Why Understanding Walk-In Coolers Matters for Your Business

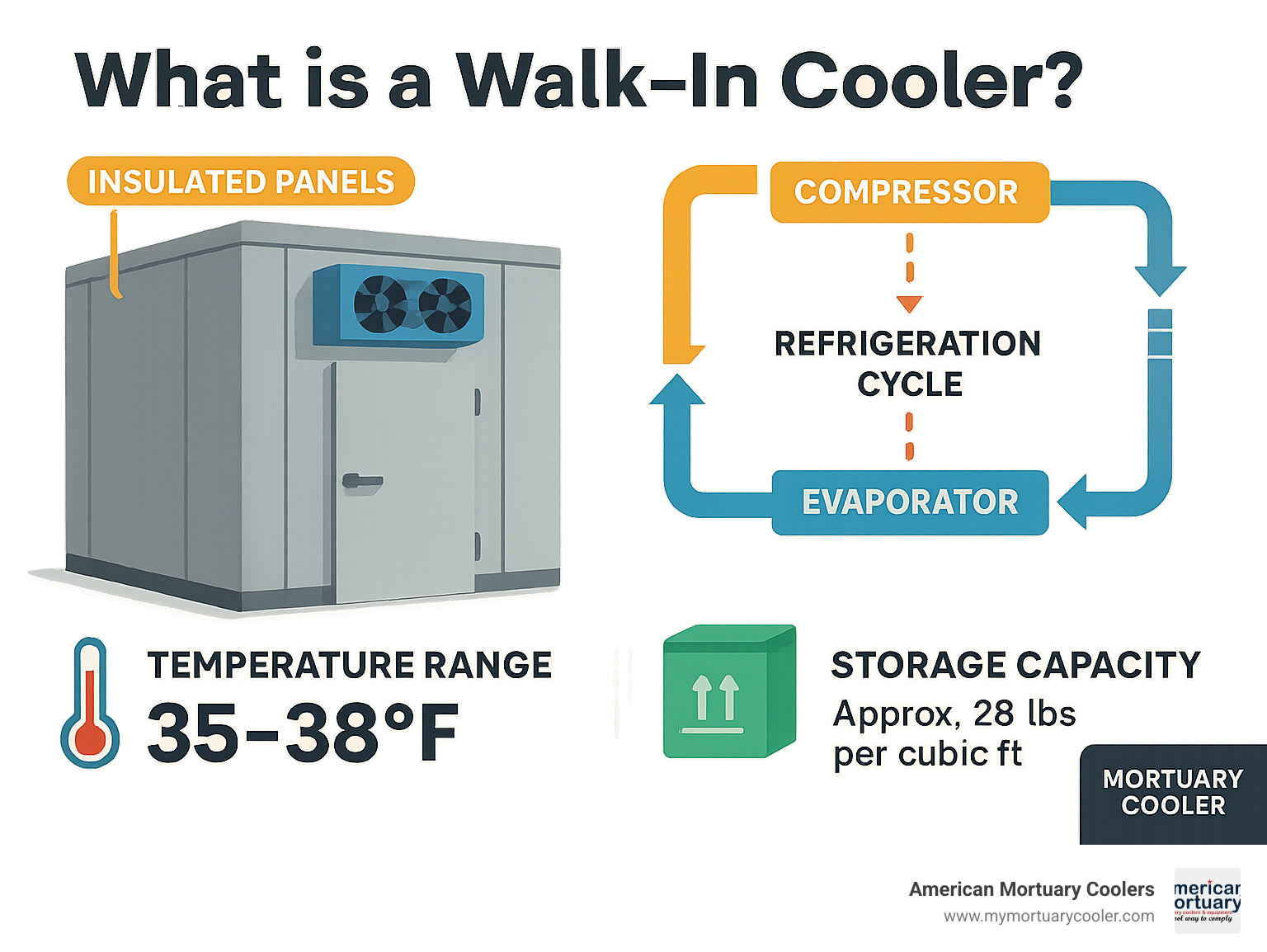

What is walk-in cooler technology is essential knowledge for any business that needs reliable cold storage. A walk-in cooler is a large, insulated refrigerated room designed for employees to walk into and store perishable goods at consistent temperatures, typically between 35-38°F.

Quick Answer for Walk-In Cooler Basics:

- Purpose: Medium-term cold storage for perishable items

- Temperature Range: 35-38°F (coolers) vs. below 0°F (freezers)

- Key Components: Compressor, condenser, evaporator, insulated panels, doors

- Typical Lifespan: 15-20 years with proper maintenance

- Storage Capacity: Approximately 28 lbs per cubic foot

Walk-in coolers serve as the backbone of cold storage operations across industries. From restaurants preserving fresh ingredients to funeral homes maintaining dignity through proper temperature control, these units bridge the gap between short-term refrigerators and long-term warehouse storage.

The refrigeration cycle works through four stages: compression, condensation, expansion, and evaporation. This process continuously removes heat from the interior while maintaining consistent temperatures through off-cycle defrost systems that prevent ice buildup.

Understanding proper sizing, insulation materials, and maintenance requirements can mean the difference between decades of reliable service and costly equipment failures.

As Mortuary Cooler, I've spent years helping funeral home directors steer walk-in cooler selection and understand what is walk-in cooler technology that best serves their unique needs. My experience with custom cold-storage solutions has shown me that the right equipment choice upfront saves thousands in operational costs down the road.

What is walk-in cooler terms to remember:

What Is a Walk-In Cooler?

A walk-in cooler is your business's personal cold storage room. It's essentially a large refrigerated space that keeps temperatures steady between 35-38°F – perfect for preserving perishable goods without freezing them solid.

The beauty of these units lies in their name: you can actually walk inside them. Unlike cramped reach-in refrigerators where you're constantly playing Tetris with your inventory, walk-in coolers give you room to move around and organize your stored items properly.

There's a big difference between coolers and freezers. Walk-in coolers maintain that sweet spot above freezing (typically 35-38°F), while walk-in freezers drop below 0°F and can go as low as -22°F.

What is walk-in cooler technology really about? It's about finding the perfect middle ground for medium-term storage. Your regular fridge handles today's needs, massive refrigerated warehouses store inventory for months, but walk-in coolers bridge that gap beautifully – keeping your products fresh for days or weeks.

| Feature | Walk-In Cooler | Walk-In Freezer |

|---|---|---|

| Temperature Range | 35-38°F (2-3°C) | -12°F to -22°F (-24°C to -30°C) |

| Primary Use | Fresh produce, dairy, prepared foods | Frozen meat, seafood, ice cream |

| Insulation Thickness | 4 inches standard | 6 inches or more |

| Energy Consumption | Lower | Higher |

| Defrost Method | Off-cycle defrost | Electric or hot gas defrost |

Key Components of a Walk-In Cooler

Understanding what makes your walk-in cooler tick isn't just helpful – it's essential for making smart decisions about maintenance and troubleshooting.

The compressor is truly the heart of your system. It pushes refrigerant through the entire cycle, usually powered by a potential relay. Modern units must use high-efficiency motors thanks to EISA requirements – which is great news for your energy bills.

Your condenser typically lives outside the cooled space, releasing heat from the refrigerant. The condenser fan works hand-in-hand with the compressor, only running when the compressor is energized.

Inside your cooler, the evaporator does the heavy lifting of actually absorbing heat from the interior air. The evaporator fans run continuously, even when the compressor takes a break. This constant airflow allows for that clever off-cycle defrost process, where mild frost naturally melts away.

The thermostat acts like your cooler's brain, telling the compressor when to work and when to rest based on interior temperature. Digital thermostats offer much more precise control than their mechanical cousins.

Insulation panels form your cooler's protective shell – walls, ceiling, and sometimes the floor. Standard cooler panels are 4 inches thick with foam-core insulation sandwiched between metal facings. Polyurethane foam delivers impressive R-values of 6.6-8 per inch, and those cam-action locking devices make assembly surprisingly straightforward.

Doors and gaskets are your first line of defense against warm air infiltration. Heavy-duty doors with proper gaskets, reliable hinges, and safety releases keep your cooler sealed tight.

Finally, smart shelving systems maximize your storage efficiency while maintaining proper airflow. The key is choosing shelving that allows air to circulate around your stored products while providing easy access.

How Does a Walk-In Cooler Work?

The magic behind what is walk-in cooler operation lies in the refrigeration cycle – it's the same basic principle as your home air conditioner, just specialized for consistent cold storage.

During the compression stage, your compressor pressurizes refrigerant gas, cranking up both its temperature and pressure. This superheated gas then travels to the condenser.

The condensation stage is where things cool down – literally. In the condenser, that hot refrigerant gas releases its heat to the outside air and transforms into a high-pressure liquid.

Next comes the expansion stage, where high-pressure liquid refrigerant passes through an expansion valve. This dramatically drops both pressure and temperature, creating cold, low-pressure liquid refrigerant ready for action.

The evaporation stage completes the cycle beautifully. Cold refrigerant enters the evaporator coil inside your cooler, absorbs heat from the interior air, and evaporates back into gas. This heat removal process is what keeps your cooler consistently cold.

Here's where walk-in coolers get clever with off-cycle defrost. Unlike freezers that need aggressive defrosting systems, medium-temperature coolers use a gentler approach. When mild frost accumulates on the evaporator coil, it simply melts naturally when the compressor cycles off. Those continuously running evaporator fans circulate 35-39°F air over the coil, melting away frost buildup without any drama.

Sizing, Materials & Design Considerations

Getting the right size for your what is walk-in cooler project starts with understanding your actual storage needs. The industry uses a simple rule of thumb: 28 pounds per cubic foot. But your real-world requirements depend on what you're storing, how it's packaged, and how often you're in and out of that cooler.

Load calculation involves two types of heat: internal and external loads. Internal load comes from your stored products, lighting, and every time someone walks through that door. External load sneaks in through your walls, floor, ceiling, and especially during those busy moments when the door stays open longer than it should.

Ambient temperature makes a huge difference. If your location heats up from 80°F to 90°F, you're looking at an 18-20% increase in cooling load. Jump to 100°F, and that load shoots up by 30%. That's why choosing the right insulation and location affects your electric bill.

Standard insulation panels range from 4-6 inches thick. Most coolers do just fine with 4-inch panels, while freezers or extreme temperature applications often need that extra 2 inches.

When it comes to system configuration, you've got three main options. Self-contained units keep everything in one tidy package – great for simple installations. Remote condensing systems separate the noisy condenser from your workspace. Multiplex systems let you run multiple evaporators off one condensing unit, perfect for larger operations.

Floor decisions matter more than you might think. If you're installing over a heated space or dealing with frozen products, you absolutely need an insulated floor. Floorless installations work great on concrete pads but require proper thermal breaks and insulation underneath.

For detailed pricing information that covers all these options, check out our comprehensive guide on walk-in cooler pricing.

Choosing the Right Insulation & Panels

The insulation you choose today will determine your energy bills for decades. I've seen too many businesses go with the cheapest option upfront, only to watch their efficiency – and their money – disappear over time.

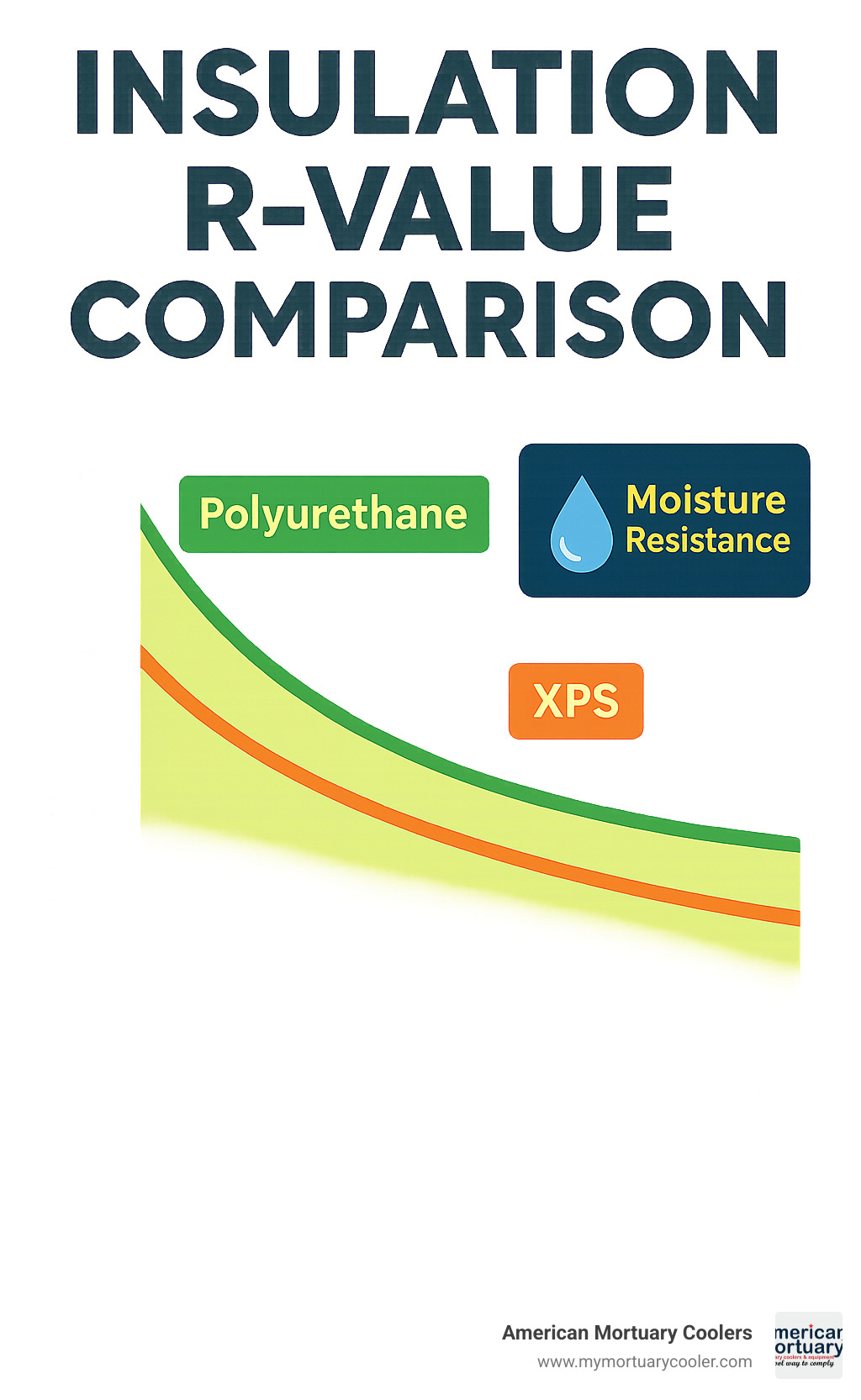

Polyurethane foam starts strong with impressive R-values of 6.6-8 per inch. It's like the sprinter of insulation materials – fantastic performance right out of the gate. But here's the catch: it only retains about 19% of its initial R-value over its lifetime. Gas diffusion slowly reduces its effectiveness, and moisture can really knock it down.

Extruded Polystyrene (XPS) takes a different approach. It starts with a more modest R-value of 5-5.6 per inch, but it's the marathon runner of insulation. XPS holds onto about 47% of its initial R-value throughout its life. Plus, it laughs at moisture where polyurethane struggles.

Modern panel construction uses cam-action locking devices that create airtight seals while making assembly surprisingly straightforward. These aren't your grandfather's walk-in panels – they lock together securely but still let you reconfigure if your needs change.

For metal skin options, you've got choices that balance cost with performance. Galvalume gives you 12 times more corrosion resistance than standard galvanized steel without breaking the budget. Painted G90 galvanized costs more but offers superior protection and color options.

Aluminum works beautifully in coastal areas where salt air wreaks havoc on other metals. Stainless steel represents the gold standard – strongest, most corrosion-resistant, and most expensive. For funeral homes where cleanliness and durability matter most, stainless often justifies its higher cost.

Locating & Installing Your Unit

Where you put your what is walk-in cooler affects everything from operating costs to maintenance headaches. Indoor installations protect your equipment from weather but add heat to your building's HVAC load. Outdoor installations keep that heat rejection outside but need extra protection from the elements.

Indoor considerations start with clearance. Your service technicians need room to work – 2 feet for ceiling-mounted systems, but only 2 inches for remote evaporators. Think about noise levels too.

Outdoor units need winter kits in most climates. These include compressor covers, crankcase heaters, and head-pressure controls that prevent operational problems when temperatures drop. Rain roofs aren't optional – they're essential for protecting electrical components.

Concrete pad preparation requires attention to detail. Your pad must be level, properly drained, and include thermal breaks under each wall panel. These thermal breaks prevent heat from conducting through the concrete and undermining your insulation efforts.

Clearance guidelines aren't suggestions – they're requirements for proper operation and maintenance access. Condensing units need adequate airflow and space for technicians to work safely.

Maintenance, Troubleshooting & Energy Efficiency

Think of your walk-in cooler like a reliable friend who just needs a little attention to keep performing at their best. Regular maintenance is honestly the secret sauce to getting those full 15-20 years out of your investment – and trust me, a little prevention beats emergency repair bills every single time.

Door seal checks should become second nature. Those rubber gaskets around your doors work harder than you might think, creating that crucial barrier between your controlled environment and the outside world. Even tiny gaps can sneak in warm, humid air that makes your compressor work overtime.

Coil cleaning might not sound glamorous, but it's absolutely critical. Your condenser and evaporator coils are like the lungs of your system. When they're clogged with dust, debris, or that mysterious fuzzy buildup, your compressor has to strain to maintain temperatures.

Temperature monitoring has come a long way from those old dial thermometers. Digital systems with alarm capabilities give you peace of mind and catch problems before they become disasters.

Smart controllers represent one of the biggest advances in refrigeration efficiency. These intelligent systems offer precise temperature control and features like demand defrost, which can slash your energy usage by up to 27%. Instead of defrosting on a rigid schedule, demand defrost only kicks in when actually needed.

The EISA requirements for high-efficiency motors might add to upfront costs, but they pay for themselves through lower energy bills. Variable-speed compressors take efficiency even further by adjusting their output to match actual cooling needs.

When you need professional help, our Walk-In Cooler Service 101 guide connects you with reliable repair providers. For hands-on troubleshooting moments, this comprehensive How to troubleshoot resource walks you through common issues step by step.

Preventing Ice & Frost Build-Up

Ice buildup is like that unwelcome guest who shows up uninvited and refuses to leave. Understanding why it happens and how to prevent it can save you serious headaches and money down the road.

Door management training for your staff makes a huge difference. Every time someone leaves a door open "just for a minute," warm humid air rushes in. That moisture has nowhere to go except onto your evaporator coils, where it freezes solid. Install door alarms if your team tends to get distracted.

Vinyl curtains act like a second line of defense, especially in busy environments. These heavy-duty strips create an air barrier while still allowing easy access.

Drain line cleaning prevents one of the most common ice formation causes. When defrost water can't drain properly, it backs up and freezes in all the wrong places. A quarterly flush with warm water and mild detergent keeps everything flowing smoothly.

Defrost timer checks ensure your system melts accumulated frost at the right intervals. Too frequent, and you're wasting energy. Too infrequent, and ice builds up faster than the system can handle.

Routine Maintenance Checklist

Building good maintenance habits doesn't have to be overwhelming. Break it down into manageable chunks, and your cooler will reward you with years of reliable service.

Weekly cleaning keeps your cooler looking professional and helps you spot problems early. A quick visual check for unusual ice patterns or frost buildup takes just minutes but can prevent major issues.

Monthly coil vacuuming should become as routine as paying bills. Dust and debris accumulate faster in some environments than others, but consistent cleaning prevents the gradual efficiency loss that sneaks up on you. While you're at it, check those door gaskets.

Quarterly professional inspections catch the technical issues that aren't obvious to the untrained eye. A qualified technician can spot refrigerant leaks, electrical problems, or component wear before they cause system failures.

Record keeping might seem tedious, but maintenance logs become invaluable for identifying patterns and planning future service. Note temperature readings, service dates, and any unusual observations.

Costs, Regulations & Innovations

When you're considering what is walk-in cooler investment means for your business, it's important to look beyond that initial price tag. The upfront cost gets your attention first, but the real story unfolds over the next 15-20 years of operation.

Think of it like buying a car – you wouldn't just look at the sticker price without considering gas mileage, insurance, and maintenance costs. High-efficiency components might make you wince at first, but they're often the gift that keeps on giving through lower monthly energy bills.

Those EISA-compliant motors I mentioned earlier? They're required by law now, but they're actually doing you a favor. Advanced features like demand defrost can slash your energy consumption by up to 27% compared to old-school time-based systems.

Smart IoT monitoring systems are changing the game completely. Imagine getting a text alert when your cooler's temperature starts creeping up, or being able to check everything from your phone while you're at home. These systems don't just prevent disasters – they help you optimize performance and plan maintenance before problems become emergencies.

For food service businesses, there's one number you absolutely must remember: 40°F. That's the USDA's magic number for safe food storage. Your walk-in cooler should maintain 35-38°F to stay comfortably within compliance while providing optimal storage conditions.

You can dive deeper into all the federal requirements at the Federal cold-storage guidelines if you want the full regulatory picture.

Regulatory Requirements & Food Safety

NSF and UL certifications aren't just fancy stickers on your equipment. These certifications mean your walk-in cooler meets strict safety and sanitation standards. If you're in food service, these aren't optional – they're your ticket to passing health inspections and keeping customers safe.

HACCP plans might sound intimidating, but they're actually pretty straightforward. Your walk-in cooler becomes what's called a "critical control point" in your food safety system. You need to monitor temperatures, know what to do when things go wrong, and keep records of everything.

Temperature logging has come a long way from those old paper charts. Digital systems with automatic logging and alarm capabilities make compliance much easier while providing better protection for your products.

Emerging Technologies

The future of what is walk-in cooler technology looks pretty exciting, and some of these innovations are already making life easier for business owners today.

High-density insulation materials are getting better every year. These advanced materials pack more thermal protection into thinner panels, which means you get more storage space or better efficiency without changing your footprint.

Variable-speed compressors are like cruise control for your cooling system. Instead of constantly turning on and off, they adjust their speed based on how much cooling you actually need. The result? Better temperature control and significant energy savings.

Remote monitoring apps are probably the most game-changing innovation for busy business owners. Picture this: you're at home on Sunday morning, and your phone buzzes with an alert that your cooler's temperature is rising. You can call for service before you lose any product.

Smart defrost systems represent the kind of behind-the-scenes intelligence that makes modern equipment so much better. Instead of running defrost cycles on a rigid schedule whether they're needed or not, these systems monitor actual conditions and only defrost when necessary.

Frequently Asked Questions about Walk-In Coolers

What size walk-in cooler do I need?

Getting the size right from the start saves you headaches and money down the road. The 28 pounds per cubic foot rule gives you a solid starting point, but your actual needs depend on several important factors.

Product density plays a huge role in your calculations. If you're storing lightweight items like bread or produce, you might not reach that 28-pound limit. But if you're dealing with dense products like meat or dairy, you could easily exceed it.

Growth planning is where many people make costly mistakes. That 6x8 cooler might handle your current needs perfectly, but what about next year? Installing a slightly larger unit now costs far less than replacing the whole system later.

Don't forget about workflow space either. You need room to move around, bring in carts, and actually work inside the cooler. Industry experts recommend keeping at least 40 inches of aisle width for smooth operations.

How long does a walk-in cooler last?

Here's the honest answer: 15-20 years with proper care. But that "proper care" part makes all the difference between a cooler that serves you faithfully for decades and one that leaves you scrambling for repairs after just a few years.

Maintenance quality is absolutely critical. I've seen well-maintained units still running strong after 25 years, while neglected ones fail catastrophically before their 10th birthday. Regular professional maintenance isn't just recommended – it's essential for getting your money's worth.

Usage patterns significantly impact lifespan too. A cooler that gets opened 50 times a day in a busy restaurant faces much more stress than one opened just a few times daily.

Component quality matters more than many people realize. Yes, higher-quality parts cost more upfront, but they often outlast cheaper alternatives by years. When you're looking at a 20-year investment, paying extra for quality components usually pays for itself.

How can I improve energy efficiency?

Energy efficiency improvements often pay for themselves surprisingly quickly, especially with rising electricity costs. The key is focusing on the changes that deliver the biggest impact.

Insulation performance should be your first priority. Over time, insulation loses effectiveness, and your energy bills creep higher. If your panels are over 10 years old and your energy costs keep climbing, upgrading the insulation might be your best investment.

Door management offers immediate savings with minimal investment. Train your staff to minimize door opening time, and consider installing vinyl strip curtains in high-traffic areas.

Smart controls represent one of the biggest opportunities for savings. Upgrading to electronic controllers with demand defrost can slash energy consumption by up to 27% compared to old-fashioned time-based systems.

Regular maintenance might seem obvious, but dirty coils alone can increase energy consumption by 30% or more. Clean coils, proper refrigerant levels, and well-functioning components all contribute to peak efficiency.

LED lighting upgrades provide a double benefit – they use less electricity and produce less heat inside the cooler. Add motion sensors, and you'll cut lighting costs even further.

Conclusion

After diving deep into what is walk-in cooler technology, you're now equipped with the knowledge to make smart decisions about your cold storage needs. These workhorses of the refrigeration world truly shine when you understand their capabilities and requirements.

The beauty of walk-in coolers lies in their versatility. Whether you're running a busy restaurant kitchen or managing a funeral home, these units adapt to your specific needs while delivering consistent performance year after year. With proper care, your investment will serve you faithfully for 15-20 years, making it one of the most reliable pieces of equipment in your facility.

Success with walk-in coolers comes down to three key factors: choosing the right size using the 28-pound-per-cubic-foot rule, selecting quality materials that stand up to daily use, and maintaining your system with regular cleaning and professional service. Get these basics right, and you'll avoid the headaches that come with poor cold storage decisions.

The technology keeps getting better too. Smart controllers that learn your usage patterns, high-efficiency motors that slash energy bills, and remote monitoring that alerts you before problems become disasters – these innovations make modern walk-in coolers more reliable and cost-effective than ever.

At American Mortuary Coolers, we've built our reputation on understanding that every business has unique cold storage challenges. Our Tennessee-based team doesn't just sell equipment; we craft custom solutions that fit your exact requirements. From our strategic locations spanning Johnson City TN to Los Angeles, we're positioned to deliver durable, reliable walk-in coolers directly to your door across all 48 contiguous states.

Whether you're in the Northeast dealing with harsh winters, the Southwest managing extreme heat, or anywhere in between, we understand the local conditions that affect your equipment performance. Our expertise spans the funeral industry's specialized needs, but our knowledge applies to any business requiring dependable cold storage.

Ready to explore your options? Our comprehensive Walk-In Coolers resource page covers everything from basic models to fully customized solutions. We'll help you steer the choices and find the perfect match for your operational needs and budget.

American Mortuary Coolers stands ready as your trusted partner for custom cold-storage solutions that deliver decades of reliable service. When you're ready to invest in equipment that works as hard as you do, we're here to make it happen with the expertise and direct delivery capabilities you deserve.