basic connections.

The engineering behind these systems is impressive. They maintain the same 1600°C operating temperatures as permanent units while meeting all the same environmental standards. The difference is that everything's been redesigned for mobility without compromising performance.

How a mobile cremation machine works

The cremation process inside a mobile cremation machine follows the same careful steps as any quality crematory, just in a more compact space. The deceased is placed in the primary combustion chamber where temperatures reach up to 1600°C – hot enough to ensure complete and dignified processing.

These units can run on natural gas, propane, or diesel depending on what's available at the deployment site. The flexibility in fuel options makes them incredibly versatile for different locations and emergency situations.

The real sophistication happens in the secondary and tertiary chambers. These handle all the emissions control and gas treatment to ensure odor-free exhaust – a critical feature when operating in populated areas or sensitive locations. The multi-stage design breaks down any harmful compounds before they leave the system.

After the cremation cycle completes, an integrated bone processor (cremulator) reduces any remaining bone fragments to the fine powder families expect. The entire process typically takes 60-90 minutes from start to finished cremains.

Key differences from fixed-site crematories

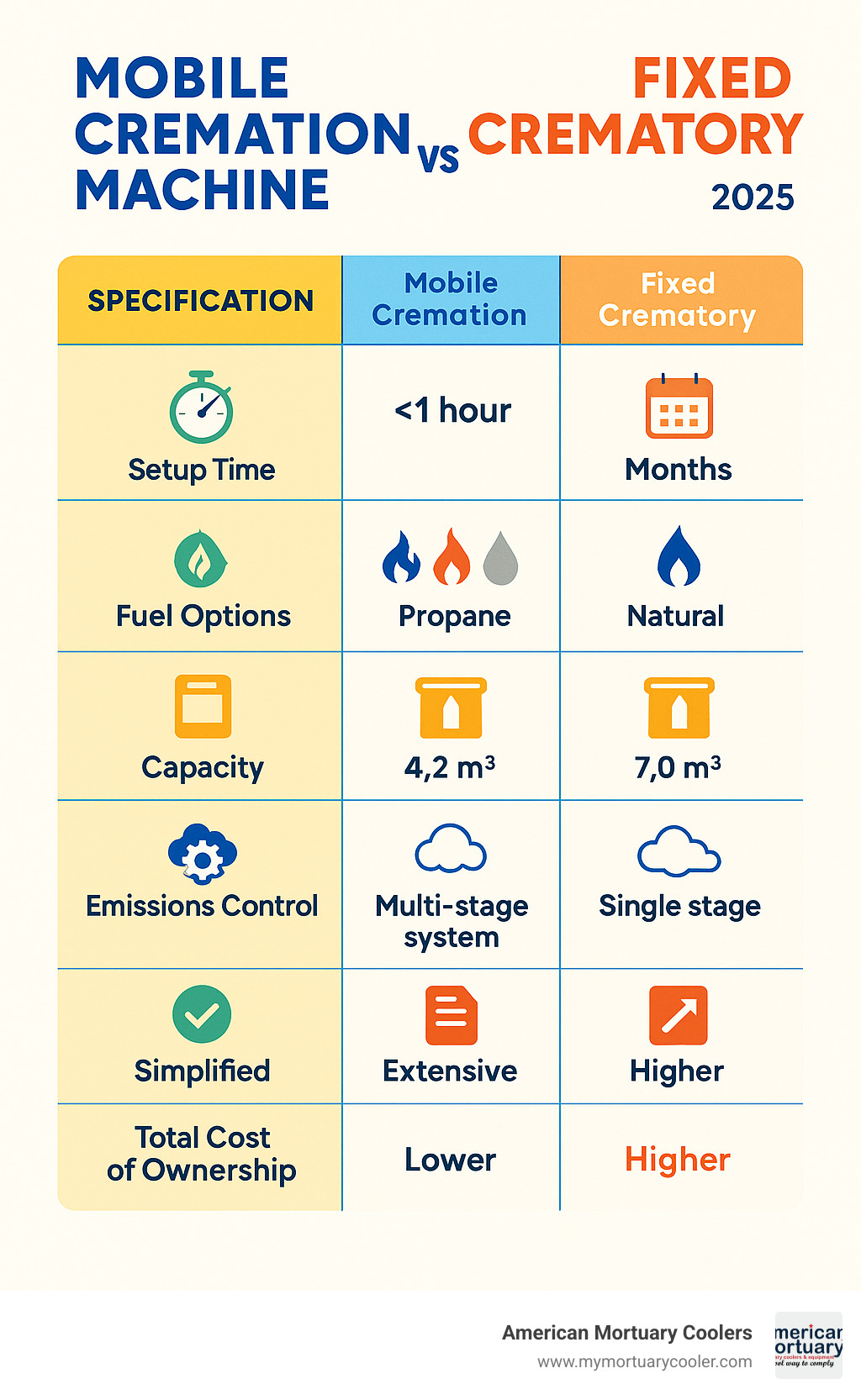

The biggest game-changer is setup time. While permanent crematories require months of construction and permitting, a mobile cremation machine can be operational in under an hour. There's no permanent stack to install – everything's self-contained within the unit.

Positioning is straightforward too. Most units can be placed using a standard forklift or crane, then connected to basic utilities. No concrete foundations, no permanent gas lines, no complex electrical installations.

The permitting process is also streamlined. Many states offer temporary permits for mobile cremation operations, especially during emergencies or for specific time periods. This flexibility has proven invaluable during the pandemic and natural disasters.

What you get is all the capability of a traditional crematory with the freedom to deploy it wherever it's needed most. For funeral homes serving large geographic areas or communities planning for surge capacity, this flexibility changes everything about how cremation services can be delivered.

Buying Considerations & Technical Specs for a Mobile Cremation Machine

Choosing the right mobile cremation machine isn't just about finding the cheapest option – it's about matching your specific operational needs with the right technical capabilities. I've seen too many funeral directors focus solely on upfront costs, only to find their unit can't handle their actual workload or deployment requirements.

Cycle time is your first major consideration, ranging from 35-90 minutes depending on unit configuration. Most commercial-grade units complete cremations in 50-70 minutes, which translates to 8-12 cremations per day during surge operations. If you're planning for emergency response scenarios, faster cycle times become critical for managing high volumes.

Fuel flexibility dramatically impacts where and how you can deploy your unit. Natural gas offers the most economical operation at roughly $15-25 per cremation, but you're limited to locations with gas line access. Propane provides excellent portability with onboard tank storage, while diesel gives you maximum deployment freedom for truly remote locations. Expect diesel consumption of 5-10 kg per cremation cycle, which adds $8-15 in fuel costs per cremation at current prices.

The primary chamber volume of 4.2 m³ is fairly standard across manufacturers, but pay attention to the secondary combustion chambers. These range from 1.13 m³ to 2.97 m³ and directly impact emissions compliance and odor control – crucial factors if you're operating near populated areas.

Modern units come standard with low-NOx burners and multi-stage scrubber systems that meet both European and EPA emission standards. The refractory lining quality varies significantly between manufacturers, so don't skimp here – cheap refractory means frequent repairs and higher long-term costs.

Electrical requirements are refreshingly simple: most units need only 230V single-phase power with total consumption under 10 kW. This means you can plug into standard industrial electrical service at most locations without special utility upgrades.

Before making your decision, I strongly recommend reviewing our comprehensive Cremation Machine Cost Breakdown: What You Need to Know guide, which covers both mobile and fixed-site financial considerations in detail.

Selecting the right mobile cremation machine

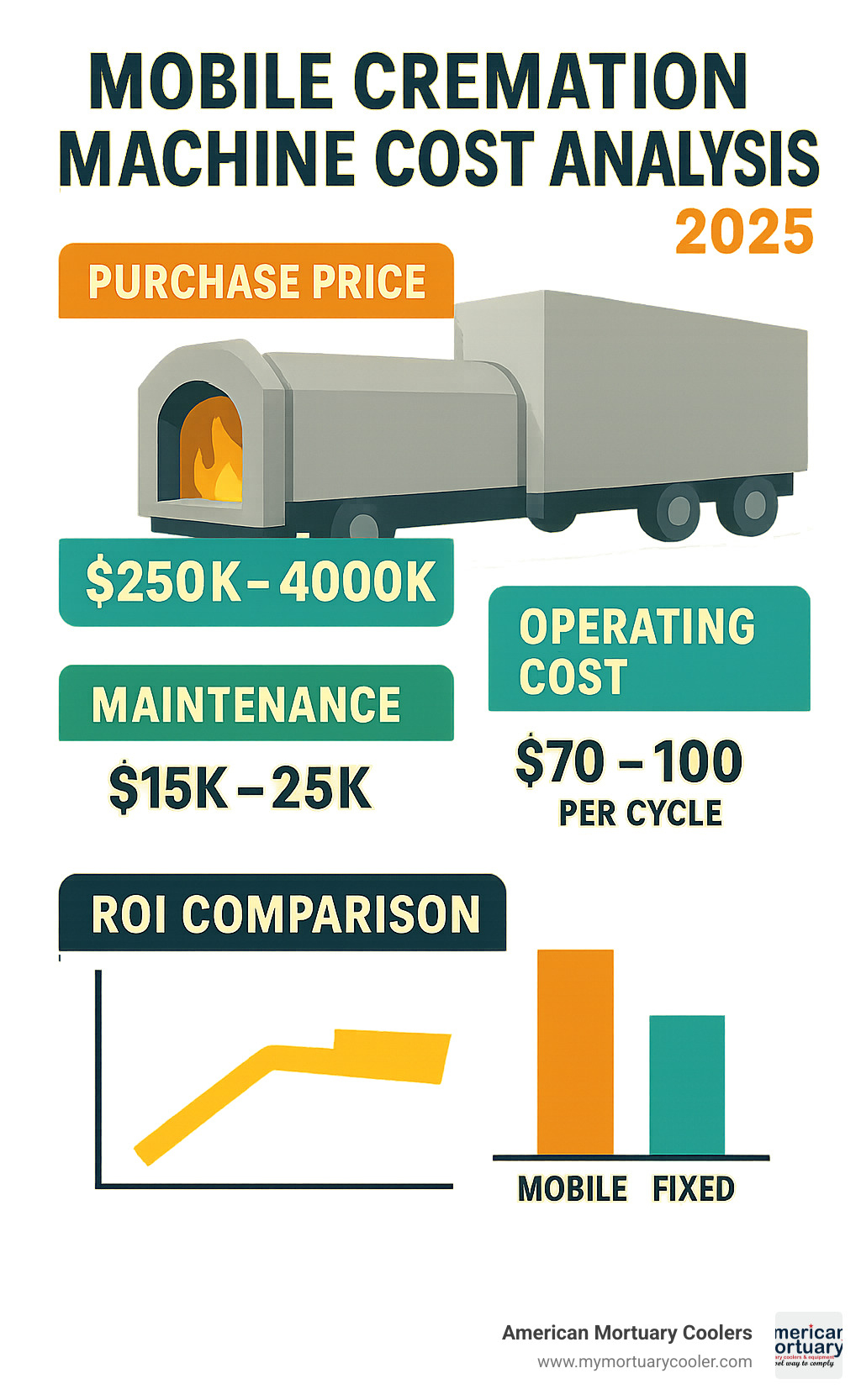

Budget versus throughput is the classic balancing act in mobile cremation equipment selection. Entry-level units start around $43,500 for basic configurations that handle occasional use, while fully-equipped containerized systems reach $300,000 or more for high-volume commercial operations.

Container size choice depends entirely on your deployment strategy. 20-foot containers offer maximum portability – they fit on standard truck chassis and can access locations where larger units simply won't fit. 40-foot units provide additional space for integrated bone processing equipment, operator comfort features, and parts storage, but you'll need specialized transport and more site preparation.

Remote monitoring capabilities have become game-changers for fleet operations. Modern systems offer cellular or satellite connectivity for real-time status monitoring, maintenance alerts, and operational data collection. If you're managing multiple units or deploying in remote areas, this technology pays for itself quickly through reduced service calls and optimized maintenance scheduling.

Look for UL listing and ISO-9001 manufacturing processes – these certifications provide assurance of quality and help streamline regulatory approval processes. For detailed emissions research and compliance documentation, manufacturers like Inciner8 provide comprehensive scientific data that's invaluable during permitting discussions.

Installation & maintenance needs

Site preparation for mobile units is wonderfully straightforward compared to fixed installations. You'll need a level 4-inch concrete pad or 6-inch asphalt surface sized for your container dimensions plus access clearances. Most units can be positioned with standard forklifts or small cranes, eliminating the need for specialized heavy equipment.

Utility connections are designed for quick setup: fuel supply hookup (natural gas line, propane tank connection, or diesel storage), standard electrical service connection, and water connection if your unit includes integrated cooling systems. The best units feature quick-connect utility interfaces that get you operational in under an hour.

Refractory inspection and replacement represents your primary maintenance concern, typically needed every 1,000-2,000 cycles depending on operating conditions and fuel type. Diesel operation tends to be harder on refractory than natural gas, so factor this into your total cost calculations.

Quarterly burner tuning ensures optimal fuel efficiency and emissions compliance – skipping this maintenance leads to higher fuel costs and potential regulatory issues. Most manufacturers provide remote diagnostic capabilities that can identify tuning needs before they become problems.

Stock a comprehensive spare parts kit including refractory bricks, burner components, temperature sensors, and control system backup modules. Given the remote deployment nature of mobile units, having critical spares readily available prevents extended downtime that could derail emergency response operations or commercial commitments.

Deployment Scenarios & Real-World Use Cases

When the COVID-19 pandemic hit, funeral homes across the country suddenly found themselves in an impossible situation. Traditional crematories were overwhelmed, and families needed dignified services for their loved ones. Mobile cremation machines became the heroes of this crisis, arriving at field hospitals and temporary morgues within hours to provide essential cremation services.

I've worked with funeral directors who had mobile units deployed to their parking lots during the worst weeks of 2020. These containerized systems kept operating around the clock, maintaining the dignity and respect every family deserves while handling volumes that would have been unthinkable just months earlier.

Natural disasters create similar challenges, but often with the added complexity of damaged infrastructure. When Hurricane Katrina devastated the Gulf Coast, traditional funeral facilities were flooded or destroyed. Mobile cremation machines proved their worth by providing essential services in disaster zones where permanent facilities couldn't operate.

The beauty of these systems really shines in remote communities. I've helped coordinate deployments to Alaskan villages, rural mountain towns, and isolated military installations where building a permanent crematory simply doesn't make economic sense. A mobile unit can serve multiple communities on a rotating schedule, bringing professional cremation services directly to families who would otherwise face long-distance transport costs.

Military camps and remote work sites represent another growing market. These locations need reliable cremation services but can't justify permanent infrastructure. The self-contained nature of mobile units makes them perfect for these specialized environments.

For funeral professionals wanting to understand more about cremation technology, our detailed guide A Practical Guide to Cremation Chambers and the Cremation Process covers the technical aspects that make these mobile systems so effective.

Disaster & emergency response advantages

The under-one-hour commissioning time is what makes mobile cremation truly for emergency response. I've seen units arrive at disaster sites and be fully operational before traditional emergency services could even complete their initial assessments. This speed isn't just impressive - it's lifesaving when public health is at stake.

Container sealing provides crucial bio-security benefits during infectious disease outbreaks. Instead of transporting potentially contaminated remains across long distances, mobile units can process them right at the source. This contained approach prevented countless exposures during COVID-19 and will be equally valuable in future health emergencies.

The odor-free operation through multi-stage post-combustion systems means these units can operate in populated areas without adding stress to already traumatized communities. Families dealing with loss don't need the additional burden of unpleasant odors or visible emissions reminding them of their grief.

Routine & commercial applications

Smart funeral home operators are finding that regional coverage strategies using mobile units can transform their business model. Instead of building multiple expensive fixed crematories, they're using mobile systems to serve wider territories while maximizing equipment utilization. One unit can serve three or four locations efficiently.

Small funeral homes are finding new opportunities through mobile unit partnerships. They can now offer complete cremation services without the massive capital investment of permanent installations. This levels the playing field and lets smaller operators compete with larger facilities.

Rental fleet operations are emerging as a specialized business model. These companies provide on-demand cremation services for facilities undergoing maintenance, temporary surge situations, or special circumstances. It's creating flexibility that simply didn't exist in the funeral industry before mobile technology matured.

Cost, Manufacturers, and Future Trends

When you're ready to invest in a mobile cremation machine, you'll find prices ranging from $43,000 for basic trailer-mounted units up to over $300,000 for fully-equipped containerized systems. This wide price range makes sense when you consider the differences in capacity, automation level, emissions control sophistication, and integrated features.

The operating costs are pretty straightforward to calculate. You're looking at 5-10 kg of diesel per hour of operation for fuel consumption. Maintenance runs about 3-5 cents per pound of remains processed, which covers everything from refractory replacement to burner maintenance and routine servicing.

There's an interesting debate happening in the industry right now about fuel versus electric cremation. Some manufacturers are exploring hybrid systems that combine traditional fuel heating with electric pre-heating. This approach can reduce overall energy consumption and emissions - something that's becoming increasingly important to funeral homes and their communities.

When it comes to manufacturers, you have several solid options to choose from. Inciner8 offers their i8-MCU system, while Matthews International brings decades of cremation expertise to their mobile units. Qingdao Yihua Environmental Protection Co. provides competitive options from overseas, and Cremsys has their MOCx modular system that takes a different approach to mobile cremation technology.

Each manufacturer has different strengths - some focus on deployment speed, others on capacity, and still others on operational features. It's worth taking time to evaluate which approach best fits your specific deployment scenarios.

For comprehensive equipment selection guidance, our article From Purchase to Pyre: Finding the Right Cremation Incinerator for Sale covers both mobile and fixed-site options to help you make the best choice.

Innovations on the horizon

The future of mobile cremation technology is getting pretty exciting. Artificial intelligence integration for burner control systems is promising improved fuel efficiency and emissions reduction through real-time combustion optimization. These smart systems actually learn from operational patterns to optimize performance automatically - kind of like having an experienced operator built right into the machine.

Hydrogen burner technology represents what could be a zero-emission future for cremation. The challenge right now is that infrastructure requirements limit practical deployment to areas with established hydrogen supply networks. But as hydrogen infrastructure expands, this could be a game-changer.

Carbon capture add-on systems are being developed to further reduce environmental impact by capturing and sequestering CO2 emissions from the cremation process. This technology is still emerging, but it shows promise for funeral homes looking to minimize their environmental footprint.

Solar pre-heating systems offer a clever way to reduce fuel consumption by using renewable energy to bring chambers to operating temperature. This is particularly valuable for installations in sunny climates with predictable solar resources - you can literally harness the sun to help with cremation operations.

Modular multi-chamber stacking is another innovation that allows single transport units to house multiple cremation chambers. This dramatically increases throughput capacity while maintaining transportability - essentially giving you more cremation power in the same footprint.

Frequently Asked Questions About Mobile Cremation Machines

When funeral directors first learn about mobile cremation machines, they often have practical questions about deployment speed, regulations, and costs. Having helped countless funeral professionals steer these decisions, I understand the importance of getting clear, straightforward answers.

The most common questions center around three key areas: how quickly these units can be up and running, what regulatory problems you'll face, and whether the economics make sense for your specific situation.

How fast can a mobile cremation machine be operational?

Here's where mobile cremation machines truly shine - you can have one fully operational in under an hour from the moment it arrives on site. That's not marketing speak; it's the reality of modern containerized design.

The process is surprisingly straightforward. A crane unloads the unit from its transport truck and positions it on your prepared concrete pad. Then it's simply a matter of connecting the plug-and-play utilities - fuel line, electrical, and water if needed. Some advanced containerized units like the i8-MCU system can be running in as little as 30 minutes with proper preparation.

The secret to hitting these rapid deployment times is advance site preparation. Having your concrete pad poured, utilities roughed in, and access routes cleared means installation happens immediately upon arrival. Modern units come with quick-connect fittings for utilities and standardized lifting points that make handling efficient and predictable.

This speed advantage becomes crucial during emergency situations when every hour counts, but it's equally valuable for routine deployments where minimizing downtime directly impacts your bottom line.

What permits and environmental controls are required?

Navigating the regulatory landscape for mobile cremation can seem daunting, but it's often more straightforward than fixed installations. Most states require air quality permits and local zoning approvals, though many jurisdictions have streamlined processes specifically for mobile units.

The regulatory focus centers on emissions control and monitoring. Your unit must demonstrate opacity levels below regulatory thresholds and maintain secondary afterburner temperatures above 850°C to ensure complete combustion of organic compounds. This is where the multi-stage post-combustion systems in modern mobile units prove their worth.

Many states offer expedited or emergency permitting for mobile cremation machines during crisis situations. These temporary permits recognize the critical need for surge capacity while maintaining environmental protection standards.

Regular stack testing and emissions monitoring requirements vary by location, but most modern mobile units are designed to exceed European emissions standards - among the world's most stringent. This over-engineering approach helps ensure compliance across different jurisdictions as you deploy the unit.

What is the total cost of ownership compared to a fixed unit?

The economics of mobile versus fixed cremation units depend heavily on your specific operational needs and usage patterns. Mobile cremation machines typically have lower initial capital costs when you factor in site preparation, construction, and permitting expenses that fixed installations require.

However, mobile units may consume slightly more fuel per cycle due to heat loss from their transportable design. This higher per-cycle operating cost is often offset by the flexibility to deploy capacity only where and when it's needed.

The real payback advantage becomes clear in surge scenarios. Instead of building permanent excess capacity that sits idle during normal periods, mobile units can be deployed temporarily when demand spikes. This approach dramatically improves return on investment for facilities with variable demand patterns.

For consistent high-volume operations, fixed installations may offer better long-term fuel efficiency. But for emergency response, multi-site coverage, or facilities needing occasional additional capacity, mobile units provide superior financial flexibility and faster payback periods.

Conclusion & Next Steps

Mobile cremation machines have fundamentally changed how we think about death care delivery. These portable systems bring dignified cremation services directly where they're needed most - whether that's a disaster zone, remote community, or overwhelmed funeral home during a crisis.

The technology has come a long way. Today's mobile units match the quality and environmental standards of permanent installations while offering something fixed crematories simply can't: the ability to be operational anywhere within an hour.

I've seen how these systems solve real problems for funeral professionals. During the pandemic, facilities that had mobile units could quickly expand capacity without the months-long construction timelines of traditional crematories. For rural funeral homes, mobile units mean they can finally offer cremation services without the massive capital investment of a permanent facility.

At American Mortuary Coolers, we've been helping funeral professionals across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania understand how mobile cremation fits into their broader equipment needs. Our experience with mortuary cooling systems gives us unique insight into how these portable cremation units work alongside comprehensive death care workflows.

The logistics matter as much as the technology itself. That's why we offer one-stop logistics support for funeral professionals considering mobile cremation solutions. We can coordinate delivery and setup of cooling systems alongside mobile cremation units, ensuring your entire remains handling process works seamlessly together.

Our direct delivery capability across all 48 contiguous states means your mobile cremation unit arrives ready for immediate deployment. No complicated shipping arrangements or multiple vendors to coordinate - just the equipment you need, when you need it.

Whether you're planning for surge capacity during emergencies, expanding into underserved markets, or simply want more operational flexibility, mobile cremation machines offer proven solutions. The future of death care is becoming more responsive to community needs, and mobile units are leading that change.

For complete funeral service operations that integrate mobile cremation with lifting equipment and other essential systems, check out our comprehensive guide to Crematory Lifts & Mortuary Equipment. This resource shows how all the pieces fit together for efficient, dignified death care.

Ready to explore how mobile cremation solutions can work with your existing mortuary cooling and handling systems? Contact our team to discuss complete death care logistics planning custom to your specific needs and service area.