Understanding Roller Decks: A Comprehensive Guide

Roller decks are multi-directional platforms fitted with cylindrical rollers that facilitate the movement of heavy objects across surfaces with minimal effort. They're commonly used in three main applications:

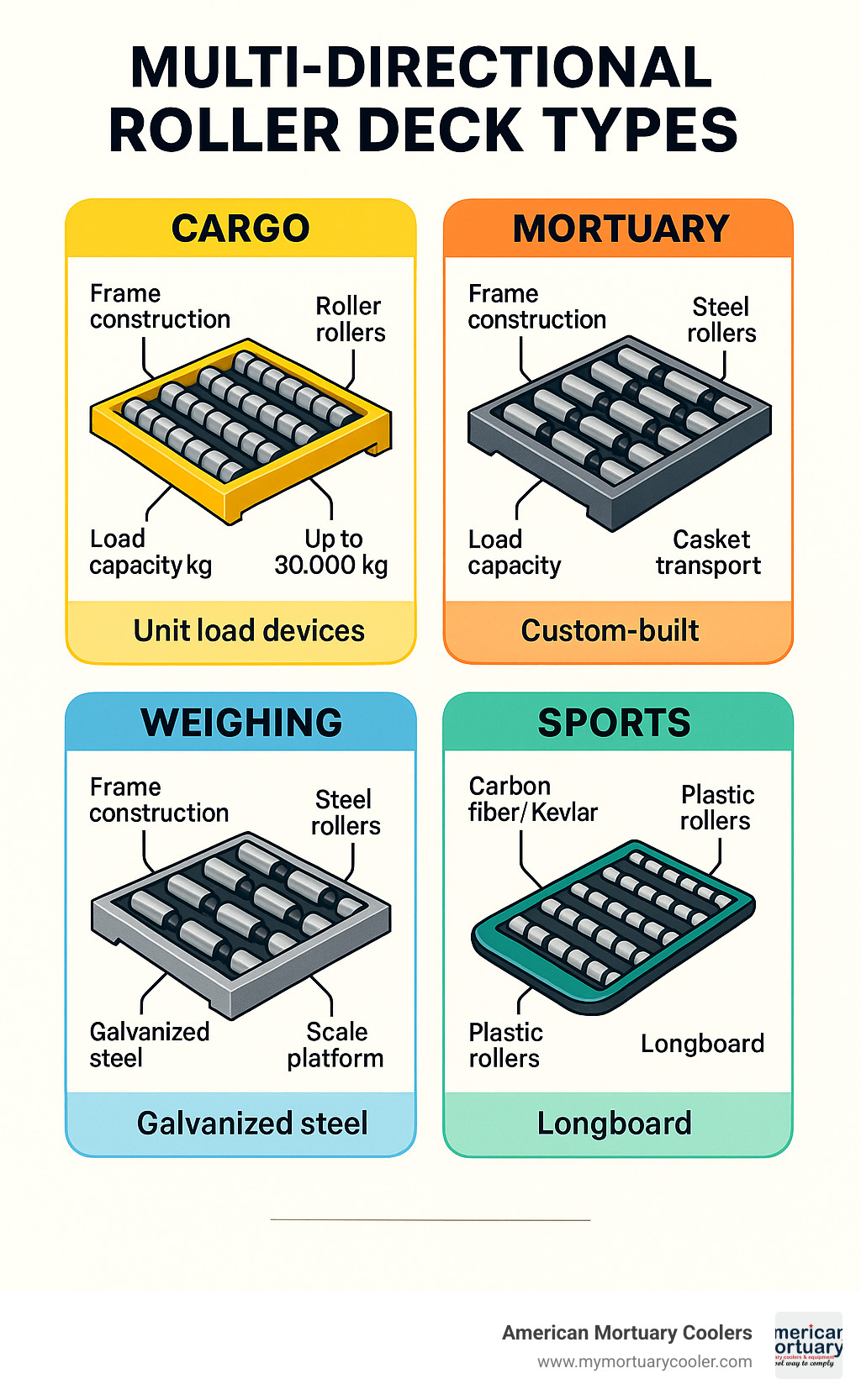

| Type | Primary Use | Key Feature |

|---|---|---|

| Cargo/Logistics | Moving Unit Load Devices (ULDs) | Multi-directional movement |

| Mortuary | Transporting caskets in vehicles | Custom-built to specifications |

| Industrial | Weighing platform attachments | Galvanized steel construction |

| Recreational | High-performance longboards | Carbon fiber/Kevlar construction |

Roller decks transform the way heavy items move in various industries by replacing manual lifting with smooth rolling transfer. From airport cargo facilities where they handle shipping containers to funeral homes where they assist with dignified casket transport, these specialized platforms significantly reduce physical strain while improving operational efficiency.

The concept is brilliantly simple yet effective: a frame fitted with parallel rollers allows objects to glide across surfaces with minimal friction. Modern designs feature galvanized steel construction for durability, with many industrial models supporting tensile loads exceeding 30,000kg while maintaining relatively light chassis weights.

Note: Don't confuse roller decks with Rolodex, the rotating card file device for contact management that became popular in the mid-20th century.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience implementing roller decks in funeral home settings to improve handling efficiency and staff safety. My work with roller decks has focused on creating custom solutions that seamlessly integrate with existing mortuary transport and storage systems.

What Is a Roller Deck? Origins, Definitions & Primary Uses

A roller deck is a specialized platform equipped with cylindrical rollers arranged in parallel rows that enable the smooth, low-friction movement of heavy objects. These clever devices first appeared in material handling applications, where workers needed efficient ways to move heavy loads without powered equipment.

The science behind roller decks is beautifully simple: they replace sliding friction with rolling friction, dramatically reducing the force needed to move heavy items. This ingenious design allows a single person to easily maneuver objects that would otherwise require several people or mechanical help.

Industrial roller decks first became popular in warehouses and factories during the mid-20th century, but the concept has since found homes in numerous industries. Today, you'll spot roller decks helping move cargo at airports, assisting with dignified transport in mortuaries, supporting manufacturing operations, and even appearing in recreational uses like specialized skateboards.

"When we install custom roller decks in mortuary vehicles, we're continuing a long tradition of using simple mechanical advantage to solve complex handling problems," explains our lead fabricator at American Mortuary Coolers. "The same principles that make these systems work in cargo applications translate perfectly to the dignified transport of caskets."

The roller decks concept from warehouses to morgues

The evolution of roller decks from warehouse staples to specialized applications like mortuary transport shows how good ideas naturally find new purposes. In warehouses, these systems make moving palletized goods and shipping containers across staging areas almost effortless.

The aviation industry acceptd roller decks for handling Unit Load Devices (ULDs) – those standardized containers and pallets used for aircraft freight, mail, and baggage. These cargo containers need smooth, controlled movement during loading and unloading, making roller decks the perfect match.

The mortuary industry adopted this technology to address the unique challenges of casket handling. At American Mortuary Coolers, we've witnessed how these systems transform operations in funeral homes throughout Tennessee and beyond. Integrating roller decks into mortuary cooler racks has revolutionized body storage and handling, creating safer working conditions and more dignified care processes.

Our mortuary racks for walk-in body coolers use roller deck principles to enable smooth transfer of remains from transport gurneys to storage positions. This thoughtful design minimizes physical strain on staff while ensuring respectful handling of the deceased – something we take very seriously.

When a Rolodex isn't a Roller Deck: clearing the confusion

Let's clear up a common mix-up: despite the similar-sounding names, a Rolodex is completely different from a roller deck. The Rolodex, invented in 1956 by Danish engineer Hildaur Neilsen, is a rotating card file device used to store contact information. Its clever name combines "rolling" and "index," and it became so common in offices that people used "Rolodex" for any rotating contact file – kind of like how people say "Kleenex" for any tissue.

The Rolodex became such a cultural icon that it's now displayed in the Smithsonian. In business language, someone's "Rolodex" came to represent their professional network – executives with "powerful Rolodexes" were those with valuable business connections.

Interestingly, in small-world network theory (the academic study of how people connect), researchers have used the concept of a Rolodex to describe the valuable connections linking board members and executives across companies. This usage highlights the value of professional relationships – something completely different from the physical handling capabilities of roller decks.

The Wikimedia Commons has a wonderful collection of Rolodex images showing how this office classic evolved over time, standing in stark contrast to the industrial utility of modern roller decks that we use in our mortuary equipment.

Roller Decks by Industry: Cargo, Mortuary, Sports & More

Roller decks have found their way into all sorts of industries, each with their own special twist on this simple but clever invention. It's amazing how one basic concept – rollers on a platform – can solve so many different challenges across such diverse fields.

Cargo & Airport roller decks

If you've ever watched airport ground crews handling those massive cargo containers, you've seen roller decks in action. These workhorses of the aviation world make moving Unit Load Devices (ULDs) look almost effortless, despite their enormous weight.

Companies like Talos have perfected these systems for aviation needs. What makes airport roller decks special is their multi-directional movement capability – cargo handlers can easily change the direction of those massive containers without needing to lift them. This is a game-changer in tight airport spaces where precision matters.

The numbers tell the story of how crucial these systems are: Talos maintains an inventory of over 5,000 OEM parts for their caster and roller deck systems, with 95% of orders shipping within 24 hours. When planes need to be loaded and unloaded on tight schedules, every minute counts.

Most airport roller decks are built from galvanized steel that stands up to weather and constant use. They're designed with standardized dimensions to ensure they play nicely with aircraft loading systems – because when you're loading a 747, there's no room for misalignment.

Mortuary & Funeral roller decks

In our work at American Mortuary Coolers, we've seen how roller decks have transformed funeral operations. The challenges in this industry are unique – dignity and respect are paramount, but staff safety is equally important.

Vehicle roller beds are one of our most requested items. These specialized roller decks install in hearses and other funeral vehicles to make casket handling smoother and safer. What makes these systems special are thoughtful features like flip-out carpet sections that protect vehicle bumpers, adjustable bier pins that keep caskets secure during transport, and removable roller assemblies that let funeral directors reconfigure their vehicles as needed.

Our mortuary cooler systems also incorporate roller deck technology in clever ways. As we explain in our tug for racks guide, these systems make it possible for staff to move deceased loved ones with dignity and minimal physical strain.

"Before we installed roller decks, it took three of us to safely move remains from the preparation room to storage," one funeral director told us recently. "Now one person can handle it safely. It's better for our staff and more dignified for families."

Sports & Recreation roller decks (longboard)

In perhaps the most surprising application, roller deck engineering has revolutionized longboard skateboarding. The same principles that help move cargo containers have been adapted to create high-performance boards for distance riding and downhill speed.

The Sportster model is what longboard enthusiasts call "legendary" – and for good reason. Its carbon fiber construction creates an incredible strength-to-weight ratio that would impress any engineer. We're talking about a recreational roller deck that weighs just 1,100g but can handle tensile loads exceeding 30,000kg!

The innovations here are impressive: Hybridweave Carbon/Kevlar sandwich construction provides strength and abrasion resistance, while deep deck spaces under the axle pivot allow for larger wheels. Some models feature fender-enclosed wheels that keep debris out and improve safety at high speeds.

The Sportster has smashed multiple world records for long-distance riding, while the beautifully crafted Woody model earned the prestigious Red Dot Design Award. It's a perfect example of how roller deck principles can be reimagined for completely different purposes – from moving cargo containers to breaking skateboarding records.

At American Mortuary Coolers, we may not be building record-breaking skateboards, but we apply the same innovative thinking to our mortuary roller deck systems. Whether it's helping funeral homes improve efficiency or creating custom solutions for unique challenges, we're proud to be part of this versatile technology's evolution.

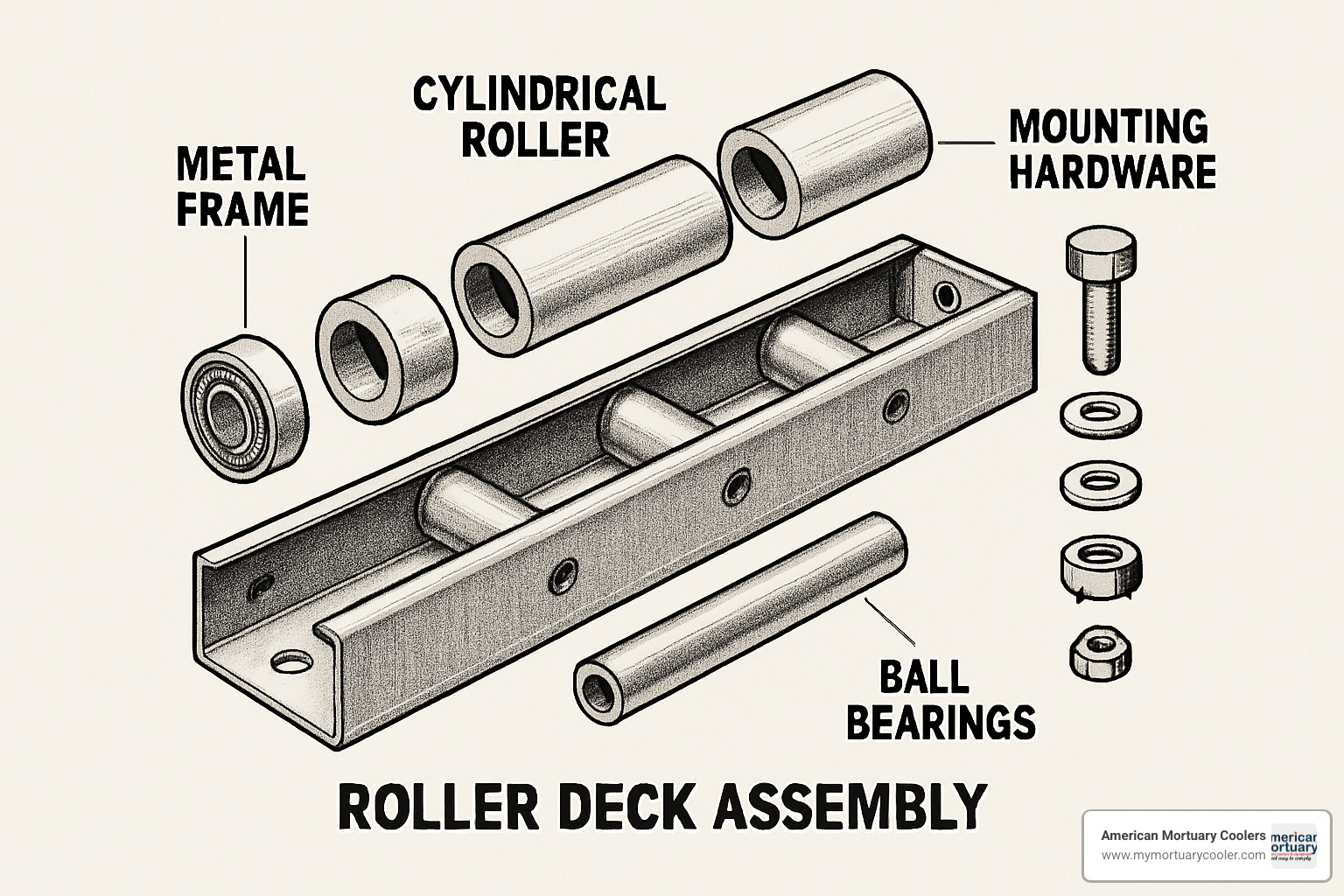

Anatomy of Modern Roller Decks: Components, Materials & Specs

Let's peek under the hood of modern roller decks and see what makes these workhorses tick. After decades of tweaking and improving, today's designs blend strength, durability, and smart engineering to create platforms that make moving heavy objects feel almost effortless.

When you look at any roller deck, you'll notice five essential parts working together. The frame provides the backbone, supporting everything else while distributing weight evenly. The roller assemblies do the actual work of creating smooth movement, while high-quality bearings inside those rollers ensure they spin freely with minimal resistance. Safety features like stops and non-skid surfaces protect both operators and cargo, and finally, mounting hardware secures the deck to vehicles, scales, or other equipment.

"The beauty of a well-designed roller deck is how these simple components work together," explains our lead technician at American Mortuary Coolers. "It's not rocket science, but when engineered correctly, these systems make previously difficult tasks remarkably easy."

Materials matter tremendously in roller deck performance. Galvanized steel remains the gold standard for industrial and cargo applications, offering excellent corrosion resistance and durability in tough environments. For specialized uses like high-performance sports decks, carbon fiber delivers an incredible strength-to-weight ratio. When abrasion resistance is critical, Kevlar components provide outstanding durability. In food handling or medical settings, stainless steel offers easy cleaning and chemical resistance, while some recreational decks use 3-D plywood for natural flex and visual appeal.

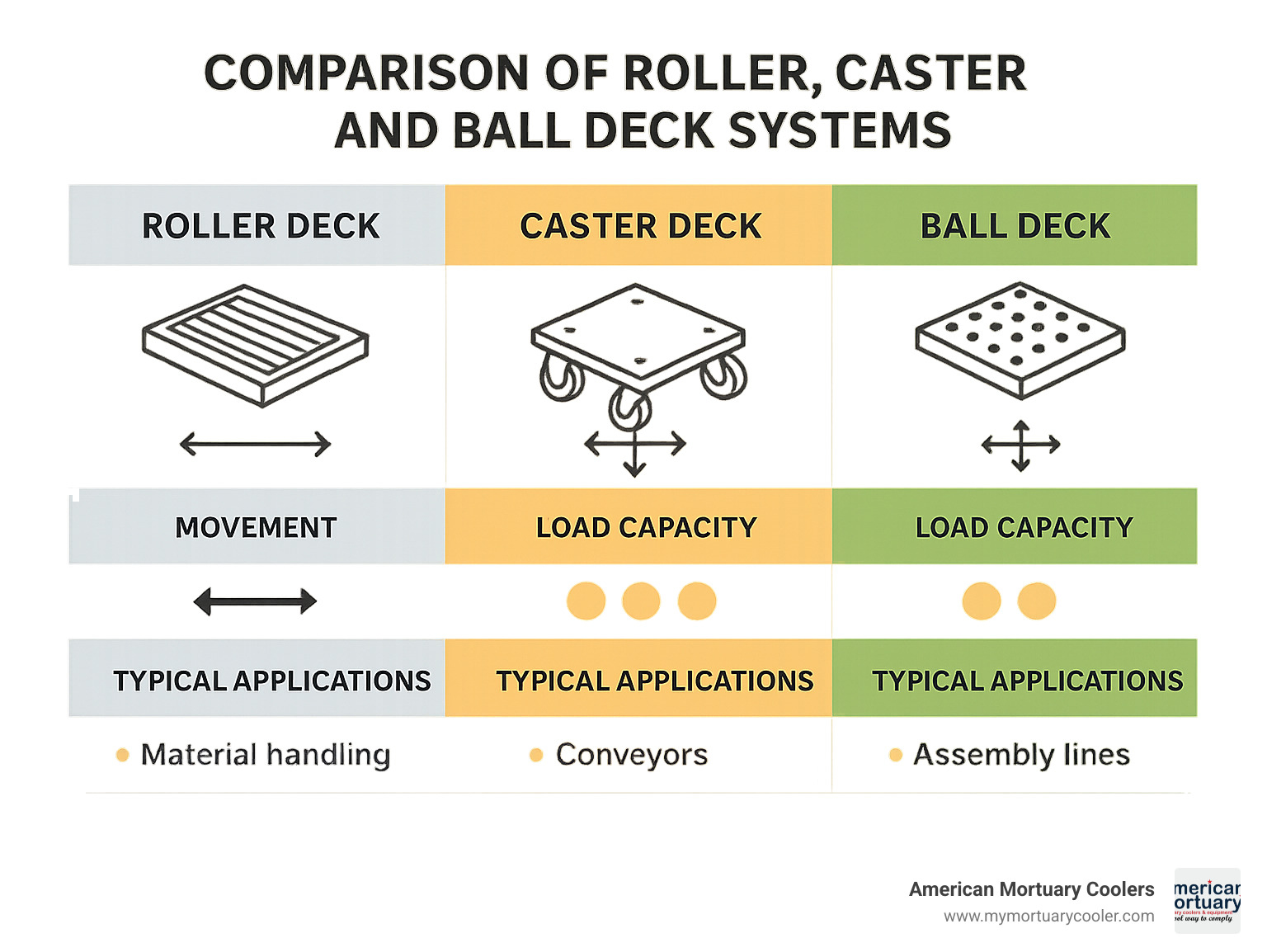

People often confuse roller, caster, and ball decks – understandably so! While they share similar purposes, they function differently. Our comparison chart helps clarify:

Typical roller decks dimensions & load ratings

When it comes to sizing, roller decks typically follow standardized dimensions to ensure compatibility with existing equipment. For weighing applications, you'll commonly find decks measuring 31.5" × 23.6", 19.7" × 15.7", or 15.7" × 11.8" – perfectly sized to work with popular bench and floor scales like ABK, AFK, BCT, and others.

The strength of these platforms might surprise you. Industrial roller decks crafted from galvanized steel can handle tensile loads exceeding 30,000kg while maintaining remarkably light chassis weights around 1,100g for high-performance models. This impressive strength-to-weight ratio comes from thoughtful engineering and material selection.

In our mortuary work at American Mortuary Coolers, we take a different approach. Rather than off-the-shelf solutions, we custom-build roller decks to match exact vehicle interiors and casket dimensions. These systems prioritize smooth, dignified transport and ease of use for funeral professionals.

"I remember designing a custom roller deck for a funeral home with unique vehicle dimensions," shares our design specialist. "The director had struggled for years with an ill-fitting system. When we installed the custom solution, he actually got emotional seeing how perfectly it integrated with his vehicles. That's when you know you've solved a real problem."

Key components every roller deck shares

Despite their differences, all roller decks share fundamental components that make them work:

The rollers themselves might be made from hard rubber, polyurethane, or metal, depending on the application. These cylindrical components are precisely spaced to support loads evenly while allowing smooth movement in the desired direction.

Inside those rollers, bearings do the crucial work of reducing friction. Most industrial roller decks use sealed ball bearings that need minimal maintenance while providing years of reliable service. The quality of these bearings often determines how smoothly a system will operate over time.

The frame structure ties everything together, providing rigidity and load-bearing capacity. In most industrial applications, galvanized steel offers the ideal balance of strength and weight, though specialized applications might use aluminum or even carbon fiber composites.

Safety features vary by application but might include non-skid walking surfaces to prevent operator slips, stops or guards to control movement, locking mechanisms to secure loads during transport, and protective elements like the flip-out carpet sections we use in our mortuary applications to protect both vehicles and caskets.

The mounting systems connect the roller deck to whatever it's installed on. Some simply sit on weighing platforms, while others – like our vehicle systems – use either permanent or removable mounting hardware depending on the customer's needs.

At American Mortuary Coolers, we've spent years perfecting these components for mortuary applications, creating systems that integrate seamlessly with funeral vehicles and storage facilities while maintaining the dignified atmosphere essential to funeral services.

Benefits, Safety & Innovations of Roller Decks

When I talk with funeral directors about why they love their roller decks, their faces light up as they describe how these simple platforms have transformed their daily operations. It's not just about moving heavy things more easily—though that's certainly a major plus—it's about creating dignity in the handling process while keeping staff safe and operations smooth.

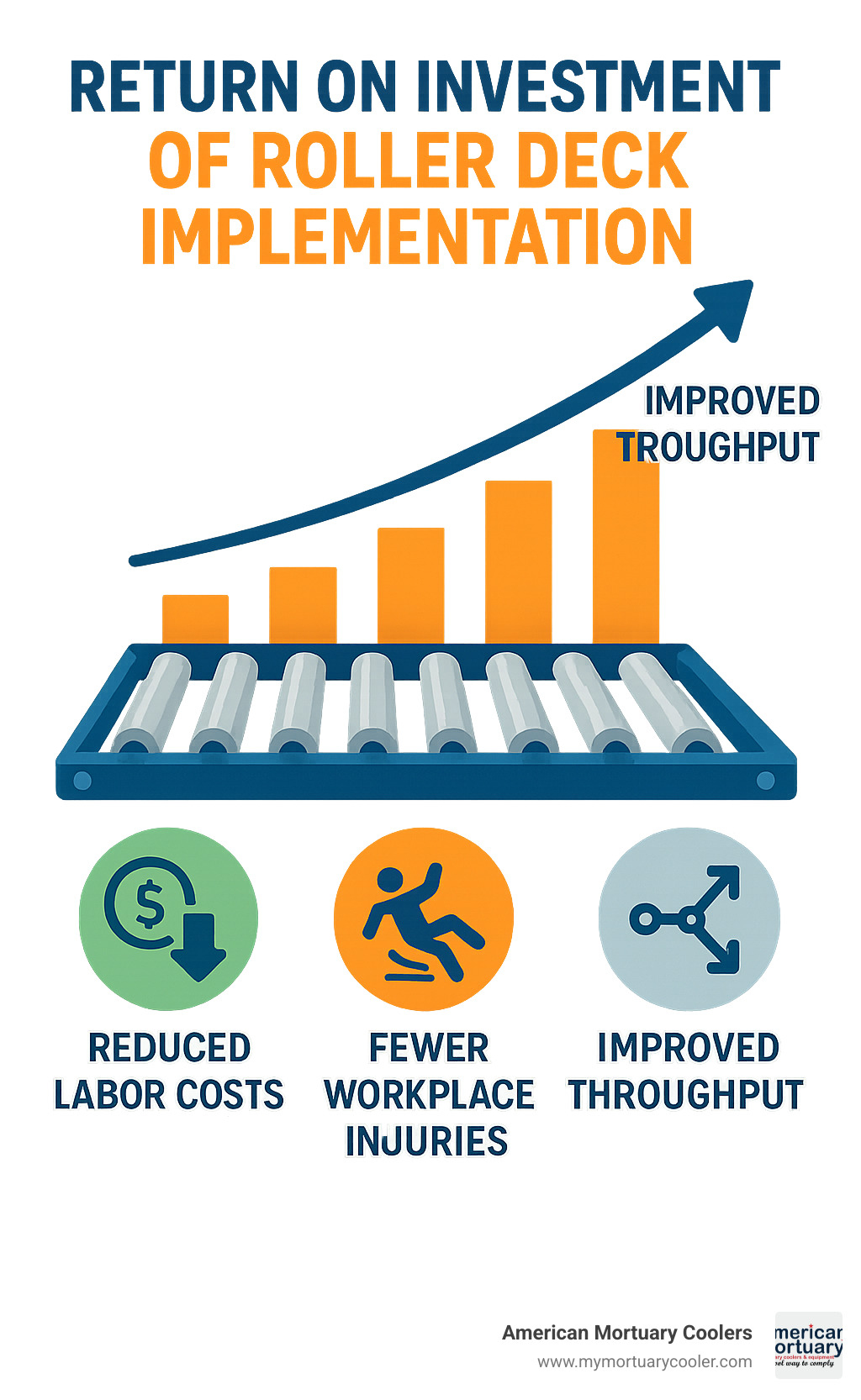

How roller decks improve efficiency & safety

The beauty of roller decks lies in how they transform physically demanding tasks into manageable ones. Instead of three staff members struggling to maneuver a casket into a hearse, a single person can now guide it smoothly with minimal effort. This reduction in manual handling isn't just convenient—it's preventing the back injuries and strains that have long plagued funeral service professionals.

"Before we installed roller decks in our removal vehicles, we were constantly worried about staff injuries," shares one of our Tennessee funeral home customers. "Now, our team can focus on providing compassionate care instead of worrying about the physical demands of casket handling."

The multi-directional movement capability of modern roller decks means you're not limited to moving in straight lines. This proves invaluable in tight spaces like cooler rooms or when maneuvering around corners in hallways. Items glide effortlessly in any direction needed, eliminating awkward lifting and repositioning that often leads to accidents.

For busy funeral homes, the efficiency gains translate directly to better service. When transfers between vehicles, preparation rooms, and visitation spaces happen smoothly, everything stays on schedule. Families notice this seamless operation, even if they don't realize the roller decks working quietly behind the scenes are what make it possible.

Most quality roller decks come with a 2-year warranty—a testament to their durability and the manufacturers' confidence in their products. When properly maintained, these systems provide dependable performance for years of continuous use, making them a wise investment for any funeral operation.

Breakthrough designs to watch

The world of roller decks is surprisingly innovative, with new materials and designs constantly pushing the boundaries of what's possible. Some of the most exciting developments we're watching include:

Hybrid composite construction is revolutionizing how roller decks are built. By combining carbon fiber with Kevlar, manufacturers create platforms that are incredibly strong yet lightweight. These materials resist corrosion and stand up to harsh cleaning chemicals—a major advantage in mortuary settings where sanitation is paramount.

I recently toured a facility that installed roller decks with integrated weighing systems. This clever innovation allows funeral homes to discreetly confirm weights during transfers without additional handling steps. The scales seamlessly integrate with the roller deck surface, maintaining dignity throughout the process while ensuring proper equipment selection.

The recreational longboard industry has become an unexpected source of roller deck innovation. The Sportster world record design, with its fender-enclosed wheels and deep drop deck, has influenced how we think about platform stability and movement control. We've adapted similar principles to create more stable transfer systems for our mortuary customers.

"We're constantly borrowing good ideas from other industries," explains our head fabricator at American Mortuary Coolers. "When we saw how the waste management sector was using the RolliSkate system to move heavy containers, we immediately recognized applications for mortuary transport. That cross-pollination of ideas drives our innovation."

Bracket platform designs represent another breakthrough worth watching. By separating the support structure from the rolling surface, these systems maximize usable space while minimizing overall dimensions. For mortuary vehicles where every inch counts, this approach allows us to create custom roller decks that perfectly fit specific vehicle interiors without sacrificing functionality.

At American Mortuary Coolers, we're particularly excited about integrating these innovations into our custom solutions. Each advance in materials and design helps us create roller decks that better serve funeral professionals, making their challenging work a little easier while maintaining the dignity that families deserve.

Buyer's Checklist & Top Rolodex Alternatives

Ready to invest in a roller deck system? Let's walk through what you need to consider before making your purchase. I've helped dozens of funeral homes select the right equipment, and I've found that a little preparation goes a long way toward ensuring you get exactly what you need.

Choosing the right roller deck for your application

Finding the perfect roller deck is like choosing a good pair of shoes – it needs to fit just right and handle your specific needs. Start by carefully assessing your load requirements. I always recommend selecting a system rated at least 25% above your maximum anticipated weight. This built-in safety margin ensures your equipment will perform reliably even under occasional stress.

Space constraints matter tremendously, especially in vehicle installations. One funeral director I worked with in Nashville learned this lesson the hard way when his custom roller deck was off by just two inches – making installation impossible without vehicle modifications. Take precise measurements and consider any access limitations that might affect installation or operation.

The materials used in your roller deck should match your working environment. Most of our funeral home customers prefer galvanized steel for its excellent durability and professional appearance. However, if you're working in environments where sanitation is paramount, stainless steel offers better resistance to cleaning chemicals. For specialized applications where weight is a concern, composite materials provide an excellent strength-to-weight ratio.

Consider how you'll actually move items on your roller deck. Some operations need multi-directional movement for precise positioning, while others prioritize stability in a single direction. Our mortuary roller beds can be customized to provide exactly the right balance for your specific needs.

Speaking of customization – don't settle for off-the-shelf solutions if they don't meet your exact requirements. At American Mortuary Coolers, we build mortuary roller beds in any size, shape, color, or special construction to fit your exact specifications. One Tennessee funeral home even requested a custom burgundy finish to match their fleet of vehicles – a small detail that made a big difference in the professional presentation.

When timing matters, work with vendors who can deliver quickly. The best suppliers maintain large inventories (over 5,000 critical OEM parts) with impressive shipping capabilities – 95% of orders shipping within 24 hours means you won't be left waiting when you need equipment.

For more information about how roller deck technology integrates with broader mortuary storage systems, check out our guide to morgue storage options. It'll help you see the bigger picture of how these components work together.

Maintenance, service & training essentials

Even the best roller deck needs proper care to deliver years of reliable service. Think of maintenance like dental checkups – regular attention prevents painful problems down the road.

Establish a regular maintenance schedule to inspect rollers, bearings, and structural components. Small issues can become big problems if left unaddressed. One of our Mississippi clients noticed slight binding in one corner of their roller deck during routine inspection – catching a failing bearing before it caused a major failure during a service.

When parts do need replacement, always use genuine OEM components. I've seen how aftermarket parts can compromise performance and safety. The small savings isn't worth the risk, especially in our industry where dignity and reliability are paramount.

For critical applications, choose vendors offering round-the-clock support. At American Mortuary Coolers, we understand that funeral services don't follow a 9-to-5 schedule, which is why we provide 24/7 technical assistance. When a funeral home in Arkansas experienced an issue with their roller deck on a Saturday evening, our team walked them through a simple adjustment that had them back in service within an hour.

Training is absolutely essential – not just for safety, but for getting the most from your investment. We always provide hands-on training for funeral home staff, covering proper loading techniques, weight distribution principles, and basic maintenance procedures. The confidence this builds is invaluable during services when everything needs to work flawlessly.

Keep detailed records of your equipment, including model information, maintenance history, and manufacturer contacts. This simple step saves tremendous time and frustration when service or parts are needed. We provide a maintenance log with all our installations to make this easy.

Rolodex alternatives for modern contact management

While we're focused on roller decks, I should clear up a common confusion. Despite the similar name, a Rolodex is something entirely different – it's that rotating contact file device that was a fixture on office desks for decades.

Today's businesses have largely moved beyond physical Rolodex devices to digital solutions. Modern Customer Relationship Management (CRM) platforms like Salesforce, HubSpot, and Zoho CRM have revolutionized how businesses manage contacts. These sophisticated systems don't just store names and numbers – they track interactions, manage sales processes, and facilitate team collaboration.

For those who appreciate the simplicity of the original Rolodex, several digital applications mimic its straightforward approach to contact organization. These "digital Rolodex" apps maintain the ease of use while adding modern conveniences like cloud syncing and mobile access.

In executive circles, specialized board network systems now track and analyze connections between board members across companies. This formalizes what was once represented by an executive's personal Rolodex. Fascinating academic research like The Price of a CEO's Rolodex examines how these professional networks influence corporate governance and executive compensation.

As I often tell our clients, the transition from physical Rolodex to digital contact management parallels what we've seen in material handling – from manual processes to engineered solutions like roller decks. The fundamental needs remain the same, but the tools have become more sophisticated and efficient, saving time and reducing physical strain.

Frequently Asked Questions about Roller Decks

What's the difference between roller, caster and ball decks?

When folks ask me about roller decks versus other material handling systems, I like to explain it in simple terms. Think of them as cousins in the same family - related but with different personalities and strengths!

Roller decks feature those parallel cylindrical rollers we've been discussing throughout this guide. They're excellent for moving heavy loads in a controlled, primarily linear direction. Picture those rollers all lined up, helping caskets glide smoothly into a hearse or cargo containers moving efficiently through an airport terminal. Some of our more advanced designs allow you to change the roller orientation, giving you movement in different directions when needed.

Caster decks take a different approach. They use swivel casters (wheels in frames that rotate completely) to enable movement in any direction. While they offer fantastic flexibility, they sometimes sacrifice a bit of stability when handling particularly heavy loads. I've seen funeral homes choose these for specific applications where maneuverability trumps raw strength.

Ball decks are the precision instruments of the family. They use ball transfer units - essentially bearings mounted in cups - creating a surface where items can effortlessly glide in any direction. They're wonderful for precise positioning but typically can't handle the heavier loads that roller decks manage with ease.

Choosing between these systems really comes down to what matters most in your specific situation: load capacity, directional control, or maximum flexibility.

How often should roller decks be serviced?

Taking care of your roller decks isn't complicated, but it does require some attention to ensure they continue performing at their best. In my years working with funeral homes across Tennessee, I've found that a simple maintenance schedule keeps these systems running smoothly for years.

For busy funeral homes with roller decks in constant use, I recommend a quick visual inspection weekly. Just take a moment to look over the rollers, bearings, and frame for any signs of wear or damage. For lighter-use environments, monthly checks should suffice.

More thorough preventive maintenance should happen every 6-12 months, depending on how heavily you use the system. This is when you'll want a qualified technician to lubricate bearings, check all mounting hardware, and assess how the rollers are holding up. At American Mortuary Coolers, we typically recommend quarterly service checks for mortuary vehicle roller beds that see frequent use, with a more comprehensive annual maintenance to maximize their lifespan.

Rather than replacing components on a fixed schedule, I suggest watching for the signs that something needs attention: unusual noise during operation, visible wear on the rollers, or inconsistent rolling performance. And of course, if your roller deck experiences any unusual stress or impact, it's worth doing a thorough inspection regardless of when maintenance was last performed.

Taking these simple steps will keep your roller deck performing reliably when you need it most – which in our industry, is every single day.

Can roller decks be retrofitted to existing equipment?

"Can I add a roller deck to my existing equipment?" is one of the most common questions I hear from funeral directors looking to improve their operations without replacing entire systems. The good news is that yes, in most cases, roller decks can be successfully retrofitted to your current setup.

Before jumping into a retrofit project, there are a few important considerations to keep in mind. First, take a close look at your existing equipment to ensure it has suitable mounting points for the roller deck system. Sometimes we need to create custom adapter brackets, but in my experience, there's almost always a way to make it work.

Weight and space constraints matter too. Your existing equipment needs to accommodate both the physical dimensions and the additional weight of the roller deck without compromising structural integrity. This is especially important in vehicle applications, where weight distribution affects handling.

I always remind customers to think about how the retrofitted system will integrate with their current workflows. Sometimes a small adjustment in process can make a big difference in efficiency. We typically provide training for staff to ensure everyone can take full advantage of the new capabilities.

For mortuary transport specifically, any retrofitted systems must comply with relevant regulations and industry standards. At American Mortuary Coolers, we're well-versed in these requirements and design our custom solutions accordingly.

The process is often straightforward for weighing applications, as our roller decks are designed to fit directly onto compatible bench and floor scales. For mortuary vehicles, we create custom-designed roller beds that can be installed in existing hearses or transport vehicles, typically with minimal modification to the vehicle interior.

I recently worked with a family-owned funeral home that added our roller deck system to their five-year-old transport vehicle, and the director told me it was like getting a brand new vehicle at a fraction of the cost. These kinds of retrofits not only improve functionality but can significantly extend the useful life of your existing equipment.

Conclusion

Roller decks are one of those brilliant inventions that make you wonder how we managed before they came along. They take a simple idea – replacing sliding with rolling – and turn it into solutions that make work easier across so many different industries.

At American Mortuary Coolers, we've acceptd roller deck technology as a cornerstone of our offerings to funeral homes. Our custom-built mortuary roller beds aren't just pieces of equipment – they're thoughtfully designed tools that help funeral directors provide dignified care while protecting their own wellbeing.

"The right equipment makes all the difference in our profession," one of our long-time customers told me recently. "These roller decks have saved my back and improved how smoothly we can serve families during difficult times."

Being based in Tennessee gives us a central location to serve funeral homes across all 48 contiguous states. Whether you're in a small-town funeral home in Johnson City or managing a busy operation in Chicago, we deliver custom solutions that fit your specific space and needs.

What I find fascinating about roller deck technology is how it continues to evolve. The same basic principle works across such different applications – from the heavy-duty galvanized steel decks moving cargo containers at airports to the sophisticated carbon fiber/Kevlar composites in high-performance longboards. Each represents engineering that solves real-world challenges with neat simplicity.

Our team takes pride in staying current with these innovations, incorporating the best materials and designs into our mortuary solutions. After all, funeral professionals deserve equipment that's as dedicated to excellence as they are.

I invite you to learn more about our custom mortuary solutions, including our specialized roller deck systems for transport vehicles and cooler storage, by visiting our one-stop shop for mortuary coolers. We're always happy to discuss how we can create the perfect roller deck solution for your funeral home's unique requirements.

In an industry centered on providing comfort during difficult times, having the right equipment isn't just about efficiency – it's about creating the space for you to focus on what matters most: caring for families with compassion and dignity.