Why Air Trays Are Essential Across Multiple Industries

An air tray is a purpose-built container that uses controlled airflow, smart weight distribution, or both to solve very specific challenges. You’ll see them everywhere from funeral homes and greenhouses to home kitchens.

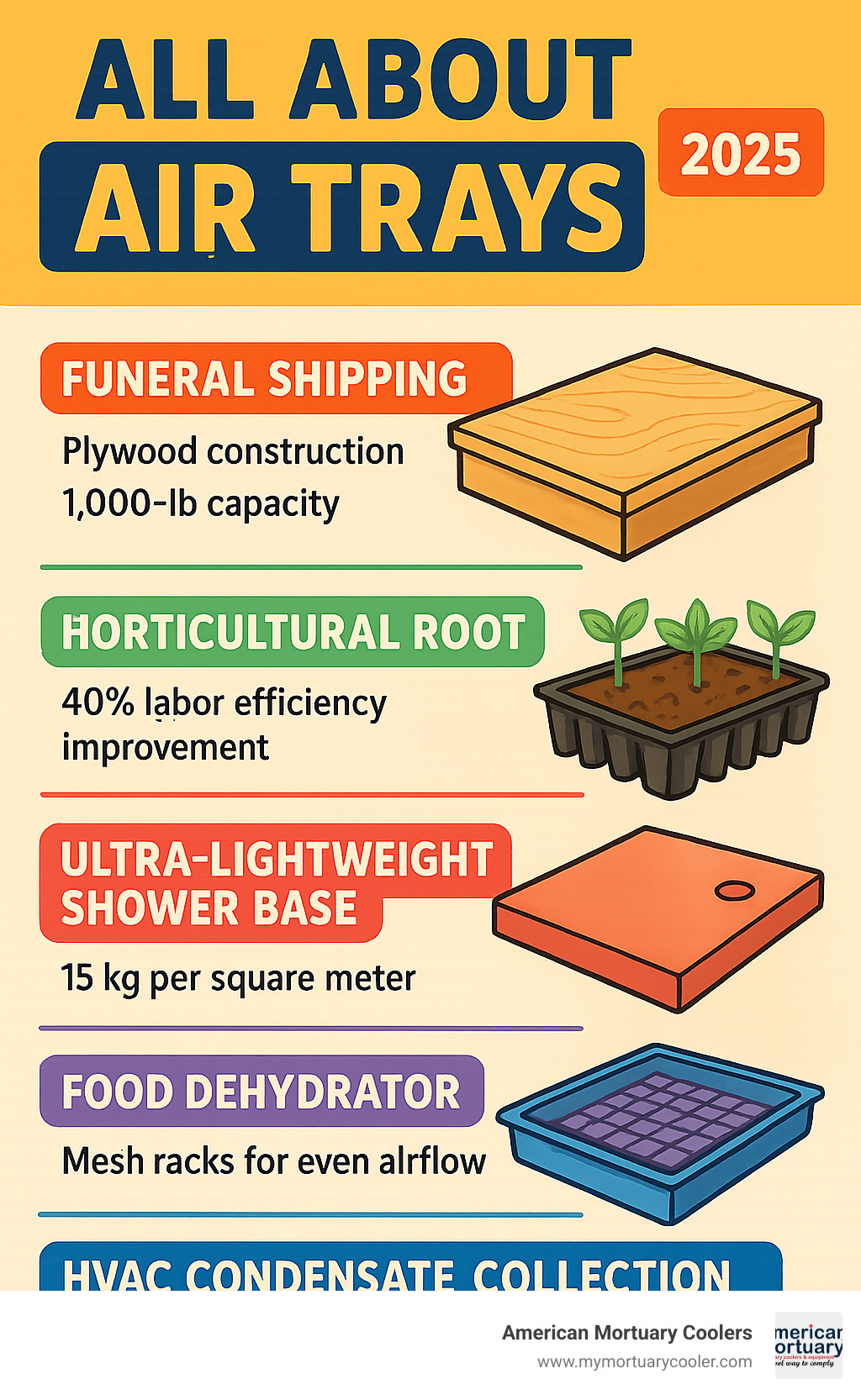

Quick Air Tray Overview:

- Funeral Industry: Certified shipping containers (1,000-lb capacity, heat-treated wood)

- Horticulture: Root-air-pruning trays that boost plant quality while cutting labor up to 40%

- Home Improvement: Ultra-light shower bases roughly 70% lighter than mineral options

- Food Processing: Dehydrator racks and air-fry baskets for even heat circulation

- HVAC Systems: Condensate collection trays that keep A/C units drip-free

The same core idea—better airflow—meets very different goals. In funeral service, it means meeting strict international shipping rules. In horticulture, it prevents root circling and creates stronger plants.

I’m Mortuary Cooler, a national supplier of mortuary equipment. Working with funeral directors across the country, I’ve sourced compliant air-tray solutions that protect both families and reputations.

Simple guide to air tray:

Air Tray Basics: Definition and Core Functions

Think of an air tray as a specialized container that's been engineered to do more than just hold things. These aren't your typical storage boxes – they're purpose-built solutions that use air circulation, weight distribution, or both to solve real problems across different industries.

The beauty of air trays lies in their versatility. Whether you're shipping human remains internationally, growing healthier plants, or building a lightweight shower base, there's likely an air tray designed specifically for your needs.

What Is an Air Tray?

An air tray is essentially a standardized container system designed for very specific transport, storage, or processing challenges. The term has interesting roots in aviation, where engineers needed lightweight yet certified containers that could safely handle cargo transport.

Today, the air tray concept has expanded far beyond airplanes. You'll find them in funeral homes as shipping containers, in nurseries as plant propagation systems, and even in home kitchens as food dehydrator racks. What ties them all together is their focus on maximizing airflow where it counts most.

The standardized aspect is crucial here. A funeral director in Tennessee needs to know that their air tray will meet the same international shipping standards as one used in California. This consistency makes these containers reliable tools for professional use.

How Does an Air Tray Differ from Other Trays?

Air trays aren't just regular containers with a fancy name. They're built to handle specific challenges that ordinary trays simply can't manage.

Certification matters big time. Funeral shipping air trays come with bug-stamp certification and use heat-treated wood to meet USDA-APHIS international shipping regulations. Try shipping human remains internationally with a regular wooden crate, and you'll quickly find why this certification exists.

Airflow design sets them apart. While most containers have solid bottoms and walls, many air trays feature perforated or open-wall construction. Horticultural versions use this design for root air-pruning – essentially letting air reach the roots to prevent them from growing in circles. Food dehydrator trays maximize heat circulation to dry foods evenly.

Weight-rated construction goes beyond typical specs. Funeral air trays use specially engineered plywood that can support up to 1,000 pounds safely. That's not something you'll find in your average shipping container.

Materials are chosen for performance, not just cost. Ultra-lightweight XPS foam cores in shower bases, slip-resistant ABS plastic in airline serving trays – every material choice serves a specific purpose rather than just being "good enough" for general use.

Types of Air Trays Across Industries

When you start looking around, you'll find air tray systems everywhere - and each industry has put its own spin on the basic concept. From shipping human remains safely across continents to growing healthier plants, these specialized containers solve real problems that regular trays just can't handle.

Funeral & Mortuary Shipping Air Trays

In our line of work at American Mortuary Coolers, we've seen how crucial proper shipping containers are for funeral homes. Air trays for mortuary shipping aren't just boxes - they're precision-engineered systems that protect what matters most during transport.

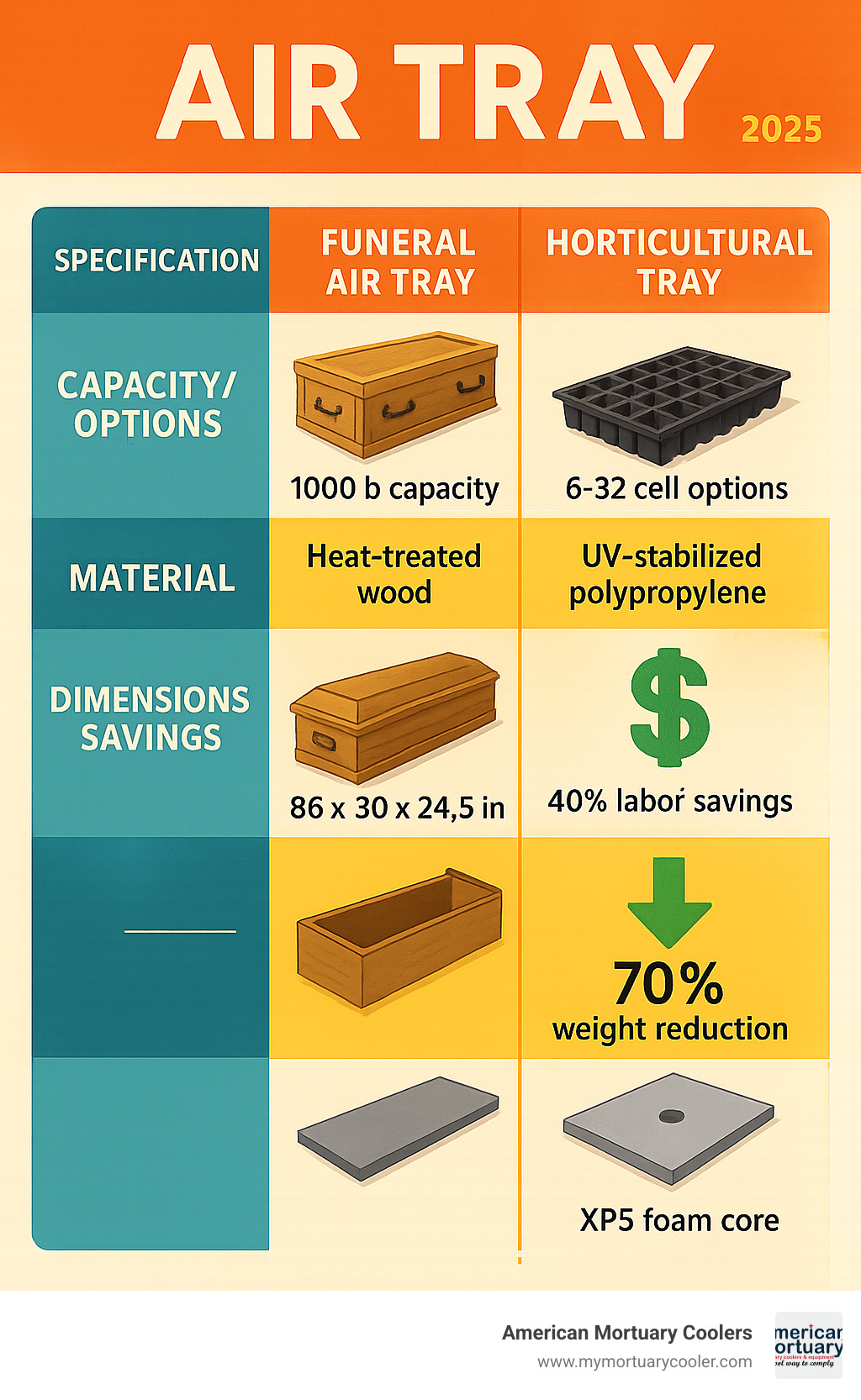

These containers start with a sturdy plywood base paired with a corrugated lid, all held together by heavy-duty nylon straps. But what really sets them apart is their incredible 1,000-lb capacity rating, achieved through third-party weight testing that ensures they can handle even the most challenging shipments.

The standard adult air tray measures 86" x 30" x 24.5" inside, giving plenty of room while keeping the overall weight manageable at around 50 pounds. Every piece of wood is heat-treated and carries the required bug-stamp certification for international shipping - no customs headaches or delayed shipments.

What comes in the box makes all the difference too. You get the complete shipping solution: the air tray itself, a protective casket bag, packing slip envelope, and all the securing straps you need. For the full technical details, check out the Shipper_AirTray.pdf specifications.

Having worked with funeral directors from Tennessee to California, we know that reputation is everything in this business. The right air tray protects both your clients' needs and your professional standing.

Horticultural Root Air Trays

Plant growers finded something amazing when they started letting air reach root systems properly. The Blackmore Air Tray takes advantage of this natural process, creating healthier plants through what's called air pruning.

Here's how it works: instead of roots circling around inside a solid container (which weakens the plant), the air circulation naturally "prunes" root tips when they reach the tray walls. This triggers the plant to develop a more fibrous root system that's better at absorbing nutrients and fighting off disease.

The numbers tell the story. Commercial growers report 40% labor savings when switching to these systems, with cell options ranging from 6 to 32 cells per tray depending on what you're growing. The Blackmore Company Air Tray® system includes smart features like integrated racks that lift trays for airflow on both sides while still allowing forklift access.

It's one of those simple ideas that makes you wonder why nobody thought of it sooner - except they did, and now it's revolutionizing how plants are grown commercially.

Air Tray Shower Bases

If you've ever tried to haul a traditional shower base upstairs, you'll appreciate this innovation. Air tray shower bases weigh just 15 kg/m² - that's 70% lighter than the standard 40 kg/m² mineral-based alternatives that usually require a small crew to install.

The secret is in the construction. These bases use a high-density XPS foam core sandwiched between a durable fiberglass and cement-mesh base and topped with an antibacterial, anti-slip gel coat surface. The result is a shower base that one person can handle during installation while still providing the durability you need.

The environmental benefits are impressive too. The lighter weight means 60% less CO₂ emissions during transport, and the patent-protected manufacturing process reduces resin usage by 80%. It's a win for your back, your wallet, and the planet.

Food Dehydrator Air Trays

Food dehydrator air trays focus on one thing: getting hot air to every surface of whatever you're drying. These mesh racks - usually made from stainless steel or food-grade plastic - create the even airflow that makes the difference between perfectly dried fruit and burnt edges with soggy centers.

The stackable design maximizes your dehydrator's capacity while the open mesh construction ensures unrestricted airflow. Easy-clean surfaces resist staining and odor retention, which anyone who's dried garlic or onions will appreciate.

Some newer copper-coated versions can cut cooking time and energy usage by up to 50% compared to traditional solid trays. That's faster results with lower electricity bills.

HVAC & Airline Service Trays

HVAC condensate collection trays solve an annoying problem most homeowners don't think about until it becomes a bigger issue. These polymer pans catch the water that drips from air conditioning units, preventing stagnant pools that breed mosquitoes while eliminating that constant dripping noise.

Airline serving trays represent the other end of the spectrum - lightweight slip-resistant ABS plastic trays designed to work safely even during turbulence. They include fixed compartments and clear labeling to help flight attendants serve efficiently while keeping everything secure when the plane hits rough air.

Construction, Materials & Regulations

Building a reliable air tray is like constructing a bridge - every material choice and design decision must serve a specific purpose. The engineering varies dramatically depending on whether you're shipping human remains internationally or growing plants in a greenhouse, but the underlying principles remain consistent: durability, compliance, and functionality.

Funeral Shipping Air Tray Construction

When you're entrusting someone's loved one to an air tray, every detail matters. That's why funeral shipping containers follow such precise construction standards. The foundation starts with a 3/8″ plywood bottom that's been engineered to handle serious weight - we're talking about supporting up to 1,000 pounds without flexing or failing.

The 1×4 lumber sides create sturdy walls that won't buckle during transport, while the double-wall corrugated lid provides protection without adding unnecessary weight. Six 1½″ poly handles are strategically placed so funeral home staff can safely lift and maneuver the container. Three sets of ¾″ poly tie-down straps with double-locking buckles secure everything in place.

A clear casket bag provides additional protection, while corner covers prevent those frustrating dings and scratches that can happen during handling. The interior corrugated panel adds an extra layer of cushioning - because when you're shipping someone's final journey, there's no such thing as being too careful.

Material Science Behind Root Air Trays

Plant growers have found something fascinating about roots - they actually prefer a little stress. That's where the science behind horticultural air trays gets interesting. These containers use recycled polypropylene as their base material, but it's what they add to it that makes the difference.

UV stabilizers are mixed right into the plastic to prevent sun damage. Without these additives, outdoor containers would crack and fade within months. The open-wall design that makes these trays work for root pruning would actually weaken a traditional container.

The material engineers had to find that sweet spot where the plastic is strong enough for repeated use but designed with openings that expose root tips to air. When roots hit air instead of more soil, they naturally prune themselves, creating that dense, fibrous root system that plants love.

Compliance Checklist for International Transit

International shipping regulations might seem overwhelming, but they exist for good reasons. When air tray containers cross borders, they're subject to strict rules designed to protect both countries from invasive species and ensure safe transport.

ISPM-15 compliance is the big one - all wooden components must be heat-treated and marked with a bug stamp. This isn't just bureaucratic red tape. The USDA-APHIS established these regulations after finding how wooden packaging materials were accidentally spreading invasive insects and diseases between countries.

Weight testing requires third-party verification that containers can actually support their stated limits. Airline acceptance adds another layer of requirements. International air transport associations have specific rules about dimensions and construction that must be met before containers can be loaded onto planes.

At American Mortuary Coolers, we've seen what happens when these requirements aren't met. Shipments get returned, families face delays, and funeral homes deal with frustrated clients. That's why we always recommend working with suppliers who understand these regulations inside and out.

For funeral professionals who want to dive deeper into compliance requirements, check out More info about funeral home supplies for comprehensive guidance on meeting industry standards.

Benefits and ROI of Using Air Trays

When you invest in the right air tray system, you're not just buying a container - you're investing in peace of mind, efficiency, and often significant cost savings. These specialized systems pay for themselves through improved operations, reduced risks, and environmental benefits that add up over time.

Funeral Industry Advantages

As funeral directors, we understand that every detail matters when serving families during their most difficult moments. Air trays provide protection that goes far beyond simple shipping containers.

Damage prevention stands as the most critical benefit. When a casket arrives damaged after international shipping, you're not just dealing with replacement costs - you're managing a family's heartbreak during an already devastating time. The robust plywood construction and specialized securing systems in funeral air trays dramatically reduce this risk.

Regulatory compliance has become increasingly complex, especially since USDA-APHIS regulations tightened in 2004. Using certified air tray systems with proper bug-stamp certification eliminates the nightmare of shipments being returned or held up at customs.

Your professional reputation depends on reliable service. Families trust you to handle their loved one's final journey with dignity and care. The complete solution approach of professional air trays - with included casket bags, documentation envelopes, and proper strapping systems - demonstrates the attention to detail that families expect.

Horticulture & Agriculture Gains

Commercial growers have documented impressive results after switching to air tray systems. The 40% labor savings that many users report comes from multiple efficiency improvements working together.

Faster rooting occurs because air-pruning stimulates more vigorous root development. Plants spend less time in propagation, which means faster turnover and increased production capacity. This biological advantage translates directly to improved profitability.

Transplant success rates improve significantly. Plants grown in air tray systems develop more fibrous, healthy root systems that handle the stress of transplanting much better. Reduced plant loss means better margins and happier customers.

Culinary & Home Improvement Payoffs

Consumer applications of air tray technology deliver benefits you can see and feel immediately.

Crisper cooking results from improved airflow in food dehydrator trays. The mesh construction allows heat to circulate evenly, producing more consistent results. Some copper-coated designs reduce cooking time and energy usage by up to 50%, which adds up to real savings over time.

DIY shower installation transforms from a multi-person job requiring professional help into a manageable weekend project. The ultra-lightweight shower bases at just 15 kg/m² - 70% lighter than traditional options - make single-person installation realistic for most homeowners.

Environmental impact improvements come from multiple sources. Lower shipping emissions due to reduced weight, decreased resin usage (80% reduction in some designs), and improved energy efficiency during use all contribute to a smaller environmental footprint.

The return on investment becomes clear when you add up these benefits over time. Whether you're shipping internationally, growing plants commercially, or improving your home, the right air tray system pays for itself through improved efficiency, reduced risks, and better results.

Selecting, Customizing & Maintaining Your Air Tray

Finding the perfect air tray for your needs doesn't have to be overwhelming. Think of it like buying a truck - you wouldn't choose a pickup for moving furniture when you need a semi for cross-country hauling. The same logic applies to air trays.

Key Buying Considerations

Application fit is everything when selecting an air tray. A funeral director shipping remains internationally needs completely different specifications than a nursery owner growing seedlings. The funeral professional requires heat-treated wood with bug-stamp certification, while the grower needs UV-resistant materials that can handle outdoor conditions year-round.

Material durability determines whether your investment pays off over time. If you're using air trays outdoors, UV-resistant materials are non-negotiable. For food applications, you'll need food-grade certifications that meet health department standards.

Certification requirements can make or break international shipments. We've seen funeral homes learn this lesson the hard way when their shipments get held up at customs because the wood wasn't properly treated. These certifications add cost, but they're absolutely essential for compliance.

Budget considerations go beyond the sticker price. Factor in maintenance costs, replacement frequency, and potential penalties for non-compliant equipment. A cheaper air tray that fails inspection can cost far more than investing in quality from the start.

Customization & Branding Options

Most manufacturers understand that your equipment reflects your professional image. Color choices for shower bases include standard options like white, black, ivory, anthracite, and gray cement. Need something specific? Custom RAL colors are available for projects with particular design requirements.

Logo printing options let funeral homes maintain brand consistency throughout the shipping process. Custom Air Trays offers branding services that can make your containers instantly recognizable while maintaining the professional appearance families expect.

Size customization is possible for special requirements, though it typically involves minimum order quantities and longer lead times.

Care, Storage & End-of-Life

Taking care of your air tray systems isn't complicated, but it does require attention to detail. Sanitization protocols are crucial for funeral air trays, which should be inspected and sanitized between uses following industry guidelines for infectious disease control.

Storage requirements vary by application. Horticultural trays need protection from UV damage when not in use, while maintaining easy access for stacking systems. A little planning in your storage area can extend equipment life significantly.

Recycling pathways are increasingly important as sustainability becomes a priority. Modern shower bases made from 100% mono PET can be fully recycled, while wooden funeral containers often qualify for standard wood waste recycling programs.

For funeral professionals expanding their equipment inventory, our guide on More info about buying morgue carts covers complementary equipment that works alongside air tray systems.

At American Mortuary Coolers, we've helped funeral homes across the country select the right equipment for their specific needs. From our base in Tennessee, we've shipped custom solutions to operations in California, Texas, and everywhere in between.

Frequently Asked Questions about Air Trays

After years of working with funeral directors from Tennessee to California, I've heard just about every question you can imagine about air tray systems. Here are the ones that come up most often, along with the straight answers you need.

How much weight can a funeral air tray support?

Here's the good news: standard funeral air trays are built tough. They're third-party weight tested to handle up to 1,000 pounds, which covers virtually every situation you'll encounter. That includes the casket, the deceased, and any personal items families want to include in the shipment.

The testing isn't just done by the manufacturer either. Independent laboratories put these containers through real-world shipping conditions to make sure they'll hold up when it matters most. Reputable manufacturers like Custom Air Trays provide you with documentation of this testing, so you have proof of what you're getting.

If you occasionally need something larger, manufacturers can build custom air trays with bigger dimensions - like 92" x 36" x 25" outside measurements - while keeping that same 1,000-pound capacity. It's reassuring to know the weight limit isn't the limiting factor.

Can air trays be reused?

This is where things get interesting because the answer completely depends on what type of air tray you're talking about.

Funeral air trays are typically single-use containers, and for good reason. Hygiene considerations are paramount, plus international shipping can be rough on these containers. That said, if one comes back in good condition from a domestic shipment and meets your sanitation requirements, some funeral homes do reuse them for domestic transport only.

Horticultural air trays are the opposite - they're specifically engineered for multiple growing seasons. The UV-stabilized materials and heavy-duty construction make them cost-effective for commercial growers who use them season after season.

Shower bases are obviously permanent installations designed to last decades, while food dehydrator trays are built for repeated use with proper cleaning between batches.

Do I need a bug stamp for domestic shipping?

No, and this is one of those regulations that trips people up unnecessarily. Bug stamp certification is only required for international shipments. The USDA-APHIS regulations from 2004 specifically target wood packaging materials crossing international borders to prevent invasive insects and diseases from spreading between countries.

For domestic shipping anywhere within the United States, standard air trays without heat treatment work perfectly fine. You won't have any regulatory issues.

That said, many funeral homes choose to use certified containers for all their shipments anyway. It keeps their procedures consistent and eliminates any chance of grabbing the wrong container for an international shipment. The bug stamp certification does add to the cost, but it can simplify your inventory management.

Just remember: if you're shipping internationally, that bug stamp is absolutely non-negotiable. Shipments without proper certification get returned or held up at customs, creating delays and extra costs that nobody wants to deal with during an already difficult time.

Conclusion

Step back and you’ll see a single engineering principle—optimized airflow—solving wildly different problems. An air tray can safely move a loved one across borders, help a tomato seedling grow stronger roots, or let a homeowner install a shower base solo.

For funeral professionals, reliability and compliance come first. Using certified air trays protects families and preserves your reputation, whether you serve Tennessee, Georgia, Illinois, or any of the regions American Mortuary Coolers reaches.

Materials keep getting lighter, stronger, and greener. A 70% weight reduction in shower bases or a 40% labor saving in plant propagation isn’t just a talking point—it’s real money back in your budget.

Ready to round out your equipment lineup? Our Comprehensive Guide to Funeral Home Supplies shows how to build a setup that serves families with dignity while keeping operations smooth.