Why Funeral Mortuary Equipment is Essential for Professional Death Care

Funeral mortuary equipment forms the backbone of every professional death care facility, ensuring dignified handling of the deceased while maintaining the highest standards of safety and hygiene. From the initial removal to final disposition, specialized equipment enables funeral directors to provide compassionate service while protecting both staff and families.

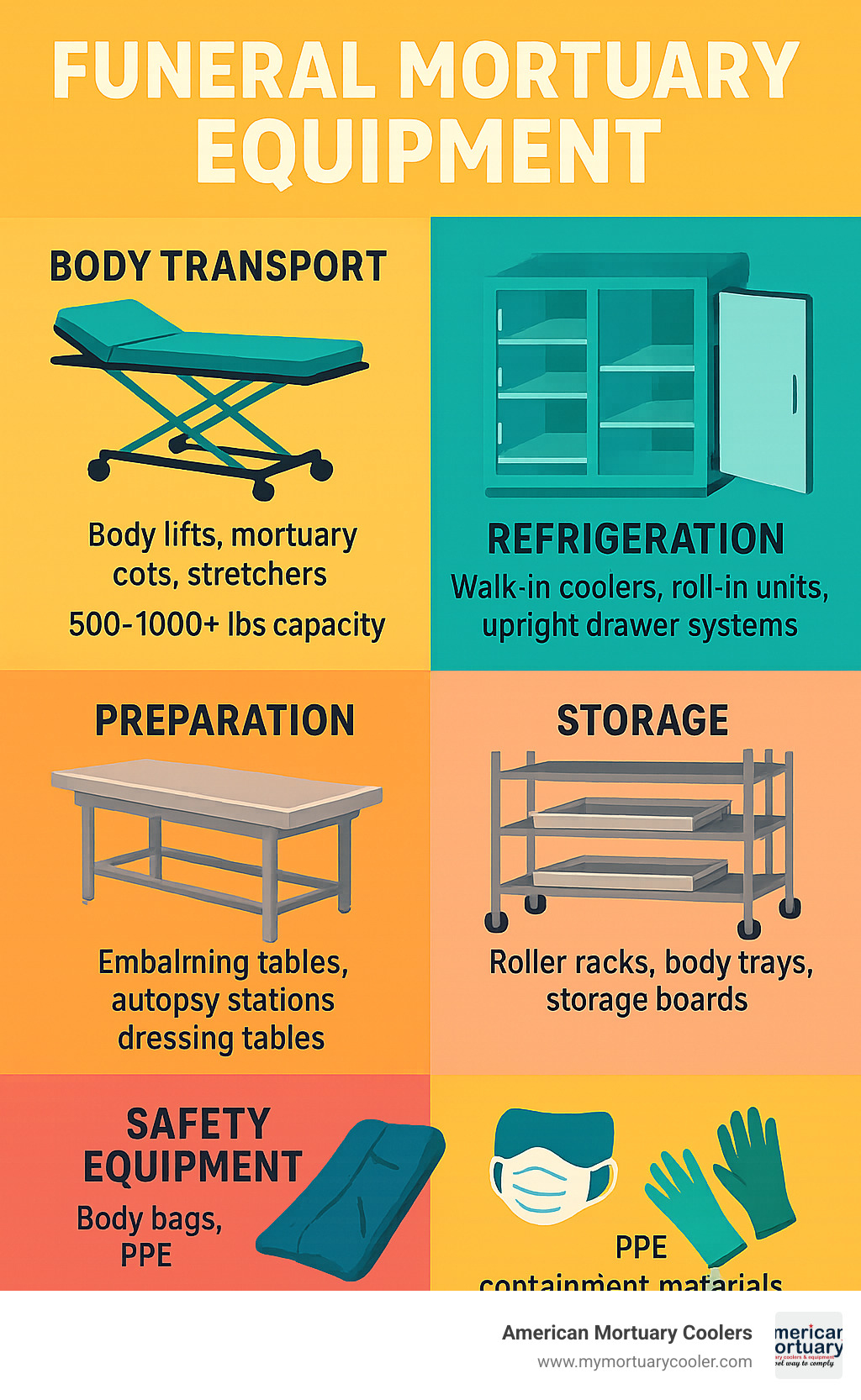

Essential funeral mortuary equipment includes:

- Body transport equipment - mortuary cots, stretchers, and body lifts (500-1000+ lbs capacity)

- Refrigeration systems - walk-in coolers, roll-in units, and upright drawer systems

- Preparation equipment - embalming tables, autopsy stations, and dressing tables

- Storage solutions - roller racks, body trays, and storage boards

- Vehicle equipment - church trucks, casket trolleys, and transport decks

- Safety supplies - body bags, PPE, and containment materials

Modern funeral mortuary equipment emphasizes durability through materials like stainless steel 304, zinc-treated steel, and composite plastics. Standard mortuary cots support 500 lbs, while bariatric versions handle over 1000 lbs to meet changing demographic needs. Battery-powered lifts and multi-level stretchers enable one-person operation, reducing workplace injuries.

As one industry expert noted: "The quality combined with price is better than I have seen" - reflecting how today's equipment balances performance with value.

I'm Mortuary Cooler, a national level mortuary cooler supplier with extensive experience helping funeral homes select the right funeral mortuary equipment for their specific needs. My expertise spans refrigeration systems, transport equipment, and the practical challenges funeral directors face when outfitting their facilities.

Funeral mortuary equipment vocab to learn:

Understanding Funeral Mortuary Equipment: Purpose, Terminology, Materials

When you step into a modern mortuary, every piece of funeral mortuary equipment serves a deeper purpose than you might first realize. These aren't just tools—they're the foundation that allows funeral professionals to honor the deceased with dignity while keeping everyone safe and healthy.

Think of mortuary work as a carefully choreographed process. Each stage requires specific equipment designed for that exact moment in the journey. The removal stage starts with first-call equipment that helps transport someone from their place of passing. Next comes preparation, where embalming tables and autopsy stations provide the workspace needed for body care. Storage relies on refrigeration systems to maintain proper conditions, while viewing equipment helps create peaceful presentation spaces. Finally, final disposition equipment handles the last steps, whether that's cremation or cemetery preparation.

This workflow approach helps funeral directors choose the right equipment for each step, rather than trying to make one piece of gear do everything.

Materials That Matter

The materials used in funeral mortuary equipment tell a story of durability, safety, and respect. Stainless steel 304 leads the way for body trays, trolleys, and embalming tables. Why this specific grade? It resists corrosion beautifully and cleans easily—two must-haves in mortuary work. As one industry professional put it, "Use stainless steel 304 for body trays and trolleys—easy to clean and highly durable."

Zinc-treated steel forms the backbone of lifts and racks. This material gives you the strength to handle heavy loads safely while fighting off corrosion in demanding environments. Meanwhile, PVC and composite materials handle the detail work. PVC trolley toppers protect caskets from scratches, while composite aluminum and plastic components keep drawers and doors operating smoothly and quietly.

Body bags deserve special mention here. Quality bags use 8-mil to 15-mil PVC construction with heat-sealed seams. This isn't overkill—it's essential for leak-proof containment that protects everyone involved.

Powder and epoxy coatings might seem like small details, but they prevent chipping and peeling that could compromise hygiene. These finishes also make thorough cleaning and disinfection much easier, which matters more than you might think in daily operations.

Quality funeral mortuary equipment meets strict standards too. OSHA safety requirements, FDA regulations for medical devices, and CE marking for international markets all ensure equipment performs reliably when you need it most. Many products also carry ISO 9001 certification, which means consistent manufacturing quality you can count on.

Understanding these materials and standards helps you make informed decisions about equipment that will serve your facility well for years to come. After all, this equipment needs to handle both the technical demands of mortuary work and the emotional weight of helping families during difficult times.

Essential Funeral Mortuary Equipment and Their Uses

Understanding Funeral Mortuary Equipment Categories

Every funeral home needs the right funeral mortuary equipment to handle each stage of care with dignity and safety. Let me walk you through the five main categories that keep operations running smoothly.

Removal equipment gets you through those challenging first calls. When you're working in tight spaces or difficult locations, equipment like the MOBI F500™ Multi-Level Funeral Cot becomes your best friend. With its 500-lb capacity and one-person operation, it takes the strain off your back while maintaining professionalism. You'll also want backboards, slider boards, and transfer boards in your toolkit—they're lifesavers when navigating stairs or narrow hallways.

Preparation equipment centers around your embalming room setup. A quality embalming table with hydraulic height adjustment and a 35" x 85" stainless steel top makes all the difference in your daily work. Those 3" drain troughs with 6" stems aren't just nice features—they actually minimize spillage and keep your workspace cleaner. Autopsy tables serve the specialized needs of post-mortem examinations, while dedicated dressing tables give you proper space for final presentation preparation.

Your storage solutions need to work as hard as you do. Roller racks come in 2-tier, 3-tier, and 4-tier configurations, and the industrial-grade stainless steel versions can handle over 7,000 lbs per tier. Whether you choose end-loading or side-loading access depends on your facility layout. Body trays maintain that standard 23" width, so you know they'll fit with most storage systems.

Vehicle equipment keeps your transport operations professional. Church trucks and casket trolleys need to glide smoothly and handle weight reliably. Double-deck systems are brilliant for funeral vans—they effectively double your cargo capacity. Single-deck systems work perfectly for standard vehicles and offer rock-solid casket transport.

Cremation equipment demands specialized tools. Battery-powered scissor lifts can reach heights over 80 inches while handling loads exceeding 1000 lbs. You'll also need scales with ramps, remains processors, and various crematory supplies to complete the process safely.

Choosing the Right Funeral Mortuary Equipment: Cots vs Stretchers vs Body Lifts

Picking between mortuary cots, stretchers, and body lifts doesn't have to be complicated. Each serves specific purposes, and understanding their strengths helps you make smart equipment decisions.

| Equipment Type | Load Capacity | Best Use | Key Features |

|---|---|---|---|

| Standard Mortuary Cot | 500 lbs | General transport | One-person operation, multi-level |

| Bariatric Stretcher | 1000+ lbs | Oversized transfers | Reinforced construction, wider platform |

| Battery-Powered Lift | 900-1000+ lbs | Vertical transfers | Scissor mechanism, digital scale option |

| Manual Hydraulic Lift | 600-900 lbs | Prep room use | Foot pedal operation, compact design |

Standard mortuary cots handle most of your daily transport needs beautifully. The MOBI F500™ tops the popularity charts for good reason—its multi-level adjustment and 500-lb capacity with one-person operation make it incredibly practical. You get locking wheels, side rails, and comfortable mattresses that show families you care about dignity.

Bariatric stretchers address a growing reality in our industry. The MOBI F1200™ handles over 1000 lbs while still being maneuverable enough for tight spaces. These units feature beefed-up frames, wider platforms, and improved stability systems that give you confidence during difficult transfers.

Body lifts solve the vertical transfer challenge that every funeral director faces. Battery-powered models eliminate the headaches of hydraulic maintenance while giving you precise positioning control. Many include optional digital scales—handy for accurate weight measurement without extra equipment.

The key is matching equipment to your facility's specific needs. A smaller funeral home might prioritize versatile cots, while high-volume facilities often benefit from specialized lifts and bariatric options.

Mortuary Refrigeration Options Explained

Proper refrigeration isn't just about preservation—it's about preventing disease transmission and maintaining professional standards. Your choice depends on space, volume, and workflow preferences.

Walk-in coolers give you maximum storage capacity and easy access when you're handling multiple cases. These systems typically come with impressive 15-year panel warranties and 5-year mechanical parts warranties. The construction includes properly insulated panels, commercial-grade refrigeration systems, and ventilation designed to keep your staff safe during extended work periods.

Roll-in coolers eliminate the back-breaking work of transferring bodies multiple times. You can wheel gurneys and stretchers directly into storage, which works particularly well in hospital morgues and larger funeral homes with steady volume. The convenience factor alone makes these worth considering.

Upright drawer systems offer individual body storage that maximizes your floor space efficiently. Each drawer operates independently, giving you privacy and organization benefits that families appreciate. Many include digital temperature monitoring and alarm systems that alert you to any issues before they become problems.

Mobile refrigeration units serve as your backup plan during emergencies or facility maintenance. These trailer-mounted systems provide temporary cooling capacity when your permanent installation needs service or during mass casualty events.

Temperature control stays critical across all systems. Most mortuary coolers maintain that sweet spot of 35-40°F (2-4°C) for short-term storage. Some offer freezer capabilities for longer-term preservation needs. Energy efficiency features like LED lighting, high-efficiency compressors, and smart defrost cycles help keep operating costs reasonable.

For detailed specifications and requirements, see our More info about cooler requirements.

Choosing, Maintaining & Financing Equipment While Staying Ahead of Innovations

Selection Criteria for Professional Equipment

Choosing the right funeral mortuary equipment comes down to three key factors: will it keep your staff safe, does it meet compliance standards, and can it handle your daily workload? These aren't just nice-to-have features - they're essential for running a professional death care facility.

When evaluating equipment, look for FDA, CE, and ISO 9001 certifications first. These stamps of approval mean the equipment has been tested and meets strict safety standards. Load capacity matters too - while standard 500-lb equipment works for most situations, you'll want some bariatric options rated for 1000+ lbs to serve all families with dignity.

Three brands consistently earn praise from funeral directors across the country. Ferno has been crafting quality mortuary products since 1955, with their church trucks known for durability and easy cleaning. Mobi Medical focuses on US manufacturing using industrial-grade stainless steel construction that stands up to daily use. Link brings over 20 years of North American experience, particularly in mortuary deck systems that funeral homes rely on every day.

Warranties and Maintenance

Quality funeral mortuary equipment should come with solid warranty protection. Standard mortuary cots typically include one-year coverage, while mortuary coolers often feature impressive 15-year panel warranties and 5-year mechanical parts coverage. Many pieces are built to last 20 years or more when properly maintained.

Preventative maintenance doesn't have to be complicated, but it needs to be consistent. Daily cleaning and sanitization of all surfaces keeps your facility safe and professional. Weekly checks of moving parts and safety mechanisms catch small problems before they become big ones. Monthly electrical system testing and quarterly refrigeration service keep everything running smoothly. Don't forget that annual comprehensive safety inspection - it's often required by local regulations anyway.

Cleaning protocols must meet OSHA bloodborne pathogen standards. Use EPA-approved disinfectants on all equipment surfaces, and make sure your staff follows proper PPE procedures during maintenance. It's not just about compliance - it's about protecting the people who work for you.

Financing Options

Let's be honest - quality funeral mortuary equipment represents a significant investment. The good news is that most suppliers understand this and offer flexible financing solutions.

Payment plans can break large purchases into manageable chunks. Some vendors offer arrangements like "3 payments of $995.00 each" for major equipment purchases. Leasing programs spread costs over 3-5 year terms and often include upgrade options when newer technology becomes available. Bulk discounts reward facilities that purchase multiple pieces at once, while trade-in programs provide credit for existing equipment toward new purchases.

Innovation Trends

The funeral mortuary equipment industry keeps evolving, and some recent innovations are genuinely game-changing. Battery-powered lifts eliminate the hassle of hydraulic fluid maintenance while providing precise positioning control. Many include digital weight scales and can reach heights over 80 inches - perfect for loading taller vehicles.

IoT temperature monitoring lets you keep an eye on your mortuary coolers from anywhere. Your smartphone will alert you to temperature deviations or equipment malfunctions, giving you peace of mind whether you're at home or across town.

Bariatric equipment addresses real demographic changes in our communities. Stretchers and lifts rated for 1000+ lbs capacity aren't just nice to have anymore - they're essential for serving all families with equal dignity and care.

Eco-friendly materials are becoming more common too. Recyclable plastics and energy-efficient refrigeration systems reduce environmental impact while maintaining the performance standards your facility needs.

For additional safety information, consult Latest research on mortuary safety and our Essential Mortuary Equipment guide.

Innovations, Regional Needs & Best-Practice Standards

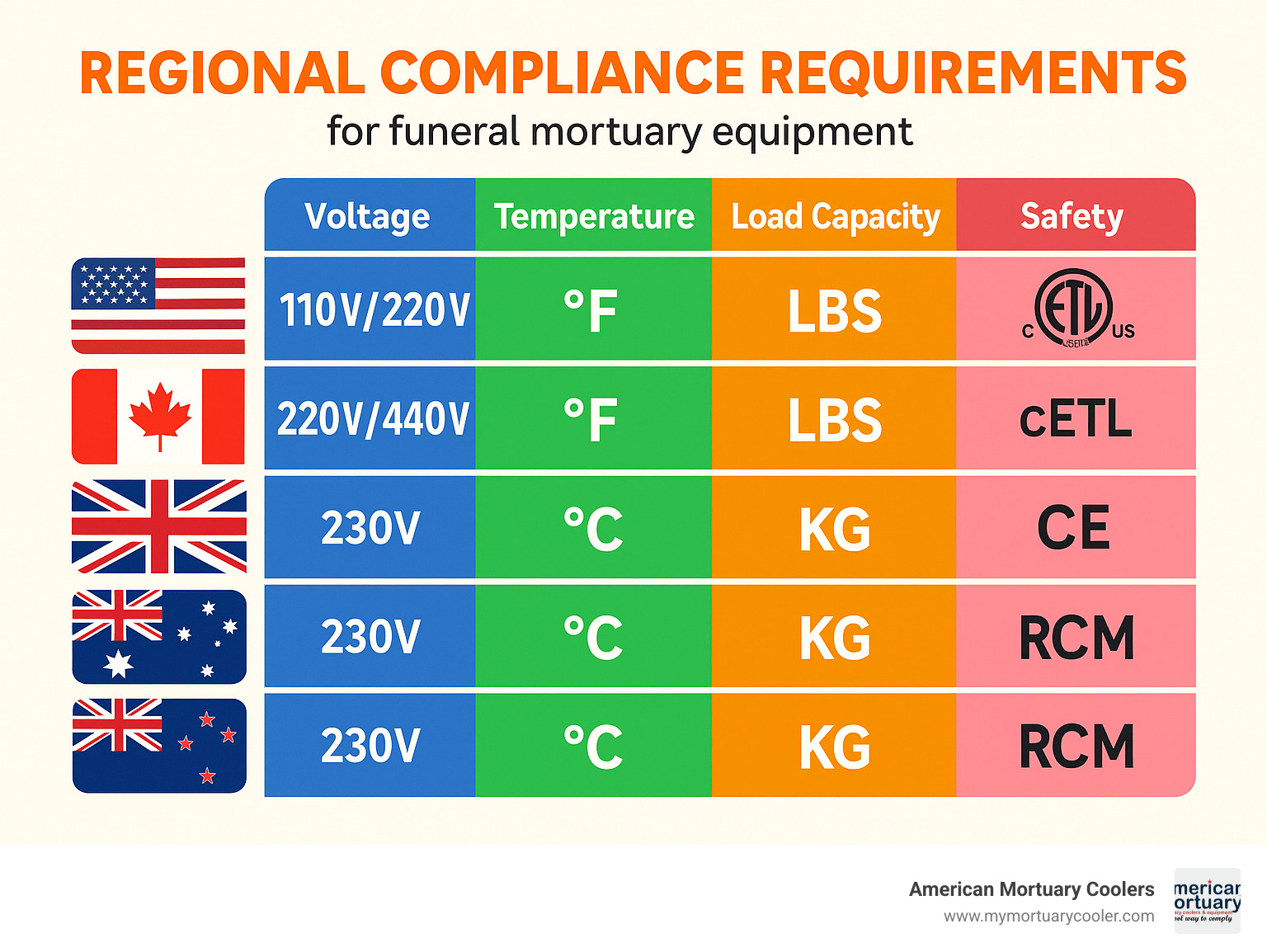

When we work with funeral homes across different regions, one thing becomes crystal clear: funeral mortuary equipment needs vary dramatically based on where you're located. What works perfectly in Tennessee might need significant modifications in British Columbia or Queensland.

United States and Canada

Electrical requirements create the first major consideration. US facilities run on standard 110V/220V systems, while many Canadian locations require 220V/440V configurations. We've learned this lesson the hard way - there's nothing quite like finding your new mortuary cooler won't plug into the wall after delivery.

Regional weather patterns demand serious attention too. Hurricane-proof walk-in coolers aren't just nice-to-have features along the Gulf Coast - they're essential. From our experience serving facilities from Columbia, South Carolina to Dallas, Texas, we've seen how severe weather can impact operations. Reinforced panels and secure anchoring systems make the difference between staying operational and facing weeks of downtime.

Bariatric equipment needs also shift by region. Midwest and Southeast facilities often require higher percentages of heavy-duty stretchers and lifts rated for 1000+ pounds. It's simply matching equipment to demographic realities in each area.

International Considerations

European markets bring their own unique requirements. CE marking compliance becomes mandatory, and everything switches to metric specifications. Load ratings, dimensions, and temperature controls all need conversion - and it's not just about slapping different labels on the same equipment.

Australia and New Zealand present fascinating challenges. Remote outback transport requirements mean mobile refrigeration units need extra durability for long hauls over rough terrain. Plus, different electrical standards mean careful specification review before any equipment ships.

Compliance Standards

Ventilation standards vary more than most people realize. Some jurisdictions mandate specific air exchange rates in preparation rooms, while others focus on specialized exhaust systems for embalming areas. We always recommend checking local codes before finalizing equipment specifications.

The recent focus on pandemic-ready PPE has changed many facility requirements. Improved containment materials and upgraded ventilation systems have become standard requests rather than special additions.

Electronic record integration represents one of the most exciting developments we're seeing. Modern equipment can now interface directly with facility management systems, automatically tracking usage patterns and maintenance schedules. It's the kind of innovation that makes daily operations smoother while ensuring nothing gets overlooked.

The beauty of working in this industry lies in solving these regional puzzles. Each location brings unique requirements, but the goal remains the same - providing dignified, professional death care regardless of geography or local regulations.

Frequently Asked Questions about Funeral Mortuary Equipment

What load capacity should a mortuary cot handle?

When selecting funeral mortuary equipment, load capacity becomes one of your most critical decisions. I recommend starting with 500 lbs as your absolute minimum for standard mortuary cots, but here's what I've learned after years of helping funeral homes make this choice.

The MOBI F500™ Multi-Level Funeral Cot represents what most facilities consider their workhorse equipment. With its 500-lb capacity and one-person operation, it handles the majority of cases efficiently. But demographic trends tell a different story about what you'll actually need.

Bariatric cases are becoming more common, and nothing disrupts your workflow like finding your equipment can't handle a particular case. That's why I often suggest facilities invest in bariatric-capable equipment with 1000+ lb capacity from the start. The MOBI F1200™ provides that extra capacity while maintaining the maneuverability you need.

Consider your local demographics carefully. If you're serving areas where larger body sizes are more prevalent, that higher-capacity equipment isn't just nice to have - it's essential for maintaining your professional standards.

How does a walk-in body refrigerator differ from a roll-in cooler?

This question comes up constantly, and the answer really depends on how your facility operates day-to-day.

Walk-in coolers create large, accessible spaces that your staff can actually enter. Think of them as refrigerated rooms where you can store multiple bodies and move around freely during placement and retrieval. These systems typically come with 15-year panel warranties and offer the most storage capacity for your dollar.

Roll-in coolers work completely differently. Each body stays on its gurney or stretcher and slides into individual compartments that you access from outside the unit. You get better organization, individual temperature control for each compartment, and improved privacy for families.

The workflow differences are significant. Walk-in systems work beautifully for facilities with high volume or longer storage periods. Roll-in systems shine in busy environments like hospital morgues where you need frequent access and better organization.

Cost considerations matter too. Walk-in systems typically cost less per body stored, while roll-in systems offer operational advantages that can save time and labor in busy facilities.

What maintenance schedule keeps equipment compliant and safe?

Proper maintenance isn't just about keeping your funeral mortuary equipment running - it's about protecting your staff, maintaining regulatory compliance, and ensuring your equipment lasts its full expected lifespan of 20+ years.

Daily maintenance forms your foundation. Clean and sanitize all surfaces with EPA-approved disinfectants, and do a quick visual inspection for obvious damage or wear before each use. This takes just a few minutes but prevents major problems.

Weekly tasks involve checking moving parts, testing safety mechanisms, and verifying that all controls work properly. Lubricate hinges, wheels, and adjustment mechanisms according to manufacturer specifications. This prevents the squeaks and sticking that make equipment harder to use.

Monthly maintenance steps up to testing electrical systems, alarms, and temperature monitoring equipment. Document all readings and maintain service logs - regulatory inspectors love seeing proper documentation, and it helps you spot problems before they become emergencies.

Quarterly professional service becomes essential for refrigeration systems. This includes cleaning coils, checking refrigerant levels, and calibrating temperature controls. Many facilities schedule this seasonally to stay on track.

Annual comprehensive inspections cover safety testing, electrical systems, and major component replacement as needed. Most manufacturers require annual professional service to maintain warranty coverage, so this protects your investment too.

The equipment is designed to last decades with proper care, but neglect can turn a 20-year investment into a 5-year headache. Regular maintenance actually saves money in the long run.

Conclusion

When you step back and look at the bigger picture, funeral mortuary equipment represents something much deeper than just tools of the trade. It's about honoring the people who've passed while protecting the families who trust you with their most difficult moments. Every mortuary cot, every refrigeration system, every body lift plays a vital role in maintaining the dignity that every person deserves.

The right equipment choices ripple through your entire operation. Stainless steel 304 construction means fewer repairs and easier cleaning. Battery-powered lifts protect your staff from injury while improving efficiency. Bariatric-capable equipment ensures you're prepared for whatever challenges walk through your doors. These aren't just features on a spec sheet - they're investments in your ability to serve families with compassion and professionalism.

We've seen how the landscape is changing. Demographics are shifting, regulations are evolving, and families' expectations continue to rise. The funeral directors who thrive are those who plan ahead, choosing funeral mortuary equipment that meets today's needs while preparing for tomorrow's challenges. Whether that's upgrading to IoT temperature monitoring or investing in higher-capacity transport equipment, staying current matters.

The financial side doesn't have to be overwhelming either. With financing options, bulk discounts, and comprehensive warranties extending up to 15 years on some equipment, quality suppliers make it possible to outfit your facility properly without breaking the bank. The key is working with partners who understand your unique needs and regional requirements.

At American Mortuary Coolers, we've built our reputation on understanding exactly what funeral directors face every day. Our custom solutions aren't just built in Tennessee - they're crafted with the insight that comes from years of listening to professionals like you. When we deliver directly across the contiguous 48 states, we're not just shipping equipment - we're delivering peace of mind.

Your families deserve the best care you can provide, and your staff deserves equipment that makes their challenging work safer and more efficient. The right funeral mortuary equipment makes both possible, creating a foundation for the respectful, dignified service that defines professional death care.

For comprehensive guidance on making the best equipment choices for your facility, our Equip Your Funeral Home Right: Top Picks for Mortuary Equipment resource provides the detailed information you need to make decisions that will serve your families well for years to come.