Why Auto Scissor Lifts Are Essential for Modern Workplaces

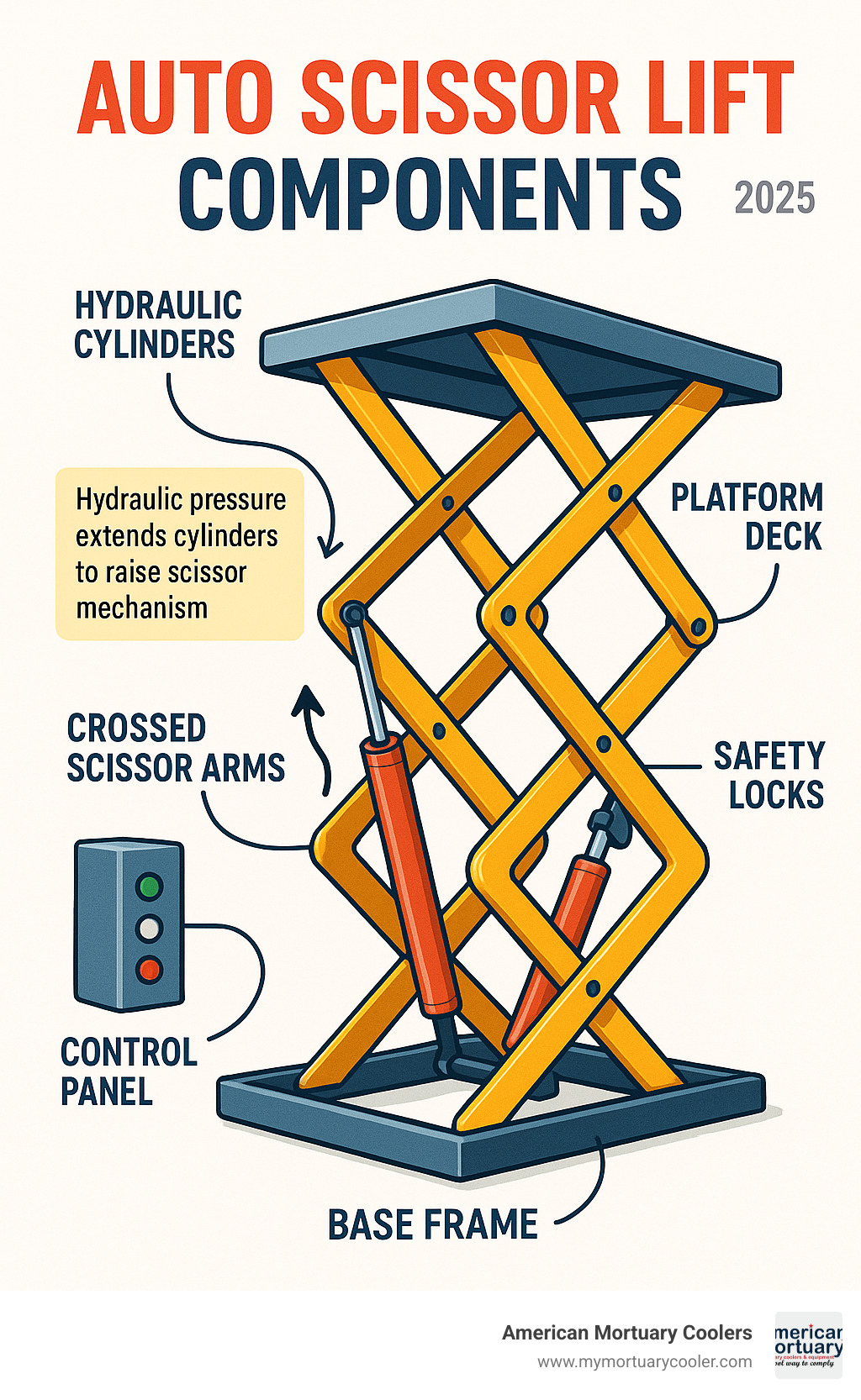

An auto scissor lift is a hydraulic lifting platform that uses crossed metal supports (resembling scissors) to raise vehicles, equipment, or personnel to different working heights. Here's what you need to know:

Key Features:

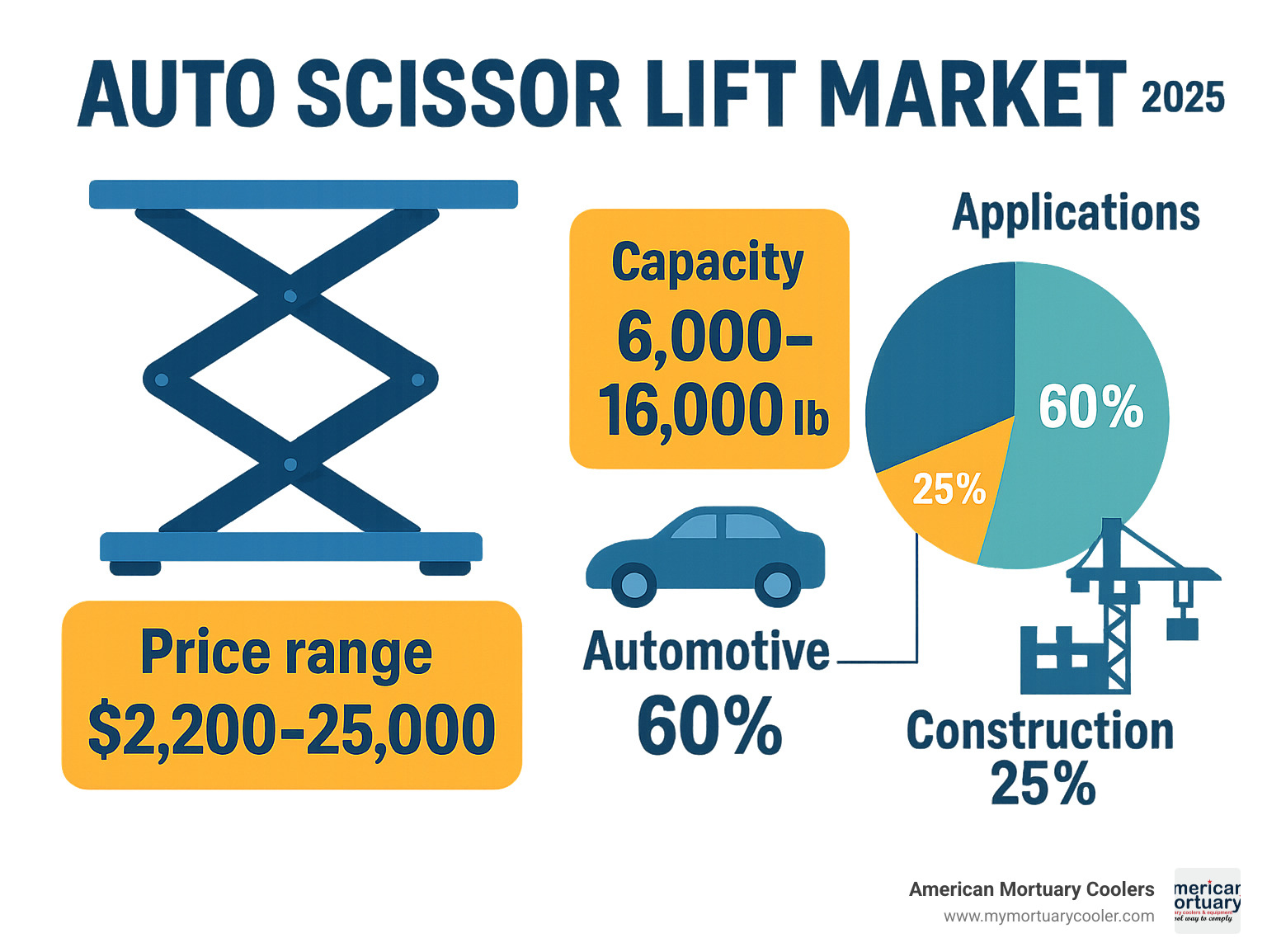

- Lifting capacity: 6,000-16,000 lbs for most automotive models

- Types: Portable, stationary, alignment, full-rise, mid-rise, low-rise

- Power sources: Hydraulic, electric, or diesel

- Applications: Auto repair, mortuaries, warehouses, construction sites

Main Benefits:

- Space-efficient design fits in tight workshops

- Stable platform for safe liftd work

- Ergonomic access reduces worker strain

- Versatile for multiple vehicle types

Auto scissor lifts have become the go-to solution for professionals who need reliable lifting power without the overhead clearance requirements of traditional two-post lifts. As one funeral home operator noted about their hydraulic lift: "The mortuary stretcher is great! We already used it for 450 pounds... smooth and easy to operate."

These lifts serve diverse industries - from automotive repair shops using mid-rise models like the BendPak MD-6XP (6,000 lb capacity) to funeral homes requiring specialized body and casket lifts, to construction sites deploying rough-terrain models with up to 50% gradeability for steep inclines.

The versatility extends to power options too. Electric models work well indoors, while diesel-powered units like the GTJZ series can reach working heights up to 17.86 meters and handle challenging outdoor terrain with four-wheel drive capability.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral professionals select the right lifting equipment, including specialized auto scissor lift systems for body and casket handling. My background in mortuary equipment has shown me how critical proper lifting solutions are for both safety and operational efficiency.

Auto scissor lift helpful reading:

Auto Scissor Lift 101: Mechanics, Types & Applications

Think of an auto scissor lift as a powerful mechanical marvel that's surprisingly straightforward. The magic happens when a hydraulic system pushes pressurized fluid through lift cylinders, which then extend and push against those distinctive crossed-arms that give the lift its "scissor" name. It's like watching a giant pair of scissors unfold in reverse - except these scissors can handle anywhere from 6,000 to 16,000 pounds with ease.

The crossed-arm design creates incredible stability that keeps your vehicle rock-steady while you work underneath. Whether you're a weekend warrior changing your own oil or a funeral director positioning a casket with care, that stable platform gives you confidence and safety.

What makes these lifts so versatile is how they adapt to different needs. Portable models like the KATOOL KT-X90E pack serious lifting power (8,000 lbs) into a compact package that won't break the bank at under $2,400. Stationary systems are the workhorses of busy operations, bolting permanently to your concrete floor and often including alignment features for precision work.

Then there are the impressive self-propelled units that combine lifting with mobility. These diesel or electric-powered platforms can travel across job sites and reach heights up to 58 feet, handling loads from 1,500 to 2,600 pounds while conquering steep grades.

How an Auto Scissor Lift Works

The hydraulic system is beautifully simple and incredibly reliable. Your hydraulic pump creates pressurized fluid that flows through the system, hitting the lift cylinders which convert that hydraulic energy into linear motion that extends the scissor arms.

Check valves act like one-way doors, preventing fluid from flowing backward and keeping your lift in position even if the pump stops. Safety locks - those mechanical bars you'll see engage automatically - provide backup support that's completely independent of the hydraulic system.

Modern lifts use electric controls with proportional joysticks that give you fingertip control over lifting and lowering speeds. The real genius is in the fail-safe design - even if you lose hydraulic pressure completely, those mechanical safety locks prevent disaster.

Main Types of Auto Scissor Lifts

Portable mid-rise lifts are the sweet spot for most operations. Models like the BendPak MD-6XP deliver nearly 45 inches of rise with 6,000 to 10,000 pounds of capacity, and you can wheel them between service bays as needed.

Flush-mount systems install level with your floor, eliminating trip hazards while giving you complete undercarriage access. Alignment racks combine heavy lifting with precision measurement - the AMGO AX-12A handles 12,000 pounds while providing turnplates and slip plates for comprehensive wheel alignment services.

Heavy-duty full-rise lifts raise vehicles 6 to 8 feet off the ground, giving you standing room for transmission work and complete undercarriage access. Low-profile pad lifts use individual lifting points instead of a continuous platform, staying incredibly low when retracted.

Rough-terrain aerial platforms are the outdoor workhorses with four-wheel drive capability, handling grades up to 50 percent for challenging construction sites.

Primary Applications & Industries

Auto repair shops rely on auto scissor lifts for everything from brake jobs to oil changes. Mid-rise models are especially popular because they give mechanics comfortable working height without needing the overhead clearance of two-post lifts.

Detailing operations use low-rise and mid-rise lifts to position vehicles perfectly for thorough cleaning, making wheel wells and undercarriages easily accessible.

Funeral homes need specialized scissor lifts that handle bodies and caskets with dignity and safety. These units often feature stainless steel construction for easy sanitization and may include built-in scales. More info about mortuary lifts covers the specific requirements for this sensitive application.

Warehouses depend on scissor lifts for inventory management, allowing workers to safely reach high shelving and loading docks with platform capacities ranging from 1,500 to 2,600 pounds.

Construction sites use self-propelled aerial platforms for tasks requiring heights up to 58 feet, with rough-terrain capable units going where the work needs to be done.

Safety Standards & Buying Checklist for Auto Scissor Lifts

When it comes to auto scissor lifts, safety isn't negotiable. I've worked with funeral homes and service shops long enough to know that cutting corners on safety standards can lead to devastating consequences - both for your workers and your business.

The foundation of lift safety starts with proper certification. In North America, you'll want to look for ANSI/ALI ALCTV-2017 compliance, which sets the gold standard for automotive lift design, testing, and installation. If you're dealing with international equipment, CE marking shows European safety compliance, while UL 201 certification covers the electrical components that power your lift.

But certifications are just the beginning. The real safety happens in the mechanical features built into your auto scissor lift. Mechanical safety locks should automatically engage at multiple height positions - these are your lifeline if hydraulic pressure fails. I can't stress this enough: never operate a lift without properly functioning safety locks.

Flow restrictors might sound technical, but they're simple lifesavers. They control descent speed, preventing your lift from dropping like a rock if a hydraulic line ruptures. Similarly, emergency descent systems let you safely lower the platform even during power outages or hydraulic failures.

Modern lifts often include load sensors that monitor weight distribution across the platform. These smart systems won't let you lift if the load is too heavy or positioned dangerously. It's like having a safety inspector built right into your equipment.

For comprehensive safety resources and inspection guidelines, www.autolift.org offers invaluable information that every lift owner should bookmark.

Essential Safety Features

The best auto scissor lifts think ahead of human error. Auto-engage locks activate automatically as your platform rises - no remembering required, no shortcuts possible. This single feature prevents more accidents than any other safety mechanism.

Redundant hydraulic hoses provide backup protection. If one line fails, the others keep supporting your load during controlled emergency lowering. It's the same principle airlines use - multiple systems doing the same critical job.

Velocity fuses act like emergency brakes for your hydraulic system. They detect when fluid is moving too fast (indicating a burst hose) and immediately shut off flow. The result? Controlled descent instead of catastrophic failure.

Certifications & Compliance

The ALI Gold Label is your assurance that a lift meets or exceeds industry safety standards. Insurance companies often require this certification, and for good reason - it represents rigorous third-party testing and verification.

CE marking opens doors if you're importing equipment or working with international standards. ISO9001 certification tells you the manufacturer maintains consistent quality control processes throughout production.

Don't forget about local building codes. Your perfect lift isn't perfect if it can't be legally installed in your facility. Check anchoring requirements, electrical codes, and workplace safety regulations before you buy.

Choosing the Right Capacity & Specs

Selecting your auto scissor lift capacity requires honest assessment of your heaviest loads - plus a safety margin. 6,000 lbs handles most passenger cars beautifully, while 9,000-10,000 lbs accommodates full-size trucks and SUVs. For heavy-duty pickups and commercial vans, step up to 12,000 lbs. Anything over 16,000 lbs enters commercial vehicle territory.

Platform length matters more than you might think. Standard platforms around 168-180 inches work for typical vehicles, but long-wheelbase trucks and vans need 200+ inches. Extended platforms cost more but eliminate the frustration of vehicles that don't quite fit.

Rise height depends on your work. Low-rise lifts (12-24 inches) excel at oil changes and basic maintenance. Mid-rise models (36-48 inches) provide comfortable working height for brake jobs and general repairs. Full-rise lifts (60+ inches) are essential for transmission work and complete undercarriage access.

Your concrete foundation needs attention too. Most lifts require 4-6 inch minimum thickness for proper anchoring. Thinner concrete means reinforcement or alternative mounting methods - factor this into your installation budget.

Power requirements vary significantly. Single-phase 220V works for smaller lifts, but larger units often need three-phase 440V for optimal performance.

| Power Type | Advantages | Disadvantages | Best Applications |

|---|---|---|---|

| Hydraulic (Electric) | Quiet operation, precise control, indoor use | Requires electrical connection, limited mobility | Fixed installations, indoor workshops |

| Diesel | High power, mobile, rough terrain capability | Noisy, emissions, outdoor use primarily | Construction sites, outdoor maintenance |

| Battery Electric | Quiet, mobile, zero emissions | Limited runtime, charging requirements | Indoor aerial work, clean environments |

Installation, Operation & Maintenance Best Practices

Getting your auto scissor lift installed properly is absolutely critical - and honestly, it's where we see most problems down the road. A rushed installation today means headaches, safety issues, and expensive repairs tomorrow.

The whole process starts with a thorough site survey. You need to verify that your concrete is thick enough (usually 4-6 inches minimum), level within the manufacturer's specs, and structurally sound. The electrical hookup should always be handled by a qualified electrician with dedicated circuits, proper grounding, and emergency shutoff switches.

For our friends in the funeral industry, we strongly recommend checking out our guide on Safe Handling Practices with Mortuary Lift Equipment. Mortuary applications have unique considerations that standard automotive installations don't address.

Installation Steps

Floor Survey comes first - measure thickness at multiple points, check for level using a precision level, and look for any cracks or structural issues. Any problems you find now need to be fixed before you go further.

Drilling Anchors requires patience and precision. Use the manufacturer's template to mark every hole location exactly. When drilling, follow the specs to the letter - the right depth, the right diameter, and clean holes free of concrete dust and debris.

Routing Hoses & Cables requires planning ahead. Map out your hydraulic lines and electrical cables to avoid pinch points, high-traffic areas, and anywhere they might get damaged. Use protective conduit wherever lines might be exposed.

Initial Testing isn't optional - it's your safety net. Run through every function including safety lock engagement, emergency stops, and a full load test according to the manufacturer's specifications.

Daily Operation Tips — Auto Scissor Lift

Load Positioning is where many accidents happen, so take this seriously. Always center your load on the platform and make sure the weight is distributed evenly. For vehicles, position the lift points at the manufacturer's recommended locations - usually reinforced frame spots that can handle the load safely.

Balance Points matter more than most people realize. Before you start lifting, double-check that everything is stable and properly positioned. A load that shifts during operation can create dangerous situations fast.

Lock Engagement should be automatic, but always verify those safety locks are engaging as the platform rises. Never rely only on hydraulic pressure to support a load. Those mechanical locks are your backup system.

Good operator training makes all the difference. Everyone who uses the lift needs to understand proper procedures, load limits, and emergency shutdown procedures.

Maintenance Schedule

Weekly Lubrication keeps everything moving smoothly. Hit all the pivot points and sliding surfaces according to the manufacturer's lubrication chart. Use only the recommended lubricants - the wrong grease can actually attract dirt or break down under pressure.

Monthly Hose Inspection is your early warning system for hydraulic problems. Look for signs of wear, cracking, bulging, or damage on every hose. Pay extra attention to spots where hoses bend or touch other components. If a hose looks questionable at all, replace it immediately.

Annual Pressure Testing should be done by a qualified technician who can verify that your hydraulic system is operating within proper parameters. This catches potential problems before they cause failures or safety issues.

Documentation might seem like paperwork for paperwork's sake, but it's actually important. Keep detailed logs of maintenance dates, procedures performed, and any issues you find. This documentation often comes in handy for warranty claims and safety inspections.

The bottom line? A little attention to proper installation and regular maintenance keeps your auto scissor lift running safely and reliably for years. Cut corners here, and you'll pay for it later.

Pricing, Accessories, Innovations & FAQs

When you're shopping for an auto scissor lift, you'll find options spanning from $2,200 for basic portable models all the way up to $25,000 for heavy-duty commercial units. The good news? There's likely a perfect fit for your budget and needs.

Entry-level portable lifts like the KATOOL KT-X90E start around $2,400 and deliver solid 8,000 lb capacity - more than enough for most home garages and smaller shops. For established businesses, mid-range professional models typically run $6,000-$12,000 and include features like flush-mount installation, alignment capabilities, and higher capacity ratings.

Heavy-duty commercial lifts can exceed $20,000, especially for specialized applications like the AMGO AX-16A with its impressive 16,000 lb capacity, or self-propelled aerial platforms reaching working heights over 50 feet.

Financing options through programs like TimePayment offer flexible terms for qualified buyers. Many businesses find that productivity gains and reduced worker compensation claims more than justify the investment.

Popular accessories can transform your auto scissor lift from good to great. Rolling bridge jacks provide additional support points for tricky service jobs, while LED lighting systems eliminate those frustrating shadows that make detail work challenging. Drive-on ramps are a game-changer for low-clearance sports cars.

Recent innovations are genuinely exciting. Wireless control systems eliminate the hassle of tangled cords, while built-in diagnostic capabilities help prevent problems before they become expensive downtime. Some manufacturers are even incorporating AI-powered predictive maintenance systems that monitor lift performance and predict potential failures.

Price Ranges & Financing

Entry-level portable lifts ($2,200-$4,000) represent the most accessible entry point into professional lifting equipment. Basic mid-rise lifts like the Tuxedo MR6K-48X offer 6,000 lb capacity with manual controls and all essential safety features.

Mid-tier professional models ($6,000-$12,000) deliver the features that busy shops demand. Full-featured lifts with flush-mount options, alignment capabilities, and higher capacities dominate this range. The BendPak MD-6XP exemplifies this category perfectly.

Heavy-duty fleet models ($15,000-$25,000+) serve high-volume operations that can't afford downtime. These commercial-grade lifts often include specialized features like extended platforms, integrated alignment systems, and capacities reaching 16,000 lbs or more.

Popular Accessories

Turnplates and slip plates are essential for any shop doing wheel alignment work. These accessories allow wheels to move freely during alignment procedures while maintaining vehicle stability.

Rolling bridge jacks solve those frustrating moments when you need additional lifting points for specialized service work. Bolt-on ramps extend your lift's versatility by accommodating long-wheelbase vehicles or providing gentler approach angles for low-clearance sports cars.

LED lighting systems eliminate the shadows and dark spots that make quality service work challenging. Modern LED systems provide bright, even illumination that reduces eye strain and improves service quality.

Latest Innovations in Auto Scissor Lifts

Lithium battery power represents a major leap forward for mobile and aerial work platforms. New battery technology provides longer runtime and faster charging compared to traditional lead-acid batteries.

IoT sensors are changing lift maintenance from reactive to proactive. Internet-connected sensors monitor lift performance continuously, track usage patterns, and provide real-time alerts for maintenance needs or safety concerns.

Remote diagnostics allow manufacturers to monitor lift performance from their facilities, identifying potential problems before they cause expensive downtime. This technology provides predictive maintenance recommendations based on actual usage data.

Advanced safety systems incorporate multiple redundant safety features that go far beyond traditional mechanical locks. Modern lifts include load monitoring systems, automatic emergency stops, and improved operator protection features.

The integration of these technologies means today's auto scissor lifts are smarter, safer, and more reliable than ever before. For scientific insights into ergonomic benefits, researchers have documented significant improvements in worker safety and productivity - you can explore scientific research on ergonomic lifting for detailed findings.

Frequently Asked Questions about Auto Scissor Lifts

What capacity do I need for my auto scissor lift?

Choose a capacity at least 25% higher than your heaviest vehicle's curb weight. For most automotive applications, 9,000-10,000 lbs handles everything from compact cars to full-size trucks beautifully.

Can I install an auto scissor lift in my home garage?

Absolutely! You'll need adequate concrete thickness (minimum 4-6 inches), proper electrical service, and sufficient ceiling height. Mid-rise lifts often work best for home garages because they provide excellent working height without requiring excessive overhead clearance.

How often should I service the hydraulics?

Monthly visual inspections are essential, with annual professional service recommended for most applications. High-use commercial lifts may require more frequent attention. Always follow manufacturer recommendations and keep detailed maintenance records.

What's the difference between hydraulic and electric power?

Hydraulic systems use pressurized fluid for lifting power and typically offer higher capacity with more precise control. Electric systems refer to the power source - the electric motor that drives the hydraulic pump. Most modern lifts use electric motors to power hydraulic systems.

Do I need special permits for installation?

Requirements vary by location, but most installations require electrical permits and may require structural permits for anchor installation. Check with local building authorities before beginning installation.

Can these lifts handle specialized applications beyond automotive work?

Definitely! Auto scissor lifts serve diverse industries effectively. Funeral homes use specialized versions for body and casket handling, warehouses employ them for inventory management, and construction sites rely on self-propelled models for aerial work.

Conclusion

Choosing the right auto scissor lift is one of those decisions that ripples through your operation for years to come. It affects how safely your team works, how efficiently they complete jobs, and ultimately, how profitable your business becomes. After walking through all the technical details, safety standards, and options available, the message is clear: never cut corners when it comes to safety and quality.

The smart approach starts with honest capacity planning. Size your lift at least 25% above your heaviest regular load - it's better to have headroom than to push equipment beyond its limits. Safety certification isn't negotiable either. That ANSI/ALI gold label isn't just a nice-to-have sticker; it's your assurance that the lift meets rigorous safety standards.

Even the best auto scissor lift is only as good as its installation. Professional installation by qualified technicians isn't where you want to save a few dollars. Poor installation can turn quality equipment into a liability. The same goes for maintenance - those weekly grease points and monthly hose inspections aren't suggestions, they're insurance policies against costly failures.

Here at American Mortuary Coolers, we've spent years understanding what makes equipment truly reliable. While we focus on crafting custom mortuary coolers and specialized equipment for funeral homes throughout Tennessee and across the contiguous 48 states, we work closely with funeral professionals who depend on auto scissor lifts for the most sensitive and important work imaginable.

Our experience delivering durable, custom solutions has taught us that the best equipment combines solid engineering with thoughtful design. Whether you're lifting vehicles in an auto shop or handling precious cargo in a funeral home, the fundamentals remain the same: prioritize safety, choose proven quality, and partner with suppliers who truly understand your needs.

For funeral professionals looking for specialized lifting guidance, we've created a comprehensive resource that dives deep into mortuary-specific applications: The Ultimate Guide to Mortuary Lift Products – American Mortuary Coolers.

An auto scissor lift represents more than just a piece of equipment - it's an investment in your team's safety, your operation's efficiency, and your professional reputation. Take the time to evaluate your real needs, ask tough questions of potential suppliers, and choose equipment that will serve you reliably for decades, not just years.

Your operators will appreciate working with quality equipment that makes their jobs safer and easier. Your customers will benefit from the improved service quality that comes with proper tools. And your bottom line will reflect the smart decision to invest in equipment that works when you need it most.