What Exactly Is a Large Walk-In Cooler and Why You Need One

Ever walked into a refrigerated space that feels more like a small building than a fridge? That's exactly what a large walk in cooler is – a spacious, climate-controlled environment that transforms how businesses handle cold storage needs.

At its core, a large walk in cooler is a commercial refrigeration powerhouse, typically spanning over 400 square feet of floor space. These aren't your standard kitchen coolers – they're industrial-strength cold rooms that can stretch up to an impressive 40' x 40' with ceiling heights reaching up to 28 feet. Imagine a space where you could easily store hundreds of items while maintaining perfect temperature control!

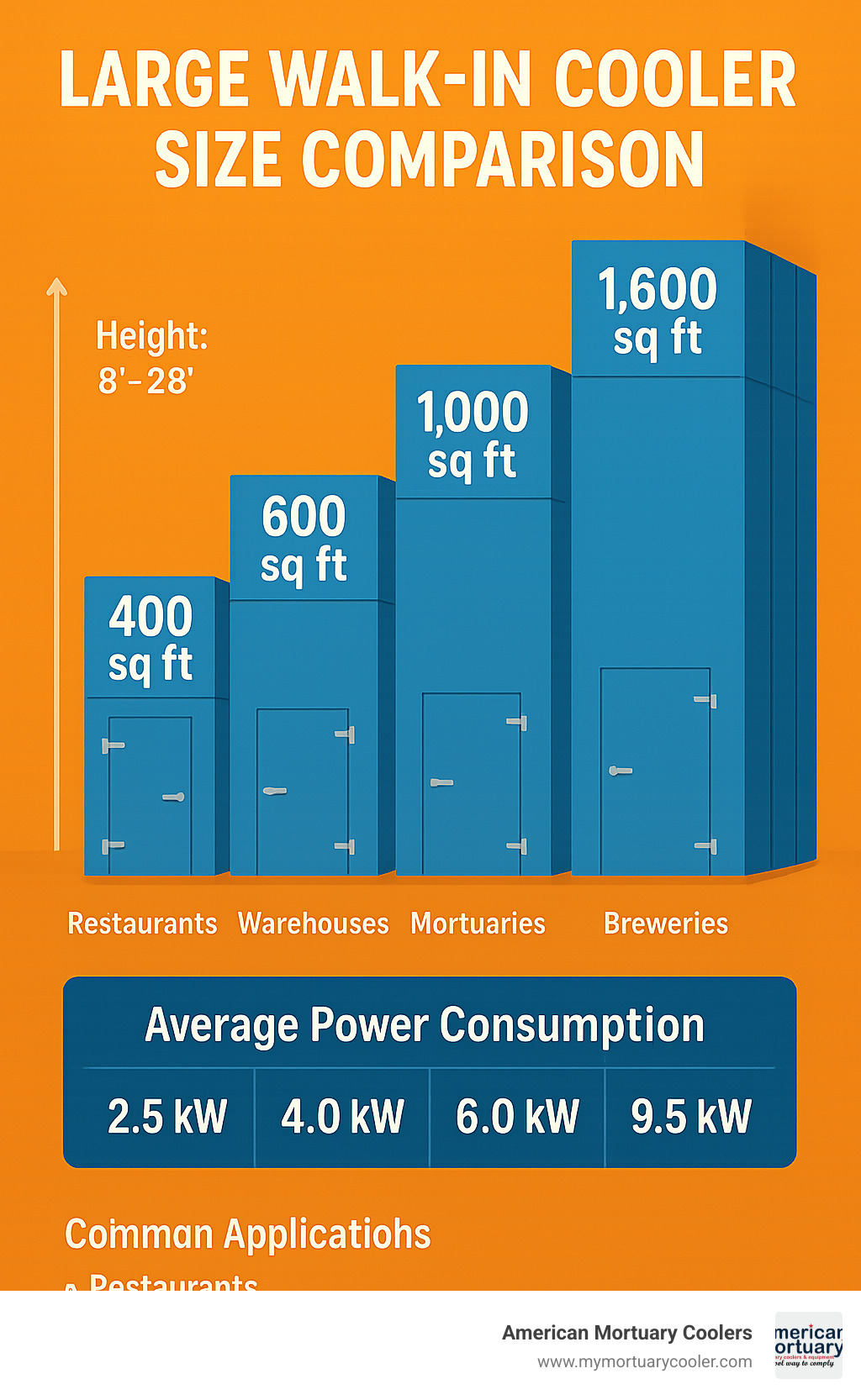

| Large Walk-In Cooler Quick Facts |

|---|

| Size Range: 400-1,600 square feet |

| Typical Heights: 8'-28' |

| Temperature Range: 35°F-55°F (1.7°C-12.8°C) |

| Insulation: 4" thick panels (R-29 rating) |

| Applications: Food service, warehousing, mortuaries, breweries, pharmaceuticals |

| Construction: Panelized or one-piece fiberglass |

What makes these coolers truly special is their industrial-grade construction. Unlike smaller units, a large walk in cooler features reinforced flooring designed to support heavy equipment like pallet jacks and forklifts. The refrigeration systems pack serious cooling power, custom-engineered to maintain consistent temperatures even with frequent door openings and large inventory loads.

For businesses handling temperature-sensitive products, these coolers aren't just convenient – they're essential infrastructure. A properly sized large walk in cooler becomes the backbone of efficient operations, improving workflow, ensuring product integrity, and providing room to grow as your business expands. The smart design balances upfront investment with long-term energy savings, featuring cutting-edge insulation that exceeds federal energy standards.

Hi there! I'm from American Mortuary Coolers, a national supplier specializing in mortuary coolers for funeral homes, hospitals, and medical facilities across the country. We've helped countless clients find the perfect cold storage solution for their unique needs, bringing specialized knowledge of temperature-controlled environments to every project we undertake.

Looking for more information about specific cooler options? We've got you covered with these helpful resources:

Understanding the Large Walk-In Cooler Landscape

When we talk about large walk in coolers, we're not just describing bigger versions of what you'd find in a corner restaurant. We're talking about serious, industrial-scale refrigeration that transforms how businesses operate. These cooling giants are the unsung heroes behind many successful commercial operations.

A true large walk in cooler starts at approximately 400 square feet—roughly the size of a two-car garage—and can stretch to an impressive 40' x 40' footprint with ceilings soaring up to 28 feet high. That's enough space to store thousands of products while maintaining perfect temperature throughout the entire area.

The secret to these coolers' performance lies in their insulation. Most large walk in coolers feature 4-inch thick foamed-in-place urethane insulation, achieving an R-29 rating for coolers and R-32 for freezers. This exceeds the Energy Independence and Security Act (EISA) requirements, which mandate a minimum R-25 for commercial refrigeration.

I recently spoke with Bob Dews from Whiteside Brewing Co., who couldn't be happier with his custom large walk in cooler: "Tamara orchestrated our special needs with your engineering department to produce a perfect fit! Kudos to your company for providing superior customer service and a quality product!"

Size Benchmarks for a Large Walk In Cooler

In commercial refrigeration, size definitely matters. At American Mortuary Coolers, we consider 400 square feet the starting point for what qualifies as "large." From there, the sky's the limit—we've installed cooling chambers up to 1,600 square feet for operations that demand massive cold storage capacity.

The sizing typically falls into three categories: Medium-Large units range from 400-800 square feet (think 20' x 20' to 20' x 40'), Large units span 800-1,200 square feet, and Extra-Large installations stretch from 1,200 up to 1,600 square feet.

Construction methods adapt to these dimensions too. Smaller units within this range usually employ panelized construction—pre-fabricated insulated panels assembled on-site like a high-tech puzzle. For truly massive installations exceeding 1,000 square feet, some manufacturers offer one-piece seamless fiberglass construction that arrives fully assembled, eliminating potential weak points where panels would otherwise join.

As one manufacturer representative told me, "Our seamless design eliminates hot spots and dramatically improves energy efficiency—particularly valuable when you're cooling spaces the size of a small house!"

How a Large Walk In Cooler Differs from Standard Units

A large walk in cooler isn't just a scaled-up version of its smaller cousins—it's reimagined from the ground up to handle industrial demands. The differences become clear the moment you step inside one.

Floor loading capacity is dramatically improved, supporting 1,200+ pounds per square foot compared to the 600-800 pounds typical of standard units. This means you can drive fully-loaded forklifts directly inside without worrying about damaging the floor—a game-changer for warehouse operations.

Refrigeration systems scale up accordingly, with multiple evaporators strategically positioned throughout the space. These connect to remote condensing units with 3-5 horsepower or more, ensuring even cooling throughout these vast spaces.

When ceiling spans exceed 20 feet, structural reinforcement becomes essential. Steel I-beams or specially reinforced ceiling panels prevent sagging over time, even in the largest installations.

Many of our clients appreciate the dual-zone capabilities of these larger units. Internal partition walls create multiple temperature zones within the same structure, allowing different products to be stored at their ideal temperatures. For mortuaries handling both bodies and sensitive materials, this feature is invaluable.

Advanced monitoring systems round out the package, with sophisticated digital controllers and remote monitoring capabilities that alert staff to any temperature fluctuations before they become problems.

One of our funeral home clients summed it up perfectly: "The ability to separate our storage areas while maintaining the specific temperature requirements for each has transformed our operation. Plus, the reinforced flooring means we can move heavy equipment in and out without any concerns."

Who Uses Large Walk-In Coolers & Why They Matter

When you think about large walk in coolers, you might picture vast, chilly rooms filled with products waiting for their next destination. And you'd be right! These impressive refrigeration systems have become essential infrastructure for businesses across numerous industries where keeping things cool—and doing it at scale—really matters.

Food Service and Distribution

The food industry absolutely depends on large walk in coolers to keep massive quantities of perishable goods fresh before they make their way to your local restaurants, schools, and grocery stores. These aren't your average coolers—we're talking about 1,000+ square foot spaces maintaining that perfect 35°F to 40°F sweet spot that preserves freshness. They're designed with wide aisles and reinforced floors so forklifts can easily move pallets of produce, dairy, and meats without breaking a sweat (though in those temperatures, you might!).

Cold Storage Warehousing

If you've ever wondered where all your food goes before it reaches the store, the answer might be inside a massive cold storage warehouse. These facilities use industrial-sized large walk in coolers that can span what feels like football fields. They serve as the behind-the-scenes heroes of our food supply chain, often featuring multiple temperature zones under one roof to accommodate everything from leafy greens to frozen pizzas.

Breweries and Beverage Production

Your favorite craft beer likely spent some quality time in a specialized large walk in cooler. Breweries need precise cooling environments for fermentation, conditioning, and storing their finished liquid gold. A brewery producing at scale typically needs 800+ square feet of cooler space with humidity controls that would make a weather forecaster jealous. These environments aren't just cold—they're calibrated to maintain the exact conditions that keep those hoppy flavors just right.

Mortuary and Medical Facilities

At American Mortuary Coolers, this is our specialty. We design large walk in coolers for hospitals, medical examiners, and funeral homes that need dignified, temperature-controlled environments. These installations typically range from 400-800 square feet and feature redundant cooling systems—because in this industry, reliability isn't just convenient, it's absolutely essential. Our coolers provide the perfect balance of technical performance and respectful design for these sensitive environments.

Floral Industry

Those beautiful flower arrangements you see at weddings and special events? They likely spent time in a large walk in cooler designed specifically for floral preservation. These spaces aren't just cold—they're carefully humidified to keep those delicate blooms looking their best. Wholesale florists use these specialized environments to extend the life of their colorful inventory before it heads to your local flower shop.

Pharmaceutical and Research

When it comes to storing medications or biological samples, precision is everything. Pharmaceutical companies and research labs use large walk in coolers with the most advanced temperature monitoring systems available. These aren't just coolers—they're scientific instruments that maintain exact conditions for products where even a one-degree temperature fluctuation could mean millions in losses.

Government and Institutional

From military bases to prison kitchens, government facilities rely on large walk in coolers that meet strict specifications while handling the demands of feeding hundreds or thousands daily. These heavy-duty units often come with special security features and are built to withstand years of intense use.

Core Benefits for Commercial & Industrial Operations

So why do businesses invest in these refrigerated giants? The benefits go way beyond just keeping things cold.

A properly designed large walk in cooler transforms how a business operates. With all that bulk storage capacity, companies can buy in larger quantities (hello, volume discounts!) and simplify their inventory tracking by keeping everything in one place instead of scattered across multiple smaller units.

The workflow improvements alone can justify the investment. Imagine the difference between sending staff to five different coolers versus one centralized location with organized shelving and clear traffic patterns. One of our food distribution clients told us, "Our 1,200 square foot walk-in cooler has become the heart of our operation. We've cut product loss by over 30% and eliminated the bottlenecks that used to slow us down during peak season."

For businesses handling sensitive products, these coolers provide peace of mind through consistent temperatures that protect inventory and help meet strict regulatory requirements. Whether it's maintaining food safety standards or pharmaceutical storage regulations, a reliable large walk in cooler keeps businesses compliant.

Perhaps most importantly, these coolers offer room to grow. Many are designed with future expansion in mind, allowing businesses to scale up without starting from scratch. And with industrial-grade components and redundant systems, they provide the kind of reliability that protects both products and profits when it matters most.

When you consider how a large walk in cooler touches so many industries that affect our daily lives—from the food we eat to the medicines we take—it's clear these aren't just big refrigerators. They're essential infrastructure that keeps our modern world running smoothly, one cool degree at a time.

Buying Checklist: Features, Performance & Compliance

Shopping for a large walk in cooler feels a bit like buying a car—there's a lot to consider beyond just the sticker price. Let me walk you through what matters most so you can make a choice you'll be happy with for years to come.

Insulation Systems

The walls of your large walk in cooler are its first line of defense against the outside world, and the insulation inside them makes all the difference.

Most quality coolers use polyurethane (PU) foam—it's the gold standard, giving you R-29 to R-32 values in just 4" thick panels. This foam gets injected between the panel walls and expands to fill every nook and cranny, creating a seamless barrier against heat.

Some budget options use expanded polystyrene (EPS) instead. While it's cheaper upfront, you'll need thicker 5-6" panels to get similar performance, and you might see that "savings" disappear in your monthly energy bills.

I've had customers tell me time and again that investing in quality polyisocyanurate insulation paid for itself within just a few years. As one customer put it, "I'd rather cry once when buying than every month when the electric bill arrives."

Door Packages

In a large walk in cooler, doors are like windows in your home—they're where most of your energy escapes. This becomes even more important when you're cooling thousands of square feet.

For staff access, standard swing doors (36" to 60" wide) work well, while double doors spanning 60" to 96" let you move larger items through. If space is tight, sliding doors make sense, especially for openings over 8 feet wide.

High-traffic facilities often benefit from power-operated doors that open and close quickly, keeping precious cold air where it belongs—inside your cooler.

Whatever style you choose, make sure it includes the essentials: triple-seal magnetic gaskets that create an airtight seal, heavy-duty hinges that won't sag over time, protective kick plates, interior safety releases (so nobody gets accidentally locked in), and self-closing mechanisms.

Lighting Systems

Good lighting isn't just about seeing what's inside—it's about safety and efficiency. LED lighting has become the standard for large walk in coolers, and for good reason. They use less energy, last much longer, and actually perform better in cold environments than old-school fluorescents.

Make sure any fixtures you choose are vapor-proof—moisture and electricity don't play well together. For really large spaces, consider motion sensors that only light up areas when someone's working there, saving energy when sections sit empty.

Humidity Control

Temperature is only half the story in many applications. The right humidity level can dramatically extend product life and maintain quality.

Dew point sensors help prevent condensation problems by monitoring when moisture might start forming. For specialized needs like floral storage or certain pharmaceuticals, dedicated humidity control systems can maintain specific relative humidity alongside temperature.

Don't forget about water management—all that moisture pulled from the air has to go somewhere, so proper drain systems are essential in large walk in coolers.

Compliance and Certification

This part might not be exciting, but it's absolutely essential. Your cooler needs to meet various standards to ensure it's safe, efficient, and legal to operate.

NSF Standard 7 certification confirms your unit meets food safety requirements. UL listing ensures all electrical components won't burn your building down. The Energy Independence and Security Act (EISA) sets minimum efficiency standards that all coolers must meet (at least R-25 insulation).

If you're in California, you'll need to comply with Proposition 65 requirements. WARNING: Attention California Residents-This product can expose you to chemicals...

And don't forget local building codes—they vary by location but might include specific requirements for electrical work, structural elements, or mechanical systems.

Temperature & Humidity Control Specs

Most large walk in coolers keep temperatures between +34°F and +45°F, with 35°F being the sweet spot for general refrigeration. Maintaining consistent temperatures becomes trickier as coolers get bigger, which is why quality units use digital controllers with multiple sensors throughout the space.

A good system will keep temperatures within 2 degrees of your target, even in massive spaces exceeding 1,000 square feet. For specialized applications like floral storage, humidity control systems maintain relative humidity between 50% and 95%, depending on what you're storing.

I remember a floral distributor who installed one of our 600 square foot units with humidity control. They called me a month later, absolutely thrilled that their flowers were lasting nearly 40% longer. "We're throwing away far less inventory now," they told me. "The cooler paid for the humidity upgrade in just a few months."

Construction Materials & Panel Systems

The outer skin of your large walk in cooler needs to stand up to daily abuse while maintaining its insulating properties.

Most coolers use galvalume steel (26-gauge) for a good balance of durability and cost. For harsh environments or when sanitation is critical, stainless steel offers superior protection. Aluminum works well for outdoor installations where weight and corrosion resistance matter, while one-piece fiberglass construction provides seamless protection for the most demanding applications.

Inside those panels, most large walk in coolers use 4" thick urethane foam with tongue-and-groove edges and cam-lock fasteners that pull panels tightly together. These create an airtight seal when properly installed.

As for flooring, you have options based on how you'll use the space. Insulated NSF aluminum floors support loads up to 1,200 lbs—perfect for carts and light equipment. Heavy-duty reinforced floors stand up to pallet jacks and limited forklift traffic. Some installations use a floorless design, building directly over properly insulated concrete slabs.

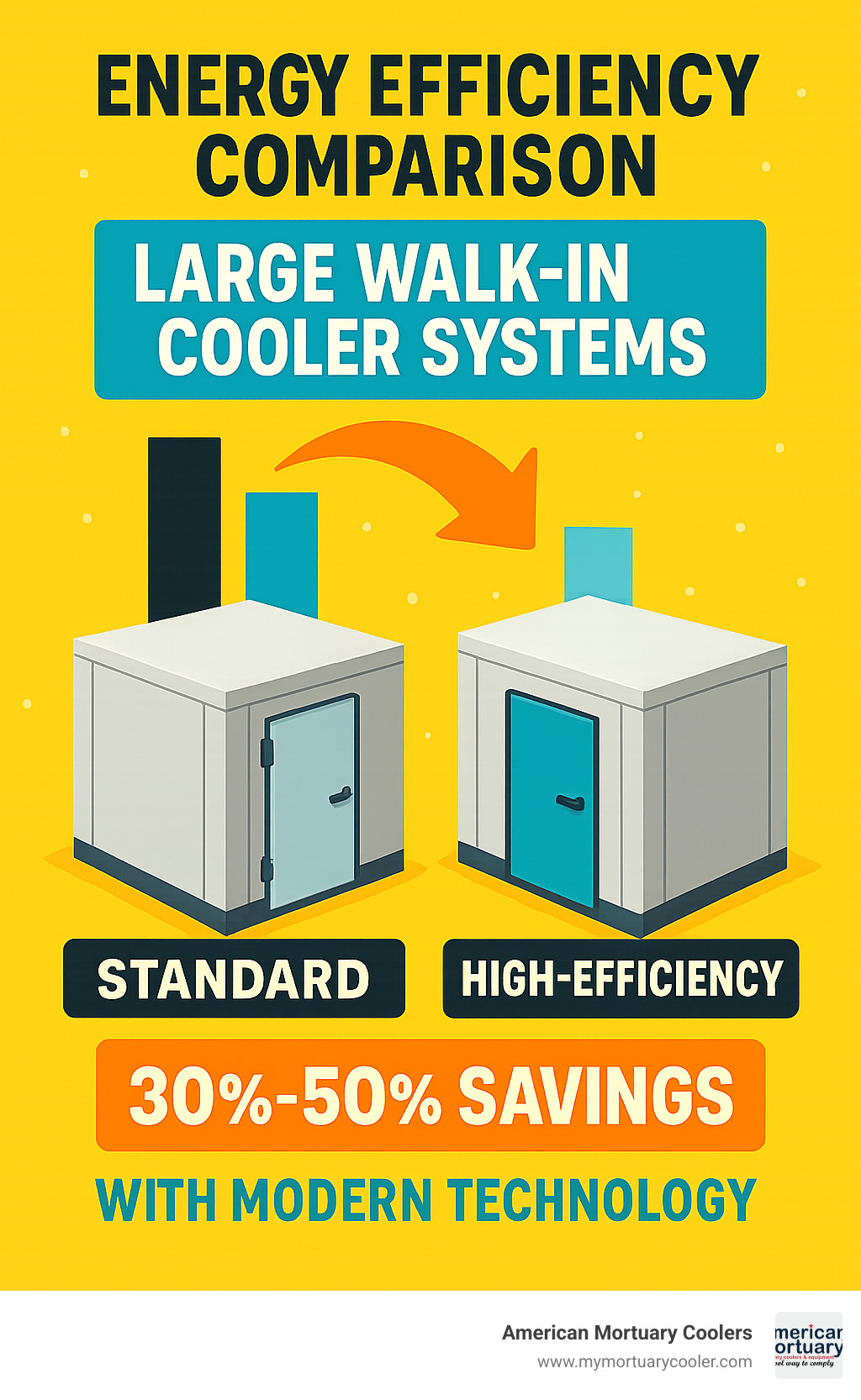

Energy Efficiency Technologies

Your monthly electric bill will quickly remind you that cooling thousands of cubic feet isn't cheap. That's why energy-efficient components make such a difference in large walk in coolers.

EC (Electronically Commutated) motors adjust their speed based on actual cooling demand rather than running at full blast all the time, cutting energy use by 30-50%. Variable-speed compressors work similarly, modulating their output to match exactly what's needed rather than cycling on and off.

Some systems even capture waste heat from refrigeration equipment and repurpose it for water heating or space heating elsewhere in your facility. Smart defrost systems only run when actually needed, not on a fixed schedule, reducing energy waste and temperature fluctuations.

Certifications & Standards You Can't Ignore

When investing in a large walk in cooler, certain certifications ensure you're getting a safe, compliant unit that performs as promised.

NSF Standard 7 certification verifies your cooler meets food safety requirements. UL listing confirms electrical components meet safety standards. ASTM E84 testing measures fire resistance, with quality panels achieving ratings of 25 or less for flame spread and 450 or less for smoke development.

The Energy Independence and Security Act (EISA) requires minimum efficiency standards, including R-25 insulation for coolers and R-32 for freezers. And don't forget local building codes, which may include requirements for seismic anchoring, electrical specifications, or structural considerations.

At American Mortuary Coolers, we exceed these minimum standards with R-29 for coolers and R-32 for freezers. As we like to tell our customers, "Building to minimum code means your cooler is the worst one legally allowed to be built." That's why we aim higher.

From Planning to Operation: Sizing, Installation & Lifecycle Costs

The journey from concept to a fully operational large walk in cooler isn't something that happens overnight. It's a thoughtful process that typically unfolds over 3-6 months for custom installations. Let's walk through what you can expect when bringing your cold storage vision to life.

Calculating the Right Large Walk In Cooler Footprint

When clients call us at American Mortuary Coolers, their first question is often "what size do I need?" The answer requires looking beyond your current situation and into your future.

Start by calculating your current storage needs in cubic feet, then add about 20% for aisles and access space—because a cooler packed to the gills is a workflow nightmare! Next, factor in another 20-30% for future growth. We've learned from experience that most businesses should plan for at least 3-5 years of projected growth when sizing a large walk in cooler.

Your product turnover rate matters too. If you're constantly moving inventory in and out, you might manage with a smaller footprint. But if products stay longer, you'll need more breathing room.

I remember working with a food distribution company who initially wanted an 800 square foot cooler based on their current inventory. After we chatted about their growth projections and seasonal peaks, they opted for a 1,200 square foot solution. Three years later, they called to thank us—during their peak season, they were at 85% capacity. Had they gone smaller, they'd be facing a costly expansion or replacement.

Installation Pathways & Site Requirements

There are two main ways to install large walk in coolers, and each has its own timeline and requirements:

Most commonly, we use panelized construction where components arrive flat-packed and are assembled on-site by our specialized technicians. This approach takes 2-5 days for large installations but allows us to install in locations with limited access—perfect for those tricky indoor spaces or facilities with narrow doorways.

Alternatively, prefabricated one-piece units arrive fully assembled and can be installed in just 1-2 days. The catch? You'll need adequate crane or forklift access, which limits where these can go.

Regardless of which approach works for you, you'll need a level concrete slab rated for the anticipated load, proper condensate drainage, adequate electrical service (typically 208-230V, 3-phase for large units), and sufficient clearance for condenser units and maintenance access.

"All walk-ins are test assembled in our plant before shipment," I often tell clients. "This extra step guarantees a smooth on-site installation and saves everyone headaches down the road."

Cost Factors, Financing & Warranty

When budgeting for your large walk in cooler, the investment extends well beyond the initial purchase price. These systems typically have a 15-20 year lifespan, so think of it as a long-term operational asset.

Initial costs typically range from $80-$150 per square foot installed, with variables including:

- Panel grade and finish (expect a 20-30% premium for stainless steel)

- Refrigeration capacity (typically 25-40% of total system cost)

- Site preparation (usually $5,000-$15,000 for large installations)

- Accessories and options (adding 10-25% to the base system cost)

Don't let sticker shock deter you—financing options abound. At American Mortuary Coolers, we offer competitive financing through trusted partners, with programs specially designed for funeral homes and medical facilities. Many of our clients opt for equipment leasing with terms from 2-7 years, 100% financing options with no down payment, or rental programs for temporary needs.

Quality systems come with robust warranty coverage, typically including a 20-year panel warranty, 5-year door warranty, 5-year compressor warranty, and 1-year parts warranty. We also offer optional extended labor warranties up to 3 years for complete peace of mind.

Maintenance & Service Roadmap

A large walk in cooler is like any significant piece of equipment—it needs regular TLC to perform at its best. We recommend quarterly inspections to check door gaskets, clear drain lines, clean evaporator and condenser coils, and verify control system function.

Semi-annually, have a professional check refrigeration system performance, inspect electrical components, lubricate moving parts, and calibrate temperature controls. Once a year, schedule a comprehensive refrigeration service, structural inspection, door alignment adjustment, and control system evaluation.

Many of our modern coolers include remote monitoring capabilities that alert you to potential issues before they cause system failures or product loss. These smart systems can reduce maintenance costs by 15-20% while improving reliability—something particularly important when you're storing sensitive items.

"The maintenance schedule might seem intensive," one of our long-time customers recently told me, "but it's saved us thousands in prevented emergency repairs and product loss. It's insurance you can't afford to skip."

For more detailed information about features and pricing options, visit our Complete Guide to Walk-In Cooler Features and Prices.

Pitfalls, Case Studies & Leading Brands

Let's face it – even with the best planning, setting up a large walk in cooler isn't always smooth sailing. I've seen plenty of businesses make costly mistakes that could have been avoided with a little insider knowledge. Let me walk you through some common pitfalls, share some success stories, and introduce you to manufacturers we trust.

Common Mistakes to Avoid

The most heartbreaking mistake I see? Undersizing. Too many businesses focus only on current needs without thinking about growth. Within just 2-3 years, that perfectly-sized cooler becomes frustratingly inadequate during busy periods.

Poor airflow design is another headache waiting to happen. A large walk in cooler isn't just a big box that stays cold – it needs carefully engineered airflow patterns. I remember visiting a food processing facility with significant temperature fluctuations in their 1,200 square foot cooler. The issue? All evaporators were clustered on one wall, creating freezing zones near the units and warm spots at the opposite end. Simply redistributing those evaporators solved the problem and cut their energy bill by 22%!

Floor problems can literally bring your operation to a halt. These massive coolers place tremendous weight on your foundation, and skimping on proper floor preparation leads to moisture infiltration, structural issues, and even frost heaving that can damage your entire unit.

Those high-traffic doorways? They're magnets for condensation and ice without proper door heaters, quality gaskets, and perfect alignment. I've seen businesses struggle with doors that won't seal properly, creating constant temperature fluctuations and energy waste.

And don't get me started on mismatched refrigeration systems! An undersized system runs constantly, wearing out prematurely, while an oversized one short-cycles and creates humidity nightmares. Finding that perfect balance requires expertise.

Leading Manufacturers in the Large Cooler Market

After years in this industry, I've developed relationships with manufacturers who consistently deliver quality products:

Polar King stands out with their seamless fiberglass outdoor units featuring one-piece construction. Their coolers (up to 16' wide and 65' long) eliminate panel seams – a common source of air leakage and energy inefficiency.

U.S. Cooler has earned their reputation for excellent customer support and high-quality panelized systems. Their cam-lock panel connections create secure seals, and they can customize configurations up to an impressive 40' x 40'.

American Walk-In Coolers proudly offers 100% USA-made panels with nationwide direct shipping. I particularly appreciate their attention to durability details – heavy-duty triple hinges, flush doors, and diamond kick plates that stand up to demanding environments.

At American Mortuary Coolers, we partner with these trusted manufacturers to deliver solutions specifically designed for funeral homes and medical facilities across the country, from the Southeast to the Pacific regions.

Real-World Installation Case Studies

Let me share some success stories that showcase what's possible with the right large walk in cooler solution:

A regional food distributor in Dallas came to us needing a massive 30,000 square foot cold storage facility with multiple temperature zones. The challenge wasn't just size – they needed careful planning for traffic flow and product segregation. We designed a system with reinforced flooring for heavy forklift traffic, multiple access points featuring high-speed doors, a comprehensive remote monitoring system, and energy-efficient LED lighting with motion sensors. Five years later, they're enjoying 99.8% uptime with energy costs 28% below industry averages.

A Chicago medical research laboratory presented a different challenge – they needed absolutely precise temperature control (±1°F) in a 600 square foot walk-in storing millions of dollars of temperature-sensitive materials. Our solution included redundant refrigeration systems with automatic failover, UPS backup for critical controls, and 24/7 remote monitoring. As their facility manager told me, "When you're storing millions of dollars worth of research materials, reliability isn't optional." Their system has maintained perfect stability through power outages and extreme weather events.

One of my favorite projects was for a growing craft brewery in Atlanta. They needed an 800 square foot cooler with dual-temperature capabilities for different stages of the brewing process. We created partitioned spaces with separate temperature controls, installed floor drains for cleaning and processing, added extra-wide doors for moving fermentation tanks, and implemented humidity control for specific products. The head brewer later told me, "The ability to maintain different temperature zones within our walk-in has given us tremendous flexibility. We can condition, ferment, and store in a single facility, which has streamlined our entire operation."

For more insights about specialized cooling solutions, check out our detailed article on Top Morgue Walk-In Coolers Reviewed.

Frequently Asked Questions about Large Walk-In Coolers

What temperature range should my large walk in cooler maintain?

When it comes to large walk in coolers, temperature isn't a one-size-fits-all situation. Most units are designed to keep things comfortable between 35°F and 55°F (1.7°C to 12.8°C), with 35°F being the sweet spot for general food storage.

Your ideal temperature really depends on what you're storing. Fresh produce and most perishables are happiest around 35°F-40°F, while your floral arrangements need a slightly different approach – about 36°F-38°F with careful humidity control to keep those blossoms looking their best. Dairy products prefer the cooler end of the spectrum at 33°F-38°F, and if you're in the beverage business, your kegs and drinks will do nicely at 36°F-40°F.

Wine collectors, you'll want things a bit warmer at 45°F-55°F. And for our funeral industry friends, mortuary applications generally require a steady 35°F-38°F for proper preservation.

"We've found that maintaining a consistent 36°F throughout our cooler has been ideal for our funeral home," shares one of our long-time customers. "It's cool enough for proper preservation but not so cold that it creates other issues."

Consistency is just as important as the number on the thermostat. A well-designed large walk in cooler should maintain temperatures within about 2 degrees throughout the entire space – even in those massive 1,000+ square foot installations. If you need temperatures below freezing, you'll need to look at freezer systems instead of standard coolers.

Some of our more sophisticated installations include dual-temperature capabilities, allowing different sections to maintain different ranges – perfect for businesses with diverse storage needs.

How much electricity does a large walk in cooler use per month?

I won't sugarcoat it – large walk in coolers do consume significant electricity, but exactly how much varies widely based on several factors. Let me give you some real-world figures to work with.

For a well-insulated 1,000 square foot cooler maintaining 35°F when it's 75°F outside, you're looking at approximately 8,000-10,000 kWh per month with a basic system. Upgrade to high-efficiency components, and you might bring that down to 5,000-7,000 kWh monthly.

What really drives your electric bill? Door openings are a major factor – frequent access can increase energy usage by 30-50%. It's like cooling your house with the windows open! The temperature outside matters too; hotter weather means your system works harder. And when you're constantly adding warm products that need to be cooled down, that's additional energy your system needs to expend.

The quality of your insulation makes a substantial difference. We've seen upgrading from R-25 to R-29 insulation reduce energy use by about 15%. And modern equipment like EC motors and variable-speed compressors can dramatically cut consumption.

One of our food distribution customers in Missouri told us: "After upgrading to EC motors and LED lighting in our 1,200 square foot cooler, we saw our monthly energy costs drop by nearly a third. The investment paid for itself faster than we expected – under 18 months."

Many newer large walk in coolers include energy monitoring systems that let you track consumption in real-time. This data helps identify when and where you're using the most energy, so you can make smart adjustments to your operations.

Can I expand or relocate my large walk in cooler later?

Yes, you absolutely can! But how easy (and cost-effective) that process will be depends largely on how your cooler was built in the first place.

Panelized Systems offer the most flexibility. These are like sophisticated building blocks – they can be disassembled and reassembled, with additional panels added when you need more space. One of our customers in Pittsburgh started with an 800 square foot cooler but positioned it strategically with expansion in mind. Three years later, when business was booming, we simply removed one wall and expanded to 1,200 square feet without disrupting their daily operations.

One-Piece Fiberglass Units are a bit trickier to expand but can typically be relocated as complete units. Some manufacturers offer modular designs that allow multiple units to be joined together when you need more space.

If expansion might be in your future, here's what I recommend during your initial installation: Position your cooler with at least one wall accessible for potential expansion. Make sure your electrical service has capacity for growth – upgrading electrical later can be expensive. Select refrigeration equipment that can be supplemented rather than completely replaced. And always keep documentation of your panel types and specifications for future matching.

When expanding, your refrigeration capacity needs to increase proportionally to the new space. Your structural support may need reinforcement, and floor systems must be properly joined for seamless operation.

At American Mortuary Coolers, we've helped dozens of funeral homes plan their cooler installations with future growth in mind. One funeral director in Tennessee told me, "When we added that second location three years later, being able to expand our existing cooler instead of starting from scratch saved us nearly $30,000."

For more detailed information about mortuary cooler options specifically, check out our Ultimate Guide to Choosing a Walk-In Mortuary Cooler.

Conclusion

A large walk in cooler represents a significant investment in your business infrastructure, but when properly specified, installed, and maintained, it delivers tremendous value through improved operational efficiency, product protection, and scalability for future growth.

At American Mortuary Coolers, we understand that each application has unique requirements, particularly in the sensitive field of mortuary services. Our team has walked alongside countless funeral homes, hospitals, and medical facilities across the country as they've steerd the complex process of selecting the perfect cold storage solution.

We've seen how the right large walk in cooler can transform operations – from the relief on a funeral director's face when they no longer worry about capacity issues during busy periods to the satisfaction of a hospital administrator who finally has a reliable, energy-efficient solution.

Our nationwide service network covers Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, Pittsburgh PA, with comprehensive regional coverage throughout the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions. This means you'll never be left without support, no matter where you're located.

When you partner with us, you're getting more than just a cold storage unit. You're gaining a trusted advisor who will guide you through every step – from those initial sizing calculations (that so many get wrong) through installation and the ongoing service relationship that ensures decades of reliable performance.

We focus on creating durable, energy-efficient solutions custom to your specific needs, with direct delivery across the contiguous 48 states. And yes, we understand the unique requirements of the funeral industry – it's our specialty, after all.

The right large walk in cooler is more than just a refrigerated box—it's a critical operational asset that supports your business goals while protecting valuable inventory. By understanding the options, avoiding those common pitfalls we discussed, and working with experienced professionals who understand your industry, you can ensure your investment delivers optimal performance for decades to come.

For those seeking even more comprehensive guidance on selecting the perfect walk-in cooler for specialized applications, we invite you to explore our Ultimate Guide to Choosing a Walk-In Mortuary Cooler. It's packed with insights specifically for funeral professionals.

Contact American Mortuary Coolers today, and let's have a conversation about your specific requirements. We've helped hundreds of funeral professionals find their perfect cold storage solution – and we'd be honored to do the same for you.