Understanding Cold Room Terminology and Applications

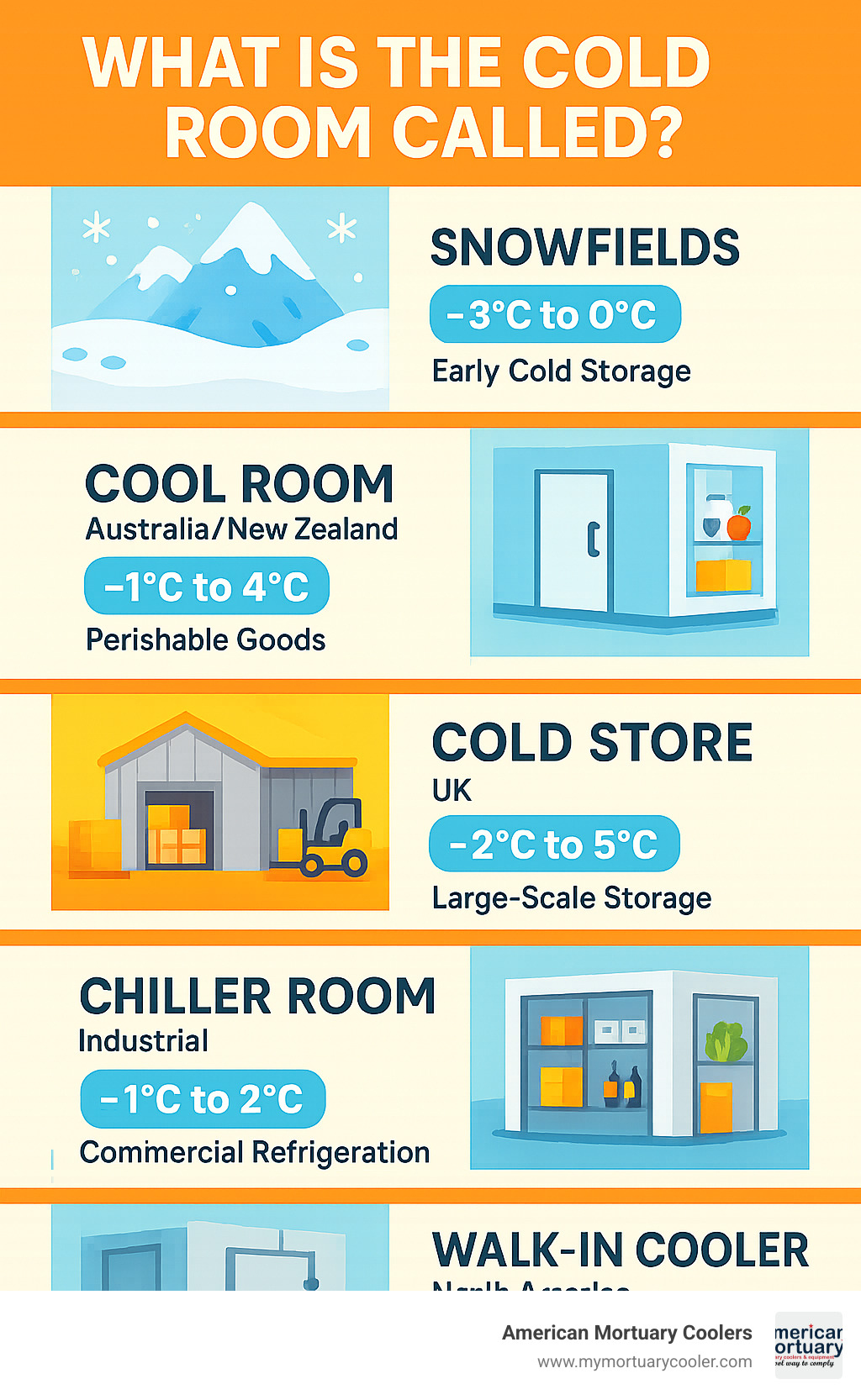

What is the cold room called depends on your location and industry, but the most common terms include walk-in cooler, chiller room, cool room, and cold store. These refrigerated spaces go by different names around the world:

- Walk-in cooler/freezer - Most common in North America

- Cool room/coolroom - Standard in Australia and New Zealand

- Chiller room - Used in commercial and industrial settings

- Cold store - Traditional term for large-scale facilities

- Walk-in fridge - Casual term in food service

- Refrigerated chamber - Technical/scientific applications

Cold rooms are temperature-controlled storage spaces that maintain specific conditions below outdoor temperatures to preserve perishable goods. From early "snowfields" to today's high-tech modular systems, these facilities serve industries from food service to pharmaceuticals to mortuary services.

As American Mortuary Coolers, a Tennessee-based mortuary cooler supplier, we've helped funeral homes nationwide understand what is the cold room called in their specific applications and select the right equipment for their needs.

Find more about what is the cold room called:

What Is the Cold Room Called? Common Names Around the World

If you've ever wondered what is the cold room called in different parts of the world, you're in for an interesting journey through language and culture.

Here in North America, we call them walk-in coolers or walk-in freezers, depending on temperature. The name makes perfect sense - these are refrigerated spaces large enough that you literally walk into them.

Head to Australia or New Zealand, and you'll hear cool rooms or coolroom. You might also hear cool store for bigger facilities.

In the United Kingdom and Europe, the traditional term is cold store. This name has serious history - it goes back to the late 1800s when these facilities became essential for storing meat, cheese, and other perishables. The famous Nine Elms Cold Store in London could hold 16,000 tons of food from 1965 to 1979.

In industrial settings, you'll often hear chiller room used instead. This term is popular in pharmaceutical companies, food processing plants, and other industries where precise temperature control is critical.

Key Synonyms & Regional Variants for "what is the cold room called"

The variety of names tells a fascinating story about how different cultures have approached food preservation. Traditional domestic terms include pantry and larder for smaller, household-scale storage areas. The word cellar often comes up for underground storage spaces.

Specialized modern terminology includes controlled atmosphere rooms or CA storage. These control humidity, oxygen, carbon dioxide, and other factors to extend freshness up to 25 days longer than regular refrigeration.

Archaic terms like buttery (for beverages), still room (from large estates), and spence (Scottish variant) remind us that people have been solving cold storage challenges for centuries.

Origins of the Phrase "what is the cold room called" in Industry Jargon

The story of what is the cold room called is really the story of refrigeration. Before mechanical cooling, people built snowfields - walled pits where they stored snow and ice to keep food from spoiling.

The shipping industry played a huge role in standardizing terminology. When companies started moving perishable goods globally, they needed consistent language. Cold store became the go-to term in international trade.

Today's terminology reflects both technology and practical needs. Walk-in cooler emphasizes human-scale spaces. Chiller room focuses on cooling function. Cool room suggests cold but not freezing.

At American Mortuary Coolers, we work with funeral homes across all 48 contiguous states, so we hear every variation. Whether a client calls it a mortuary cooler, body cooler, or refrigerated chamber, we understand their essential equipment needs.

Types of Cold Rooms and Their Purposes

When people ask what is the cold room called, the answer often depends on temperature range. Each type serves specific purposes based on how cold it needs to be.

Positive temperature cold rooms keep things cool but not frozen, operating between 0°C and 15°C (32°F to 59°F). These are perfect for fresh produce, dairy products, cut flowers, and many pharmaceuticals.

Negative temperature cold rooms maintain temperatures from 0°C down to -40°C (32°F to -40°F). These are essential for frozen foods, ice cream storage, meat processing, and long-term preservation. Ultra-low freezers can reach -50°C to -80°C (-58°F to -112°F) for laboratory and pharmaceutical storage.

Medium-low temperature rooms operate between 0°C and -18°C (32°F to -0.4°F), while ultra-low temperature rooms can reach -60°C (-76°F) for specialized biological storage.

Size matters too. Small cold rooms up to 30 cubic meters work for restaurants. Medium facilities up to 200 cubic meters serve larger operations. Large industrial cold rooms can exceed 3,000 cubic meters.

Blast chillers and deep-freezing tunnels represent speed-focused cold storage. Blast chillers drop product temperatures quickly, minimizing ice crystal formation. Deep-freezing tunnels operate at -30°C to -40°C with automated systems.

Modular cold rooms use prefabricated panels for quick assembly and potential relocation. Industrial-scale systems are permanent concrete installations built for longevity.

Differentiating a Cold Room vs. Freezer Room

Understanding the difference goes beyond temperature numbers. When someone asks what is the cold room called, they need to know which category fits their needs.

| Specification | Cold Room | Freezer Room |

|---|---|---|

| Temperature Range | -2°C to 10°C (28°F to 50°F) | -18°C to -40°C (0°F to -40°F) |

| Primary Use | Short-term fresh storage | Long-term frozen storage |

| Typical Products | Produce, dairy, flowers | Meat, ice cream, frozen foods |

| Storage Duration | Days to weeks | Weeks to months |

| Energy Consumption | Lower | Higher |

Cold rooms excel at keeping fresh products without freezing them. Vegetables and flowers continue to "breathe" in storage, making humidity control as important as temperature.

Freezer rooms pause biological processes by freezing everything solid, enabling long-term storage that cold rooms can't match. However, freezing can damage cellular structure - try freezing lettuce and you'll get mush.

Energy requirements differ significantly. Freezer rooms need more powerful refrigeration and better insulation, translating to higher costs.

Specialized Cold Rooms: Mortuary, CA Storage & Ultra-Low Labs

Some applications require such specific conditions they've created new categories with specialized terminology.

Mortuary cold rooms maintain 2°C to 4°C (36°F to 39°F) to preserve human remains with dignity. These require stainless steel construction, precise temperature control, emergency backup systems, and regulatory compliance.

At American Mortuary Coolers, we've learned that terminology matters - whether you call it a "mortuary cooler," "body storage unit," or "refrigerated mortuary cabinet" can affect regulatory approval.

Controlled Atmosphere (CA) Storage manages humidity, oxygen, carbon dioxide, and ethylene levels beyond just temperature. Research shows CA storage extends freshness by approximately 25 days over conventional cold rooms.

Ultra-low laboratory freezers serve pharmaceutical and research applications requiring temperatures down to -80°C (-112°F) for vaccines, biological samples, and research materials.

For detailed guidance on mortuary applications, see our comprehensive guide to mortuary cold rooms.

Anatomy: Components, Materials & How They Work

When people ask what is the cold room called, they often want to understand how these systems work. Think of a cold room as a sophisticated puzzle where every piece must fit perfectly.

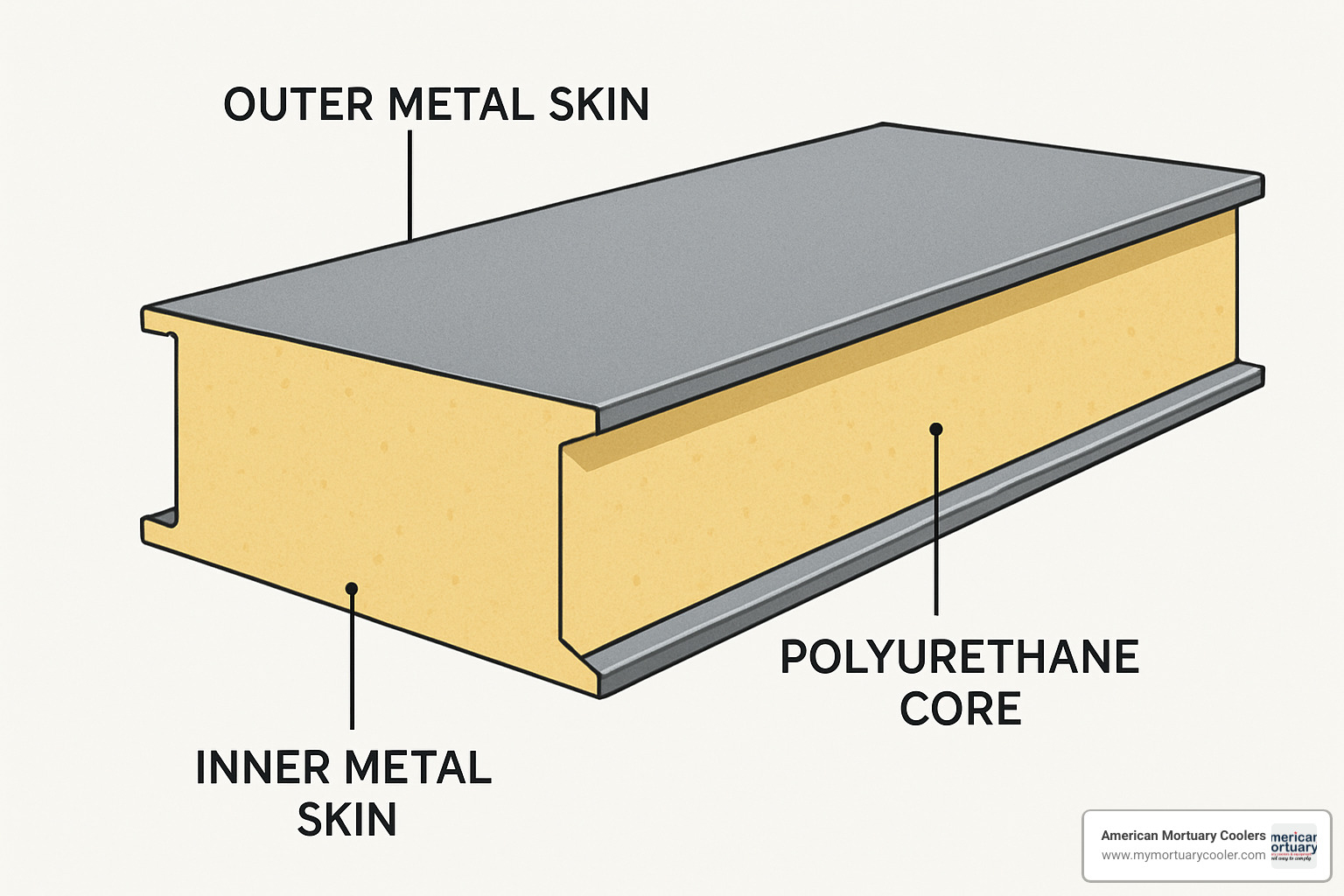

The heart lies in insulated sandwich panels - engineered marvels with metal skins and polyurethane foam core. Panel thickness varies from 4 inches for moderate cooling up to 12 inches for extreme temperatures. Polyurethane efficiently stops heat transfer while providing structural strength.

The refrigeration system works like your home refrigerator, just larger scale. The compressor pumps refrigerant through the system. The condenser releases heat outside, while the evaporator absorbs heat from inside the cold room.

Doors and gaskets are critical components. Poor sealing wastes energy and compromises temperature control. Quality doors include self-closing mechanisms, emergency release systems, and magnetic gaskets creating airtight seals.

Control and monitoring systems have evolved from simple thermostats to digital controllers providing precise temperature control, remote monitoring, and data logging for compliance.

Construction Materials That Maximize Efficiency

Material selection makes or breaks performance. High-density polyurethane foam provides excellent thermal properties and structural strength. Stainless steel skins resist corrosion and meet sanitation requirements for mortuary and food service applications.

Cam-lock panel connections provide tight assembly while maintaining flexibility for future changes. Vapor barriers prevent moisture infiltration that could compromise insulation.

Technology Inside: Refrigeration Cycle & Monitoring

The refrigeration cycle starts with the compressor pressurizing refrigerant gas. This flows to the condenser, where it releases heat and condenses to liquid. The liquid passes through an expansion valve reducing pressure and temperature before entering the evaporator.

Variable speed compressors adjust cooling output to match demand, reducing energy consumption by 20-30% while providing better temperature control.

Remote monitoring systems enable real-time oversight from anywhere with internet access. You can track temperature trends, receive alarm notifications, and monitor energy consumption.

Data logging has become important for regulatory compliance, automatically recording temperature, humidity, and system performance for HACCP and regulatory requirements.

Designing or Choosing the Right Cold Room

Choosing the right cold room starts with understanding exactly what you're trying to accomplish. When clients ask us what is the cold room called for their needs, we begin by understanding their requirements.

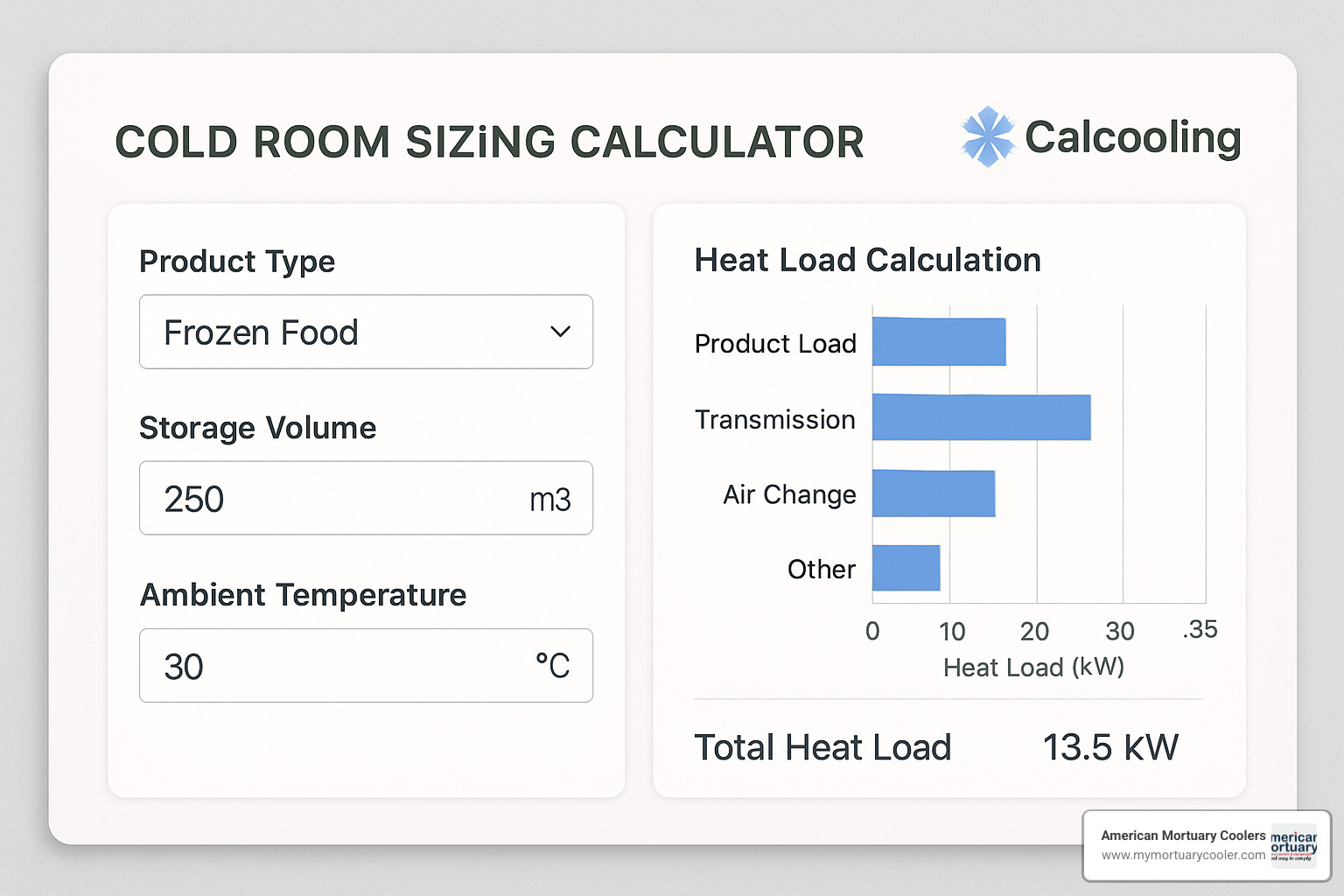

The first step is capacity sizing in terms of heat load. Every door opening, warm product entry, and internal equipment generates heat your refrigeration system must remove. Plan for peak capacity, not average - a funeral home might normally store two bodies but need space for eight during emergencies.

Product type drives design decisions. Fresh flowers need different conditions than pharmaceuticals. Human remains require specific temperature ranges differing from food storage.

Site constraints include floor space, ceiling height, electrical service capacity, and drainage. Don't forget installation access - panels must fit through doorways and around corners.

Compliance requirements vary by industry and location. Funeral homes have different regulations than restaurants. Food service must meet health department standards for interior finishes and drainage.

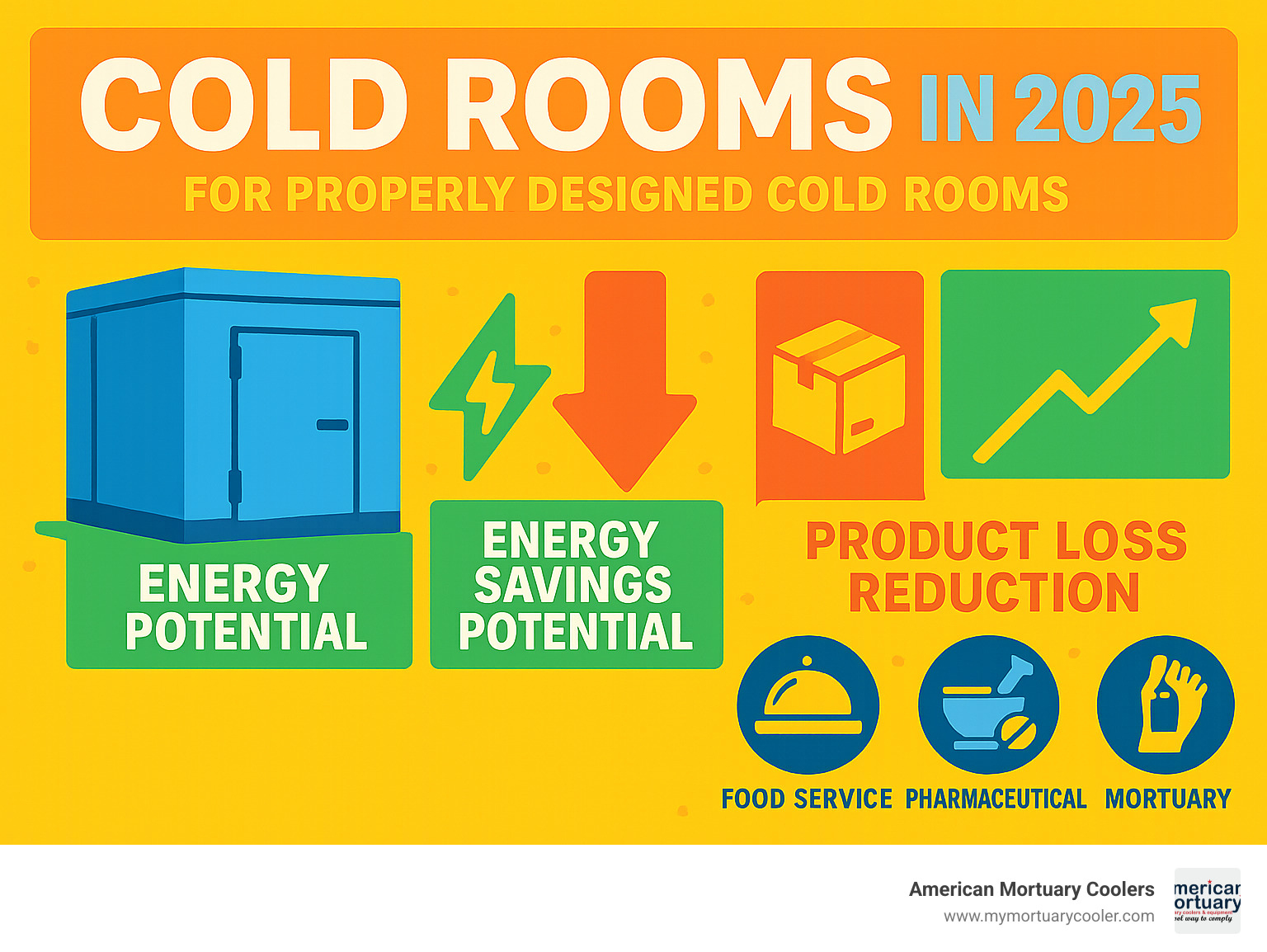

A quality cold room typically pays for itself within three to five years through energy savings and reduced product loss.

Positive vs Negative Temperature Selection Guide for "what is the cold room called" Projects

The choice between positive and negative temperature systems affects everything from initial investment to monthly bills.

Positive temperature systems operate between 0°C and 15°C (32°F to 59°F) for fresh produce, dairy, pharmaceuticals, flowers, and mortuary applications (2°C to 4°C).

Negative temperature systems maintain -18°C to -40°C (0°F to -40°F) for long-term meat storage, ice cream, and frozen distribution.

Energy differences are significant. Sub-zero temperatures require much more power due to greater temperature differences. Freezing preserves for months but can damage cellular structure, while fresh storage maintains texture and nutrition with limited duration.

Some clients choose dual-temperature systems providing both zones in one installation for maximum flexibility.

Key Mistakes to Avoid When Specifying "what is the cold room called" for Your Facility

Under-insulation is the most expensive mistake. Minimum thickness might meet codes but costs hundreds annually in energy bills. Inadequate insulation causes temperature swings and overworks equipment.

Wrong door type creates daily frustrations. Consider actual usage patterns - will people carry heavy items? Need hands-free operation? Frequent opening throughout the day?

Ignoring humidity control can ruin products and create maintenance issues. Different products need different humidity levels.

Lack of emergency release isn't just dangerous - it's illegal. Every walk-in cold room must have interior release mechanisms.

Don't overlook access considerations like door width, ramp requirements, adequate lighting, and non-slip flooring.

For detailed guidance, check our practical guide to understanding walk-in coolers.

Frequently Asked Questions about Cold Rooms

When people ask us what is the cold room called at American Mortuary Coolers, they often have deeper questions about how these systems work and what they can do. Here are the three most common questions we hear from clients across the country.

What products are typically stored in a cold room?

The answer might surprise you - cold rooms store far more than just food! While restaurants and grocery stores use them for fresh produce, dairy products, meat and seafood, beverages, and prepared foods, that's just the beginning of the story.

Different products need different temperatures to stay fresh. Local vegetables and fruits do best at 0°C, while tropical fruits prefer a warmer 5-13°C. Dairy products need that sweet spot of 2-4°C to maintain quality and safety.

But here's where it gets interesting - non-food applications are huge. Pharmaceutical companies store vaccines and insulin in cold rooms with precise temperature control. Florists use them to keep cut flowers fresh during transport and extend their vase life. Chemical companies slow down reactions by storing temperature-sensitive materials in controlled environments.

In our specialty at American Mortuary Coolers, we provide cold rooms that preserve human remains at 2-4°C while families prepare for services. Research laboratories store biological samples, testing materials, and sensitive reagents. The versatility of these systems makes them essential across industries you might never think of.

How does a cold room differ from a walk-in freezer?

This is where understanding what is the cold room called really matters, because the names tell you about the function. The main difference comes down to temperature and purpose.

Cold rooms work in that -2°C to 10°C range (28°F to 50°F) - perfect for keeping things fresh without freezing them. Walk-in freezers go much colder, from -18°C to -40°C (0°F to -40°F), designed for long-term frozen storage.

The construction differences are significant too. Freezers need thicker insulation, more powerful refrigeration systems, and special defrost mechanisms. They require better door sealing and sometimes heated door frames to prevent ice buildup. Your energy bills will be noticeably higher with freezers because they're fighting a much bigger temperature difference.

But the real difference is what happens to your products. Cold rooms keep fresh items at their best - maintaining texture, flavor, and nutrition. Freezers stop biological processes cold (literally!) for long-term storage, but freezing can damage the cellular structure of some products. A head of lettuce stored in a cold room stays crisp and fresh. Put it in a freezer, and you'll have lettuce soup when it thaws.

Can cold rooms be relocated or expanded later?

This is one of the smartest questions we get, and the answer is mostly yes - if you choose the right system from the start.

Modern modular cold rooms are specifically designed with flexibility in mind. Those prefabricated panels with cam-lock connections can be taken apart, moved, and put back together at a new location. We've helped clients relocate their systems when they've outgrown their space or moved facilities.

However, relocation isn't a DIY project. It requires professional expertise to avoid damaging panels, refrigeration components, and control systems. Proper disassembly, careful transport, and expert reassembly ensure your system keeps working like new and maintains its warranty coverage. Some elements like concrete floors or hardwired electrical connections obviously can't make the move.

Expansion is often easier than relocation. Modular systems are designed to accept additional panels to increase storage capacity. The main things to consider are whether your refrigeration system can handle the extra load and if you have the physical space.

At American Mortuary Coolers, we always design our systems with future flexibility in mind. We use modular components that make expansion or reconfiguration straightforward as your needs change. It's one of those details that might not seem important today but can save you thousands down the road.

Conclusion

Understanding what is the cold room called opens the door to temperature-controlled storage that touches nearly every aspect of modern life. From ancient "snowfields" to today's precision-controlled systems, we've advanced significantly in preserving what matters most.

The beauty of cold room terminology lies in its diversity. Whether you're in Tennessee calling it a walk-in cooler, in Australia referring to your cool room, or in the UK managing a cold store, you're part of a global community preserving quality through temperature control.

At American Mortuary Coolers, we've found that getting the terminology right is the first step toward getting the solution right. When funeral directors call asking about "body coolers" or "mortuary refrigeration units," we understand they're seeking reliable, dignified preservation during their most important work.

Our Tennessee roots give us perspective on both Southern hospitality and practical engineering. We've learned that durability matters more than fancy features, and nationwide delivery across the contiguous 48 states means nothing if equipment doesn't perform when families need it most.

Properly designed cold rooms provide energy savings that typically pay for themselves within three to five years. Reduced product loss through precise environmental control protects your investment. Food safety improvements through consistent temperatures protect businesses and consumers. In mortuary applications, proper refrigeration ensures regulatory compliance while providing families time for arrangements.

The future continues advancing with improved refrigerants, smarter controls, and better building integration. But fundamentals remain: understanding your needs, using correct terminology, and choosing reliable equipment.

For funeral professionals, stakes are particularly high. Families trust you during difficult moments, and equipment must work flawlessly. That's why we focus on durable, custom mortuary solutions rather than generic equipment.

From consultation through installation and support, we provide expertise needed to steer cold room selection complexities. Whether replacing aging equipment, expanding facilities, or opening new locations, understanding what is the cold room called helps ensure you get exactly what you need.

Terminology may vary, but commitment to quality preservation remains constant. Whatever you call your cold room, ensure it's built to serve your community with reliability and dignity.

For additional guidance on selecting reliable manufacturers and avoiding pitfalls, see our practical guide to choosing a reliable mortuary cold room manufacturer.