Why Table Battery Selection Matters for Medical and Industrial Equipment

A table battery is a specialized rechargeable power source designed to provide reliable, portable power for medical and industrial tables that require mobility or backup power during outages. These batteries are essential for surgical tables, MRI imaging equipment, examination tables, and industrial lift platforms.

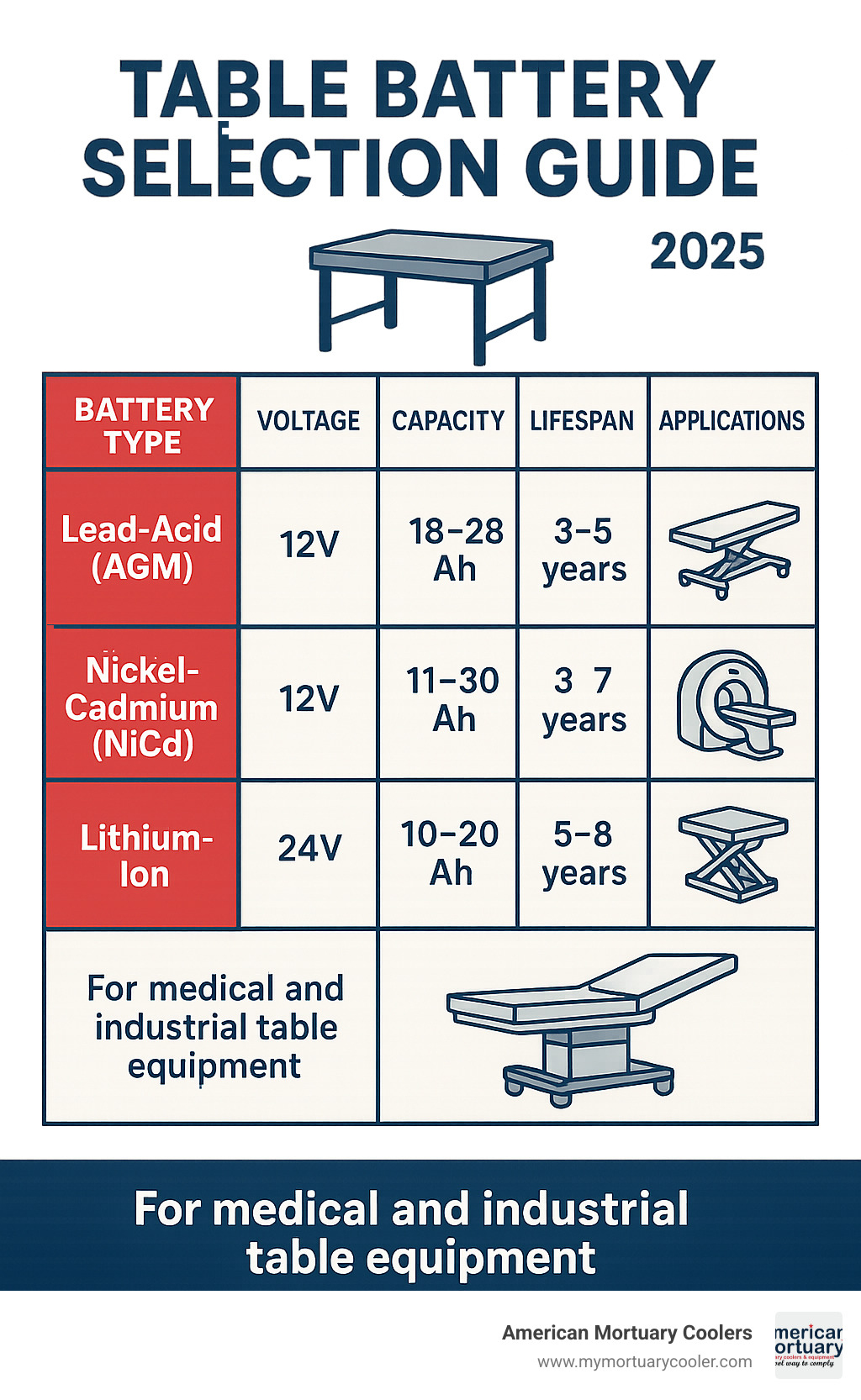

Key Table Battery Types:

- Lead-Acid (AGM) - Most common, 12V/18-28Ah, 3-5 year lifespan

- Nickel-Cadmium (NiCd) - High discharge rates, industrial applications

- Lithium-Ion - Lightweight, longer runtime, higher cost

- Sealed designs - Leak-proof, maintenance-free operation

Common Specifications:

- Voltage: 6V, 12V, or 24V systems

- Capacity: 10Ah to 28Ah typical range

- Weight: 11-25 lbs depending on chemistry

- Terminals: Spring clips, nut & bolt, or F2 tabs

The typical lifetime expectancy for a high-quality table battery, such as those used in surgical tables, is 3-5 years. However, factors like discharge cycles, temperature extremes, and maintenance practices significantly impact actual performance. Replacement batteries for surgical tables often require 2 batteries per unit, each delivering 12V/28Ah of power for reliable operation.

Choosing the wrong table battery can lead to equipment failures during critical procedures, unexpected downtime, and costly emergency replacements. Understanding voltage requirements, capacity needs, and compatibility ensures your medical or industrial tables maintain consistent performance when you need them most.

We're American Mortuary Coolers, a national-level mortuary equipment supplier specializing in custom cooling solutions and related equipment for funeral homes across America. Through years of working with funeral directors on complete facility setups, we've seen how proper table battery selection directly impacts operational reliability and service quality.

What Is a Table Battery?

Think of a table battery as the heart that keeps your medical or industrial equipment beating when wall power isn't available. These aren't your everyday car batteries – they're specially engineered power sources designed to handle the unique demands of equipment that needs to move around or keep working when the lights go out.

In the funeral industry, we see these batteries powering everything from surgical tables during preparation procedures to MRI tables in facilities that offer advanced services. Imaging tables in radiology departments rely on them for smooth, precise movements during diagnostic work. And in industrial settings, lift tables and positioning equipment use these reliable power sources to keep operations running smoothly, even during power outages.

The chemistry inside these batteries makes all the difference. Lead-acid batteries with Absorbed Glass Mat (AGM) technology are the workhorses of the industry – reliable, affordable, and virtually leak-proof even when turned upside down. They're also DOT 60 classified, which makes shipping them a breeze.

Nickel-Cadmium (NiCd) batteries are the marathon runners – they can handle high discharge rates and shrug off temperature extremes that would leave other batteries gasping. Nickel-Metal Hydride (NiMH) batteries offer better capacity than NiCd while maintaining similar toughness. At the premium end, lithium-ion batteries deliver the longest runtime and lightest weight, though your wallet will definitely feel the difference upfront.

Here's something interesting: Scientific research on battery capacity trends shows that a battery rated at 28Ah over 20 hours might only deliver 22Ah when you need power quickly over 5 hours. It's like the difference between a leisurely walk and a sprint – the same battery performs differently depending on what you ask of it.

Table Battery Basics

The magic of a table battery lies in giving your equipment freedom to move. No more hunting for outlets or dealing with extension cords snaking across the floor. Your tables can go wherever they're needed, positioned exactly right without being tied down by power cords.

But mobility is just part of the story. When the power goes out – and it will eventually – these batteries become your lifeline. In our experience working with funeral homes across the country, we've seen how a reliable backup power system can mean the difference between maintaining service and having to reschedule families during their most difficult times.

Cordless operation brings unexpected benefits beyond just mobility. Trip hazards disappear when there are no cords to stumble over. Setup becomes faster and simpler. Equipment can be positioned in tight spaces or clustered together without playing electrical Tetris with outlet locations. It's one of those improvements that seems small until you experience the freedom it provides.

Key Specifications, Types & Performance Factors

Choosing the right table battery feels a bit like buying a car - you need to match the specs to how you'll actually use it. The most critical specification is voltage, and this one's non-negotiable. Your equipment expects exactly what it was designed for, whether that's 6V for specialized MRI table lighting, 12V for most surgical and examination tables, or 24V for heavy-duty industrial applications.

Amp-hour capacity (Ah) determines your runtime - think of it as your fuel tank size. A higher Ah rating means longer operation between charges, but it also means a bigger, heavier battery. Speaking of weight, this matters more than you might think. These batteries often live in equipment that needs to roll around, so an extra 10 pounds can make a real difference during a busy day.

Terminal types need to match your equipment's connections perfectly. Spring terminals make battery swaps quick and easy - great when you're in a hurry. Nut and bolt terminals provide rock-solid connections for equipment that vibrates or moves frequently. F2 tabs work well in tight spaces where every inch counts.

Physical dimensions can make or break your battery choice. We've seen folks order the perfect battery only to find it won't fit in their equipment's battery compartment. Always measure twice, order once.

Leak-proof design isn't just nice to have - it's essential in medical environments where spills could contaminate sterile areas or damage expensive equipment. Self-discharge rates tell you how well a battery holds its charge when sitting idle. Lower rates mean less frequent charging and fewer surprises when you need the equipment to work.

Warranty terms vary widely, and they're worth paying attention to. Quality replacement batteries typically include a 1-year full replacement warranty, with some manufacturers offering up to 3 years of coverage. Many warranties even cover shipping costs, which matters when you're dealing with 20+ pound batteries.

| Battery Type | Voltage | Typical Capacity | Weight | Lifespan | Self-Discharge/Month | Cost Range |

|---|---|---|---|---|---|---|

| Lead-Acid (AGM) | 6V-12V | 18-28Ah | 18-25 lbs | 3-5 years | 3-5% | $50-150 |

| NiCd | 6V-24V | 10-20Ah | 15-20 lbs | 2-4 years | 20-30% | $75-200 |

| NiMH | 6V-12V | 15-25Ah | 12-18 lbs | 3-4 years | 30-35% | $100-250 |

| Lithium-Ion | 12V-24V | 20-40Ah | 8-15 lbs | 5-8 years | 2-5% | $200-500 |

Choosing the Right Table Battery for Your Equipment

Getting the right table battery match requires understanding what your specific equipment actually needs, not just what the manual says. Surgical suites demand the highest reliability since equipment failures during procedures can be serious business. Most surgical facilities stick with sealed lead-acid batteries because they've proven themselves over decades of use. The Enersys DataSafe NPX100RFR battery has become a go-to choice for surgical tables, replacing multiple Steris and Amsco models with reliable performance.

MRI compatibility adds another layer of complexity. Those powerful magnetic fields don't play nice with certain battery chemistries and metal components. The Sentinelle Table Battery 6V HDM was specifically engineered for MRI environments, offering leak-proof operation with spring terminals that make installation straightforward while staying compatible with magnetic resonance equipment.

Imaging table load profiles vary dramatically depending on how you use the equipment. Tables running extended procedures need higher capacity batteries to avoid mid-procedure power issues. Quick diagnostic imaging setups might prioritize fast charging over maximum runtime. Think about your typical day - how long are procedures, how often do you use the table, and when can you realistically charge batteries?

In mortuary work, we've learned that reliability and leak-proof operation aren't just preferences - they're requirements. Facilities using stainless-steel tables consistently get the best results from AGM batteries that handle demanding environments while delivering consistent performance day after day.

Modeling Aging & Self-Discharge in a Table Battery

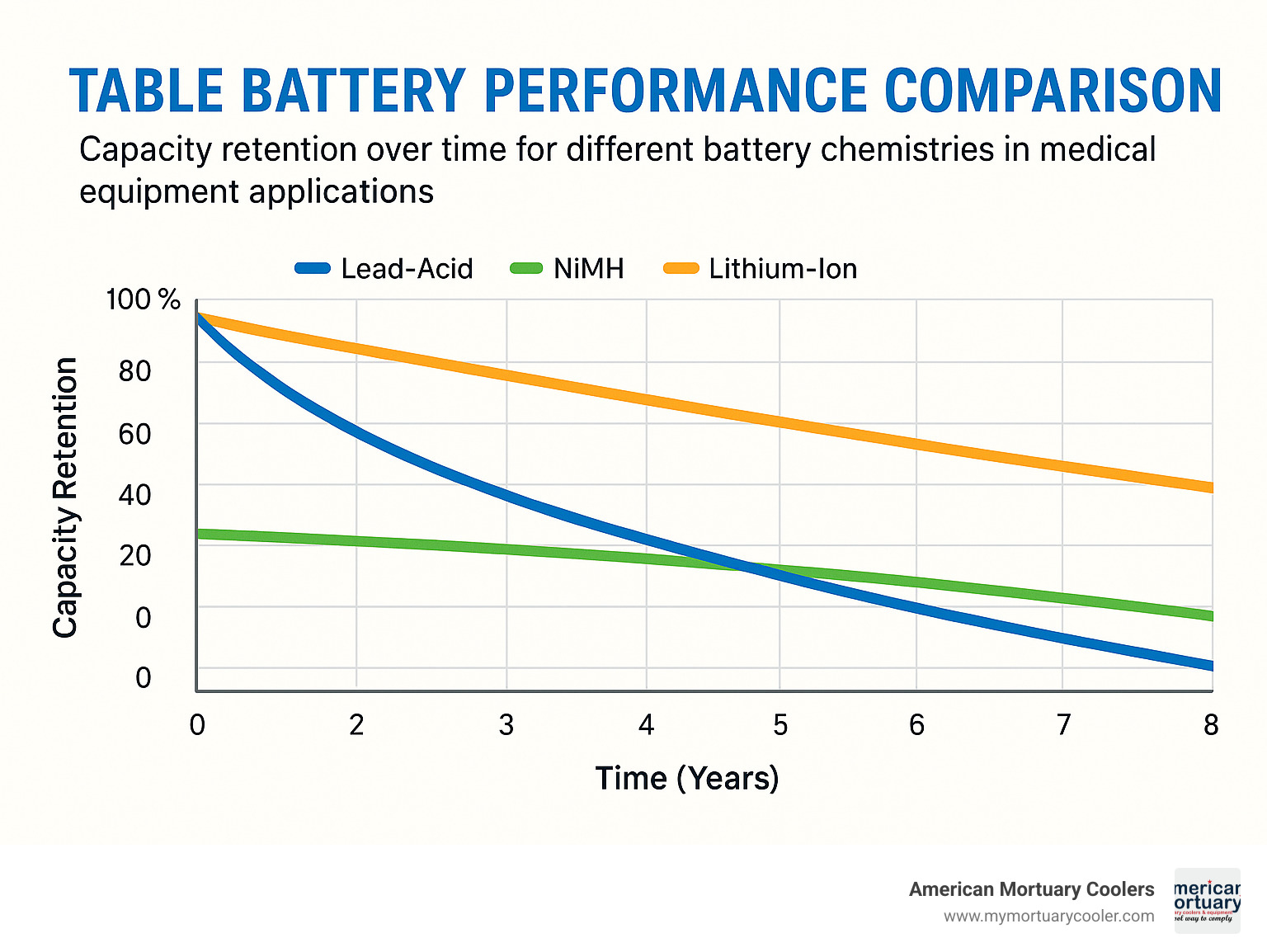

Every table battery ages, but understanding how and why helps you plan replacements before they leave you stranded. Battery aging happens two ways: cycling aging from regular charge and discharge cycles, and calendar aging that occurs just from the passage of time, even when the battery sits unused.

Temperature effects play a huge role in aging. A battery running at 104°F ages roughly twice as fast as one operating at room temperature. This is why battery compartments with good ventilation last longer than those tucked into hot, cramped spaces.

Cycle count directly impacts lifespan, with each full charge and discharge cycle taking a small toll on total capacity. Deep discharges are particularly hard on batteries - draining a lead-acid battery below 50% capacity significantly shortens its life. That's why quality medical tables include low-voltage cutoffs to prevent damaging deep discharge events.

Calendar fade happens even to batteries that rarely get used. Internal chemical processes gradually reduce capacity over time, with the rate depending on temperature and charge level. Storing batteries at 40-60% charge in cool conditions minimizes this aging process.

Modern battery management systems use lookup-table modeling to predict performance degradation based on these factors. The Battery Reference Values database shows how dramatically performance can vary between manufacturers and models, even when the basic specifications look similar. This variation explains why choosing batteries from reputable manufacturers with proven medical equipment track records makes such a difference in real-world performance.

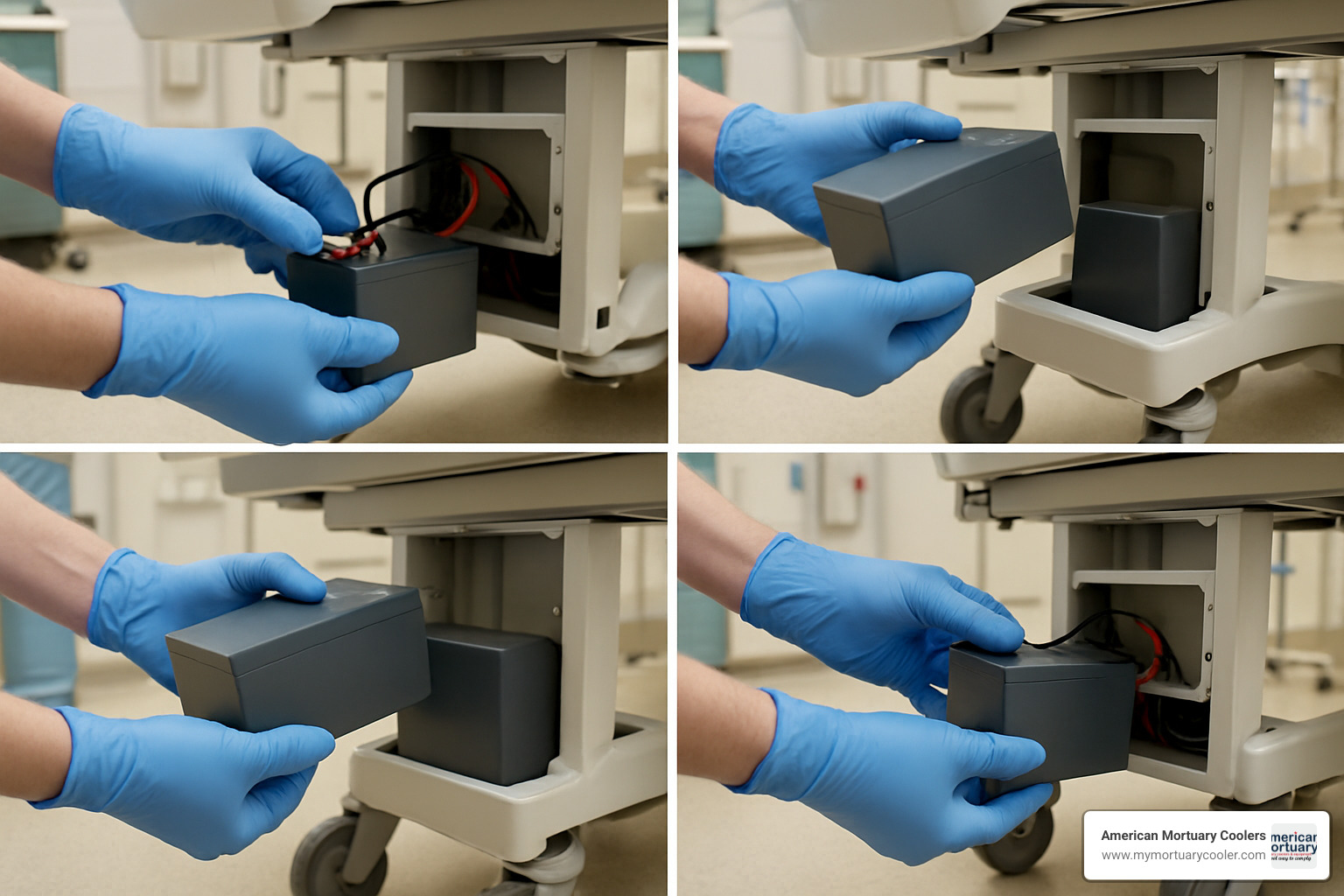

Selection, Installation & Maintenance Best Practices

Getting the right table battery for your equipment isn't just about picking the first one that fits—it's about making smart choices that'll keep your tables running smoothly for years to come. We've seen too many facilities learn this lesson the hard way when their equipment fails during critical moments.

The most important rule? Voltage matching is absolutely non-negotiable. Using the wrong voltage can fry your equipment's electronics or create serious safety hazards. Always double-check your equipment manual or call the manufacturer if you're not 100% certain. Trust us, a five-minute phone call beats explaining to your boss why the table stopped working mid-procedure.

Capacity headroom is your insurance policy against unexpected situations. We recommend going 20-30% above your minimum power needs. Think of it like buying a truck—you don't want one that can barely haul your heaviest load. If your equipment needs 16Ah for a typical day, get at least a 20-22Ah battery. This extra capacity handles battery aging, temperature swings, and those unexpectedly long procedures that always seem to happen at the worst times.

Terminal cleaning might sound boring, but it's one of those simple tasks that prevents big headaches later. Corroded terminals are like trying to drink through a clogged straw—everything slows down and eventually stops working. A quick monthly cleaning with a wire brush and a dab of petroleum jelly keeps connections solid and prevents those mysterious power issues that pop up at the worst moments.

Your charging routine makes a huge difference in how long your batteries last. Most table batteries prefer complete charge cycles rather than constant topping off. It's like getting a good night's sleep versus a bunch of short naps—the complete cycle keeps everything running better. Just don't overcharge them, especially lead-acid batteries. Modern smart chargers handle this automatically, but older chargers might need some babysitting.

Environment control affects your batteries more than you might think. They're happiest in normal room temperatures between 68-77°F. Hot conditions age batteries faster, while cold temperatures temporarily reduce their power output. Make sure your battery compartments have decent ventilation—batteries get warm during charging and need to cool down properly.

Preventive testing is like taking your car for regular oil changes. Monthly voltage checks under load can spot problems before they cause equipment failures. Many smart facilities keep simple logs of battery performance to track trends and plan replacements before emergencies happen.

Maintenance Schedule & Replacement Signs

A good maintenance routine doesn't have to be complicated, but it needs to be consistent. Monthly checks should include looking for physical damage, cleaning terminals, and testing voltage under load. It takes maybe 15 minutes but can save you from equipment failures during critical procedures.

Quarterly deep-cycle conditioning helps maintain capacity, especially for NiCd and NiMH batteries. This prevents the dreaded "memory effect" where batteries forget how to use their full capacity. Think of it as exercise for your batteries—they need to stretch their legs occasionally to stay in shape.

Annual capacity testing gives you hard data on battery condition. This involves fully charging the battery, then timing how long it powers a known load. When batteries drop below 80% of their rated capacity, it's time to start shopping for replacements.

Recognizing replacement signs early can save you from embarrassing equipment failures. Slow lift operation is usually the first warning sign—if your table moves like it's stuck in molasses, the battery is probably losing its punch. Longer recharge times also indicate aging batteries, as their internal resistance increases with age.

Voltage sag under load is another red flag. A healthy battery maintains steady voltage during normal operation. If voltage drops significantly when the table is working, the battery's internal resistance has likely increased beyond acceptable levels.

Don't ignore equipment alarms—they're your early warning system. These alarms activate when battery voltage drops below safe operating levels, giving you time to plan replacement before complete failure. It's like your car's check engine light—annoying but important.

Physical symptoms like visible corrosion around terminals, case swelling, or any signs of leakage mean immediate replacement. These indicate internal damage that could lead to sudden failure or safety hazards.

Upgrade Options & Trade-Offs

Higher-Ah battery packs can extend your equipment's runtime, but they come with trade-offs. Bigger batteries are heavier and may not fit in existing compartments. Before upgrading, consider whether the extended runtime is worth the extra weight and potential modifications needed.

Li-ion retrofits offer impressive advantages—50-100% more runtime while weighing 40-60% less than lead-acid batteries. The catch? They cost 3-4 times more upfront, and your existing charger might need upgrading. For facilities that rely heavily on battery power, the investment often pays off through reduced maintenance and longer service life.

The weight versus runtime decision depends on your specific needs. If your equipment moves frequently, excessive battery weight makes tables harder to maneuver and may exceed floor loading limits. For stationary equipment, maximizing runtime might be more important than minimizing weight.

Total cost analysis should look beyond the sticker price. While lithium-ion batteries cost more initially, their longer lifespan and lower maintenance can result in lower costs over 5-10 years. Factor in replacement labor costs too—lighter batteries are much easier and safer to install.

For facilities using specialized equipment like embalming tables, battery selection might be influenced by the specific requirements of preparation procedures and the need for reliable positioning during extended processes.

Safety, Environmental & End-of-Life Considerations

When it comes to table battery safety, medical environments demand the highest standards of protection. That's why spill-proof AGM batteries have become the gold standard for surgical tables and medical equipment. These batteries use absorbed glass mat technology to lock the electrolyte inside, which means even if the battery case cracks, you won't have dangerous acid spilling onto expensive equipment or creating slip hazards in sterile environments.

The DOT 60 transport class designation makes life much easier when you need replacement batteries shipped to your facility. This classification recognizes that properly sealed batteries are safe to transport as non-hazardous materials, which translates to faster shipping times and lower costs. No special handling fees or hazmat paperwork required.

Modern table batteries are engineered with environmental responsibility in mind. They're mercury-free and cadmium-free, meeting all EPA compliance standards for safe disposal. This wasn't always the case - older battery technologies contained heavy metals that posed serious environmental risks. Today's batteries eliminate these concerns while delivering better performance.

Personal protective equipment might seem like overkill for "sealed" batteries, but smart facilities don't take chances. Safety glasses and nitrile gloves should be standard equipment whenever you're swapping batteries. Even the best seals can fail over time, and battery acid has a way of finding the most inconvenient places to leak.

Recycling programs represent the responsible choice for end-of-life battery disposal. While modern batteries meet EPA requirements for landfill disposal, recycling recovers valuable materials like lead, lithium, and rare earth elements. Many battery suppliers offer take-back programs, and some will even provide shipping labels for returning old batteries when you purchase replacements.

Local regulations can add another layer of requirements beyond federal EPA standards. Some municipalities prohibit battery disposal in regular waste streams entirely, requiring delivery to certified recycling facilities. A quick call to your local environmental authority can save headaches later - and some areas offer free battery collection events that make disposal convenient and cost-effective.

For facilities operating autopsy tables, battery safety considerations extend to chemical resistance and decontamination procedures. The sealed design of modern AGM batteries makes them compatible with standard cleaning protocols while maintaining their protective benefits.

At American Mortuary Coolers, we've seen how proper battery selection and handling practices contribute to safer, more reliable facility operations. The small investment in safety equipment and responsible disposal pays dividends in equipment longevity and peace of mind.

Frequently Asked Questions about Table Batteries

How long does a quality table battery typically last?

A high-quality table battery typically lasts 3-5 years under normal operating conditions. However, actual lifespan depends on several factors including usage patterns, charging practices, environmental conditions, and battery chemistry. Lead-acid AGM batteries commonly used in surgical tables generally achieve 3-4 years of reliable service, while premium lithium-ion batteries can last 5-8 years.

Factors that extend battery life include regular charging, avoiding deep discharge cycles, maintaining proper operating temperatures, and following manufacturer maintenance recommendations. Conversely, frequent deep discharges, exposure to extreme temperatures, and irregular charging can significantly reduce lifespan.

What are the first signs my table battery should be replaced?

The first signs of table battery deterioration typically include slower equipment operation, longer charging times, and reduced runtime between charges. If your table takes noticeably longer to raise or lower, or if positioning adjustments seem sluggish, the battery may be losing capacity.

Voltage sag under load is another early indicator - if equipment performance varies during operation or if low-battery warnings appear more frequently, it's time to test battery capacity. Physical signs like terminal corrosion, case swelling, or any visible damage also indicate replacement needs.

Many modern tables include battery monitoring systems that provide early warnings. Don't wait for complete failure - proactive replacement prevents unexpected downtime during critical procedures.

Can I upgrade to a higher-capacity chemistry without modifying my table?

Upgrading to a higher-capacity table battery chemistry is often possible but requires careful consideration of several factors. The new battery must match the original voltage exactly and fit within existing mounting constraints. Physical dimensions, weight, and terminal configuration must all be compatible.

Charging system compatibility is crucial when upgrading battery chemistry. Lithium-ion batteries require different charging profiles than lead-acid batteries and may need charging system modifications. However, upgrading from one lead-acid type to another (such as from standard to AGM) typically requires no modifications.

Consult your equipment manufacturer before making chemistry changes. They can advise on compatibility and any necessary modifications to ensure safe, reliable operation.

Conclusion

Choosing the right table battery isn't just about specs and numbers—it's about ensuring your equipment works flawlessly when lives and livelihoods depend on it. Whether you're running a busy surgical suite or managing a mortuary facility, battery failure at the wrong moment can turn a routine procedure into a crisis.

We've walked through everything from voltage matching to battery chemistry trade-offs, maintenance schedules to upgrade options. The key takeaway? Don't wait for failure to force your hand. A quality table battery with proper care will serve you faithfully for 3-5 years, but only if you choose wisely from the start.

At American Mortuary Coolers, we've seen how the right equipment choices ripple through entire operations. Over our years delivering custom solutions nationwide, we've learned that reliability starts with the components you can't see—like the battery quietly powering your table through another successful procedure.

The investment in a proper table battery pays for itself many times over. Better uptime means smoother operations. Reliable power means safer procedures. Quality components mean fewer emergency calls and rushed replacements.

Your tables work hard for you every day. Return the favor by giving them the power they deserve. When you're ready for personalized guidance on table battery selection or any other equipment needs, we're here to help. Our team understands the technical details and can translate them into practical solutions that work for your specific situation.

Contact us today for expert advice custom to your facility's needs. We deliver durable, custom solutions across all 48 contiguous states, because reliable equipment shouldn't be a luxury—it should be standard. Learn more about our complete range of mortuary equipment and cooling solutions at our website.