Why Lift Handles Are Essential Hardware Components

Lift handles are specialized hardware components designed to provide secure grip points for lifting, opening, and manipulating panels, doors, hatches, and equipment across numerous industries. Unlike standard pulls or knobs, lift handles are engineered to bear significant weight while offering ergonomic advantages that reduce strain during operation.

Key Types of Lift Handles:

- Flush Mount - Sits flat when not in use, ideal for smooth surfaces

- Surface Mount - Projects from surface, easier to grip

- Ring Pull - Circular design for 360-degree access

- Spring-Loaded - Automatically returns to closed position

- Detachable - Can be removed when not needed

Common Applications:

- Marine hatches and deck hardware

- Industrial machinery panels

- Furniture and cabinetry

- Window sash systems

- Mortuary equipment

- RV and awning systems

Over 500 lift handles were purchased on Amazon in the past month alone, demonstrating their widespread utility. These components serve critical functions in industries ranging from marine applications (where 316 stainless steel handles resist saltwater corrosion) to mortuary facilities (where hygienic, durable hardware is essential).

Modern lift handles incorporate advanced materials like glass-fiber reinforced polyamide, which can withstand tensile loads up to 784 pounds while maintaining chemical resistance. The E-Z Lift Handle, made from high-quality American steel, exemplifies how proper design reduces back strain and improves workplace ergonomics.

As a Mortuary Cooler supplier with extensive experience delivering mortuary equipment nationwide, we've seen how the right lift handles can make the difference between smooth daily operations and costly equipment failures. Quality lift handles are particularly crucial in mortuary applications where reliability, hygiene, and durability directly impact service quality.

Understanding Lift Handles: Functions, Types, and Materials

Lift handles are carefully engineered components that make the difference between struggling with a heavy panel and effortlessly accessing what you need. Whether you're dealing with a marine hatch in choppy waters or a mortuary cooler door that gets opened dozens of times a day, the right handle makes all the difference.

Core Functions of Lift Handles

Lift handles do much more than provide a place to put your hands:

Grip and lift functions spread weight across your entire grip, not just your fingertips. Studies show that well-designed handles can cut your lifting effort by up to 30%.

Secure and latch functions often work together. Many handles incorporate locking mechanisms or pair perfectly with latches. This is crucial in marine applications where a panel that pops open unexpectedly isn't just inconvenient - it's dangerous.

Vibration control is where spring-loaded handles really shine. These handles eliminate annoying chatter while keeping everything secure.

Main Types of Lift Handles

Flush handles sit completely flat when not in use, needing only a tiny 3/64" profile. Perfect when you need a clean look or tight clearances. Marine-grade flush handles from companies like Suncor pack serious strength into a package that weighs just 0.26 pounds.

Surface-mount handles stick out from the surface, making them easier to grab but requiring more clearance space. They're typically simpler to install and give you better leverage.

Ring pull handles offer 360-degree access that's invaluable in cramped spaces. When you're working at odd angles or in tight quarters, being able to grab from any direction is a game-changer.

Spring-loaded handles automatically snap back to position, keeping things tidy and quiet. The spring gives you nice tactile feedback too.

Detachable handles can be removed when you don't need them - great for security or preventing damage during transport. The E-Z Lift Handle is a perfect example, giving you ergonomic benefits while working with various tools.

Locking handles combine security with functionality. They're available with standardized key numbers, which is handy if you're managing multiple pieces of equipment.

Materials and Their Impact on Durability

316 stainless steel is the champion for marine environments. It laughs at saltwater corrosion and can handle decades of abuse while still looking good.

304 stainless steel gives you excellent corrosion resistance at a friendlier price point. Unless you're dealing with direct saltwater exposure, it'll serve you well.

Glass-fiber reinforced polyamide can handle up to 784 pounds of pulling force. Companies like Jergens and ELESA make handles from this material that resist chemicals, handle temperatures up to 210°F, and work perfectly in food processing or pharmaceutical environments.

Zinc and brass offer that traditional look with solid strength. Chrome-plated versions bump up the corrosion resistance while keeping that attractive finish.

Leather still has its place, especially in restoration work. Quality leather handles can literally last over a century when properly made.

| Material | Best For | Strength | Cost | Corrosion Resistance |

|---|---|---|---|---|

| 316 Stainless Steel | Marine, harsh environments | Excellent | High | Superior |

| 304 Stainless Steel | General purpose, indoor | Very Good | Medium | Very Good |

| Glass-Fiber Polyamide | Chemical, food processing | Up to 784 lbs | Medium | Excellent |

| Brass/Zinc | Decorative, light duty | Good | Low-Medium | Fair |

For marine applications where quality matters, the Flush Lift Handle – Suncor Stainless represents top-tier 316 stainless steel construction with precision casting that's built to last.

At American Mortuary Coolers, we've seen how the right handle choice affects daily operations. When mortuary equipment gets used constantly, having handles that won't fail, corrode, or become difficult to operate isn't just convenient - it's essential for maintaining professional service standards.

How to Select the Right Lift Handles for Your Application

Choosing the right lift handles doesn't have to be complicated. The key is understanding your specific needs and matching them to the right combination of materials, design, and capacity.

Load rating should be your first consideration. Calculate the actual weight you'll be lifting, then add a safety margin of at least 50%. For example, if you're lifting a 200-pound panel, choose handles rated for at least 300 pounds. The ELESA® glass-fiber reinforced handles range from 560 to 784 pounds capacity, making them suitable for most heavy-duty applications.

Environmental conditions will dictate your material choice. Saltwater environments absolutely require 316 stainless steel. Chemical exposure calls for glass-fiber polyamide construction, while indoor furniture applications can use brass or even leather.

Compliance requirements matter more than many people realize. RoHS compliance is mandatory for electronic equipment, while some facilities require specific certifications for safety or hygiene standards. Always verify these requirements before making your selection.

Industry-Specific Requirements for Lift Handles

Marine applications present unique challenges that standard hardware simply can't handle. The combination of salt spray, constant moisture, and temperature fluctuations destroys inferior materials quickly. Over 100 Marine Grade Stainless Steel Heavy-Duty Flush Lifting Handles were purchased last month alone, showing how seriously boat owners take this requirement.

Industrial machinery environments expose lift handles to chemicals, oils, and temperature extremes. Glass-fiber reinforced polyamide excels here, resisting solvents and maintaining strength up to 210°F.

Mortuary equipment demands the highest standards for both hygiene and reliability. Stainless steel construction allows thorough sterilization while providing the durability needed for daily use. Equipment failure in this environment isn't just inconvenient - it can disrupt critical services during families' most difficult times. Our guide on Lift Your Standards with These Hydraulic Mortuary Trolleys explores how proper hardware selection affects overall equipment performance.

Furniture and cabinetry applications balance aesthetics with functionality. Flush-mount designs complement modern minimalist styles while providing adequate strength for daily use.

Window restoration projects often require specific historical patterns. Victorian, Arts & Crafts, and Eastlake designs from the 1880s remain popular choices, with prices ranging from $5.99 for basic stamped brass lifts to $36.99 for forged-bronze combination lock and lift mechanisms.

Size, Ergonomics, and Safety Considerations for Lift Handles

Tensile strength requirements go beyond simple weight calculations. Dynamic loading during lifting creates forces significantly higher than static weight. ELESA® handles demonstrate this principle clearly - their 4.21" length model handles 560 pounds, while the 10.31" version manages 784 pounds.

Grip comfort affects both safety and user fatigue. Handles must accommodate gloved hands in industrial settings while providing secure grip when wet. Most quality handles fall within the optimal 1 to 1.5-inch diameter range based on ergonomic studies.

Anti-pinch design prevents finger injuries that can occur when handles snap back into position. Spring-loaded handles that return smoothly to flush position eliminate this risk while maintaining clean aesthetics.

Mounting integrity often gets overlooked until failure occurs. Load forces must distribute properly across all mounting points to prevent catastrophic failure. Standard #8 screws work for most applications, but high-load situations require reinforcement plates or larger fasteners.

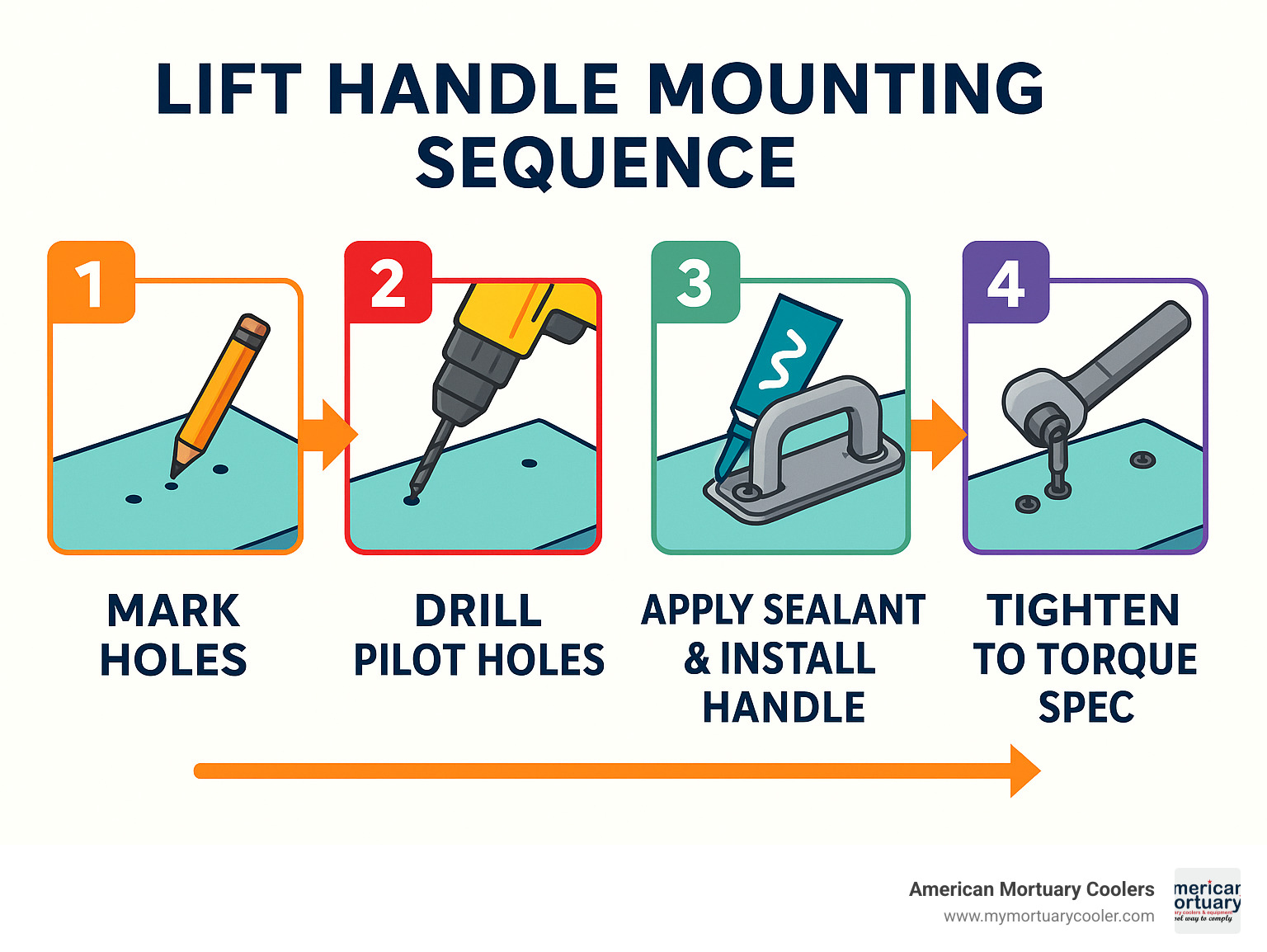

Installation & Best Practices for Lift Handles

Proper installation ensures optimal performance and longevity of lift handles. Our field experience has shown that installation errors cause more handle failures than material defects or wear.

Surface-Mount vs Recessed Install of Lift Handles

Surface-Mount Installation: Generally simpler, requiring only pilot holes and appropriate fasteners. The handle projects from the surface, providing excellent leverage but requiring clearance space. Key considerations include:

- Use pilot holes slightly smaller than fastener diameter to ensure secure grip

- Apply thread-locking compound to prevent loosening from vibration

- Consider backing plates for thin materials to distribute load

Recessed Installation: More complex but provides flush appearance when closed. Critical steps include:

- Precise cutout dimensions - tolerance matters significantly

- Proper sealing to prevent water infiltration in marine applications

- Adequate material thickness around cutout edges to maintain strength

Safety & Maintenance Tips for Lift Handles

Routine Inspection: Check mounting fasteners quarterly in high-use applications. Look for signs of loosening, corrosion, or material fatigue around mounting points.

Corrosion Prevention: Even stainless steel requires maintenance. Remove salt deposits in marine environments and apply appropriate lubricants to moving parts.

Load Limit Adherence: Respect manufacturer specifications. Overloading causes gradual failure that may not be immediately apparent but compromises long-term reliability.

Cleaning Protocols: Use compatible cleaners - avoid chlorine-based products on stainless steel, and use mild detergents on plastic handles to prevent chemical degradation.

Top Industries, Brands, and Innovations in Lift Handles

The lift handles market is fascinating because it touches so many different industries - each with their own unique challenges and requirements. From the rolling seas to the quiet halls of funeral homes, these simple yet crucial components keep our world moving smoothly.

Marine applications drive some of the most demanding requirements. When you're dealing with saltwater, storms, and the need for absolute reliability, there's no room for cheap hardware. The RV and awning industry has similar needs - handles must work flawlessly whether you're in the Arizona desert or a Maine campground.

Trunk restoration enthusiasts know that authentic hardware can make or break a project. Finding the right Victorian-era handle isn't just about function - it's about preserving history. Meanwhile, mortuary equipment demands the highest standards of hygiene and reliability. At American Mortuary Coolers, we've seen how the right hardware choices directly impact daily operations and service quality.

Industrial machinery applications push materials to their limits with chemical exposure, temperature extremes, and constant use. It's amazing how something as simple as a handle can make the difference between smooth operations and costly downtime.

Emerging Trends in Lift Handle Design

Innovation never stops, even in something as basic as lift handles. Lightweight alloys are revolutionizing the industry - we're seeing mortuary lifts that weigh just 395 pounds while supporting over 1,000 pounds capacity. That's engineering at its finest.

Anti-microbial coatings are becoming essential in healthcare and food service. These special finishes actively reduce bacteria growth on handle surfaces, which is crucial when cleanliness can literally be a matter of life and death.

Smart locking technology is bringing handles into the digital age. Electronic locks integrated with traditional lift mechanisms provide security without sacrificing the simple reliability that makes handles so dependable.

Modern aesthetics matter more than ever. Architects and designers want clean lines and minimalist appearance, but they still need handles that work perfectly day after day. It's a challenging balance, but the best manufacturers are pulling it off beautifully.

Notable Brands and What Sets Them Apart

ELESA® has earned respect through pure engineering excellence. Their plastic handles might surprise you - glass-fiber reinforced polyamide construction delivers tensile strengths up to 784 pounds while resisting chemicals and temperatures up to 210°F. That's serious performance from what looks like "just plastic."

The E-Z Lift Handle represents American manufacturing at its best. Available at ACE Hardware stores nationwide, these handles focus on ergonomic design that actually reduces back strain. When you're lifting heavy panels all day, that attention to human factors makes a real difference.

Suncor specializes in marine hardware with precision-cast 316 stainless steel construction. Their handles weigh just 0.26 pounds but handle serious marine and industrial applications. The attention to corrosion resistance detail makes them the go-to choice for saltwater environments.

Sea-Dog offers comprehensive marine hardware including their Quality Marine Hardware line. Their cabinet and hatch hardware options are designed specifically for the unique challenges of marine environments.

Jergens brings industrial focus with emphasis on durability and chemical resistance. They're particularly strong in manufacturing and processing environments where failure isn't an option.

Hoppe represents European engineering excellence with emphasis on security integration and aesthetic design. They're popular in architectural applications where form and function must work together seamlessly.

Each brand has found its niche by understanding what their customers really need - not just a handle, but a solution that works reliably in their specific environment.

Maintenance, Troubleshooting, and Lifecycle Management

Taking care of your lift handles makes a huge difference in how long they last and how well they work. We've learned this over our years servicing mortuary equipment across the Southeast. A little preventive care costs way less than scrambling to find replacement parts when something breaks at the worst possible moment.

Most handle problems start small and get bigger over time. A little wobble becomes a loose screw, which becomes a stripped hole, which becomes a complete replacement job. But catch these issues early, and you can usually fix them with basic tools and a few minutes of your time.

Compatible cleaners make all the difference. We've seen expensive stainless steel handles ruined by well-meaning maintenance folks using the wrong chemicals. Chlorine bleach and stainless steel don't play nice together.

Common Problems and Quick Fixes for Lift Handles

Loose screws top our list of service calls, and they're usually the easiest fix. Most of the time, it's just vibration doing its thing over months or years. The solution is simple - remove the screws, add a drop of thread-locking compound, and reinstall them to the proper torque specs.

Corrosion sneaks up on you, even with good stainless steel handles. Salt air, cleaning chemicals, and even fingerprints can start the process. The key is catching it early with routine corrosion checks. A light scrub with the right cleaner and a protective coating can stop small problems from becoming big ones.

Spring fatigue happens to the best of handles eventually. Those spring-loaded mechanisms that keep everything tight and quiet will lose their zip over time. The good news is that most quality manufacturers sell replacement springs, so you don't need to replace the whole handle.

Handle rattle drives people crazy, and it usually means something's gotten loose or worn out. Start by checking the obvious stuff - are the mounting screws tight? If tightening them doesn't help, the springs might need replacing.

Extending the Life of Your Lift Handles

Protective coatings work like sunscreen for your handles. Marine environments need specialized corrosion inhibitors, while industrial settings might need chemical-resistant treatments.

Respecting load limits might seem obvious, but you'd be surprised how often people treat handles like they're indestructible. Every handle has its limits, and staying within them protects both the hardware and the people using it.

When you can, control the environment around your handles. Controlled storage during off-seasons or covering equipment when it's not in use makes a real difference.

Keep a spare parts logistics system that makes sense for your operation. Stock up on common wear items like springs, gaskets, and fasteners. Having the right parts on hand when you need them prevents those frustrating delays.

Replacement triggers should be part of your maintenance routine. Know what to look for - excessive wear, cracks in the material, or failure signs like handles that don't return to position properly.

The bottom line is that good maintenance habits pay for themselves. A cleaning schedule that actually gets followed, regular routine inspection that catches problems early, and proper lubrication of moving parts will keep your lift handles working smoothly for years.

Frequently Asked Questions about Lift Handles

When selecting lift handles for your equipment, certain questions come up repeatedly. Based on our years of experience at American Mortuary Coolers, we've learned that getting these fundamentals right saves time, money, and headaches down the road.

What load capacity should I look for in lift handles?

The golden rule for lift handles is simple: always choose a capacity well above what you actually need. We recommend handles rated for at least twice your expected load as a basic safety margin. This isn't just about preventing catastrophic failure - it's about ensuring smooth operation over years of use.

Industrial applications often demand even higher safety factors, sometimes three to four times the working load. The ELESA® handle line perfectly illustrates the range available, starting at 560 pounds for lighter applications and reaching 784 pounds for heavy-duty use.

In our mortuary equipment, we've seen what happens when handles are undersized. A cooler door that weighs 150 pounds might seem fine with a 200-pound handle, but factor in the awkward lifting angle, potential ice buildup, and daily use over several years - suddenly that 300 or 400-pound rated handle makes much more sense.

How do lift handles differ from standard pulls and latches?

Here's where many people get confused - they're not just fancy door pulls. Lift handles are engineered specifically for weight-bearing applications with careful attention to how your hand and arm move during lifting motions.

Standard pulls work great for opening doors or drawers where you're mainly overcoming friction or spring tension. But try lifting a 100-pound panel with a decorative cabinet pull, and you'll quickly understand the difference. The grip angle is wrong, the load distribution is poor, and your hand will be screaming after a few operations.

Latches focus on securing function but often sacrifice lifting comfort entirely. Quality lift handles are the Swiss Army knife of hardware - they integrate lifting, securing, and often locking functions in a single, well-designed component.

The ergonomic difference is remarkable. A proper lift handle distributes weight across your entire grip surface, positions your wrist naturally, and often includes features like anti-slip texturing or comfortable grip materials.

Can I retrofit spring-loaded lift handles onto existing panels?

The short answer is usually yes, but the devil's in the details. Most applications allow retrofitting, though you'll need to pay attention to the cutout requirements since spring-loaded handles typically need larger openings than simple pulls.

Start by measuring your existing cutouts carefully and comparing them to the manufacturer's specifications. In many cases, you can make minor modifications to accommodate the upgrade - and trust us, the improved functionality usually justifies the extra effort.

The spring-loaded design eliminates that annoying rattle you get with loose handles, automatically returns the handle to a flush position, and provides tactile feedback during operation. We've retrofitted countless pieces of equipment over the years, and customers consistently tell us it's one of those small changes that makes a big difference in daily use.

One word of caution: make sure your panel material has adequate thickness around the cutout edges. The spring mechanism requires proper support, and thin materials may need reinforcement plates to handle the installation properly.

Conclusion

Choosing the right lift handles doesn't have to be overwhelming once you understand what matters most. Think of it like picking the right tool for the job - you need something that matches your specific needs while standing up to daily use.

The most important thing is being honest about your requirements. If you're working in a marine environment, don't try to save money with basic steel handles that'll rust out in a year. If you need to lift heavy panels regularly, invest in handles rated well above your actual loads. Your back (and your budget) will thank you later.

Material choice makes all the difference. Stainless steel for marine and medical applications, reinforced plastics for chemical environments, and traditional materials like brass or leather when aesthetics matter. Each has its place, and the right choice depends entirely on where and how you'll use them.

We've seen this at American Mortuary Coolers. After years of delivering custom mortuary equipment across all 48 contiguous states, we know that reliable hardware separates professional operations from constant headaches. When a mortuary cooler's lift handles fail during a critical moment, it's not just inconvenient - it affects families during their most difficult times.

Quality components cost more upfront but save money over time. A $50 marine-grade handle that lasts 20 years beats a $15 handle you replace every two years. Plus, you avoid the downtime and frustration of unexpected failures.

For applications requiring more than just handles, our More info about Choosing a Hydraulic Lift Pump guide covers complete lifting systems that work alongside quality handles.

Remember the basics: match the handle to your environment, respect load limits, and maintain them properly. Whether you choose ELESA's engineered plastics, Suncor's precision stainless steel, or E-Z Lift's ergonomic designs, proper selection and care will give you years of reliable service.

The perfect lift handle is simply one that does its job quietly and reliably, day after day. Invest wisely, install carefully, and maintain regularly - your handles will take care of you for years to come.