Why Cooler Door Handles Are Critical for Temperature Control

Cooler door handles are specialized hardware components that provide secure grip and leverage for opening refrigerated doors while maintaining proper seal compression to preserve internal temperatures. These handles come in various styles including pull handles, recessed handles, locking handles, and custom branded designs, with prices ranging from $17.79 for basic models to over $400 for premium locking handle kits.

Key cooler door handle types and applications:

- Pull handles - Standard chrome or stainless steel for walk-in coolers

- Recessed handles - Flush-mount design for tight spaces and clean aesthetics

- Locking handles - Keyed cylinders for security in commercial applications

- Custom handles - Branded designs shaped like bottles, cans, or logos

- Safety release handles - Interior releases prevent entrapment in walk-ins

Every walk-in cooler, freezer, and display case depends on properly functioning handles to maintain the gasket seal that keeps cold air in and warm air out. When handles fail or become loose, energy costs increase and compressor life decreases due to temperature fluctuations.

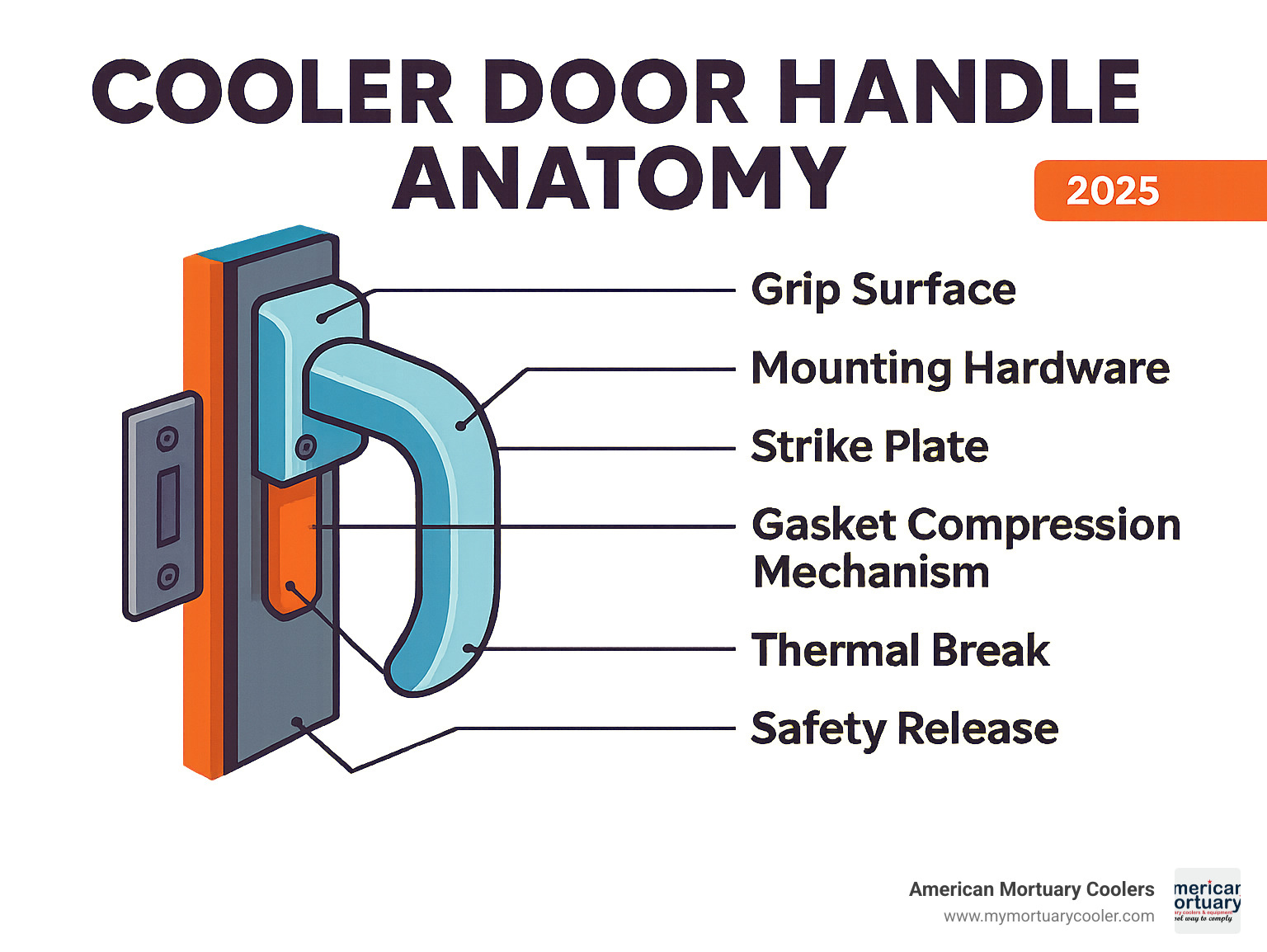

The handle mechanism works by providing leverage to compress door gaskets against the frame, creating an airtight seal. Quality handles also include thermal breaks to prevent condensation and may feature anti-microbial coatings for food safety compliance.

I'm Mortuary Cooler, a national-level mortuary cooler supplier specializing in commercial refrigeration equipment including cooler door handles and related hardware. With experience in mortuary and commercial cooling applications, I've helped funeral homes and businesses select the right handle solutions for their specific temperature control needs.

Cooler door handles terms to remember:

Cooler Door Handles 101: Definition & Primary Function

Cooler door handles are precision-engineered components that connect to sophisticated sealing systems. When you pull the handle, you activate a pull handle mechanism that works with the plug handle (the latching part) and safety release system to create the perfect latch interface for proper sealing.

These handles include thermal breaks - insulation built into the handle that prevents heat transfer through metal components. Without thermal breaks, condensation would drip constantly. All commercial-grade handles must meet NSF compliance standards for food safety regulations.

How cooler door handles keep temperatures stable

The key is compression sealing. When you close a cooler door properly, the handle system creates precise pressure to squeeze the door gasket against the frame. This gasket pressure must be perfect - too loose allows air leaks, too tight damages the gasket.

Proper compression can reduce energy use by up to 15%. The anti-condensate design prevents moisture buildup and freezing, which would create seal gaps.

Why every walk-in, freezer, or display case relies on quality cooler door handles

Energy efficiency is the primary benefit. When handles maintain proper sealing, compressors don't work overtime, extending compressor life and reducing energy bills.

User safety is equally important. Walk-in coolers require interior safety releases to prevent entrapment. Quality handle systems include these releases as standard equipment.

In mortuary applications at American Mortuary Coolers, we see how critical this reliability becomes. Temperature fluctuations aren't just about efficiency - they're about maintaining the dignity and trust that families place in funeral professionals.

Types, Materials & Safety Features

Cooler door handles come in several key types for different applications:

Recessed handles sit flush with the door surface, creating clean lines that won't catch on equipment or clothing. Perfect for tight spaces.

Extruded handles are built into the door during manufacturing for maximum durability, but require full door replacement if they break.

Full-length handles stretch across most door height, providing multiple grip points for heavy doors or high-traffic areas.

Locking handles add keyed cylinders for security in retail or storage applications.

The critical safety feature is the inside release mechanism - a literal lifesaver that allows anyone trapped inside to open the door from within.

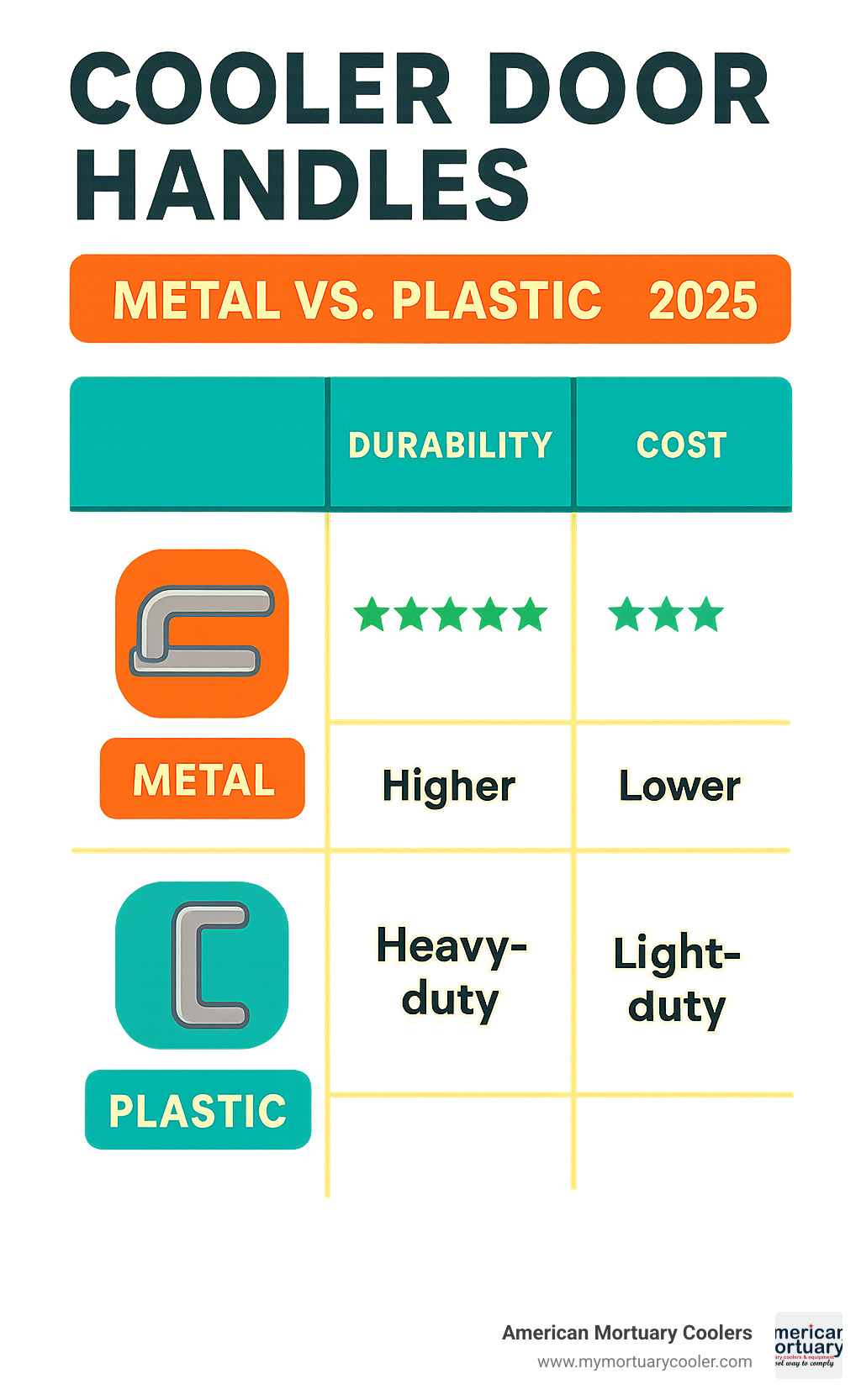

Material choice affects durability and cost. Zinc alloy dominates commercial applications with excellent strength and chrome plating compatibility. Stainless steel provides superior corrosion resistance for high-moisture environments. Anodized aluminum offers lightweight durability, while polymer handles provide budget-friendly solutions.

Anti-microbial coatings are increasingly popular in food service and healthcare applications.

Cooler door handles for walk-in vs reach-in vs display coolers

Walk-in coolers require offset strikes that accommodate varying door thicknesses and cam-lift hinges for smooth operation. Freezer heat wire integration prevents handles from freezing solid.

Reach-in coolers face constant use - sometimes hundreds of operations daily - requiring ergonomic designs to prevent repetitive stress injuries.

Display coolers must balance functionality with aesthetics since they're sales tools first.

For mortuary applications, An Essential Guide to Mortuary Cold Room Doors and Your Best Options provides specific guidance for preservation environments.

LIGHTBOX & branded cooler door handles

LIGHTBOX handles incorporate LED illumination, changing ordinary hardware into 24/7 promotional tools positioned exactly where purchasing decisions happen.

Branded handles shaped like bottles, cans, or logos provide permanent promotional impact that reinforces brand identity with every customer interaction.

Customization involves precision molds that replicate product packaging down to the smallest detail, with adjustable hardware ensuring compatibility with virtually any cooler door design.

Choosing and Customizing the Perfect Handle

Selecting the right cooler door handles depends on your specific environment and demands.

Commercial kitchens need bulletproof stainless steel construction with NSF approval to handle temperature swings and aggressive cleaning chemicals.

Mortuary applications require handles that work flawlessly at extreme temperatures while providing solid grip through thick protective gloves. Intensive cleaning protocols demand superior corrosion resistance.

Grocery and retail environments face constant public use, requiring handles that look good and work smoothly while standing up to potential abuse. Security features may be necessary.

Industrial warehouse settings need extra protection from forklift bumps and harsh chemicals, sometimes requiring protective guards or reinforced mounting systems.

Don't forget ADA compliance considerations for operating force and handle positioning requirements.

Cooler door handles for walk-in mortuary freezers

Mortuary freezer applications face unique challenges. Extreme temperature swings create expansion and contraction stresses that destroy standard handles.

Glove-friendly grip design becomes crucial when staff work with thick protective equipment. Handle surfaces must provide secure grip without sharp edges that could tear protective gear.

Corrosion resistance is critical given intensive disinfection protocols. Temperature swing tolerance ensures handles maintain structural integrity despite constant cycling between extreme temperatures.

At American Mortuary Coolers, we've developed specialized handle solutions tested in actual mortuary environments. For comprehensive guidance, Doorway to Preservation: Selecting Mortuary Dead Body Storage Freezer Doors provides detailed technical information.

Cost & lead-time considerations when ordering custom cooler door handles

Standard handle kits typically cost $20-$60 for basic chrome-plated models with quick availability and proven reliability.

Premium locking systems often exceed $200-$400 for sophisticated models with keyed cylinders, heavy-duty construction, and specialized finishes.

Custom molds for branded handles require substantial upfront investment but deliver unique promotional value, making minimum order quantities important for cost planning.

Lead times vary dramatically - standard handles ship within days, while custom molded handles may require 6-12 weeks. Planning ahead is crucial for tight deadlines.

Installing, Maintaining & Troubleshooting Cooler Door Handles

Proper installation of cooler door handles ensures years of reliable service. Most installations are straightforward with the right approach.

Torque specifications typically fall between 15-25 foot-pounds for standard installations. Adjustable strike plates accommodate offset ranges from -1/8" to 3/8", allowing fine-tuning of handle engagement and gasket pressure.

After installation, perform a gasket check by sliding paper around the entire door perimeter. If paper slides easily anywhere, the gasket isn't compressed enough.

Maintenance is simple - apply food-grade lubricant to pivot points and latch mechanisms once or twice yearly. Regular inspections catch problems early: loose mounting bolts, worn gaskets, and proper door alignment.

Common failures include loose screws from vibration, misalignment from door settling, and broken springs in latch mechanisms. Many issues have simple DIY fixes if caught early.

For beverage coolers, How to Adjust a Beverage Cooler Door provides step-by-step guidance.

Cooler door handles replacement step-by-step

Replacing handles requires basic tools: screwdrivers, appropriately sized wrenches, and safety equipment.

Safety first - disconnect power to heated elements in freezer doors before starting work. Follow proper lockout/tagout procedures in commercial settings.

Start from the inside, removing interior components first, then exterior handle and strike plate. Take photos before disassembly and document wire connections.

After installation, perform seal testing using visual inspection and the paper-slide test. The seal should be uniform around the entire door perimeter.

For mortuary applications, The Definitive Guide to Mortuary Dead Body Storage Freezer Door Maintenance provides detailed preservation-specific guidance.

Innovations extending handle lifespan

Advanced anti-corrosion plating technologies offer superior protection, literally doubling or tripling handle lifespan in demanding applications.

Anti-microbial additives built into materials provide continuous bacterial protection. 3D-printed prototypes make custom handles more accessible by reducing development costs.

Smart sensor integration represents cutting-edge technology, monitoring door status, tracking temperature variations, and logging usage patterns while providing maintenance alerts.

Sustainability initiatives drive development of handles from recycled materials designed for end-of-life recyclability.

Brands, Prices & Emerging Trends

Several manufacturers dominate the cooler door handles market:

Kason leads with over 221 door hardware products, built on reliability and compatibility tested in real-world commercial environments.

Keil focuses on heavy-duty applications with W19 and W38 series handles designed for high-traffic commercial facilities.

Component Hardware provides cost-effective aftermarket alternatives without sacrificing quality, offering significant budget savings.

MIV (BMP Group) brings European engineering precision, with 80% of production exported worldwide.

US Cooler's ReFridge division offers OEM replacement parts for perfect compatibility with their walk-in systems.

The OEM versus aftermarket decision typically comes down to priorities: OEM parts guarantee perfect fit at premium prices, while aftermarket alternatives offer substantial savings with proper compatibility research.

Smart sensor handles represent emerging technology for monitoring door operation and usage patterns. Sustainability initiatives focus on recycled materials and end-of-life recyclability.

Cooler door handles driving energy-efficient door seals

Handle design directly impacts energy efficiency through several mechanisms:

Thermal break inserts prevent heat transfer through metal components, eliminating condensation problems.

Compression leverage provides mechanical advantage for consistent gasket compression without requiring excessive force.

Reduced icing results from proper sealing and anti-condensate features, preventing ice buildup that compromises sealing systems.

Modern handles are evolving beyond simple hardware into integral components of high-performance refrigeration systems, actively contributing to energy efficiency rather than just facilitating door operation.

Frequently Asked Questions about Cooler Door Handles

How do I pick the right cooler door handle offset?

Offset refers to how far the handle's strike plate extends to meet the door frame when closed. Most cooler door handles have adjustable strikes set from -1/8" to 3/8".

Measure the gap between door surface and frame when properly positioned for sealing. Flush-mount doors need minimal offset, while plug doors that fit into frame openings need positive offset for proper latch engagement.

Pro tip: photograph and measure current offset settings before removing existing handles to ensure proper replacement setup.

What's the difference between a locking and non-locking handle kit?

Non-locking handles provide straightforward operation with required interior safety releases, perfect for staff access areas where security isn't a concern.

Locking handle kits add keyed cylinders preventing unauthorized access while maintaining interior safety releases. Essential for retail environments or secure storage areas.

Locking handles typically cost $100-200 more but pay for themselves quickly if inventory shrinkage or unauthorized access are concerns.

How often should cooler door handles be cleaned and inspected?

Daily cleaning is standard in food service using NSF-approved sanitizers. Weekly visual inspections should check for loose bolts, worn gaskets, and proper alignment. Monthly comprehensive maintenance includes torque checking, lubrication, and seal integrity testing.

Watch for warning signs requiring immediate attention: difficulty operating doors, visible ice buildup, or handle looseness. These compromise both energy efficiency and safety.

Conclusion & Next Steps

Choosing the right cooler door handles isn't just about hardware—it's about protecting your investment, ensuring safety, and maintaining the precise temperature control that your business depends on. Whether you're running a busy restaurant kitchen, managing a retail display case, or operating a mortuary facility, the handle you select today will impact your operations for years to come.

We've covered everything from basic pull handles starting at $20 to premium custom solutions exceeding $400. The key is matching your handle choice to your specific needs. Energy efficiency comes from proper gasket compression, safety requires reliable interior releases, and durability depends on selecting materials that can withstand your operating environment.

At American Mortuary Coolers, we've seen how the right handle can make the difference between smooth daily operations and costly temperature control problems. Our experience across mortuary, commercial kitchen, and industrial applications has taught us that there's no one-size-fits-all solution—each application has unique requirements that deserve careful consideration.

Planning your next steps starts with honest assessment of your current situation. Are your existing handles causing energy waste through poor sealing? Do you need improved security features? Would custom branding provide promotional value? These questions guide the selection process toward solutions that deliver real value.

Our nationwide delivery network serves all contiguous 48 states from strategic locations including Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA. This coverage ensures we can support your cooler door handle needs whether you're in the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, or Pacific regions.

Custom solutions remain our specialty, particularly for mortuary applications where standard commercial handles may not meet the demanding requirements of preservation environments. We understand that temperature fluctuations aren't just inconvenient—they can compromise the dignity and integrity of the services you provide.

For comprehensive guidance on complete door system selection, including how handles integrate with overall performance, The Definitive Guide to Walk-In Cooler Doors provides the technical depth needed for informed decision-making.

Ready to move forward? Our technical team combines decades of refrigeration experience with practical understanding of real-world applications. We'll help you steer the options, understand the trade-offs, and select handles that deliver reliable performance at competitive prices.

Whether you need a simple replacement handle or a completely custom solution, we're here to help. Contact us for personalized recommendations that match your specific requirements, budget, and timeline. Because when it comes to cooler door handles, the right choice makes all the difference.