Understanding Ventilated Cabinets: Safety and Functionality

A ventilated cabinet is a specialized storage unit designed to safely contain hazardous materials while preventing the buildup of dangerous fumes, vapors, or heat through controlled airflow systems.

Quick Answer: What is a Ventilated Cabinet?

- Purpose: Safely stores chemicals, specimens, or equipment while controlling fumes/vapors

- Function: Uses mechanical fans or passive systems to remove harmful air

- Types: Chemical storage, flammable liquid, gas cylinder, mortuary tissue, and electronics cabinets

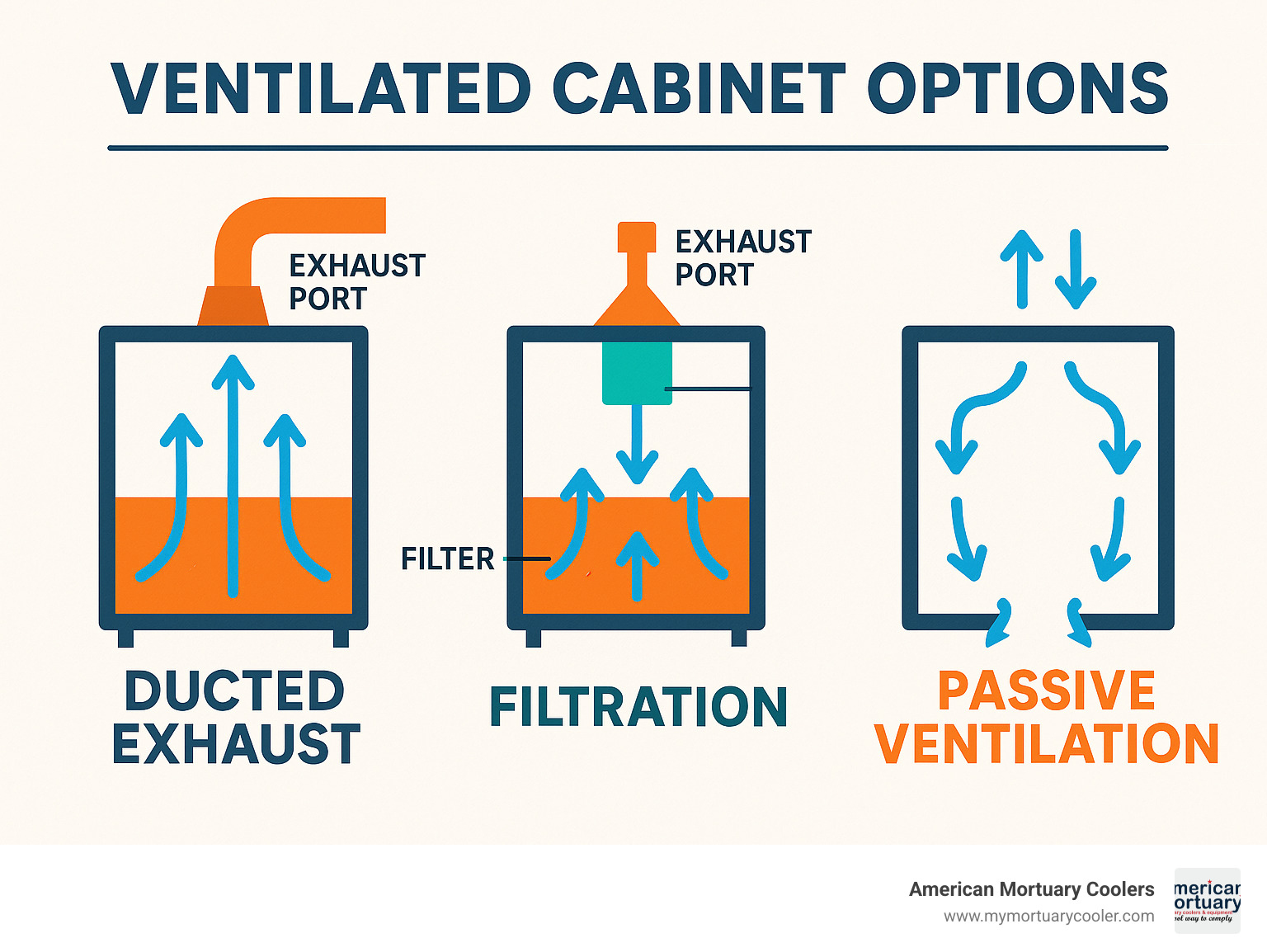

- Ventilation Methods: Ducted (connected to building exhaust) or filtered (self-contained)

- Key Benefits: Protects staff, prevents fume buildup, ensures regulatory compliance

- When Required: Mandatory for toxic chemicals, corrosives, and many gases; optional but often recommended for flammables

Ventilated cabinets play a crucial role in laboratory, industrial, and medical settings where the safe storage of hazardous materials is essential. Unlike standard storage cabinets, these specialized units incorporate airflow management systems that actively remove or filter dangerous vapors, preventing their accumulation and potential harm to personnel or the environment.

The decision to use a ventilated cabinet often stems from safety regulations, material hazard classifications, or specific operational needs. While not all storage situations require ventilation (and in some cases, like certain flammable storage, improper ventilation can actually compromise fire protection), understanding when and how to implement ventilated storage is critical for workplace safety.

I'm Mortuary Cooler, with over 15 years of experience designing and implementing ventilated cabinet solutions for funeral homes, medical facilities, and laboratories nationwide. My expertise in ventilated cabinet systems has helped hundreds of facilities meet compliance requirements while protecting staff from harmful chemical exposure.

Ventilated cabinet terms made easy:

What Is a Ventilated Cabinet and How Does It Work?

Ever wonder what keeps dangerous chemical fumes from filling up your lab or workplace? That's where a ventilated cabinet comes in! These specialized storage units do much more than just hold your materials—they actively work to keep you and your environment safe.

At its heart, a ventilated cabinet creates a controlled environment that prevents harmful vapors, fumes, or heat from building up inside. The magic happens through carefully designed airflow patterns and negative pressure—meaning air wants to flow into the cabinet rather than escape when you open the doors.

Think of it as a one-way street for air. When working properly, these cabinets ensure that what goes in (hazardous vapors) doesn't come out into your breathing space.

The main components that make this possible include:

- Ducted Exhaust Systems that connect to your building's ventilation, whisking away dangerous air to the outside world

- Filtration Systems with activated charcoal that trap and neutralize harmful chemicals before clean air returns to the room

- Retention Trays that catch spills before they spread and create more vapors

- Pressure Differential Controls that maintain the negative pressure needed for safety

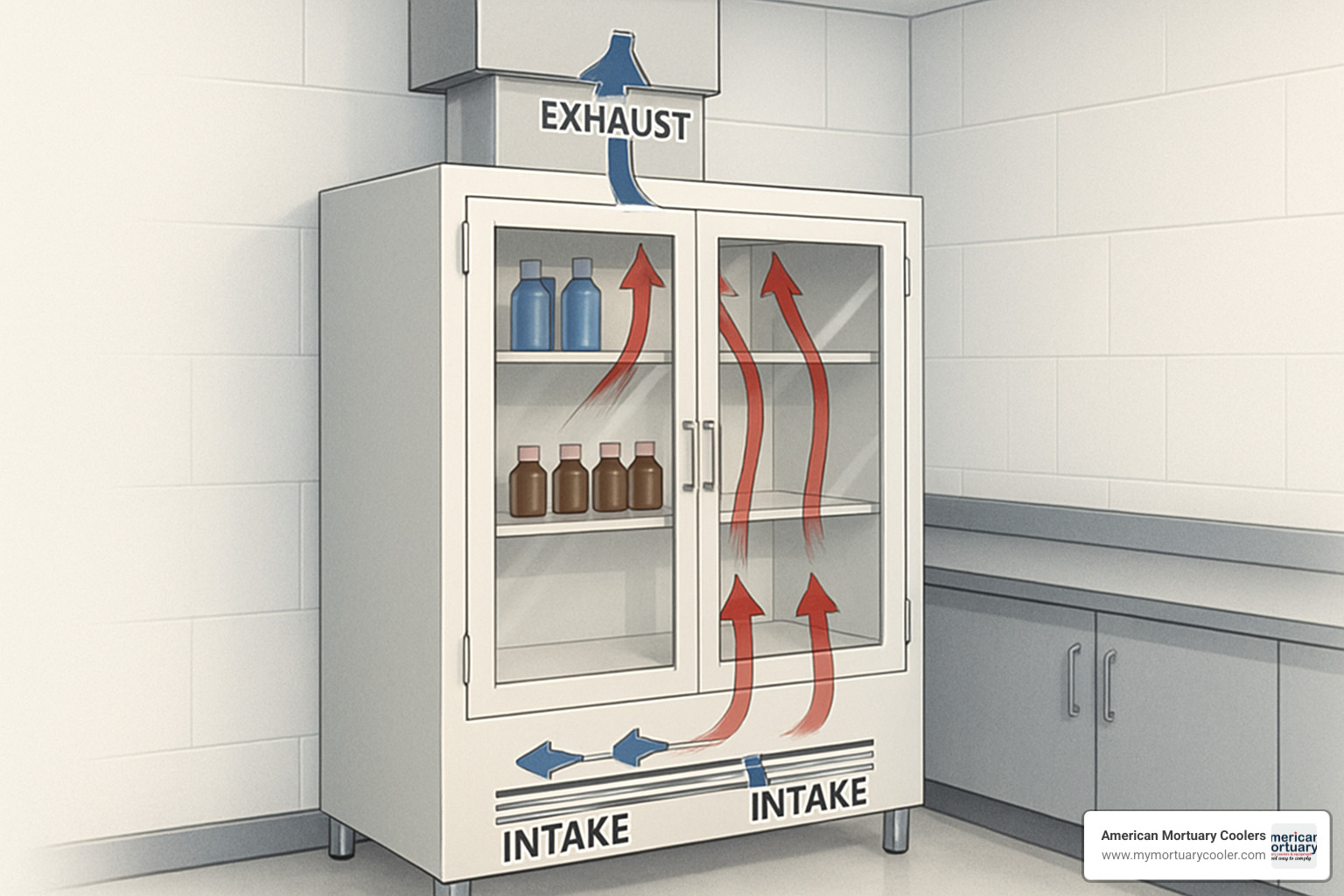

Most ventilated cabinets are cleverly designed with air intake at the bottom and exhaust at the top. This isn't random—many chemical vapors are heavier than air, so this layout creates a natural flow that captures fumes where they're most likely to collect.

Here at American Mortuary Coolers, our ventilated cabinets include spill containment systems with retention sumps that can handle accidental leaks. These sumps don't just prevent hazardous materials from spreading—they also reduce the surface area of spilled liquids, meaning less evaporation and fewer dangerous vapors.

Mechanical vs Passive Ventilated Cabinet Systems

When it comes to moving air through a ventilated cabinet, you have two main options:

Mechanical Ventilation Systems are like the hardworking employees who never take a day off. They use powered fans to actively move air, delivering consistent airflow (typically 75-150 CFM depending on cabinet size). Yes, they need electricity and regular maintenance, but they provide reliable performance that's critical for high-risk applications. They're a bit like having an insurance policy—they cost a little more to run but provide peace of mind.

Passive Ventilation Systems are the minimalists of the ventilation world. With no moving parts or electricity needs, they rely on natural air movement through strategically placed vents. They're low-maintenance and energy-free, but they're best suited for less hazardous materials since airflow can vary based on room conditions.

For our mortuary tissue storage cabinets, we typically recommend mechanical systems that deliver 100-125 CFM through a 6-inch duct. This consistent airflow effectively controls formalin fumes, keeping your workspace safe and comfortable.

Ventilated Cabinet Airflow Basics

Your ventilated cabinet is working hard behind the scenes with three main jobs:

Vapor Removal is the primary mission—continuously extracting potentially harmful chemical vapors before they reach dangerous levels. Think of it as a 24/7 security guard for your air quality.

Temperature Control prevents heat buildup in electronics cabinets or maintains stable temperatures for sensitive materials. This is especially important for equipment that generates heat or specimens that require specific storage conditions.

Particulate Capture removes airborne dust or particles that might contaminate your stored items—critical in clean environments like labs or medical facilities.

Good ventilation design considers several key factors: how often the air needs to be completely replaced (measured in air changes per hour), strategic placement of vents to avoid "dead zones," filter efficiency for specific contaminants, and whether the vapors you're dealing with are heavier or lighter than air.

With the right ventilated cabinet, you can store potentially dangerous materials with confidence, knowing that harmful vapors are being actively managed rather than building up to dangerous levels. It's not just about storage—it's about creating a safer workplace for everyone.

Types of Ventilated Cabinets & When Ventilation Is Required

Ever wonder what kind of ventilated cabinet might be right for your needs? The truth is, these safety workhorses come in many specialized forms, each designed with specific materials and hazards in mind.

Chemical Storage Ventilated Cabinets

When it comes to safely storing laboratory chemicals, not just any cabinet will do. Ventilated cabinets for chemicals feature thoughtfully designed elements like adjustable shelving that accommodates everything from tiny 20ml bottles to larger 1L containers.

The interiors are built with chemical-resistant surfaces that won't degrade when exposed to harsh substances. Spills happen to everyone, which is why these cabinets include retention trays to capture any accidents before they become bigger problems. Depending on your facility's setup, you can choose between filtered systems that clean and recirculate air or ducted options that connect to your building's exhaust.

Companies like Erlab offer models ranging from compact units that use just 12W of power to larger cabinets requiring 45W, depending on your storage needs.

Flammable & Combustible Liquid Cabinets – Ventilate or Not?

Here's a surprising fact that confuses many people: flammable storage cabinets don't actually need ventilation for fire safety purposes. In fact, the National Fire Protection Association (NFPA 30) doesn't require it, and improper venting might actually make your cabinet less safe during a fire.

These cabinets are specifically designed to protect their contents during fires by keeping internal temperatures below the flashpoint of stored materials. Those bung plugs that come with your cabinet? They're meant to stay in place unless you have a specific reason to ventilate.

If odors or vapors are a concern, you can ventilate according to NFPA guidelines, but it must be done correctly. This means using rigid metal piping that matches the cabinet's construction quality, installing flame arresters at vent openings, and making sure vents lead outdoors or to approved exhaust systems—never directly into your workspace. Keep total vent piping under 25 feet for best results.

As the UC Davis Fire Department wisely points out, "While cabinet manufacturers may provide the bungs for venting, ventilation for flammable storage cabinets is NOT required or recommended by the NFPA or CFC."

Toxic & Corrosive Chemical Cabinets – Ventilation a Must

Unlike their flammable cousins, cabinets for toxic and corrosive chemicals absolutely need proper ventilation. The risks here are different, and so are the solutions.

For toxic chemical cabinets, excellent ventilation prevents dangerous vapor buildup. Simple air slots won't cut it—these cabinets typically connect to external exhaust systems and often include activated charcoal filtration to trap specific contaminants.

When it comes to corrosive chemicals, the cabinets themselves need protection too. That's why we build them from corrosion-resistant materials like 304 stainless steel, including all ventilation components. Smart designs incorporate neutralizing liners or sumps to contain and neutralize small spills. And remember—acids and bases should never share storage space!

At American Mortuary Coolers, our funeral home cabinets feature the same 304 stainless steel construction with specialized ventilation systems designed specifically for embalming chemicals. We understand that funeral professionals face unique chemical challenges, and our cabinets are built accordingly.

Gas Cylinder Ventilated Cabinets

Gas cylinder storage presents its own set of challenges. These specialized ventilated cabinets keep compressed gas cylinders secure while providing continuous airflow to prevent dangerous gas accumulation if leaks occur.

Safety standards from OSHA, NFPA 55, and the International Fire Code guide their design. You'll find these cabinets built with heavy-duty 11 or 12-gauge steel and equipped with robust securing mechanisms—brackets, straps, and chains—to keep cylinders upright and stable.

The self-closing doors typically feature clear-wire windows for easy visual inspection without opening the cabinet. Top exhaust vents (usually 6 inches in diameter) connect to ventilation systems that move significant amounts of air—from 175 CFM for single-cylinder cabinets up to 600 CFM for units holding four cylinders.

These cabinets come in various sizes to fit your needs, from compact models (18"W × 18"D × 39"H) all the way up to larger units (48"W × 19"D × 75"H) for tall cylinders. Some even offer optional 165°F-rated sprinkler heads for additional fire protection.

Specialty Ventilated Cabinet Options for Electronics & Morgue Tissue

Electronics cooling cabinets focus more on heat management than chemical control. Their mesh or perforated doors maximize airflow, and many include temperature-activated fans that kick in when things get too warm. These cabinets protect sensitive equipment from both overheating and dust buildup—two common enemies of electronic components.

Mortuary tissue storage cabinets serve a very specific and essential purpose in funeral homes and medical facilities. Built from 304 stainless steel for easy cleaning and corrosion resistance, these cabinets are designed specifically for tissue specimens preserved in formalin.

We've designed our cabinets with integrated trays that both absorb and neutralize formalin spills, protecting both specimens and staff. Proper ventilation is critical—typically 100-125 CFM through a 6-inch duct—to control formalin fumes effectively. Many funeral professionals appreciate the portable shelving systems that make specimen transport easier and safer.

Our LD500 Ventilated Tissue Storage and Transport System exemplifies this specialized design. At 31" L × 34" W × 89" H, it offers generous storage with approximately 200 lbs capacity per shelf. For facilities in earthquake-prone areas, we even offer seismic anchoring brackets for added stability and peace of mind.

Benefits, Risks & Regulatory Standards

Let's face it – storing hazardous materials isn't exactly a walk in the park. That's where ventilated cabinets come in, offering some serious advantages while helping you stay on the right side of regulations.

Key Benefits of Ventilated Cabinets

Your team's health and safety should always be priority number one. Ventilated cabinets excel at protecting your staff from potentially harmful vapors, gases, and fumes that could cause anything from headaches to serious long-term health issues. We've seen how proper ventilation transforms work environments, especially in funeral homes where chemical exposure is a daily concern.

Beyond protecting people, these cabinets help safeguard our environment by preventing hazardous substances from escaping into the air we all breathe. This supports both sustainability goals and keeps you compliant with environmental regulations – a win-win in our book!

Let's not forget about the nose factor – even when substances aren't dangerous, nobody wants to work in a space that smells like formaldehyde all day. Ventilated cabinets tackle odor control effectively, making for a much more pleasant workspace.

Many of our clients appreciate that ventilated cabinets with mesh or perforated doors allow for quick visual inventory without opening doors. This practical feature reduces exposure risks while making inventory management more efficient.

Perhaps most importantly for facility managers, using appropriate ventilated cabinets helps meet OSHA, EPA, and other regulatory requirements for hazardous material storage – keeping surprise inspections from becoming unpleasant surprises.

Potential Risks and Drawbacks

It's not all roses when it comes to ventilation. For flammable storage cabinets, improper ventilation can actually reduce fire protection by creating pathways for fire to enter the cabinet – a classic case of a solution becoming a problem.

Your utility bills might notice the addition of mechanical ventilation systems too. These systems require electricity to operate and can increase HVAC costs by exhausting conditioned air from your building. At American Mortuary Coolers, we work hard to design energy-efficient systems that minimize this impact.

Like any specialized equipment, ventilation systems need regular TLC. Scheduled inspections and maintenance ensure proper function but do add to operational costs. We typically recommend quarterly filter checks for most applications.

Perhaps the biggest risk is simply choosing the wrong type of ventilation for your specific hazards. This creates a dangerous false sense of security while failing to address actual risks – something we help clients avoid through our needs assessment process.

Key Regulatory Standards

Navigating the alphabet soup of regulations can be daunting, but understanding these standards is crucial when selecting ventilated cabinets:

NFPA 30 sets standards for flammable storage cabinets. Contrary to popular belief, it doesn't require ventilation for fire protection purposes. If you do implement ventilation, the code provides specific guidelines to follow.

NFPA 55 establishes requirements for gas cylinder storage cabinets, including detailed ventilation specifications that vary based on the gases being stored.

OSHA 1910.106 outlines requirements for flammable liquid storage, including cabinet construction and ventilation considerations when used.

The European standard EN 14470-1 covers fire-rated storage cabinets for flammable materials, with specific provisions regarding when and how ventilation should be implemented.

UL 1275 certification involves fire testing cabinets without ventilation – they must withstand exterior temperatures of 1300°F for 10 minutes, demonstrating why proper ventilation design is so important.

For specialized applications, standards like S2-93 provide safety guidelines for semiconductor manufacturing equipment, applying to certain gas cabinets used in clean rooms.

The California Fire Code (CFC) aligns with NFPA in not recommending ventilation for flammable storage cabinets unless specifically needed for vapor control – a position that sometimes surprises new clients.

Key Design Features and How to Choose the Right Ventilated Cabinet

Choosing the perfect ventilated cabinet isn't just about safety – it's about finding the right match for your specific needs. Let me walk you through what makes these cabinets special and how to select one that works for your situation.

Essential Design Features

When we build ventilated cabinets at American Mortuary Coolers, we focus on quality materials that stand the test of time. Most general-purpose cabinets use sturdy 14-gauge steel – these workhorses can handle impressive loads, with some Lyon cabinets supporting up to 1,450 pounds per shelf!

For our funeral home and medical clients, we typically recommend 304 stainless steel construction. This material isn't just beautiful – it's practically impervious to corrosion and makes sanitizing a breeze, which is essential when storing sensitive specimens.

The doors on your ventilated cabinet matter more than you might think. Solid doors provide maximum security, while clear-wire windows let you check inventory without exposing yourself to what's inside. For electronics cooling, mesh or perforated doors maximize airflow while keeping components safe. And those self-closing mechanisms? They're not just convenient – they ensure the ventilation system maintains its integrity even when users forget to close up.

The heart of any ventilated cabinet is, of course, its ventilation system. Most cabinets feature standard 6-inch diameter exhaust ports that connect to your building's ventilation. If that's not an option, standalone filtration modules with activated charcoal can capture specific contaminants. For cabinets storing flammables, spark-proof fans aren't just nice to have – they're essential safety features.

Speaking of safety, don't overlook retention sumps that contain accidental spills, flame arresters that prevent fire spread through ventilation openings, and good old-fashioned lockable doors to keep unauthorized folks out. If you're in earthquake country like many of our West Coast clients, seismic anchoring provides essential stability when the ground gets shaky.

How to Choose the Right Ventilated Cabinet

Start by asking yourself what exactly you'll be storing. Different hazards require different solutions – the cabinet perfect for flammable solvents won't necessarily work for corrosive acids or compressed gases. And if you have incompatible materials, you'll need separate storage solutions to prevent dangerous reactions.

Next, think about size and capacity. How much material will you store? What size containers will you use? Will you need heavy-duty shelving for weighty items? Be realistic about your space constraints too – measure your available floor space and ceiling height before falling in love with a cabinet that won't fit.

One of the biggest decisions is your ventilation approach. Will you connect to your building's exhaust system, or do you need a standalone filtration unit? Different materials require different airflow rates – measured in cubic feet per minute (CFM) – and some contaminants need specialized filtration media.

Budget considerations are always important, but the cheapest option upfront isn't always the most economical long-term. Factor in not just the purchase price, but also installation requirements, ongoing operational costs, and maintenance expenses. Sometimes, retrofitting existing cabinets can be a cost-effective middle ground.

At American Mortuary Coolers, we specialize in custom ventilated cabinets designed specifically for funeral homes and medical facilities. Our tissue storage cabinets feature 304 stainless steel construction with integrated ventilation systems engineered to safely handle formalin and other embalming chemicals that regular cabinets simply can't manage.

Ventilated vs. Non-Ventilated vs. Ventless Cabinets

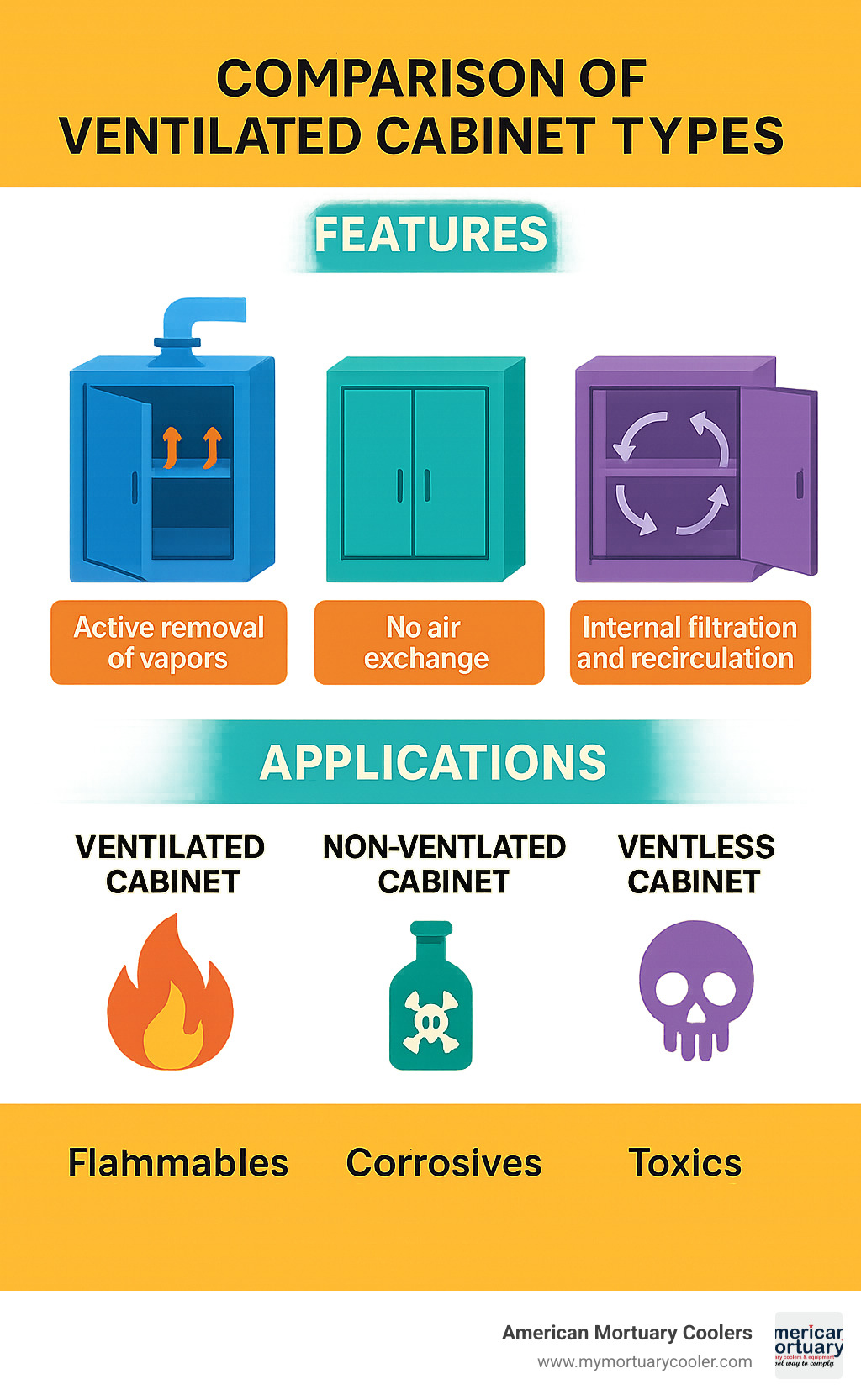

| Feature | Ventilated Cabinets | Non-Ventilated Cabinets | Ventless Cabinets |

|---|---|---|---|

| Airflow | Active removal of vapors | No air exchange | Internal filtration and recirculation |

| Applications | Toxic chemicals, corrosives, gases | Some flammables, non-volatile materials | Spray booths, some chemical storage |

| Energy Use | Moderate to high | None | Low to moderate |

| Installation | Requires ductwork or filtration | Simple placement | Self-contained |

| Maintenance | Regular filter/fan service | Minimal | Filter replacement |

| Regulatory Compliance | OSHA, NFPA (with proper setup) | NFPA 30 for flammables | Varies by application |

| Cost | Higher initial and operational | Lower initial cost | Moderate initial, ongoing filter costs |

| Best For | High-hazard materials with significant vapor concerns | Properly contained flammables, non-volatile materials | Situations where external venting is impractical |

Installation, Maintenance & Best Practices

Installing and maintaining your ventilated cabinet properly isn't just about checking boxes—it's about creating a safer workplace and protecting your investment. Let's walk through what you need to know to keep your cabinet working effectively for years to come.

Installation Guidelines

Setting up your ventilated cabinet correctly from day one prevents headaches down the road. Most cabinets come with 6-inch diameter exhaust ports, which is the industry standard for a reason—it provides optimal airflow for most applications.

When connecting your cabinet to an exhaust system, always use rigid metal piping rather than PVC or flexible tubing, especially for flammable storage. The material matters too—if you're storing corrosives, stainless steel ducting will prevent premature deterioration and potential hazards.

Keep your duct runs as short and straight as possible—ideally under 25 feet. This isn't just a suggestion; longer runs can significantly reduce airflow efficiency and create condensation problems. A slight downward slope in your ducting helps prevent any condensation from flowing back into the cabinet.

Where your exhaust ultimately goes matters tremendously. Never vent directly into work areas—this defeats the entire purpose of having a ventilated cabinet in the first place! Instead, route exhaust outside the building or into an appropriate exhaust system. Make sure discharge points are well away from building air intakes, walkways, or anything that could ignite vapors.

For flammable storage cabinets, flame arresters on ventilation openings aren't optional—they're essential safety features that prevent fire from entering the cabinet through the ventilation system.

Once installation is complete, don't just assume it's working correctly. Use an anemometer to verify proper airflow and document these initial readings. They'll serve as your baseline for future maintenance checks.

Maintenance Requirements

A ventilated cabinet isn't a "set it and forget it" piece of equipment. Regular check-ups keep it functioning optimally and safely.

Make monthly visual inspections part of your routine. Look for any signs of damage or corrosion, especially around seals and closure mechanisms. Pay special attention to retention trays and sumps—accumulated liquids or residues can compromise safety and performance.

For cabinets with filtration systems, filter changes are critical. How often depends on several factors: manufacturer recommendations, how frequently you access the cabinet, what types of chemicals you're storing, and any changes in airflow performance. Whatever schedule you establish, document every filter change in your maintenance log.

The mechanical components need love too. Fan bearings should be lubricated according to the manufacturer's timeline. Annual checks of electrical connections can prevent unexpected failures, while cleaning fan blades and ventilation pathways removes efficiency-robbing dust and debris.

Spills happen—it's how you handle them that matters. Clean up immediately, replace neutralizing materials in sumps as needed, and check for residual chemical traces that might cause long-term damage. Keep drainage systems clear to prevent backups that could create hazardous situations.

Best Practices for Ventilated Cabinet Use

How you use your cabinet day-to-day makes a tremendous difference in safety and longevity. Good inventory management is the foundation—maintain accurate records of what's stored where, and always segregate incompatible chemicals in separate cabinets. Store chemicals in properly sealed, compatible containers, and position heavier items on lower shelves to prevent accidents.

Develop consistent operational habits. Keep cabinet doors closed when not actively accessing contents—this maintains proper airflow patterns. Tighten caps on all containers before storage and clean the exterior of containers to prevent contamination. If your passive ventilated cabinet has a purge system, always use it before opening doors to clear residual vapors.

Documentation isn't exciting, but it's essential. Maintain records of all inspections and maintenance. Keep safety data sheets readily available for all stored materials. Document airflow verification tests and results. When regulations change or you introduce new materials, update your procedures accordingly.

Finally, equipment is only as good as the people using it. Train all staff thoroughly on proper cabinet use and the specific hazards of stored materials. Include cabinet operation in emergency response training and conduct refresher sessions when you install new equipment.

Here at American Mortuary Coolers, we understand that proper installation and maintenance are crucial for both safety and compliance. That's why we provide detailed maintenance guidelines with all our ventilated cabinets and offer service contracts across the contiguous 48 states. Our team ensures your systems remain in optimal condition, giving you one less thing to worry about in your day-to-day operations.

For more information on maintaining specialized equipment in funeral homes, check out our guide to Essential Mortuary Equipment: A Professional's Guide to Key Funeral Supplies.

Frequently Asked Questions about Ventilated Cabinets

When should I connect a cabinet to a building exhaust versus use a filtration box?

This is one of the most common questions we hear from funeral directors and lab managers. The answer really depends on your specific situation.

If you already have an accessible building exhaust system, that's often your best bet - especially when you're storing larger quantities of chemicals or particularly toxic substances. Building exhaust is also the way to go when local regulations mandate direct venting for your specific materials, or when you need higher airflow rates above 150 CFM. For ventilated cabinets that see heavy, continuous use, the reliability of building exhaust is hard to beat.

On the flip side, filtration boxes make perfect sense when you don't have easy access to building exhaust (or when installing ductwork would break the bank). At American Mortuary Coolers, we often recommend filtration systems to our smaller funeral home clients where running dedicated exhaust lines would cost more than the cabinet itself! Filtration is also ideal when you need the flexibility to move your ventilated cabinet occasionally, or when you're storing smaller quantities of chemicals that match well with available filter media.

I remember installing a filtration system for a family-owned funeral home in rural Kentucky - they needed proper formalin vapor control but had no practical way to install exterior ducting. The filtration box solution saved them thousands in construction costs while still providing excellent protection.

How much CFM is typically required for a single-door chemical cabinet?

The "right" airflow for your ventilated cabinet isn't one-size-fits-all. It varies based on what you're storing and the cabinet size.

For smaller chemical cabinets (under 30 inches wide), you're typically looking at 75-100 CFM. Standard single-door chemical cabinets generally need 100-125 CFM for effective ventilation. Our mortuary tissue storage cabinets specifically require 100-125 CFM through a 6-inch duct to properly control formalin vapors.

Gas storage has higher requirements - single-cylinder cabinets need around 175 CFM, while four-cylinder models can require up to 600 CFM to ensure safety.

Always check your specific cabinet's manufacturer recommendations, though. When we install ventilated cabinets at funeral homes, we carefully measure the actual airflow during setup to ensure it meets our specifications, not just the theoretical numbers.

What mistakes void compliance with NFPA or OSHA rules?

After 15+ years in this business, I've seen plenty of well-intentioned mistakes that can put your facility at risk of violations - and more importantly, compromise safety.

With flammable storage cabinets, using the wrong ventilation materials is a major issue. The NFPA is crystal clear: you need rigid metal piping, not PVC or flexible plastic tubing. Skipping flame arresters is another serious violation, as is venting directly into work areas rather than outside or into approved exhaust systems. And please, never connect multiple flammable cabinet vents together - that's specifically prohibited by NFPA 30.

Ventilated cabinet maintenance lapses are also compliance killers. Neglecting filter replacements, failing to verify and document airflow, ignoring corrosion or damage, or skipping manufacturer-recommended service can all void your compliance faster than you can say "OSHA inspection."

The way you use the cabinet matters too. Storing incompatible chemicals together, overloading shelves beyond their weight rating, leaving doors open when not actively accessing contents, or blocking ventilation openings with stored materials - all these operational errors can put you in violation.

Finally, documentation failures will trip you up even if everything else is perfect. Missing inspection records, outdated safety data sheets, lack of employee training documentation, or outdated procedures can all result in citations.

One of our funeral home clients learned this lesson the hard way - they had the right equipment but couldn't produce maintenance records during an inspection. Now we help them maintain a simple digital log of all ventilated cabinet inspections and filter changes, which has made compliance a breeze.

To stay on the right side of regulations, we strongly recommend scheduling annual professional inspections of all your ventilated cabinets and keeping detailed records of maintenance activities and airflow verifications. At American Mortuary Coolers, we can help set up a maintenance schedule that keeps your equipment both compliant and performing at its best.

Conclusion

Let's face it – when it comes to storing hazardous materials, ventilated cabinets aren't just nice to have; they're often essential for keeping everyone safe. After working with hundreds of funeral homes and medical facilities across the country, I've seen how the right cabinet can make all the difference.

Here's what I want you to remember about ventilated cabinets as you consider your options:

First, not everything needs ventilation. This surprises many people, especially when it comes to flammable storage cabinets. In fact, improper ventilation can actually make these cabinets less safe by compromising their fire protection features. Always check the specific requirements for your materials before assuming ventilation is needed.

The construction material of your cabinet matters tremendously. If you're storing corrosives or working with mortuary applications, stainless steel isn't just preferable – it's essential. I've seen perfectly good cabinets destroyed in months because someone tried to cut corners on materials. Your cabinet needs to stand up to whatever you're putting inside it.

Installation isn't a DIY project. Proper duct materials, correct routing, and appropriate airflow rates aren't just manufacturer suggestions – they're critical safety requirements. One funeral director I worked with learned this lesson the hard way when improper installation led to formalin fumes circulating back into their preparation room.

And please, don't install and forget. Regular maintenance – inspections, filter changes, performance checks – is what keeps these systems protecting your staff year after year. The best cabinet in the world won't help if its ventilation system isn't functioning properly.

At American Mortuary Coolers, we understand the unique challenges faced by funeral homes and medical facilities. Our team designs custom ventilated cabinet solutions that address your specific needs while ensuring you meet all regulatory requirements. We're particularly proud of our stainless steel cabinets for tissue storage and chemical containment – built to last and engineered for safety.

Based in Tennessee, we deliver and service our cabinets across the contiguous 48 states. Whether you're in Atlanta or Los Angeles, Chicago or Dallas, our team can help you select, install, and maintain the right equipment. We've built our reputation on understanding the specific challenges of the funeral industry and providing solutions that truly work.

I'd love to hear about your specific storage challenges. Whether you need a standard solution or something completely custom, we're here to help create a safer workspace for you and your team.

For more information about our custom ventilated cabinet options, visit our nationwide custom solutions page or give us a call. After all, when it comes to safety equipment, you deserve a partner who truly understands your needs.