Why Battery Lift Equipment is Essential for Modern Operations

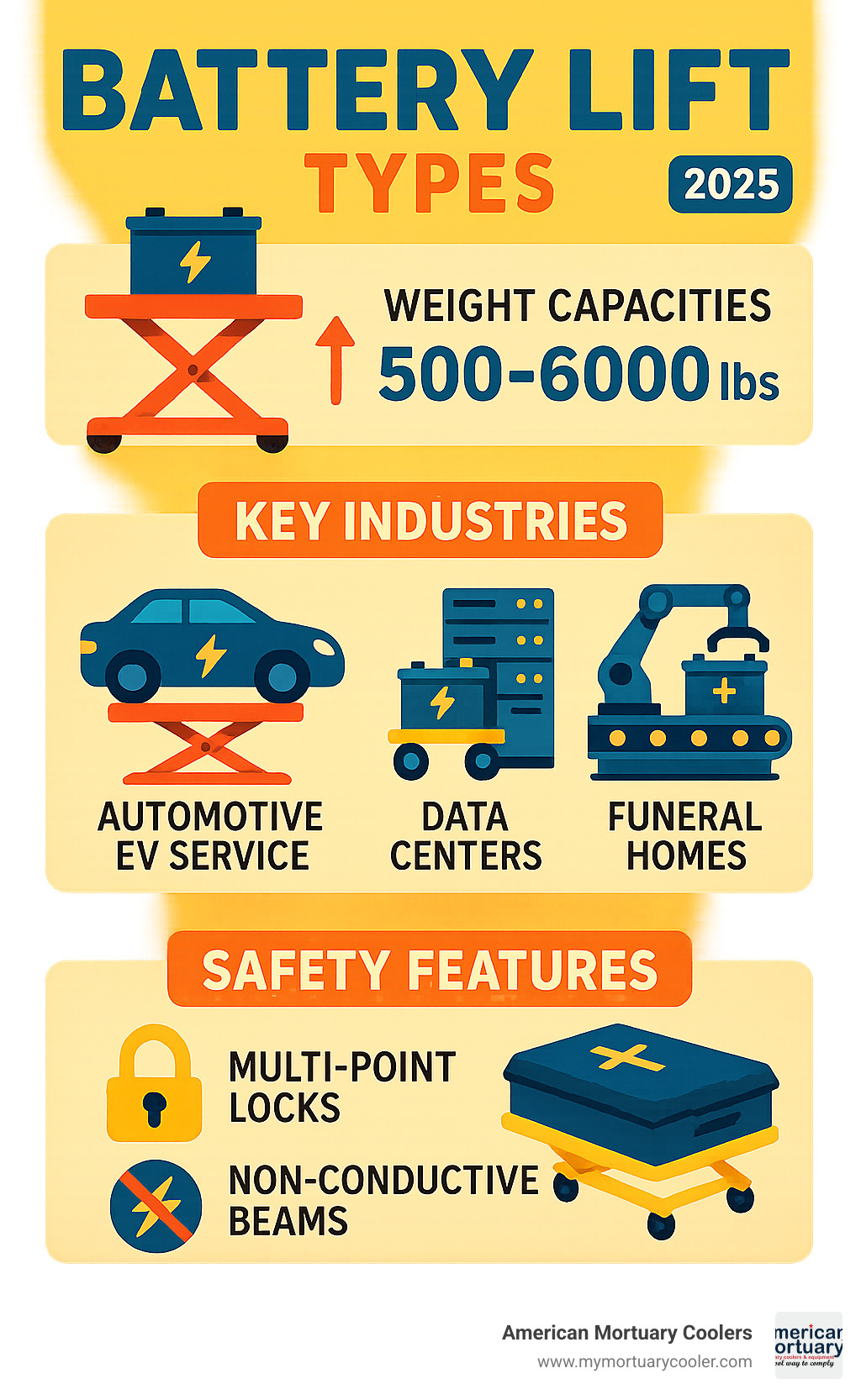

A battery lift is a specialized piece of equipment designed to safely handle, position, and transport heavy batteries in various industrial and commercial settings. These devices range from manual hydraulic units to sophisticated electric scissor tables, with capacities typically spanning from 500 to 6,000 pounds.

Key Battery Lift Applications:

- Automotive & EV Service - Handling electric vehicle battery packs (up to 4,500 lbs capacity)

- Material Handling - Forklift battery maintenance and replacement (up to 3,000 lbs)

- Data Centers - UPS battery installation and service (1,500 lb capacity units)

- Manufacturing - Cleanroom-compliant battery assembly operations

- Funeral Homes - Mortuary equipment and casket handling systems

The growing adoption of electric vehicles and increased reliance on backup power systems has created unprecedented demand for battery handling solutions. Heavy batteries pose significant safety risks when handled manually. Battery lifts eliminate these hazards while improving workplace ergonomics and operational efficiency.

Modern units feature advanced safety systems including multi-point locks, non-conductive lifting beams, and precise positioning controls. From automotive shops servicing Tesla battery packs to funeral homes managing mortuary equipment, battery lifts have become indispensable tools across diverse industries.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in material handling equipment for funeral service operations. Throughout my career, I've seen how proper battery lift systems transform workplace safety and efficiency in mortuary environments.

Battery lift terms you need:

Battery Lift Basics: Definition, Industries, Capacities

Think of a battery lift as your heavy-duty assistant that never calls in sick. These specialized machines handle the lifting, moving, and positioning of heavy batteries that would otherwise require multiple workers or result in serious injuries.

The reality is simple: batteries are getting bigger and heavier. EV battery packs can weigh over 1,000 pounds, while industrial UPS systems often weigh several hundred pounds each. Manual lifting isn't an option anymore.

A quality battery lift protects workers from injury, prevents expensive damage to delicate battery equipment, and speeds up operations significantly. Modern systems range from compact 500-pound capacity units to heavy-duty 6,000-pound systems. The BendPak Mobi-EVS EVS4500 exemplifies the high-end market with its 4,500-pound capacity and ability to lift over 6 feet in under 20 seconds.

What is a battery lift and why you need one?

A battery lift is essentially a problem-solver on wheels. Beyond lifting, these systems provide precise positioning that lets technicians work at comfortable heights. The Atlas Electric Battery Lifting Table showcases this versatility with its 3,300-pound capacity and maximum lift height of over 71 inches.

Injury reduction represents the biggest win for most businesses. Back injuries from manual lifting cost companies thousands in workers' compensation claims and lost productivity. When you invest in a proper battery lift, you're buying insurance against preventable injuries.

The efficiency boost is equally impressive. Instead of three workers struggling with a heavy battery for 30 minutes, one technician can safely position it in minutes.

Industries that rely on battery lifts every day

Automotive shops have acceptd battery lift technology as electric vehicles flood the market. Tesla Model S battery packs weigh around 1,200 pounds - definitely not something you want to deadlift.

Data centers present another compelling use case. These facilities house massive UPS battery banks requiring regular maintenance. The C&C Power Batt-Lift targets this market with its 1,500-pound capacity and compact design for tight server room aisles.

MEWP fleets depend on battery lifts for routine maintenance. Scissor lifts and boom lifts use hefty traction batteries that demand specialized handling equipment.

Forklift operations represent a massive market. BHS Battery Transfer Carriages feature 3,000-pound load capacities specifically designed for side-extraction battery systems common in warehouse operations.

Funeral homes increasingly rely on battery-powered equipment for mortuary operations. At American Mortuary Coolers, we've seen growing demand for battery-powered casket lifts and body handling equipment. These systems eliminate hydraulic fluid risks while providing reliable operation funeral directors need.

Comparing Battery Lift Types & Technologies

When shopping for a battery lift, you'll find there's no one-size-fits-all solution. This variety means you can find exactly what your operation needs, whether handling delicate mortuary equipment or massive EV battery packs.

Manual lifts might seem old-school, but they're useful for smaller operations. These hand-crank or foot-pump hydraulic systems won't break your budget, though they will give operators a workout. If you only change batteries occasionally, manual systems can make perfect sense.

Electric lifts hit the sweet spot for most businesses. The Atlas Electric Battery Lifting Table with its 3,300 lb capacity delivers consistent performance without wearing out your team. These systems provide precise control and eliminate guesswork.

For heavy applications, hydraulic lifts reign supreme. They handle whatever you throw at them, but require external hydraulic power and carry fluid leak risks.

Scissor tables like BendPak's Mobi-EVS series are clever multi-taskers. They lift batteries and provide a solid work surface - two tools for the price of one.

Specialized options include transfer carriages, lifting beams, mobile hoists, and stair-chair lifts. In funeral homes, mortuary lifts need quiet operation and easy cleaning.

| Lift Type | Power Source | Best For | Typical Capacity |

|---|---|---|---|

| Manual | Hand/foot pump | Light use, budget-conscious | 500-1,500 lbs |

| Electric | AC power | Daily operations | 1,500-4,500 lbs |

| Hydraulic | External hydraulic | Heavy industrial | 3,000-6,000 lbs |

Battery lift categories and key specs

Choosing the right battery lift starts with understanding what matters. Load rating tops the list - there's no room for error. You'll find units ranging from 500 lb capacity to BHS Battery Lifting Beams that handle 6,000 lbs with adjustable hook positions.

Lift height determines whether equipment will work in your space. The Atlas Electric Battery Lifting Table offers range from 29¼" minimum to 71¼" maximum. That versatility handles everything from low-profile batteries to high-mounted installations.

Power source affects performance and where you can use equipment. Battery-powered units like the BendPak Mobi-EVS are game-changers for flexibility. They run on onboard 12V deep-cycle batteries with 10-12 hour charging cycles.

Mobility can make or break daily operations. Universal self-locking casters let you position equipment exactly where needed, then lock it securely. The BendPak EVS4500 includes zero-throw casters for precise positioning in tight spots.

Specialized battery lift solutions for automotive, industrial & EV packs

EV battery lift systems face unique challenges. These aren't just heavy batteries - they're high-voltage systems demanding respect. Unite Automotive offers EV battery lift tables with 1-ton capacity and electric hydraulic drives using 24V low voltage control for safety. Non-conductive beams and specialized safety features are essential for electric vehicle systems.

UPS battery lift systems take a different approach. In data centers, space is precious and precision matters. The C&C Power Batt-Lift focuses on single-tech operation in tight aisles. These units feature oversized steel platforms making battery positioning foolproof.

Forklift battery lift systems are built for the long haul. When changing batteries multiple times per shift, durability isn't negotiable. BHS Battery Transfer Carriages offer configurations combining powered extraction with manual or powered lifting.

Mortuary battery lift systems require a gentler touch. In funeral homes, quiet operation and easy cleaning are as important as lifting capacity. These battery-powered systems avoid hydraulic fluid risks while providing reliable operation mortuary equipment demands.

For specialized lifting needs, check out our guide on Lift Like a Pro and explore non-conductive lifting beams for improved safety.

Safety, Ergonomics & Selection Criteria

When it comes to battery lift equipment, safety isn't just important—it's everything. I've seen too many workplace injuries from improper battery handling, and frankly, they're completely preventable with the right equipment and approach.

Modern battery lift systems come loaded with safety features that would make an overprotective parent proud. The BendPak EVS4500 doesn't mess around with tri-caster locking pins and comprehensive safety guard systems. These aren't just nice-to-have features—they're your insurance policy against accidents that can shut down operations and hurt people.

OSHA, ANSI, and CE standards govern how these lifts are designed and operated, depending on your market. These regulations aren't bureaucratic red tape—they're lessons learned from decades of industrial accidents. Following these standards protects your business legally and keeps your team safe.

Here's something many people overlook: non-conductive lifting beams. When you're dealing with batteries that might still have electrical charge, you need beams made from hardwood or composite materials. Metal beams and electricity don't play well together, and the results can be shocking—literally.

Floor locks and stability systems prevent your lift from becoming a runaway cart at the worst possible moment. The Atlas Electric Battery Lifting Table includes reinforced legs and a safety lock ladder because stability matters when you're working with thousands of pounds overhead.

The best battery lift systems allow single-technician operation. This isn't just about saving labor costs—it's about eliminating the coordination mishaps that happen when multiple people try to handle heavy, dangerous loads together.

For more detailed information about hydraulic safety systems, check out our guide on Lift Like a Pro.

How battery lifts improve safety and ergonomics

Let's talk about why your back will thank you for investing in a proper battery lift. Manual lifting of heavy batteries is the fast track to workers' compensation claims and chronic pain. These systems don't just reduce injuries—they virtually eliminate them.

Strain reduction happens in ways you might not expect. Obviously, the equipment does the heavy lifting, but that's just the beginning. Precise positioning controls mean your technicians can place batteries exactly where they need to go without awkward reaching or pretzel-like contortions.

The adjustable height capabilities bring the work to your people instead of forcing them to crawl around on the floor or stretch overhead like they're changing a light bulb in a cathedral. Your team's knees, backs, and necks will appreciate this more than you might realize.

In sensitive environments, ESD protection becomes critical. Cleanroom-compliant battery lift systems use all-electric drivetrains and materials that won't contaminate your workspace while protecting expensive electronic components from static discharge damage.

Workflow speed improvements are impressive when you stop wrestling with heavy batteries. The BendPak EVS4500 lifts to over 6 feet in less than 20 seconds. Compare that to the time it takes three people to manually wrestle a heavy battery into position, and you'll see why these systems pay for themselves quickly.

Choosing the right battery lift for your operation

Selecting the right battery lift starts with honest math about your capacity requirements. Take your heaviest battery weight and add at least 25% for safety margin. This isn't being overly cautious—it's being smart about equipment that needs to work reliably for years.

Bay space constraints often make the decision for you. Mobile scissor lifts like the BendPak Mobi-EVS series work beautifully when you need one lift to serve multiple work areas. Fixed installations make more sense when you have dedicated battery service bays and consistent workflow patterns.

Integration requirements can get complex quickly. Some facilities need lifts that work with existing hoists, conveyors, or automation systems. Alum-a-Lift has handled over 12,000 installations in more than 50 countries, so they've probably seen whatever unique challenge you're facing.

Attachment availability turns a good lift into a great investment. The BendPak EVS series includes fixture sets, telescoping arm kits, and multi-point support kits that let one piece of equipment handle various battery types and other heavy components.

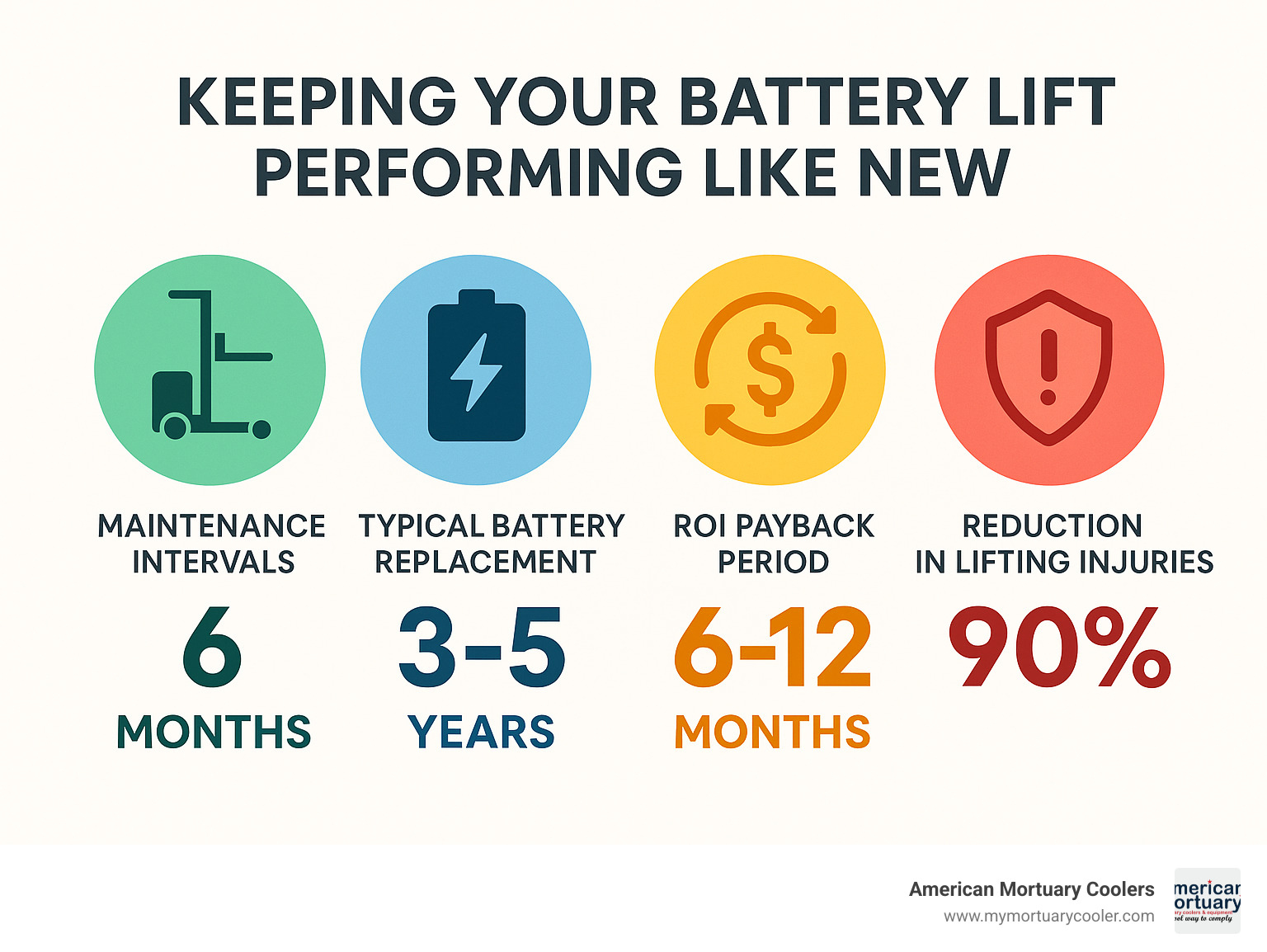

ROI calculations should include the savings you can't easily measure—like avoiding that one major injury that could cost thousands in workers' compensation and lost productivity. While the upfront cost might make you wince, most operations see payback within the first year when you factor in injury prevention, productivity gains, and equipment longevity.

At American Mortuary Coolers, we understand that proper lifting equipment isn't just about efficiency—it's about taking care of the people who take care of your business.

Future Trends, Maintenance & Integration

The battery lift industry is experiencing a technological revolution making these tools smarter, more efficient, and easier to use than ever before. Today's equipment features sophisticated technology that would have seemed like science fiction just years ago.

Onboard 12V battery packs have transformed portable lifting equipment. The BendPak Mobi-EVS series demonstrates this with rechargeable systems providing 10-12 hours of operation per charge. No more hunting for power outlets or dealing with extension cords.

The integration of automation and robotics is perhaps the most exciting development. Modern systems can automatically detect battery dimensions and adjust lifting parameters accordingly. This means less training time and fewer mistakes during critical operations.

Cleanroom electric drives have revolutionized battery handling in sensitive environments. These all-electric systems eliminate contamination risks that hydraulic fluid leaks once posed. Alum-a-Lift has pioneered cleanroom-compliant systems meeting Fed Std Class 10 (ISO 4) requirements.

Predictive maintenance sensors are changing equipment maintenance. These smart systems monitor usage patterns, load cycles, and component wear to predict when maintenance will be needed. Instead of waiting for something to break, you can address issues proactively.

Integration capabilities with existing forklifts and hoists create comprehensive material handling systems. Fork attachments like the MTC FA-6000 with 6,000 lb capacity allow existing forklifts to handle battery lifting tasks when dedicated lifts aren't available.

For additional information about non-conductive lifting beam technology, explore this Scientific research on non-conductive lifting beams.

Keeping your battery lift performing like new

Proper maintenance is key to getting maximum life and performance from your battery lift investment. Modern equipment is designed to be much more reliable and easier to maintain than older systems.

Inspection schedules should become part of your daily routine. A quick visual check for obvious damage takes just a minute but can prevent major problems. Weekly operational tests of safety systems ensure everything works when needed. Monthly detailed inspections of critical components help catch wear before it becomes a problem.

Lubrication requirements vary by system type. Hydraulic systems need regular fluid changes and seal inspections, while electric systems require periodic greasing of moving parts and electrical connection checks. The BendPak EVS series uses twin chrome-plated hydraulic cylinders with proprietary seals that extend seal life.

Battery replacement becomes necessary for battery-powered lifts after several years. The 12V deep-cycle batteries used in portable systems typically last 3-5 years, depending on usage and charging system maintenance. Proper charging procedures can significantly extend battery life.

Training programs ensure operators understand proper equipment use and safety procedures. This includes understanding load limits, proper positioning techniques, and emergency procedures. Regular refresher training helps maintain safety standards.

Emerging technology driving next-gen battery lifts

The future of battery lift technology is exciting, with innovations that will make these tools even more valuable in years ahead.

Portable EV tables represent one of the fastest-growing segments as electric vehicle adoption accelerates. These specialized units handle unique requirements of EV battery packs, including high-voltage safety systems and precise positioning needed for complex battery assemblies.

Lithium power systems are revolutionizing portable lift equipment by replacing traditional lead-acid batteries. These advanced power systems offer longer runtime, faster charging, and significantly reduced weight. The improved power-to-weight ratio enables more compact and efficient lift designs.

Autonomous positioning systems use advanced sensors and automation to precisely position batteries without operator intervention. These systems reduce training requirements and improve consistency while eliminating human error in critical positioning operations.

Data logging capabilities track equipment usage, maintenance needs, and performance metrics in real-time. This information helps optimize maintenance schedules, identify usage patterns, and justify equipment investments through detailed ROI analysis.

Frequently Asked Questions about Battery Lifts

What weight capacity should my battery lift have?

The golden rule for battery lift capacity is simple: take your heaviest battery and add at least 25% more. This safety margin isn't just a suggestion—it's essential for safe operation and equipment longevity.

If you're working with electric vehicles, most EV battery packs weigh between 800 and 1,200 pounds. That means you'll want a lift with 1,500 to 2,000 pound capacity to handle them safely. The BendPak EVS4500 with its 4,500 lb capacity gives you plenty of headroom for current and future EV applications.

Industrial operations face different challenges. Forklift batteries typically weigh 2,000 to 3,000 pounds, which means you'll need lifts with 4,000+ lb capacity. For the heaviest industrial applications, BHS Battery Lifting Beams with 6,000 lb capacity handle just about anything you'll encounter.

At American Mortuary Coolers, we've seen funeral homes underestimate their lifting needs. Even mortuary equipment batteries can be surprisingly heavy, and it's better to have too much capacity than too little. A battery lift with excess capacity will last longer and operate more smoothly than one that's constantly maxed out.

How often does a battery lift need maintenance?

Battery lift maintenance isn't complicated, but it does require consistency. Think of it like maintaining your car—regular attention prevents major problems down the road.

Daily checks should become second nature. Look for obvious damage, check for hydraulic leaks, and make sure safety systems are functioning. It takes less than five minutes but can prevent serious accidents.

Weekly operational tests verify that your safety systems work properly. Test the emergency stops, check the locking mechanisms, and ensure all controls respond correctly. This is when you'll catch small problems before they become big headaches.

Monthly detailed inspections dig deeper into your equipment's health. Check hydraulic fluid levels, inspect electrical connections, and examine moving parts for wear. Document everything—this maintenance log becomes invaluable for warranty claims and resale value.

Annual professional inspections by qualified technicians ensure your lift continues operating safely. They'll spot issues that routine maintenance might miss and can recertify your equipment for continued use.

High-use systems might need more frequent attention, while occasional-use units can sometimes extend intervals slightly. The key is establishing a routine and sticking to it.

Can one battery lift handle different battery sizes?

Modern battery lift systems are remarkably versatile, and most can handle a wide range of battery sizes with the right setup. This flexibility maximizes your equipment investment and simplifies operations.

The Atlas Electric Battery Lifting Table exemplifies this versatility. Its adjustable platform length extends from 68 1/4" to 79 3/4", while tilting angles of ±5.1° left/right and ±2.2° front/rear accommodate different battery configurations. This means one lift can handle everything from compact UPS batteries to large industrial units.

BHS Battery Lifting Beams take a different approach with adjustable hook positions in 3" increments. This system works particularly well for batteries of different lengths, allowing precise positioning regardless of battery size.

Many manufacturers offer fixture sets and adapters that dramatically expand a lift's capabilities. These accessories allow one battery lift to handle various battery types and even other heavy components, making your equipment investment work harder for you.

The versatility question becomes especially important in funeral homes where equipment needs vary widely. At American Mortuary Coolers, we've seen operations benefit tremendously from lifts that can handle both small equipment batteries and larger mortuary equipment components.

The bottom line? A well-chosen battery lift with the right accessories can handle most of what you'll throw at it, making it a smart investment for growing operations.

Conclusion

When I think about how battery lift technology has changed over the years, it's remarkable to see the change. We've gone from dangerous manual lifting that injured workers daily to sophisticated systems like the BendPak Mobi-EVS with its impressive 4,500-lb capacity, handling everything from massive EV battery packs to delicate UPS systems in data centers.

Here at American Mortuary Coolers, we've witnessed this evolution while serving funeral homes from our Tennessee base. Whether we're working with families in Atlanta, Chicago, Columbia, Dallas, Los Angeles, New York, Pittsburgh, or anywhere across the Midwest, Northeast, Rocky Mountain, Southeast, Southwest, and Pacific regions, one thing remains constant: proper lifting equipment saves lives and money.

The numbers don't lie. When funeral homes invest in the right battery lift systems, they see immediate improvements in workplace safety. Back injuries become rare instead of routine. Workers' compensation claims drop dramatically. Most importantly, your team goes home healthy every day.

Efficiency gains follow close behind safety improvements. What once required three people and significant injury risk now takes one operator and a few minutes. The C&C Power units we've seen in action can handle 1,500-lb loads with single-person operation, changing how funeral homes manage their equipment maintenance.

The cost savings speak for themselves. Between reduced insurance premiums, eliminated injury claims, and improved productivity, most battery lift systems pay for themselves within the first year. It's not just about the initial investment – it's about protecting your most valuable asset: your people.

Technology keeps advancing too. Today's battery-powered portable units eliminate the hassle of power cords and hydraulic lines. IoT integration helps predict maintenance needs before problems occur. Specialized attachments mean one lift can handle multiple tasks, maximizing your investment.

For funeral service professionals looking to upgrade their material handling capabilities, I highly recommend checking out our comprehensive resource: The Ultimate Guide to Choosing the Best Mortuary Lift System. It covers everything specific to our industry's unique needs.

The future looks bright for battery lift technology. Systems are becoming smarter, safer, and more versatile every year. In our increasingly battery-dependent world, investing in proper lifting equipment isn't just smart business – it's essential for staying competitive while keeping your team safe and productive.