Why Richardson Retractors Are Essential in Modern Surgery

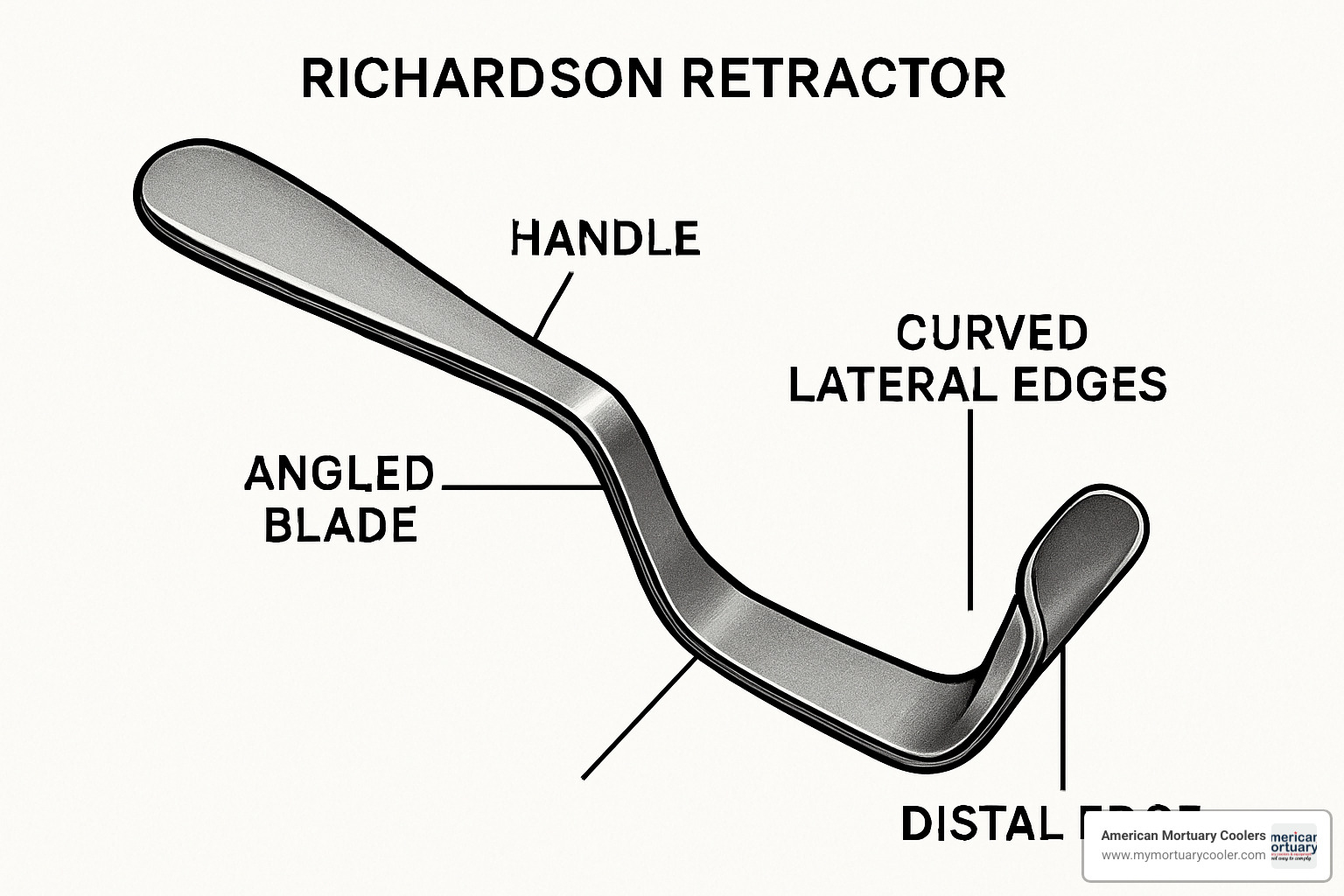

Richardson retractors are specialized hand-held surgical instruments designed to hold back soft tissue during abdominal, thoracic, and general surgical procedures. These retractors feature an angled blade with curved edges and an ergonomic handle, making them indispensable tools for maintaining clear surgical exposure.

Key Features of Richardson Retractors:

- Blade Design: Concave profile with upward-curved lateral edges and downward-turned distal edge

- Handle Options: Available in grip, lamb, or hollow loop configurations

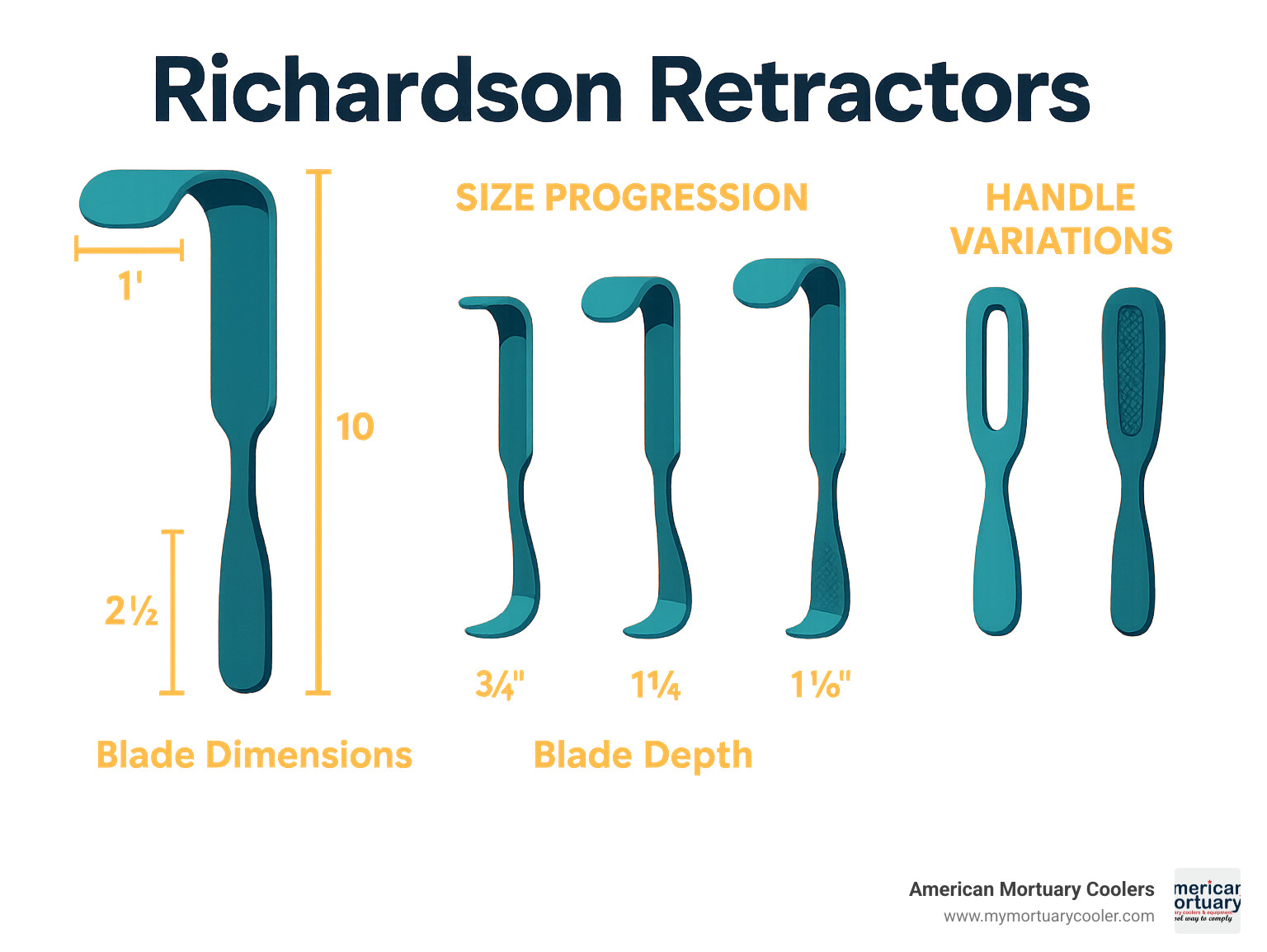

- Size Range: Blade widths from ¾" to 1⅞", depths from 1" to 2½"

- Materials: Surgical-grade German stainless steel with lifetime warranties

- Variations: Single-ended or double-ended (Richardson-Eastman) designs

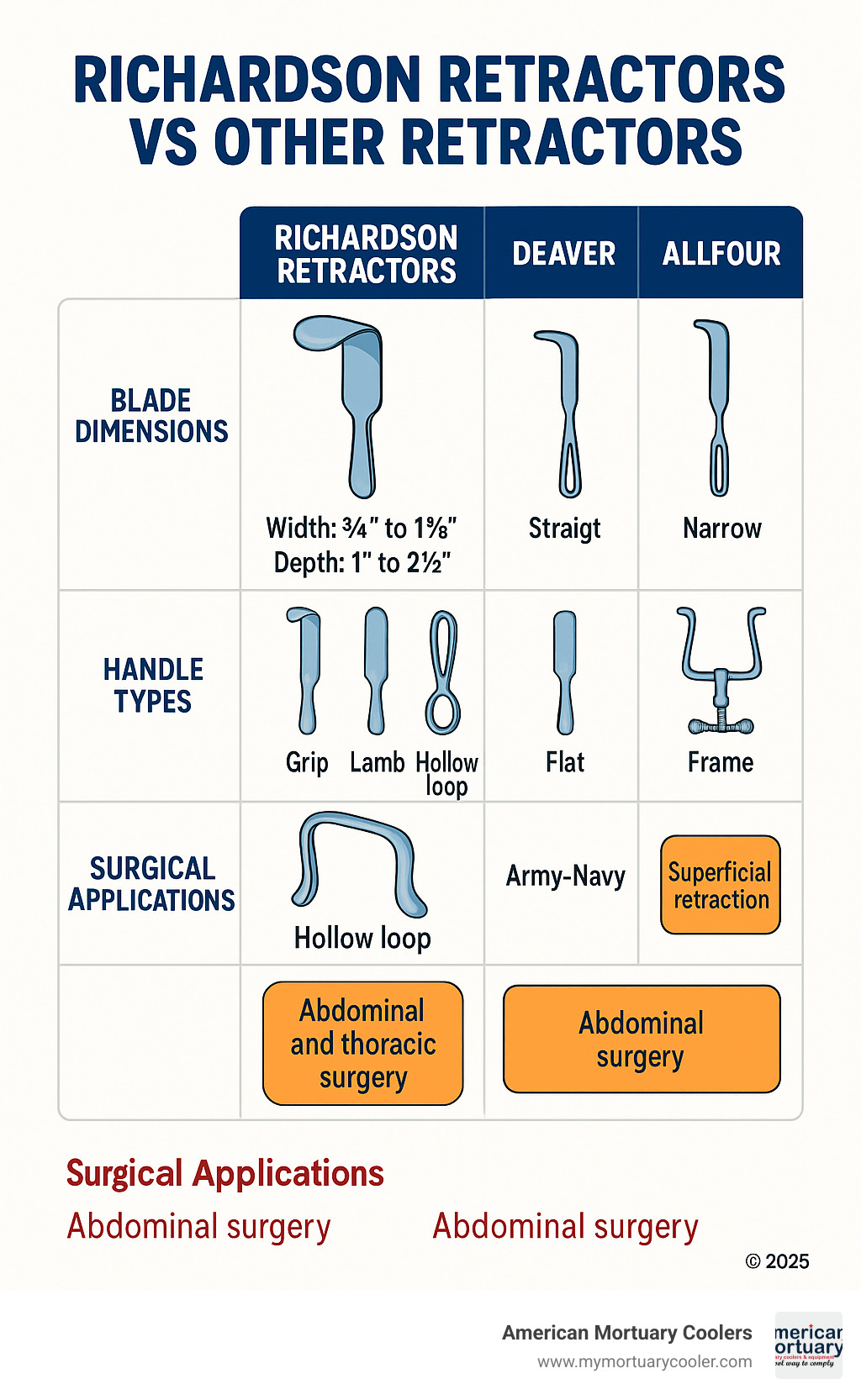

Richardson retractors differ from other common retractors like the Deaver (which has a straight blade) or Army-Navy (which is double-ended with smaller blades). The Richardson's angled design makes it particularly effective for deep tissue retraction in abdominal surgeries.

These instruments are most commonly used during laparotomies, thoracotomies, and other procedures requiring manual tissue retraction. The deeper blade variants are sometimes called "Dodd retractors" and are specifically designed for procedures requiring greater tissue displacement.

As American Mortuary Coolers, we've spent years helping funeral home directors understand the importance of quality surgical and mortuary instruments, including richardson retractors used in autopsy and preparation procedures.

Why Clear Retraction Matters

Proper tissue retraction is fundamental to surgical success. When the operative field is clearly visible, surgeons can work with precision and confidence, reducing the risk of complications and improving patient safety. Richardson retractors excel at providing this critical exposure by gently holding tissues away from the surgical site without causing trauma or obstruction.

Richardson Retractors: Definition & Core Function

Richardson retractors are hand-held instruments that hold tissues exactly where they need to be. These specialized tools feature a distinctive angled blade that's perfectly designed for reaching deep into abdominal and thoracic procedures, giving surgeons the clear view they need to work safely and effectively.

What makes Richardson retractors special is their unique blade geometry. The flat blade face has lateral edges that curve gracefully upward and a distal edge that turns downward, creating what surgeons often describe as a gentle scooping action. This design represents decades of refinement to find the perfect balance between effective tissue retraction and patient safety.

The primary function is beautifully simple: manual control over tissue positioning. While self-retaining systems have their place, sometimes you need the precision and adaptability that only comes from a skilled hand guiding the retractor.

Scientific research on tissue retraction safety confirms what surgeons have known for decades - proper retractor selection makes a real difference in patient outcomes. Richardson retractors consistently demonstrate their ability to minimize tissue trauma while maintaining the exposure surgeons need.

History of the Richardson Retractor

The Richardson retractor's story begins in the 1930s with Dr. John Richardson. Like many surgical innovations, it was born from frustration - Dr. Richardson was tired of struggling with existing retractors that couldn't provide the right combination of reach, control, and tissue protection during abdominal surgery.

Dr. Richardson's breakthrough was recognizing that the solution lay in the angle. By creating a blade that worked with the natural contours of the human body rather than against them, he developed an instrument that could reach deeper while requiring less force.

The basic design has remained remarkably stable over the decades - a testament to how well Dr. Richardson understood the fundamental challenge he was solving.

Core Surgical Roles of Richardson Retractors

Richardson retractors excel in three key areas.

During laparotomy procedures, these retractors become an extension of the surgeon's hands. The angled blade design works beautifully with the abdominal cavity's natural geometry, providing stable retraction that surgeons can maintain throughout lengthy procedures.

Thoracotomy applications showcase another strength of these versatile instruments. Chest surgery demands precision and gentle handling, especially when working around delicate structures like lungs and heart tissue.

Most importantly, Richardson retractors excel at soft-tissue elevation across all types of procedures. The curved blade design creates a smooth, controlled lift that holds tissues away from the operative field without the sharp edges or aggressive grip that can cause trauma.

Design Features, Sizes & Variations

When selecting Richardson retractors, understanding the design variations can make all the difference. These instruments come in an impressive range of sizes, with blade widths spanning from ¾" to 1⅞" and depths ranging from 1" to 2½". This variety serves specific surgical requirements.

The standard length for most Richardson retractors falls between 9½" and 10½", providing surgeons with adequate reach while maintaining comfortable control. What really sets these instruments apart is their construction from surgical-grade German stainless steel, which ensures they'll withstand countless sterilization cycles.

Blade Geometry & Ergonomic Handles

The magic of Richardson retractors lies in their thoughtfully engineered blade geometry. Those curved edges are specifically designed to cradle tissues gently while providing secure retraction during deep surgical procedures. The downward-turned distal edge acts like a gentle scoop, engaging tissues effectively without causing unnecessary trauma.

The hollow handle design is a brilliant engineering solution that reduces weight while maintaining structural integrity. The knurled or textured surfaces on many handles provide that crucial secure grip, even when things get slippery in the operating room.

Size Charts & Ordering Codes

Getting the right size Richardson retractor is crucial for surgical success. The standard sizing includes blade widths of ¾", 1", 1¼", 1½", 1¾", and 1⅞", paired with blade depths of 1", 1¼", 1½", 2", 2¼", and 2½". The overall length typically measures between 9½" (24.0 cm) and 10" (25.4 cm).

Popular configurations include the 9½" retractor with ¾" x 1" dimensions for smaller procedures, stepping up to the 10" retractor with 1¾" x 2½" dimensions for more extensive surgical access.

Single-Ended vs Double-Ended Richardson Retractors

The choice between single-ended and double-ended Richardson retractors often comes down to surgical preference and efficiency needs. Single-ended retractors offer the traditional approach—one perfectly sized blade for specific procedures.

Double-ended Richardson-Eastman retractors bring versatility to the table with two different blade sizes on opposite ends of the same instrument. This design is particularly clever for procedures requiring progressive retraction—you can start with the smaller blade for initial tissue displacement, then flip to the larger blade as the procedure advances.

The benefits of double-ended designs extend beyond convenience. They reduce instrument tray complexity, improve surgical flow by eliminating instrument exchanges, and offer cost-effectiveness for surgical facilities managing tight budgets.

Reusable vs Single-Use Options

Most Richardson retractors are built as reusable instruments from premium German stainless steel. These workhorses are designed for repeated sterilization cycles, with many manufacturers backing their quality with lifetime guarantees against defects.

The reusable instruments undergo passivation treatment to improve corrosion resistance and create smooth surface finishes that make cleaning easier. Quality manufacturers typically offer warranties ranging from 5 years to lifetime coverage.

Single-use Richardson retractors serve specific niches where sterility assurance is paramount or where reprocessing costs become prohibitive. These pre-sterilized disposable instruments eliminate the cleaning and sterilization workflow entirely.

At American Mortuary Coolers, we understand the importance of durable, reliable instruments whether you're working in a hospital operating room or a mortuary preparation room.

Surgical Applications & Comparison With Other Retractors

When you're in the operating room, having the right retractor can make the difference between a smooth procedure and a challenging one. Richardson retractors have earned their place as go-to instruments across multiple surgical specialties.

These versatile instruments shine brightest in abdominal surgery, where their angled blade design really comes into its own. During laparotomies, bowel procedures, and hepatic surgery, the curved edges grip tissues naturally while the downward-turned edge provides that essential lift you need for clear visualization.

Thoracic procedures represent another area where Richardson retractors excel. Whether you're performing lung resections, accessing cardiac structures, or exploring the mediastinum, these instruments provide the deep tissue control that shallow retractors simply can't match.

Don't overlook their value in orthopedic surgery either. When you need to retract deep tissues for joint access, the Richardson's blade geometry gives you the leverage and control to safely move tissues out of your way. Obstetric procedures like cesarean sections also benefit from their precise tissue handling capabilities.

When to Choose Richardson Over Deaver or Balfour

The Richardson versus Deaver decision often comes down to cavity shape and depth. While Deaver retractors work wonderfully for broad, shallow retraction with their straight blade design, Richardson retractors dominate in narrow cavities where you need that angled reach.

When comparing Richardson to Army-Navy retractors, size and depth matter most. Army-Navy retractors are fantastic for superficial work, but when you're going deep, the Richardson's larger blade and angled design provide the exposure you actually need.

The Richardson versus Balfour comparison is really about control philosophy. Balfour retractors give you hands-free operation through their self-retaining design, which is brilliant when you have limited personnel. But Richardson retractors offer something different - real-time manual control that lets you adjust tissue position instantly as the procedure evolves.

Your decision should consider cavity depth (Richardson wins for deep work), angled access needs (again, Richardson's strength), available personnel (you need someone to hold it), and whether you need that precise positioning control that only manual retraction provides.

Complementary Use With Self-Retaining Systems

Richardson retractors and self-retaining systems like Balfour frames or Bookwalter rings work beautifully together. This isn't an either-or situation.

The hybrid approach makes perfect sense when you think about it. Set up your Balfour frame or Bookwalter ring for primary exposure and stability, then use your Richardson retractors for those moments when you need to fine-tune tissue position or provide temporary retraction during specific steps.

This combination gives you the best of both worlds - the efficiency and personnel savings of self-retaining systems with the precision and adaptability of manual retraction.

At American Mortuary Coolers, we've learned that the best solutions often combine different approaches. Just like our custom mortuary coolers blend proven refrigeration principles with custom design, successful surgical retraction often means using the right combination of tools for each specific situation.

Materials, Handling, Cleaning & Safety

When you're investing in surgical instruments, quality matters. Richardson retractors are crafted from surgical-grade German stainless steel that's built to last. This premium material undergoes passivation treatment to resist corrosion and staining, even after thousands of sterilization cycles.

Sterilization Workflow

Getting sterilization right is crucial for patient safety, and Richardson retractors are designed to handle the process beautifully. The workflow starts with an immediate pre-rinse using cool water to remove blood and debris - timing matters here, as dried proteins become much harder to remove.

Next comes the enzymatic soak, where specialized solutions break down stubborn protein deposits. The mechanical wash phase uses ultrasonic cleaning or automated washers with neutral pH detergents to ensure thorough cleaning without damaging the instrument's surface.

Don't skip the inspection step - this is where you check for burrs, cracks, or any damage that could compromise safety. After proper wrapping and steam sterilization at the correct temperature and pressure, instruments go into dry storage until their next use.

Ergonomic & Safety Features

Modern Richardson retractors incorporate thoughtful design features that make a real difference during long procedures. The knurled handles provide a secure grip even when things get messy. This textured surface is engineered to prevent the kind of slippage that can lead to accidents.

Weight distribution is carefully balanced to reduce hand fatigue. When you're holding retraction for extended periods, every ounce matters. Some models include index finger rests that help surgeons maintain optimal control without straining their hands.

The smooth, polished edges prevent tissue snagging or tearing, while the anti-slip texture on handles ensures reliable grip throughout the procedure.

Risks & Complications

Like any surgical instrument, Richardson retractors require proper technique to avoid complications. Excessive force is probably the most common mistake - it's tempting to really crank down on tissue, but this can cause ischemia or permanent damage.

Tissue trauma from improper technique can result in unnecessary bruising or tearing. Accidental slips due to poor grip or fatigue can cause inadvertent injury. Perhaps most seriously, prolonged pressure on nerves or vessels can lead to lasting complications for patients.

The good news is these risks are easily managed with proper technique. Use just enough force to maintain exposure - no more. Rotate retraction points periodically to prevent pressure necrosis. Maintain clear communication with your surgical team about retraction needs.

More info about maintenance can help ensure your instruments perform optimally for years to come. At American Mortuary Coolers, we've seen how proper instrument care extends equipment life and improves safety.

Cost, Warranty, Customization & Selection Tips

When you're shopping for richardson retractors, you'll find prices ranging from about $54 to $190 per instrument. That might seem like a wide spread, but there's good reason for the variation.

The biggest factor affecting cost is whether you choose a single-ended or double-ended design. Double-ended Richardson-Eastman retractors cost more upfront, but they're like getting two tools in one. Size matters too when it comes to pricing. Larger instruments with deeper blade dimensions require more premium German stainless steel and more precise manufacturing.

Here's something that sets quality richardson retractors apart from cheaper alternatives: the warranty coverage. Most reputable manufacturers offer warranties ranging from 5 years all the way up to lifetime guarantees. These warranties typically cover defects in materials and workmanship, though they won't cover damage from dropping instruments or using them improperly.

Many manufacturers also offer customization options that can make your instruments truly yours. Custom logos and special blade depths are popular choices, and some surgeons even request specific ergonomic modifications based on their hand size and grip preferences.

At American Mortuary Coolers, we understand the value of quality instruments that last. Just like our custom mortuary coolers are built to serve funeral homes for decades, the best surgical instruments are investments in long-term performance and reliability.

Selecting the Right Richardson Retractor for Your Procedure

Choosing the right richardson retractor isn't just about grabbing the first one you see. It's about matching the tool to your specific needs, and several factors should guide your decision.

Patient BMI is probably the most important consideration. Larger patients require deeper blade dimensions to achieve adequate retraction through thicker tissue layers. A retractor that works perfectly for a slender patient might leave you struggling for exposure during surgery on someone with a higher BMI.

The incision depth you're planning also drives instrument selection. Shallow procedures can get by with smaller blade depths, while deep abdominal work demands the full reach that larger Richardson retractors provide.

Don't forget about your assistant's skill level when making your choice. Experienced surgical assistants can handle larger, more complex instruments with confidence. If you're working with newer team members, starting with smaller, more manageable retractors might be the smarter approach.

The instrument tray mix also plays a role in selection. If you're already carrying multiple retractors, a double-ended Richardson might help you consolidate without sacrificing capability.

Best-Practice Checklist for Optimal Exposure

Getting the most out of your richardson retractors comes down to following some tried-and-true practices that experienced surgeons have developed over decades of use.

Progressive retraction is your friend. Start with gentle pressure and gradually increase exposure as needed. This approach minimizes tissue trauma while giving you time to assess what level of retraction actually works best for your specific case.

Keep tissues moist with warm saline irrigation throughout the procedure. Dry tissues are more prone to damage and don't retract as smoothly. This simple step can make a huge difference in both tissue handling and post-operative healing.

Rotating retraction points periodically prevents pressure necrosis and keeps tissues healthy. Even the gentlest retraction can cause problems if maintained in exactly the same position for too long.

Finally, maintain a cleaning and inspection log for your instruments. Regular documentation helps you catch wear patterns early and ensures your richardson retractors stay in peak condition.

Scientific research on surgical instrument economics shows that investing in quality retractors and following proper selection guidelines leads to better surgical outcomes and lower long-term costs.

Frequently Asked Questions About Richardson Retractors

We get plenty of questions about Richardson retractors from funeral directors and medical professionals alike. Having worked with surgical instruments for years, we've learned that understanding the details makes all the difference in getting the right tool for your needs.

What differentiates Richardson-Eastman from standard Richardson retractors?

The main difference is simple: Richardson-Eastman retractors have blades on both ends, while standard Richardson retractors have just one. Think of it like getting two tools in one package.

The double-ended design gives you a smaller blade on one end for when you're starting your retraction work, and a larger blade on the other end when you need full exposure. This progression makes surgical procedures flow more smoothly since you don't have to stop and switch instruments.

From a practical standpoint, Richardson-Eastman retractors also reduce your instrument tray count. Instead of carrying multiple single-ended retractors, one double-ended instrument gives you the versatility you need.

Can I autoclave a double-ended Richardson without damage?

Absolutely! Richardson retractors are built to handle repeated sterilization cycles, whether they're single-ended or double-ended. The key is making sure you're working with quality instruments made from surgical-grade German stainless steel.

These instruments go through passivation treatment during manufacturing, which creates a protective layer that resists corrosion. We've seen Richardson retractors that have been through thousands of autoclave cycles and still perform like new.

The important thing is following proper sterilization protocols. Clean thoroughly before sterilization - any organic material left on the instrument can cause problems. Use the manufacturer's recommended temperature and pressure settings, and you shouldn't have any issues.

Most quality manufacturers back this up with warranties ranging from 5 years to lifetime, which shows their confidence in how these instruments handle repeated sterilization.

How do I minimize tissue trauma while using Richardson retractors?

Good technique is everything when it comes to preventing tissue damage with Richardson retractors. The most important rule is using just enough force to maintain exposure - no more, no less.

Avoid keeping the retractor in one spot too long. Tissues need blood flow, and constant pressure in the same location can cause problems. During longer procedures, rotate your retraction points periodically to give tissues a break.

Keep tissues moist throughout the procedure. Dry tissues are more prone to damage, so regular irrigation with warm saline helps protect delicate structures. The curved design of Richardson retractors actually helps with this since it creates natural channels for irrigation flow.

Smooth, controlled movements make a big difference too. Jerky or sudden repositioning can tear tissues that might otherwise handle gentle retraction just fine. Take your time with positioning changes, and communicate with your team about when you need to adjust retraction.

Finally, size matters. Using a retractor that's too large for the procedure puts unnecessary stress on tissues. Choose the smallest effective size for your specific needs - your patients will thank you for it.

Conclusion

When you're working in a surgical environment, having the right tools can make all the difference between a smooth procedure and a challenging one. Richardson retractors have earned their place as go-to instruments for good reason - they simply work, and they work well.

These specialized retractors bring together decades of proven design with modern manufacturing excellence. The angled blade geometry that Dr. Richardson pioneered in the 1930s continues to provide surgeons with the precise tissue control they need for complex abdominal and thoracic procedures.

What really sets Richardson retractors apart is their versatility. From the smallest ¾" blade for delicate work to the robust 1⅞" options for major procedures, there's a Richardson retractor sized perfectly for virtually any surgical challenge. The double-ended Richardson-Eastman models take this versatility even further, giving surgeons two retraction options in a single, well-balanced instrument.

At American Mortuary Coolers, we've built our reputation on understanding what professionals need from their equipment. While we focus on creating custom mortuary coolers and specialized equipment for funeral homes across Tennessee and the contiguous 48 states, we appreciate quality craftsmanship wherever we find it. The same attention to durability and precision that goes into our American-made coolers is what makes Richardson retractors such dependable surgical instruments.

The investment in quality Richardson retractors pays for itself through improved surgical outcomes, reduced procedure times, and the peace of mind that comes from using instruments you can trust. When your surgical team knows their retractors will provide consistent, reliable tissue retraction procedure after procedure, everyone can focus on what matters most - patient care.

Whether you're building a new instrument set or replacing aging equipment, understanding how to select and use Richardson retractors properly will serve your surgical program well. These instruments represent the kind of thoughtful engineering that makes challenging procedures more manageable and successful outcomes more achievable.

More info about Richardson retractor usage can help you get the most from these essential surgical tools and ensure your team is using them to their full potential.