Why Full Body Protection Matters in High-Risk Environments

A full body protective suit is a specialized garment designed to shield the entire body from chemical, biological, radiological, or physical hazards. These suits create a barrier between the wearer and dangerous substances, preventing exposure through skin contact, inhalation, or ingestion.

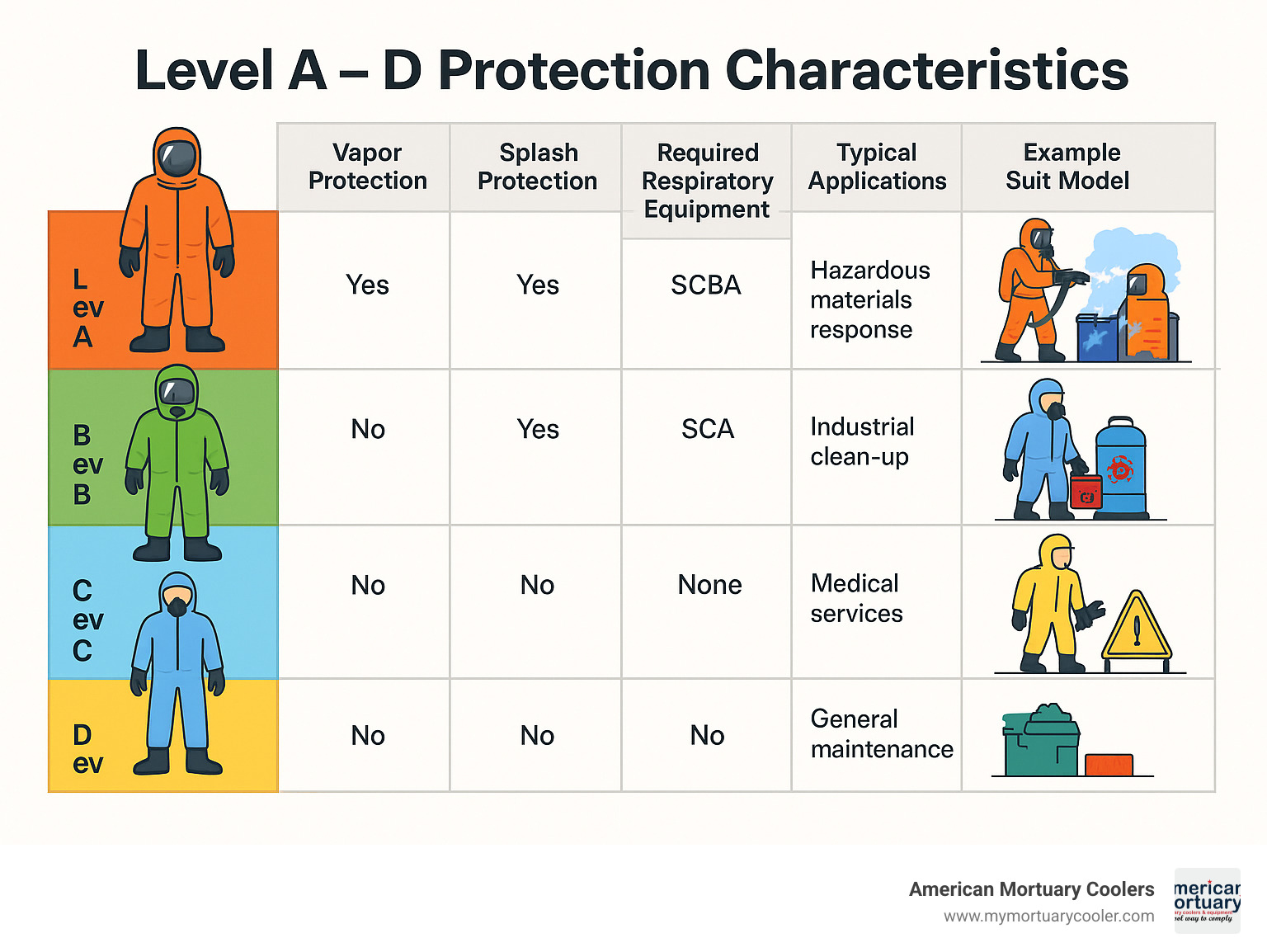

Key Types of Full Body Protective Suits:

- Level A Suits - Maximum vapor protection with fully encapsulating design (e.g., DuPont Tychem 10000)

- Level B Suits - High splash protection with supplied air respirator compatibility

- Level C Suits - Air-purifying respirator compatible for moderate chemical exposure

- Level D Suits - Basic work uniforms offering minimal protection

- Specialized Suits - Radiation protection (Demron fabric), riot control, and medical isolation

From emergency responders handling chemical spills to mortuary professionals managing infectious remains, these suits serve as the last line of defense against life-threatening exposures. The DuPont Tychem 10000 Commander EX, for example, has been successfully tested against more than 260 challenge chemicals, including chemical warfare agents like Sarin and VX.

Industries relying on full body protection include healthcare facilities managing infectious diseases, chemical plants with hazardous materials, military operations involving CBRN threats, and funeral homes handling potentially contaminated remains. The stakes are high - proper suit selection can mean the difference between safe operations and catastrophic exposure.

As we at American Mortuary Coolers have experience in mortuary equipment and safety protocols, we've seen how the right full body protective suit can protect funeral professionals during disease outbreaks and hazardous material incidents. Our background in mortuary operations has shown us that understanding protection levels and proper suit selection is critical for maintaining both worker safety and operational continuity.

What Is a Full Body Protective Suit?

Think of a full body protective suit as your personal shield against the world's most dangerous substances. It's far more than just heavy-duty clothing – it's a carefully engineered barrier system that wraps your entire body from head to toe, keeping you safe when regular work clothes simply won't cut it.

These suits serve some pretty critical purposes. They create an impermeable or semi-permeable barrier against hazardous substances, prevent contamination of your skin and clothing, and work with breathing equipment to give you a controlled, safe environment to breathe in. It's like having your own personal bubble of protection.

The magic happens through something called encapsulation. Engineers design these suits with specially constructed seams, unique closures, and integrated components like gloves, boots, and visors. The level of encapsulation varies quite a bit – fully encapsulating Level A suits create a complete barrier to the environment, while air-permeable suits let you breathe a bit easier while still blocking specific hazards.

When emergency responders rush toward a chemical spill while everyone else runs away, they're counting on their protective suits to bring them home safely. That's the kind of trust these garments need to earn every single day.

Core Functions of a Full Body Protective Suit

The chemical shield function is probably what most people think of first. Materials like Tychem TK fabric provide barrier protection against hundreds of chemicals. The impressive Tychem 10000 shows at least 30 minutes of barrier protection against 322 different challenge chemicals with no breakthrough. That protection comes from specialized polymer construction and chemical-resistant coatings that literally repel dangerous substances.

Biohazard blocking capabilities protect against infectious agents like bacteria, viruses, and other biological nasties. These suits feature sealed seams and non-permeable materials that prevent biological agents from reaching your skin or getting into your lungs. During the COVID-19 pandemic, we saw huge demand for suits meeting Biosafety Level 4 containment standards – the kind of protection you need for the most dangerous pathogens.

Radiation attenuation gets into some seriously specialized territory. Suits like the Demron Full Body Suit provide at least 50% shielding of gamma rays up to 130 KeV and block high-energy beta particles. The Demron fabric uses patented nanotechnology to achieve this protection while weighing less than 7 pounds. That's pretty remarkable when you think about it.

Impact armor functionality shows up in riot control and tactical suits like the Damascus Gear FX-1 FlexForce. These combine hard shell panels with shock-absorbing foam to protect against physical impacts while still letting you move around effectively through modular flex panel design.

Common Industries Using Full Body Protective Suits

Healthcare facilities rely on protective suits during infectious disease outbreaks, surgeries involving contaminated patients, and when handling hazardous medical waste. These suits provide critical protection for healthcare workers while preventing cross-contamination between patients – something that became painfully clear during recent global health crises.

Industrial applications span chemical manufacturing, petroleum refining, pharmaceutical production, and hazardous waste cleanup. Workers in these environments face daily exposure risks from toxic chemicals, corrosive substances, and potentially explosive atmospheres. It's serious business where the right protection can literally save lives.

Military and emergency response teams depend on CBRN-rated suits for chemical warfare defense, domestic terrorism response, and hazardous material incidents. The Joint Service Lightweight Integrated Suit Technology (JSLIST) can be laundered up to 6 times and worn for 45 days during its service life, with a total service life of 120 days out of package.

The mortuary industry requires protective suits when handling remains that may be contaminated with infectious diseases, hazardous chemicals, or radioactive materials. At American Mortuary Coolers, we understand the unique challenges funeral professionals face and the importance of proper protection during these sensitive operations. It's not just about safety – it's about being able to serve families with dignity while protecting yourself and your staff.

Sports and recreational activities also use protective suits, particularly in extreme sports where impact protection is crucial. These suits often incorporate advanced impact technology for improved flexibility and low-profile design, proving that protection doesn't always have to mean bulky and uncomfortable.

Understanding Protection Levels: Level A, B, C, D

When it comes to full body protective suits, not all protection is created equal. The EPA developed a clear hierarchy that makes choosing the right suit much easier - think of it like choosing the right tool for the job, except the job might involve deadly chemicals or biological hazards.

This system, backed by NFPA 1991 standards and OSHA HAZWOPER regulations, takes the guesswork out of protection selection. The levels range from maximum protection (Level A) down to basic work wear (Level D), with each level designed for specific types of hazards and exposure risks.

The key thing to understand is that higher protection levels come with trade-offs. You get better protection, but you'll also deal with reduced mobility, increased heat stress, and higher costs. It's all about finding the sweet spot between adequate protection and practical usability.

Getting this choice wrong can be dangerous in either direction. Too little protection puts workers at risk of exposure and injury. Too much protection can lead to heat exhaustion, accidents from reduced visibility, and budget strain that might compromise safety in other areas.

Level A: Maximum Vapor Protection

Level A suits are the gold standard when you need complete isolation from the environment. These fully encapsulating designs cover every inch of your body, including your head, creating a sealed bubble around the wearer.

The Tychem 10000 Commander EX represents the best of Level A protection. This suit has been tested against more than 260 different chemicals, including some truly nasty stuff like chemical warfare agents - we're talking Sarin, VX, and other substances you definitely don't want touching your skin.

What makes Level A special is the SCBA (self-contained breathing apparatus) requirement. The air tank goes inside the suit with you, so you're breathing completely clean air that has nothing to do with whatever toxic soup might be swirling around outside. It's like having your own personal atmosphere.

These suits feature gas-tight zippers with double storm flaps, because regular zippers just won't cut it when dealing with chemical vapors. The integrated gloves and boots mean there are no weak points where chemicals can sneak in. Some models even have dual glove systems - inner barrier gloves attached to the suit, plus outer chemical-resistant gloves for extra protection.

You'll need Level A protection when the chemical hazard is unknown, when skin contact could be immediately life-threatening, or when you're dealing with substances that require complete environmental isolation.

Level B: High Splash Guard with SCBA

Level B suits give you the same excellent respiratory protection as Level A, but they're designed primarily for liquid splash protection rather than vapor protection. Think of them as the practical middle ground when you know vapors aren't the main concern.

The Tychem Responder CSM is a great example of Level B design. It still requires SCBA or supplied air systems, so your lungs stay protected, but the suit itself allows some air movement. This makes them more comfortable for longer work periods while still blocking dangerous liquid splashes.

These suits typically feature a hooded design with face seals, plus chemical-resistant gloves and boots. The key difference from Level A is that they're not completely sealed - they breathe a bit, which helps with heat management during extended operations.

Level B makes sense when you've identified the chemical hazard and know that respiratory protection is critical, but direct skin contact with vapors isn't likely to cause immediate harm. It's perfect for many industrial cleanup situations where liquid spills are the primary concern.

Level C: Air-Purifying Respirator Compatible

Level C suits provide similar skin protection to Level B but use air-purifying respirators instead of heavy air tanks. This makes them much more practical for routine operations and extended wear periods.

The military's JSLIST (Joint Service Lightweight Integrated Suit Technology) shows how effective Level C can be. These suits are designed for chemical and biological defense but can be laundered up to 6 times and worn for 45 days during active use. That's real-world practicality.

The air-permeable design of Level C suits helps reduce heat stress while maintaining protection against specific threats. This makes them ideal for industrial applications where workers need to stay protected but also need to stay comfortable enough to do their jobs effectively.

You'll want Level C protection when the chemical is identified, concentrations are known to be manageable, and air-purifying respirators can handle the respiratory protection needs. Many industrial haz-suits fall into this category.

Level D: Basic Work Apparel

Level D represents basic work protection - think coveralls, safety glasses, and work boots. These suits protect against nuisance contamination but don't provide respiratory protection or serious chemical barriers.

The RANGER Full Coverage Disposable Protective Suit shows how affordable Level D can be, with prices starting around $9.99. These suits are typically made from materials like non-woven polypropylene and feature integrated hoods and boot covers.

Popular options like the DuPont Tyvek 400 HazMat Coverall Suit work well for professionals and home improvement projects where the main goal is keeping regular clothes clean and providing basic protection against dust and dirt.

Level D is only appropriate when there are no respiratory or skin hazards present. It's the choice when you need to look professional, stay clean, and have basic protection, but you're not dealing with anything that could actually hurt you.

At American Mortuary Coolers, we've seen how important it is to match the protection level to the actual hazards present. Whether you're dealing with infectious remains or hazardous materials, choosing the right level keeps everyone safe while allowing the work to get done efficiently.

Materials & Technologies Behind Modern Suits

The science behind modern protective suits is fascinating - and frankly, it's come a long way from the rubber rain gear that early responders used to wear. Today's full body protective suit materials represent decades of breakthroughs in chemistry and engineering, creating barriers that can literally mean the difference between life and death.

Tychem TK fabric stands out as one of the most impressive achievements in protective materials. Used in DuPont's premium suits, this material can withstand at least 30 minutes of exposure to 322 different challenge chemicals without any breakthrough. That's an incredible feat of engineering when you consider the variety of nasty substances people encounter in hazardous work environments.

But perhaps the most exciting development is Demron fabric, which tackles the challenge of radiation protection in an entirely new way. Using patented nanotechnology, this material provides at least 50% shielding against gamma rays up to 130 KeV while weighing less than 7 pounds. The fact that it's lead-free and non-toxic makes it a game-changer for radiation workers. It's impressive enough that NATO, NASA, the US National Guard, and the US Navy have all adopted this technology.

Butyl rubber remains the trusted workhorse for chemical-resistant gloves and boots. This material offers exceptional resistance to gas and vapor permeation, which is why you'll find it in the dual glove systems of Level A suits - those inner barrier gloves paired with outer butyl gloves create redundant protection that safety professionals rely on.

The way these suits are put together has evolved dramatically too. Seam sealing technology has moved far beyond simple sewn seams to sophisticated heat-sealed and taped constructions. DuPont's ThermoBond Max technology creates maximum durability under extreme conditions, while double storm flap closures provide that extra barrier protection right where suits are most vulnerable - at the zipper locations.

A challenge with protective suits has always been heat stress, and modern ventilation systems are finally addressing this critical issue. Some suits now incorporate exhaust valves for pressure regulation, while others feature self-cooling technologies that provide much better heat dissipation than the old-school impermeable suits that felt like wearing a plastic bag.

For those interested in diving deeper into the science behind these materials, there's excellent scientific research on radiation shielding available that explains the technical details.

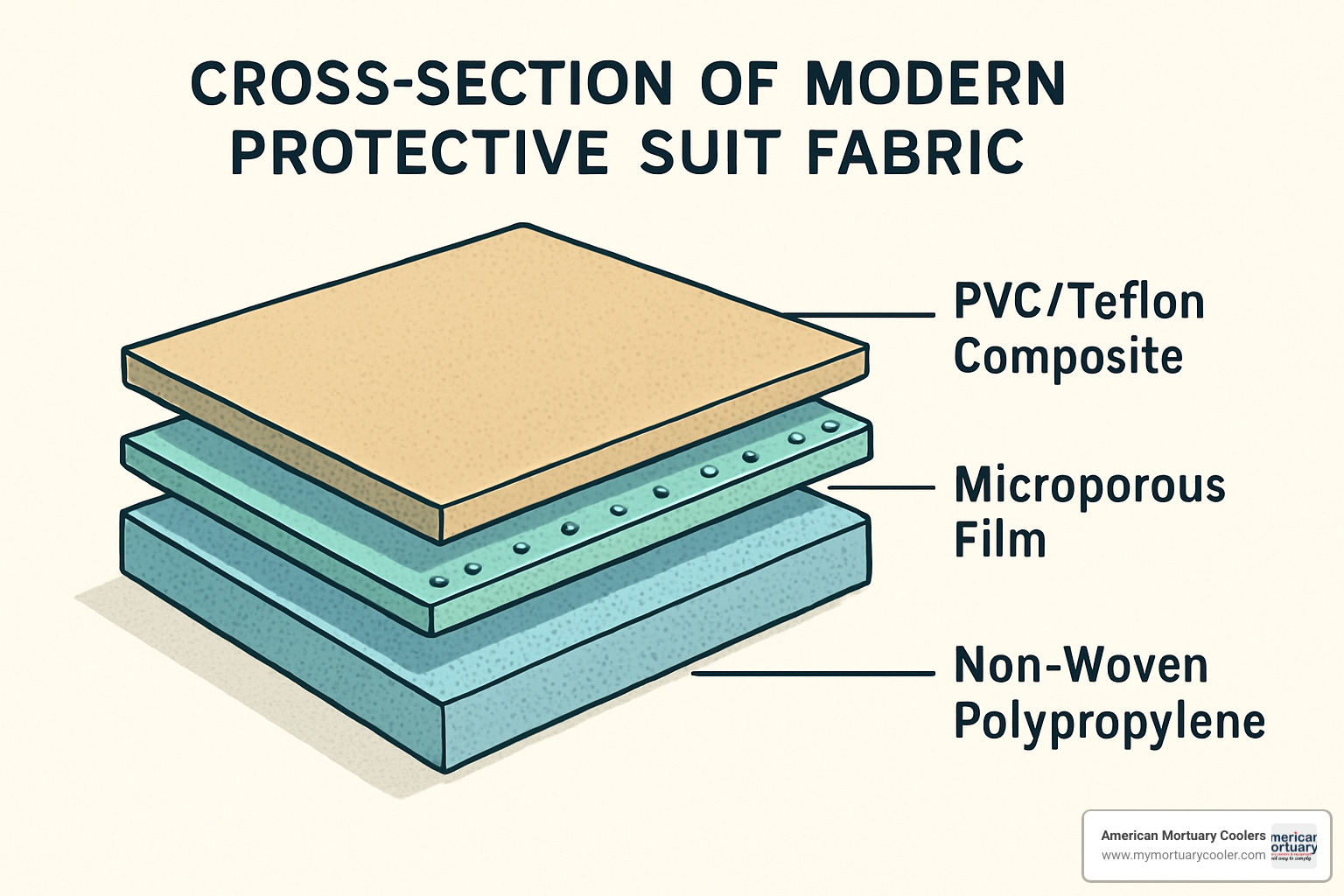

Fabric Choices and Their Protection Windows

The beauty of modern protective suit design lies in matching the right material to the specific hazard. Polypropylene-based materials, like those used in RANGER disposable suits, provide lightweight protection against non-hazardous particles while remaining breathable enough for extended wear. These non-woven fabrics strike that important balance between protection and comfort.

Microporous film laminates represent another clever solution to the breathability challenge. These materials allow water vapor to escape while blocking liquid penetration - perfect for medical and industrial applications where workers need to stay protected but can't afford to overheat during long shifts.

When it comes to face shields and viewing windows, PVC/Teflon composite materials provide the chemical resistance needed while maintaining crystal-clear visibility. The DuPont Tychem 10000, for example, features a face shield constructed from 40 mil PVC, 5 mil Teflon, and 20 mil PVC layers. This multi-layer approach gives you improved chemical and abrasion resistance without compromising your ability to see what you're doing.

Cutting-Edge Innovations in 2025

The future of protective suits is arriving faster than many people realize, and it's pretty exciting stuff. Nanotechnology laminates are revolutionizing how we think about protection by engineering materials at the molecular level. These advanced fabrics can be designed to block specific hazards while maintaining breathability and flexibility - something that seemed impossible just a few years ago.

Military applications are driving some particularly interesting developments. IR-reduction technologies in advanced suits help reduce the wearer's infrared signature for tactical operations, combining protection with stealth capabilities. It's like something out of a science fiction movie, but it's real and it's being used in the field today.

Perhaps the most promising development is smart sensor integration. Imagine wearing a full body protective suit that can detect its own integrity, monitor environmental hazards, and even track your vital signs - all in real time. These embedded monitoring systems provide immediate feedback on protection effectiveness and safety status, taking the guesswork out of hazardous operations.

The holy grail of protective suit technology might be the new air-permeable membranes that selectively block hazardous substances while allowing air circulation. These materials are finally addressing the age-old problem of heat stress that has plagued protective suit wearers for decades. By maintaining protection while significantly improving comfort and extending operational time, these innovations could transform how we approach hazardous work environments.

At American Mortuary Coolers, we've seen how important proper protection is in mortuary operations, especially during challenging situations involving infectious diseases or hazardous materials. These technological advances mean that funeral professionals can focus on their important work while staying safe and comfortable.

Choosing Your Full Body Protective Suit: Key Factors

Picking the right full body protective suit isn't something you want to get wrong. Your life might literally depend on it. The good news? With a systematic approach, you can make the right choice for your specific situation.

Start with a thorough risk assessment of your work environment. What hazards are you facing? Chemical vapors, liquid splashes, biological agents, or radiation? The DuPont Tychem 10000 fabric provides at least 30 minutes of barrier protection against hundreds of chemicals, but it won't help much against physical impacts or radiation exposure.

Consider the physical state of your hazards too. Are you dealing with vapors that can seep through tiny openings, or liquid splashes that need barrier protection? The concentration levels matter as well - higher concentrations typically require higher protection levels.

Compatibility with your other safety gear is crucial but often overlooked. Your full body protective suit needs to work seamlessly with your respirator, gloves, and boots. Level A suits must accommodate bulky SCBA systems, while all suits need to integrate properly with compatible gloves and boots. The DuPont Tychem systems solve this puzzle by offering integrated glove and boot systems that eliminate compatibility guesswork.

Getting the right fit isn't just about comfort - it's about staying alive. Poorly fitted suits create gaps where hazards can enter, or they might tear under stress. The Damascus Gear FX-1 FlexForce addresses this with multiple adjustable straps and Velcro closures that keep protective plates exactly where they need to be, even during intense physical activity.

Don't forget about certifications and regulations. NFPA 1994 Class 2 standards apply to CBRN terrorism incidents, while OSHA HAZWOPER regulations govern hazardous waste operations. Understanding which standards apply to your work ensures you're not just protected, but also compliant.

Money matters, but think beyond the sticker price. That $139.95 HAZ-SUIT might look tempting compared to the $1,199.95 MOPP-1 CBRN Protective Suit, but consider training costs, shelf life, and replacement frequency. Sometimes spending more upfront saves money in the long run.

For more comprehensive guidance on protective equipment selection, see More info about personal protective gear.

Matching Suit Type to Specific Hazards

The key to full body protective suit selection is matching your suit's capabilities to your specific threats. It's like choosing the right tool for the job - a hammer won't help you with a screw, and a Level D suit won't protect you from chemical warfare agents.

Chemical spills demand suits with proven chemical resistance ratings and adequate breakthrough times. The Tychem 10000 fabric shines here, providing at least 30 minutes of barrier protection against hundreds of chemicals. That's enough time for emergency response teams to get in, assess the situation, and get out safely.

CBRN events present the ultimate challenge, requiring protection against chemical warfare agents, biological pathogens, radioactive contamination, and nuclear fallout all at once. The MOPP-1 suit rises to this challenge, meeting ISO 6940:2004 flame-resistance standards while providing comprehensive CBRN protection for military and emergency response applications.

Biological hazards need special consideration for pathogen penetration prevention and decontamination procedures. Suits meeting Biosafety Level 4 containment standards provide the highest level of biological protection available - essential when dealing with the most dangerous pathogens known to science.

Physical impact situations, like riot control, require a completely different approach. Here, you need suits with hard shell protection and impact-absorbing materials. The Damascus Gear Imperial Full Body Protection Kit uses EVA foam padding and hard shell inserts for comprehensive impact protection that can mean the difference between going home safe and going to the hospital.

Fit, Comfort & Mobility Considerations

Getting the right fit starts with honest measurements and careful attention to manufacturer sizing charts. Don't guess or estimate - measure twice, order once. The Damascus Gear systems accommodate chest sizes from MD 38″–42″ up to XXXLG 56″–60″, ensuring most body types can find proper protection.

Adjustable straps and closure systems let you fine-tune the fit even after you've made your initial sizing decision. The Imperial Full Body Protection Kit features Velcro attachments and adjustable straps throughout the system, allowing for customized fit and security that adapts to your specific body shape.

Dual-glove systems, standard in Level A suits, provide redundant protection while maintaining the dexterity you need to do your job effectively. The inner barrier glove handles primary chemical protection, while the outer glove offers mechanical protection and improved grip for handling tools and equipment.

Weight distribution affects how long you can work safely and effectively. Nobody wants to be exhausted before the job is done. The Demron Full Body Suit's impressive weight of less than 7 lbs demonstrates how advanced materials can provide superior protection without turning you into a walking anchor.

Budget, Brands & Total Cost of Ownership

DuPont sits at the premium end of the protective suit market, and for good reason. Their Tychem 10000 Commander EX offers maximum protection backed by extensive chemical testing data and proven field performance. You pay more upfront, but you get the peace of mind that comes with decades of research and development.

Damascus Gear brings 65+ years of experience to riot control and tactical protection, offering modular systems that can be configured for your specific needs. Their reputation in law enforcement and military circles speaks to the reliability of their equipment in the most demanding situations.

Demron suits occupy a unique position in radiation protection, using nanotechnology that simply isn't available anywhere else. The $2,000 price point reflects both the specialized nature of the technology and the limited production volumes, but for radiation protection, there's really no substitute.

The pricing spectrum tells an interesting story, ranging from basic disposable suits at $5-10 to premium Level A suits exceeding $2,000. But the purchase price is just the beginning of your investment.

Total cost of ownership includes training requirements - and trust us, you need proper training. Donning and doffing procedures require specialized instruction and regular practice. Maintenance costs vary by suit type, and shelf life considerations can significantly impact your long-term expenses.

Speaking of shelf life, it varies dramatically. Level A suits typically last 5 years when properly stored, while specialized suits like the HAZ-SUIT offer virtually unlimited shelf life. Factor in disposal costs for contaminated suits, and the math gets complicated quickly.

At American Mortuary Coolers, we understand the importance of protecting workers in challenging environments. Whether you're dealing with infectious remains or hazardous materials, the right protective equipment isn't just a good idea - it's essential for safe operations and peace of mind.

Donning, Doffing, Decontamination & Disposal

Getting into a full body protective suit properly can literally be the difference between life and death. The process isn't something you can rush through or figure out on the fly - it requires careful planning, the right equipment, and often a helping hand from trained colleagues.

Before you even touch the suit, you'll need to complete pre-entry medical monitoring to ensure you're physically ready for the demanding work ahead. Next comes the critical suit inspection phase, where you'll check every seam, zipper, and component for damage. This isn't the time to find a torn glove or faulty valve. Level A suits are particularly complex since they require assistance from trained personnel to properly integrate the SCBA system and achieve proper sealing.

The step-by-step donning process follows a specific sequence that can't be altered without compromising your safety. You'll start with appropriate undergarments (cotton is often preferred for comfort and moisture absorption), then work your way outward with the suit body, followed by integrated or separate gloves and boots. Respiratory protection comes next, and finally the crucial sealing procedures.

Tape sealing represents one of the most important steps that's often overlooked by newcomers. You'll apply chemical-resistant tape at critical junctions like wrists, ankles, and waist interfaces to provide that extra barrier protection. The tape you choose must be compatible with both your suit material and the chemicals you expect to encounter - using the wrong tape can actually create weak points in your protection.

When it's time to come out, the doffing process becomes even more critical because now your suit is potentially contaminated with whatever hazards you've been working around. This is where having decontamination zones with proper wash and rinse stations becomes essential - these need to be set up before anyone enters the hazardous area, not as an afterthought.

The decontamination process itself depends entirely on what contaminants you've encountered. Some situations require multiple wash and rinse cycles with specific decontamination solutions, while others might need specialized neutralizing agents. The goal is always the same: remove every trace of hazardous material from the suit's exterior before removal begins.

Waste handling adds another layer of complexity to the process. Single-use suits like the RANGER disposable models typically get incinerated as hazardous waste, which means proper segregation and labeling from the moment they come off. Reusable suits require thorough decontamination and detailed inspection before they can be stored for future use.

If you're working with reusable suits, understanding laundering limits becomes crucial for both safety and budget planning. The JSLIST system, for example, maintains its protective properties for up to 6 wash cycles - but push beyond that limit and you're gambling with your safety. Keep detailed records of each suit's wash history to avoid any dangerous guesswork.

Reuse criteria should be established based on manufacturer recommendations, the level of contamination encountered, and the suit's physical condition after decontamination. Any suit showing signs of damage, material degradation, or contamination that can't be completely removed should be disposed of immediately - it's not worth the risk to try to squeeze one more use out of it.

Training & Certification Requirements

Respirator fit-testing isn't optional - it's mandatory for anyone using suits that require respiratory protection. This testing must happen annually and whenever you experience significant weight changes that might affect how your respirator seals to your face. A poor fit can render even the best suit useless.

HAZWOPER training requirements under 29 CFR 1910.120 spell out minimum training hours and refresher requirements for anyone working with hazardous materials. This comprehensive training covers everything from suit selection and proper use to emergency procedures that could save your life when things go wrong.

NFPA training standards add another layer of requirements specifically for emergency responders. These standards include specific drills and competency requirements that vary based on the protection levels you'll be working with. Regular practice with actual suits is essential - you can't maintain proficiency by just reading about procedures.

While vendor training videos and materials provide valuable suit-specific guidance, they can't replace hands-on training and practice. The Demron Full Body Suit may require less than an hour of basic training, but that represents familiarization rather than the operational competency you'll need in real-world situations.

At American Mortuary Coolers, we've seen how proper training makes all the difference in mortuary operations, especially during disease outbreaks or when handling potentially contaminated remains. The investment in proper training and certification always pays off when it comes to keeping your team safe and your operations running smoothly.

Frequently Asked Questions About Full Body Protective Suits

When it comes to full body protective suit selection and use, we get a lot of questions from professionals across different industries. Having worked with mortuary professionals who face unique protection challenges, we understand how important it is to get clear, practical answers about these critical safety tools.

How long is the typical shelf life of a suit?

The shelf life of protective suits varies quite a bit depending on what type you're dealing with and how you store them. Level A suits like the DuPont Tychem systems typically give you about 5 years of shelf life when you store them properly - that means cool, dry conditions away from direct sunlight and chemical vapors.

On the other end of the spectrum, the HAZ-SUIT offers something pretty remarkable - virtually unlimited shelf life thanks to its specialized fabric construction. Basic disposable suits, however, might not last as long due to material breakdown over time.

Here's the thing about storage - it really matters. Keep your suits in their original packaging whenever possible, store them in temperature-controlled environments, and keep them away from ozone, UV light, and chemical contamination. We recommend checking your stored suits regularly for any signs of wear or damage. It's like maintaining any other piece of safety equipment - a little attention goes a long way.

What additional PPE is mandatory with Level A suits?

Level A suits don't work alone - they're part of a complete protection system. The most critical component is positive-pressure SCBA or supplied air respirators, which are built right into the system. You can't separate the breathing protection from the suit because the suit itself doesn't provide any respiratory protection.

Most Level A suits come with chemical-resistant gloves and boots integrated into the design, but you'll still need to verify compatibility with your specific hazards. Beyond the basics, you might need cooling vests for longer operations (trust me, these suits can get hot), communication systems to stay in touch with your support team, and emergency escape breathing apparatus as backup.

Two-way radios or other communication devices aren't optional - they're essential for maintaining contact with support personnel during operations. When you're fully encapsulated, clear communication becomes a safety lifeline.

Can a full body protective suit be reused after decontamination?

This is one of those "it depends" answers that safety professionals know well. Some suits are designed for multiple uses, while others are strictly one-and-done.

The JSLIST system is a great example of reusable protection - it can be laundered up to 6 times while keeping its protective properties intact. That makes it practical for applications where you know you'll need repeated protection.

However, many suits are designed for single use only, especially when they've been exposed to highly toxic or persistent contaminants. The decision to reuse should always consider the manufacturer's recommendations, what kind of contaminants you encountered, how effective your decontamination procedures were, and what your post-cleaning inspection reveals.

The bottom line? Any suit showing signs of damage, persistent contamination, or material breakdown should be disposed of rather than reused. When it comes to protective equipment, safety always trumps cost considerations. At American Mortuary Coolers, we've seen how the right safety decisions protect both workers and the families they serve during difficult times.

Conclusion

Choosing the right full body protective suit isn't just about checking boxes on a safety checklist - it's about protecting lives and ensuring everyone goes home safely at the end of the day. From basic disposable suits that keep dust off your clothes to advanced Level A systems that can handle chemical warfare agents, there's a world of protection out there designed for every hazard imaginable.

The secret to getting this right lies in doing your homework. You need to understand exactly what hazards you're facing, know which protection level will keep you safe, and make sure the suit you choose actually fits your specific needs. Whether you're a healthcare worker dealing with infectious diseases, an emergency responder cleaning up hazardous spills, or a funeral professional handling potentially contaminated remains, the right full body protective suit can literally be the difference between a normal workday and a life-changing accident.

Here's something we've learned over the years: safety should always come first, even when budgets are tight. Skimping on protection can lead to serious injuries or worse, while choosing higher protection levels might cost more upfront but keeps everyone safe. When you're not sure which way to go, it's always better to err on the side of caution and get expert advice.

At American Mortuary Coolers, we've spent years working with funeral professionals across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania. We've seen how important proper protective equipment is - not just for keeping workers safe, but for making sure funeral homes can keep operating when things get challenging. Whether it's during disease outbreaks or when handling unusual cases, having the right protection gives everyone confidence to do their job properly.

Investing in quality protective suits pays off in ways you might not expect. There's the obvious benefit of keeping people safe, but you also get better regulatory compliance, reduced insurance risks, and the peace of mind that comes from knowing you're prepared for whatever comes your way. As new threats emerge and safety standards evolve, staying up-to-date with the latest protective suit technology isn't just smart - it's essential.

The bottom line is simple: the right protective equipment is an investment in your people and your operation. Don't wait until you need it to start thinking about it.

For more information about our comprehensive safety solutions and mortuary equipment, visit More info about our solutions.