Why Professional Mortuary Lifts Are Essential for Modern Funeral Operations

Quick Answer for Funeral Directors:

- 1,000-lb Capacity Lift: Heavy-duty casket and body handling without manual strain

- Decades of Proven Performance: 50+ years serving funeral homes, morgues, and hospitals worldwide

- Complete Solutions: Lifts, stair climbers, winches, tracks, and body coolers

- Safety Focus: Eliminates manual lifting to prevent back injuries (#1 funeral industry injury)

- Custom Engineering: Systems custom to fit unique facility layouts

- Grant Support: Guidance securing funding like Ohio's BWC Safety Intervention Grant

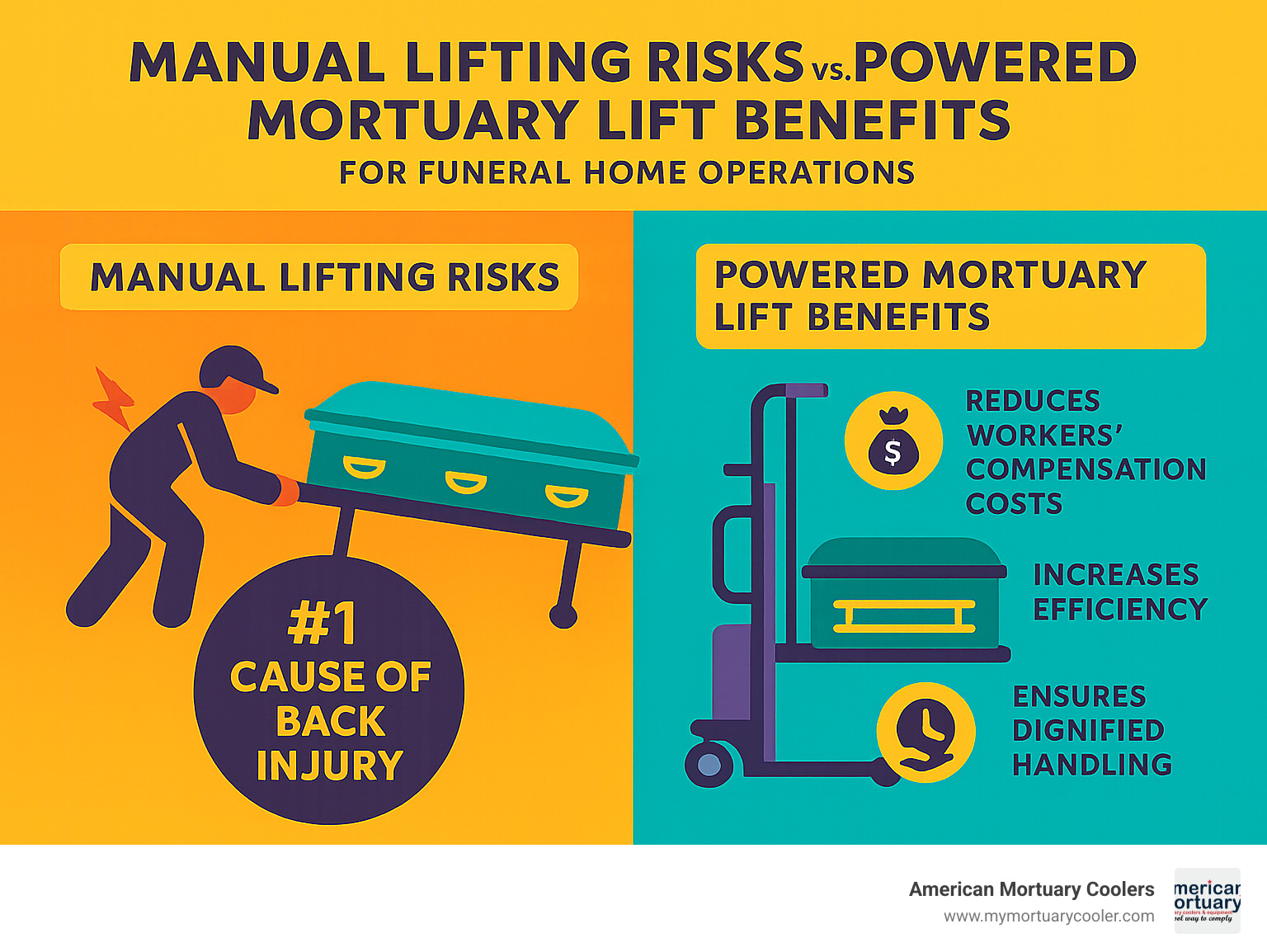

Back-related trauma is the number one injury in the funeral industry, yet many funeral homes still rely on dangerous manual lifting methods. With bariatric cases becoming more common, funeral directors need equipment rated for 1,000 pounds or more—far beyond what human strength can safely handle.

The financial impact goes beyond worker injuries. A single workers' compensation claim can cost thousands, while equipment downtime disrupts operations during families' most difficult moments. Modern funeral homes require reliable, dignified solutions that protect both staff and the families they serve.

I'm Mortuary Cooler, a national-level mortuary equipment supplier who has worked extensively with funeral directors nationwide to integrate cooling and lifting solutions. Through my experience helping facilities optimize their operations, I've seen why partnering with top-tier mortuary lift suppliers consistently delivers the most reliable and comprehensive solutions in the industry.

Key resources for mortuary lift information:

Why Leading Mortuary Lift Suppliers Set the Standard

When funeral directors need lifting equipment they can truly depend on, there’s a small group of manufacturers that keeps coming up in conversations. After working with funeral homes across the country, I've seen why these veteran builders have earned their reputation over an impressive 50-year legacy.

Here's what sets them apart: they don’t just sell equipment and walk away. They’ve built their entire business around understanding the real challenges funeral directors face every single day. When you’re dealing with bariatric cases that can weigh 400, 600, or even 800 pounds, you need equipment that won’t let you down when families are counting on you.

Their flagship 1,000-pound capacity lift has become the backbone of operations for funeral homes from Tennessee to Ireland. Whether it’s a standard case or the most challenging situation, the same reliability applies.

What really impressed me was learning about their global installations. We’re talking about equipment working flawlessly in places like Guam, Bermuda, Ireland, and England. When your lift needs to perform perfectly thousands of miles from the factory, that’s when you really see the difference between good equipment and great equipment.

Patented Engineering & Global Reach

The heavy-duty lift represents something special in mortuary equipment design. While some companies adapt generic industrial gear, leading suppliers engineer their systems from the ground up specifically for funeral service.

Their ceiling-mounted track systems solve problems that funeral directors didn't even know they had. Instead of being locked into one lifting position, these tracks let you move the lift seamlessly around your prep room. One funeral director told me it was like getting an extra staff member who never calls in sick.

I've seen installations where these custom track configurations completely transformed cramped prep rooms into efficient workspaces. The lift glides from embalming table to dressing area to casket without requiring multiple manual transfers.

The international reach isn't just impressive—it’s proof of real-world reliability. Whether it's dealing with Bermuda's humidity or fitting into compact European funeral facilities, these systems adapt while maintaining their core performance.

Safety & Efficiency Payoffs

Let's talk about the elephant in the room: back injuries are the number one injury in the funeral industry. The statistics are sobering, but they don't have to be inevitable. Quality mortuary lift equipment directly addresses the OSHA ergonomics concerns that keep funeral directors up at night.

The single-operator workflow capability changes everything. Instead of needing two or three people for heavy cases, one trained operator can safely handle transfers that previously demanded multiple staff members. This is especially valuable for smaller funeral homes or during those late-night calls when you're working with minimal staff.

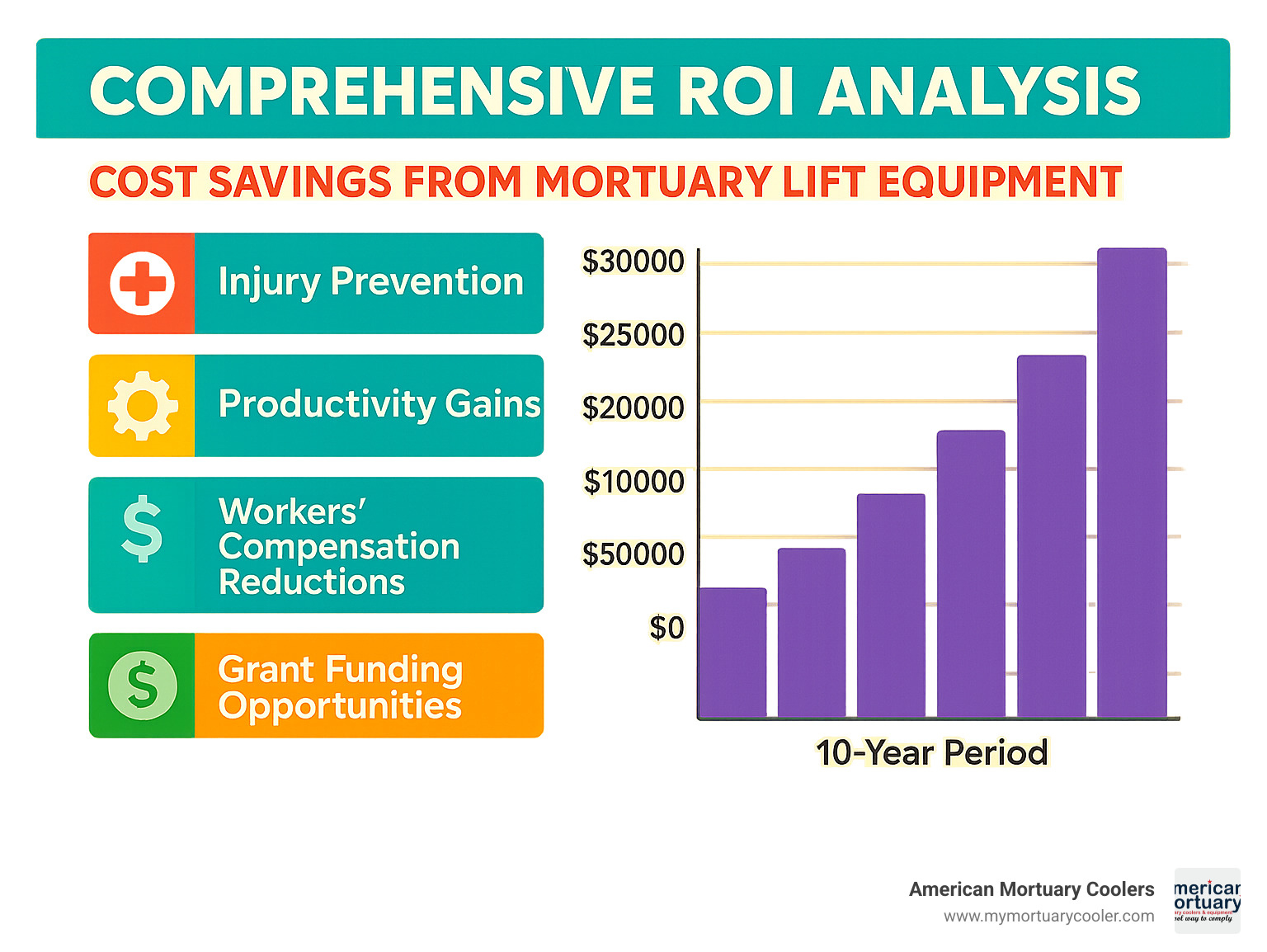

I've seen the workers' compensation savings add up quickly. One funeral home reduced their injury claims significantly after installing proper lifting equipment. When you consider that a single workers' comp claim can cost thousands, the equipment pays for itself through injury prevention alone.

Grant & Funding Support

Here's something that makes quality suppliers truly special: they help you pay for the equipment. Their expertise with the Ohio BWC Safety Intervention Grant program is remarkable.

The BWC SIG program offers a 3-to-1 matching ratio—for every dollar you spend, BWC contributes three dollars, up to $40,000 maximum over three years. That means you could potentially get 75% of your equipment costs covered.

Top suppliers have developed comprehensive application guides that streamline the entire SIG process. They provide the detailed documentation BWC requires, including equipment specifications, installation drawings, and cost justifications.

Complete Product Line from Leading Suppliers

When funeral directors visit quality mortuary lift manufacturers, they find something remarkable—a complete ecosystem of lifting solutions designed to work together seamlessly. This isn't just a collection of random equipment thrown together. Every piece is engineered to complement the others, creating what we like to call a "lifting symphony" in your prep room.

The beauty of their approach lies in the All-in-One Lifting concept. Instead of buying a lift from one company, a stair climber from another, and a winch from a third supplier, you get everything from one trusted source. We've seen too many funeral homes struggle with equipment that doesn't play nicely together—different controls, incompatible parts, multiple service contracts.

Their product lineup covers every lifting challenge you'll face: the flagship 1,000-lb capacity lift for your main prep room work, an electric stair climber for those tricky stair removals, a wireless winch for vehicle loading, plus custom track systems and body cooler integration.

Flagship 1,000-lb Capacity Casket & Body Lift—Workhorse of the Prep Room

This heavy-duty lift has earned its reputation the hard way—through decades of daily use in funeral homes worldwide. When we tell funeral directors this lift has a 1,000-pound capacity, their first reaction is often "Do we really need that much?" The answer becomes clear the first time they handle a bariatric case or need to lift a casket with a large individual.

What makes this system special is its All-in-One Lifting design. The adjustable straps work with different body sizes and casket configurations. The remote controls let you maintain appropriate distance during sensitive procedures. The maintenance-friendly design means you're not calling for service every few months.

We've worked with funeral homes where their lift has been running strong for over fifteen years. One funeral director in Michigan told us, "This thing is built like a tank, but operates like a Swiss watch." That's the kind of reliability you need when you're serving families during their most difficult moments.

Electric Stair-Climbing System

Stairs are every funeral director's nightmare during removals. We've heard too many stories of injuries, property damage, and close calls on staircases. The electric stair climber transforms this dangerous situation into a manageable task that one person can handle safely.

With its 375-pound capacity and folding handle design, the stair climber becomes your mechanical "second attendant." The electric stair-climbing mechanism does the heavy work while you guide and control the process.

The folding handle is brilliant engineering—it means you can actually fit this equipment in your removal vehicle without needing a bigger van. We've seen funeral homes add this to their standard equipment list because it makes their teams so much more confident handling difficult removals.

Wireless Casket & Gurney Winch

Loading heavy caskets into vehicles used to require multiple people and a lot of prayer that nobody would get hurt. The wireless winch changes that equation completely with its remote control and 1,000-pound pull capacity. This system enables true zero-lift loading into any removal vehicle.

The wireless remote is a game-changer. You can operate it from inside the vehicle, outside in the rain, or wherever you need to be for the best control. The system works with vans, SUVs, trucks, hearses—basically any vehicle in your fleet.

We've helped funeral homes retrofit their entire fleet with this system. The consistency across vehicles means any staff member can handle any removal vehicle confidently.

Custom Track, Gantry & Cooler Integration

Here's where things get really interesting. The custom track and gantry systems free up your prep room floor while providing lifting capability anywhere you need it. We work closely with leading suppliers to integrate these overhead systems with our cooling equipment, creating workflows that seem almost magical.

Overhead rails transform cramped prep rooms into efficient workspaces. We've seen installations where funeral directors went from struggling with tight quarters to having smooth, seamless transfers from cooling units to prep tables to dressing areas.

The space-saving benefits are particularly dramatic in older funeral homes where prep rooms weren't designed for modern equipment. The overhead approach lets you use every square foot of floor space while maintaining full lifting capability throughout the room.

For detailed specifications and configuration options, reach out to American Mortuary Coolers—we'll design a system around your exact layout and workflow.

Purchasing, Installation & Long-Term ROI

Working with established mortuary lift suppliers feels refreshingly different from typical equipment purchases. After helping dozens of funeral homes through this process, we've seen how 50 years of experience translates into a smooth, professional buying experience that actually makes sense.

The quote process starts with real conversations about your actual needs. No high-pressure sales tactics or cookie-cutter solutions. Their team wants to understand your specific challenges—whether you're dealing with tight spaces in a historic building, limited staff, or increasing numbers of bariatric cases.

Site surveys involve experienced technicians who speak funeral director language. They understand prep room workflow, space constraints, and the practical realities of funeral operations.

Step-by-Step Buying Roadmap

The needs assessment phase involves honest discussions about your current lifting challenges and future goals. We always recommend being upfront about budget constraints—their team has extensive experience creating solutions that work within various financial parameters.

CAD layout development transforms your requirements into detailed visual plans. These aren't just pretty pictures—they're precise installation blueprints that specify ceiling load requirements, electrical connections, and clearance dimensions.

Production lead times typically run 5-6 weeks for standard configurations, with custom track systems requiring additional time. Delivery coordination includes freight handling and setup scheduling designed to minimize disruption to your daily operations.

Installation & Staff Training Essentials

Ceiling load specifications require serious attention—this isn't optional homework. The engineering team provides detailed load calculations that must be verified by qualified structural engineers.

Electrical requirements are typically straightforward, with most systems running on standard 12 VDC power and on-board battery charging. However, proper electrical connections are essential for both safety and reliability.

Operator certification goes beyond basic button-pushing to cover maintenance, troubleshooting, and safety protocols. The training programs are designed specifically for funeral home staff, not generic equipment operators.

Maintenance, Warranty & Service

Routine inspections are surprisingly simple with well-designed equipment. Weekly visual checks and monthly lubrication of moving parts prevent most problems before they develop into expensive repairs.

Easy-swap parts design means your staff can handle many maintenance items without service calls. Common wear items like straps, rollers, and filters are readily available and designed for quick replacement.

U.S. phone support connects you directly with knowledgeable technicians who understand both the equipment and funeral home operations. The 20-year service life projections aren't marketing fluff—they're based on actual field experience with equipment still operating after decades of use.

Cost-Benefit Analysis & ROI

Injury cost avoidance represents the most compelling financial argument for proper lifting equipment. A single workers' compensation claim for back injury can cost $15,000 to $50,000 or more, while the right equipment eliminates the primary cause of these injuries.

Productivity gains allow funeral homes to handle increased caseloads without proportional increases in staffing costs. Single-operator capability means you're not dependent on having multiple staff members available for every transfer.

Bariatric case revenue becomes accessible when you have proper 1,000-pound capacity equipment. Many funeral homes turn away large cases because they lack safe handling capability, but with the right equipment, these cases transform from liability risks into profitable opportunities.

Grant offsets can dramatically reduce your initial investment. The Ohio BWC Safety Intervention Grant covers up to 75% of equipment costs, while other states offer similar programs. Scientific research on workplace ergonomics provides solid documentation supporting the business case for ergonomic equipment investments.

Frequently Asked Questions about Professional Mortuary Lift Equipment

After working with funeral directors nationwide for years, we've noticed the same concerns come up again and again when they're considering mortuary lift equipment. Leading suppliers have built their reputation on addressing these exact worries through thoughtful engineering and comprehensive support.

Most funeral directors worry about three main things: whether the equipment can handle their complete product range needs, how it performs with bariatric cases, and whether it can work in their unique building. These aren't just technical questions—they're about protecting families' dignity while keeping staff safe.

The good news? We've seen these systems work beautifully in everything from brand-new facilities to century-old funeral homes with quirky layouts.

How do the lifts ensure dignified, respectful body handling?

This question touches the heart of funeral service. Many directors worry that mechanical equipment might somehow diminish the respect shown to families. In reality, we've found the opposite is true.

Professional lifting equipment actually improves dignity by eliminating the awkward struggles that manual handling often requires. When staff members are wrestling with heavy lifts, fumbling with positioning, or clearly straining under the weight, it creates an uncomfortable situation for everyone involved.

The smooth, controlled movements of quality lift systems maintain stable, respectful positioning throughout every transfer. Bodies remain properly supported and positioned, without the shifting or awkward angles that can occur during manual handling.

There's also the matter of operator focus. When your staff isn't worried about their backs or struggling with physical demands, they can concentrate on what matters most—treating the deceased and their families with the respect they deserve.

We've heard from funeral directors whose families actually gained confidence after seeing professional equipment in use. Instead of wondering whether their loved one was being handled safely, families recognized the investment in proper tools as a sign of genuine care and professionalism.

What options exist for bariatric or 1,000 lb+ cases?

Bariatric cases present unique challenges that simply can't be handled safely with manual methods. The flagship 1,000-lb capacity lift is purpose-built for these situations, providing the safety margin you need even for the largest individuals.

This isn't just about raw lifting power. The system includes specialized positioning aids and attachments designed specifically for larger body handling. The adjustable straps accommodate different body sizes while maintaining secure, dignified support throughout the transfer process.

Track systems can be reinforced for heavy-duty applications when needed. The ceiling-mounted approach actually works better for bariatric cases because it distributes the load across multiple structural mounting points.

The key is ensuring your entire workflow can handle bariatric cases, not just the lift itself. This means heavy-duty stretchers, reinforced prep tables, and appropriately sized cooling units. We work with funeral homes to create complete systems where every component matches the lift's capability.

Can systems be customized for tight or historic buildings?

This might be our favorite question because the answer showcases the real engineering expertise behind quality mortuary lift suppliers. We've seen successful installations in spaces that seemed impossible at first glance.

Historic buildings present unique challenges, but they're far from impossible. Victorian-era funeral homes with narrow hallways, basement prep rooms with low ceilings, buildings with load-bearing walls in inconvenient places—we've worked with installations in all of these scenarios.

The track system flexibility is remarkable. Curved tracks can steer around obstacles, multiple elevation changes accommodate different floor levels, and compact turning radii work in surprisingly tight spaces.

Ceiling-mounted systems often work better in historic buildings than floor-mounted alternatives. They don't require modifications to original flooring or interference with architectural details that families and communities value.

The customization process starts with detailed site surveys by technicians who understand both the equipment and historic building constraints. They're not just measuring spaces—they're solving puzzles that preserve your building's integrity while dramatically improving your operational capabilities.

Conclusion

After five decades in the funeral industry, leading mortuary lift suppliers have proven time and again why they remain the gold standard for mortuary lifting equipment. We've watched countless funeral homes transform their operations with the Ultimate 1000™, The Stepper™, and complete ranges of handling solutions.

What started as a simple mission to prevent back injuries has evolved into something much bigger. Today's funeral directors face challenges our predecessors never imagined - bariatric cases that require 1,000-pound capacity, single-operator workflows, and families who expect the highest levels of professionalism during their most difficult moments.

The numbers tell the story best. Injury prevention alone justifies the investment for most funeral homes. When you consider that a single workers' compensation claim can cost $50,000 or more, equipment that eliminates the primary cause of workplace injuries becomes an obvious choice. Add in the productivity gains and grant funding opportunities like Ohio's 3-to-1 BWC matching program, and the financial case becomes overwhelming.

Here at American Mortuary Coolers, we've built our business around understanding what funeral directors really need. That's why we partner with leading mortuary lift suppliers to provide complete solutions that work together seamlessly. Our custom cooler and lift integration spans all 48 contiguous states, from our Tennessee headquarters to installations in California, New York, and everywhere in between.

The beauty of working with established industry leaders is the one-call convenience. Instead of juggling multiple suppliers who may not understand how their equipment affects your workflow, you get comprehensive solutions from companies that have been solving funeral home challenges for decades.

We've seen too many funeral directors struggle with equipment that almost works or suppliers who disappear when problems arise. The funeral families you serve deserve better. Your staff deserves better. Your professional reputation depends on choosing partners who understand that failure isn't an option in our industry.

Whether you're dealing with a historic building that requires custom engineering, a tight budget that needs creative financing, or complex workflow challenges that demand innovative solutions, the combination of proven lifting technology and custom cooling integration provides the reliability you need.

The funeral industry has always been about serving families during their most vulnerable moments. The equipment you choose should honor that responsibility with the same level of commitment and professionalism that you bring to every service.

More info about mortuary lift products provides additional details about integrating cooling and lifting solutions for optimal funeral home operations.