Why Indoor Walk-In Coolers Are Essential for Modern Businesses

An indoor walk in cooler is a temperature-controlled storage room designed for installation inside buildings, providing reliable refrigeration for businesses that need to store large quantities of perishable items safely and efficiently.

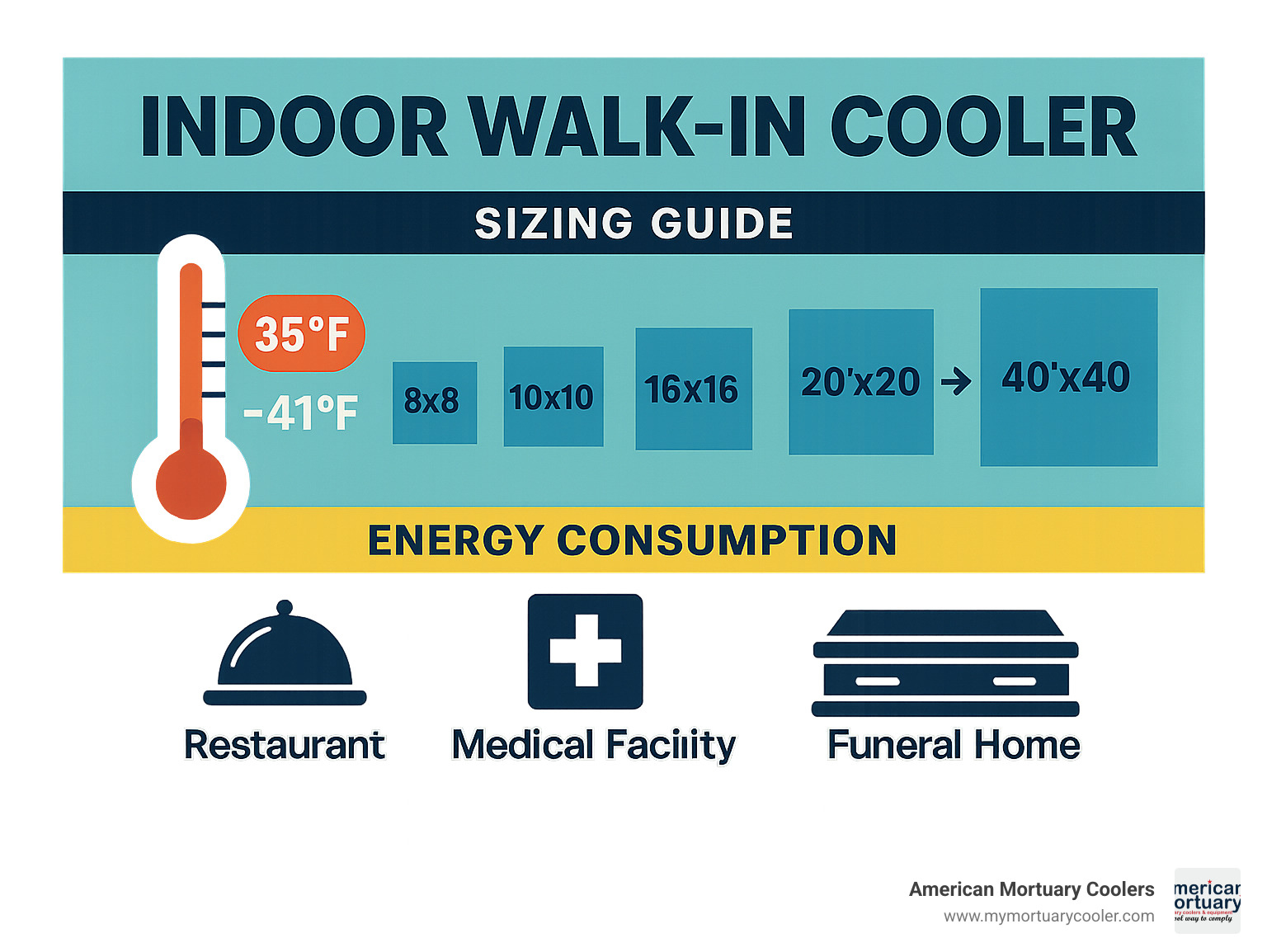

Key Features:

- Temperature Range: 35°F to 41°F (FDA maximum for commercial use)

- Standard Sizes: 8'×8' to 40'×40' with heights up to 28 feet

- Insulation: 4-inch thick urethane panels with R-29 rating

- Applications: Restaurants, grocery stores, hospitals, funeral homes, and laboratories

- Energy Efficiency: Modern units consume as little as 0.15 kWh per day

Whether you're storing food inventory, medical supplies, or temperature-sensitive materials, indoor walk-in coolers offer precise temperature control and easy access while protecting your products from spoilage. The FDA mandates that commercial refrigerated products stay at 41°F or lower, making these units not just convenient but legally required for many businesses.

Unlike outdoor units, indoor walk-in coolers protect your investment from weather damage and provide year-round accessibility. They're built with modular panels that can be customized to fit almost any space, from compact 68-square-foot units to massive warehouse-scale installations exceeding 1,600 square feet.

What Is an Indoor Walk-In Cooler?

An indoor walk in cooler is a professionally engineered cold storage room built inside your facility using modular insulated panels and commercial-grade refrigeration systems. Unlike outdoor coolers that battle weather conditions, indoor installations stay protected and provide better performance and longer equipment life.

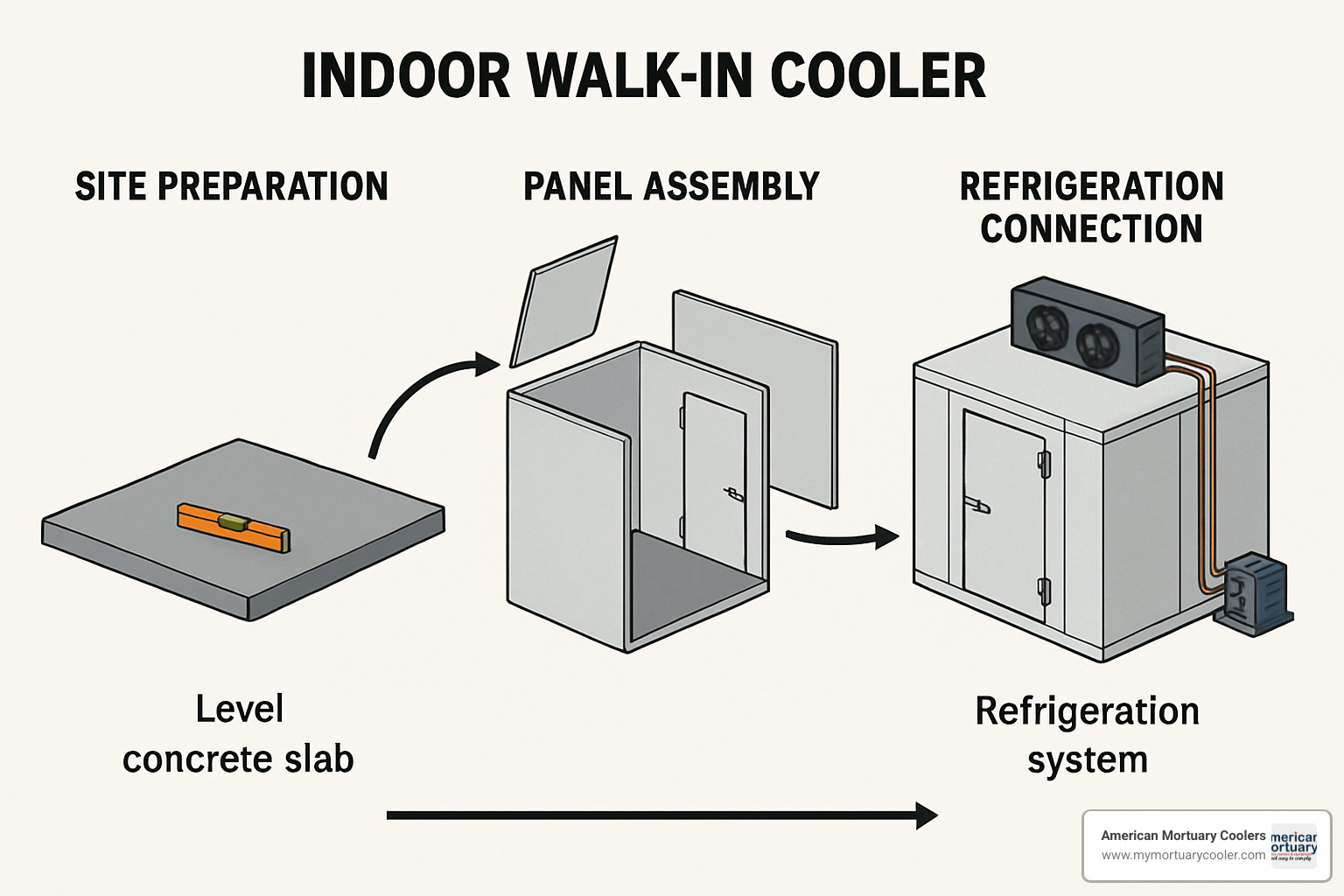

The construction uses modular insulated panels – typically 4 inches thick and filled with foamed-in-place urethane – that connect using cam-lock systems. These panels pack serious insulation power with R-values between 25-29, ensuring your cooling system operates efficiently.

What sets indoor coolers apart is their flexibility in condensing unit placement. You can install the condensing unit inside (with proper ventilation) or outside your building, depending on your space constraints and noise considerations.

For more detailed information about walk-in coolers and freezers, check out this comprehensive guide from Walk-in Coolers & Freezers | Comfort Experts Heating & Cooling.

How an Indoor Walk-In Cooler Works

Your indoor walk in cooler operates on the same basic principle as your home refrigerator – it moves heat from inside the cooler to outside. The compressor pressurizes refrigerant gas and pumps it to the condenser, which releases heat while converting refrigerant from gas to liquid.

The liquid refrigerant travels through an expansion valve, reducing pressure and temperature. This super-cooled refrigerant enters the evaporator coils inside your cooler, absorbing heat and evaporating back into gas before returning to the compressor.

The thermostat monitors temperature constantly, typically cycling on at 40°F and off at 35°F. The defrost cycle automatically melts ice buildup on evaporator coils, maintaining peak performance.

Ideal Temperature Range & Food-Safety Standards

The 38°F sweet spot represents the perfect balance between preservation and safety. The FDA's 41°F maximum is legally required for commercial food storage, but smart operators aim lower for better product protection.

| Food Category | Optimal Temperature | Maximum Safe Temp |

|---|---|---|

| Fresh Meat/Poultry | 32-36°F | 40°F |

| Dairy Products | 36-40°F | 41°F |

| Leafy Greens | 32-35°F | 40°F |

| Root Vegetables | 32-38°F | 41°F |

| Citrus Fruits | 38-42°F | 45°F |

Sizing, Layout & Customization Options

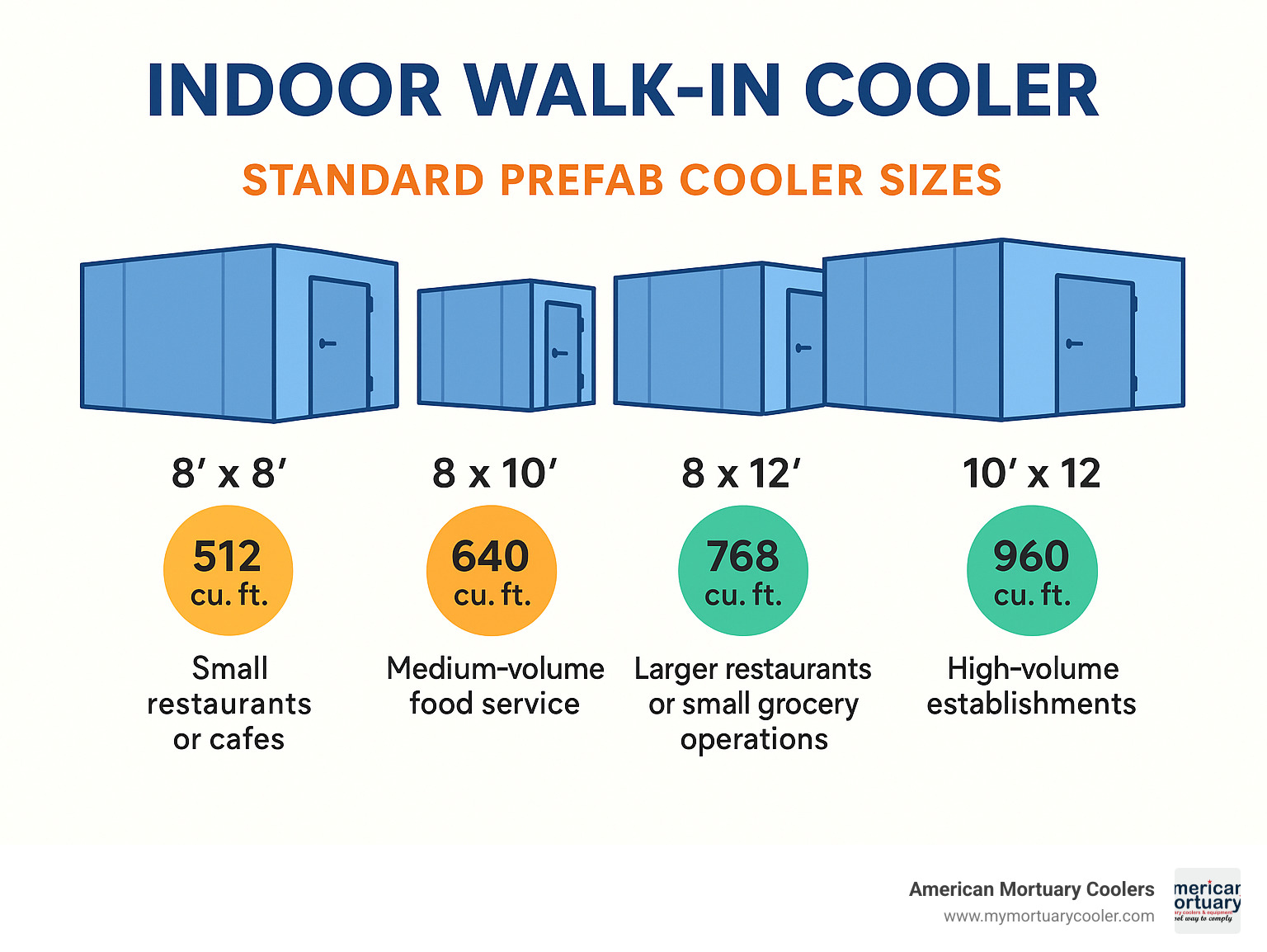

Finding the perfect size for your indoor walk in cooler requires balancing current needs with future growth. Walk-in coolers range from compact 68 square feet (8' x 8') to warehouse installations exceeding 1,600 square feet.

Most businesses find their sweet spot in standard sizes: 8' x 8' (64 sq ft) for small cafes, 8' x 10' (80 sq ft) for medium restaurants, 8' x 12' (95 sq ft) for larger operations, and 10' x 12' (120 sq ft) for high-volume establishments.

Height matters too. Standard units start at 8 feet tall, with custom options up to 28 feet for warehouse applications. You can choose floorless units (install on existing concrete) or floored units (complete insulation and moisture protection).

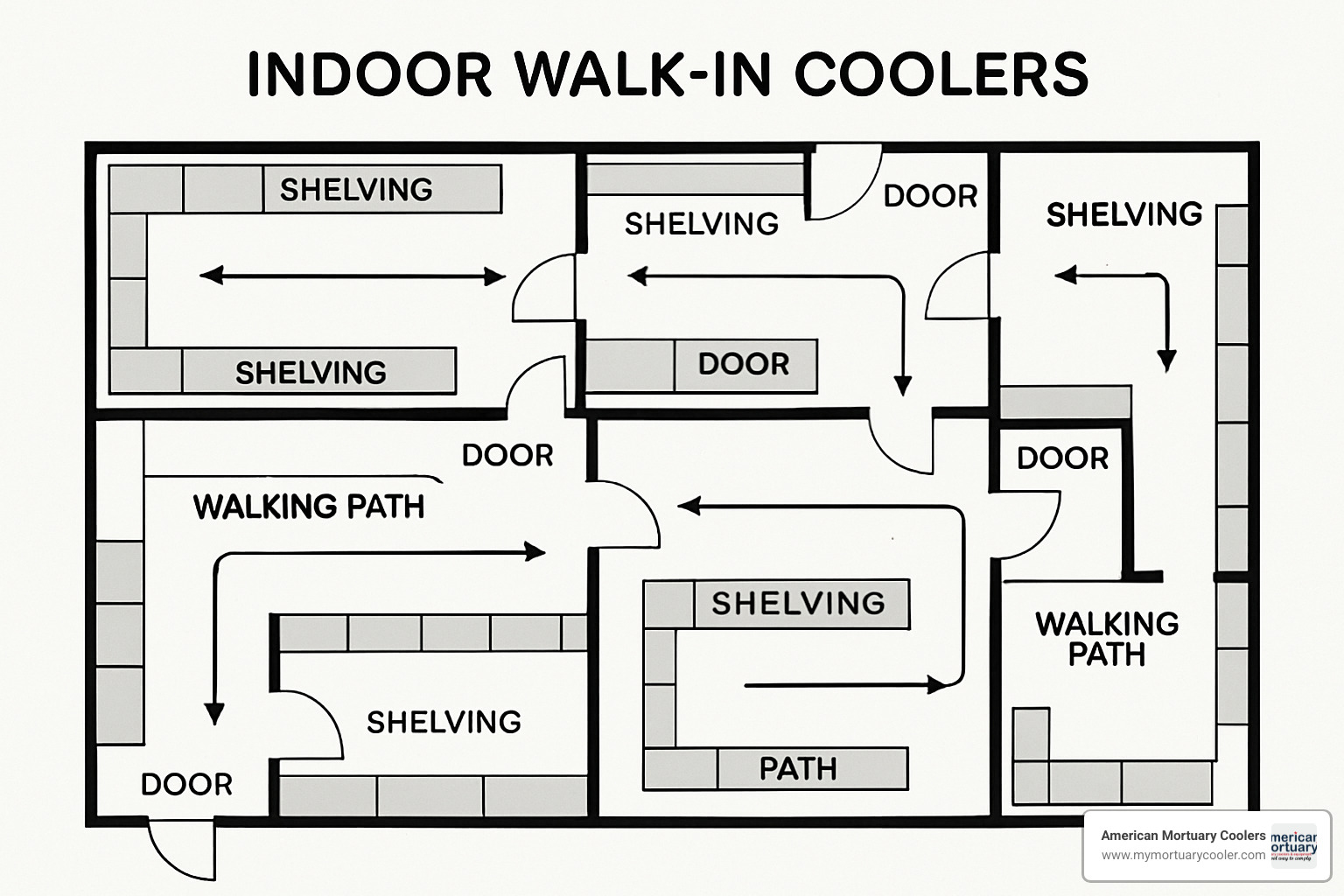

Customization options include door configurations (hinged up to 42 inches or sliding up to 10' x 10'), shelving systems (wire or solid), strip curtains for energy savings, LED lighting, and various finishes from stucco embossed to stainless steel.

Standard vs. Custom Indoor Walk-In Cooler Dimensions

Manufacturers offer prefabricated "quick-ship" units and fully custom solutions. Standard sizes like 8' x 8', 8' x 10', and 8' x 12' ship within days using modular panels with cam-lock connections.

Custom panels accommodate oddly shaped spaces, multiple access points, or specialized requirements. When calculating needs, plan for 1.5 to 2 cubic feet of cooler space per cubic foot of daily inventory turnover.

Popular Industry Applications

Restaurants typically use 8' x 10' to 10' x 12' units with wire shelving and strip curtains for quick access and easy cleaning. Breweries need custom heights and specialized racking for kegs and bottles. Florists prefer smaller units (6' x 8' to 8' x 10') with gentle air circulation. Laboratories demand precision monitoring and backup power considerations. Schools require large-scale storage for cafeteria operations. Funeral homes need custom solutions fitting existing layouts while maintaining accessibility.

Installation, Energy Efficiency & Compliance

Proper indoor walk in cooler installation starts with a level concrete slab accurate to within ¼ inch per 10 feet. Most units require 208-230V power with single or three-phase connections, handled by licensed electricians to maintain warranty validity.

Indoor condensers need 3 feet of clearance on all sides for proper airflow. Poor ventilation leads to premature equipment failure and high energy bills. Professional installation typically takes 1-2 days for standard units.

Certifications include UL listed components for electrical safety, NSF/ANSI 7 for food contact surfaces, ASTM E84 for flame spread ratings, and EISA compliance for energy efficiency standards.

Energy-Saving Components

Modern systems feature LED lighting (75% less energy than incandescent), EC fan motors (30% less energy with variable speed), high-efficiency condensers, and PVC strip curtains that prevent 20-30% cold air loss during door openings.

Remote condensing units reduce building HVAC load by moving heat-generating components outside your conditioned space.

Regulatory Certifications & Safety Features

Interior safety releases ensure anyone accidentally locked inside can exit immediately – required by most building codes. Door alarms alert when doors stay open too long, while temperature alarms trigger when internal temperatures exceed safe ranges.

Modern units include magnetic door gaskets, self-closing hinges, and vapor-proof lighting fixtures designed for humid refrigerated environments.

Operation, Maintenance & Cost of Ownership

Effective indoor walk in cooler operation requires smart daily habits and routine maintenance. Check temperatures twice daily with digital thermometers and maintain written logs for health department compliance. Keep backup analog thermometers for power outages.

Smart load management prevents overloading that restricts air circulation. Pre-cool new inventory when possible to avoid forcing your compressor to run constantly.

Quarterly maintenance includes gasket inspection (damaged seals double energy costs), condenser coil cleaning (dirty coils reduce efficiency 20-30%), and drain line checks to prevent clogs and mold growth.

Routine Cleaning & Sanitization

Use eco-friendly, food-safe cleaners on NSF/ANSI 7 certified surfaces. Clean drain lines monthly to prevent standing water and bacteria growth. Pay special attention to door gaskets using soft brushes and mild detergent.

Maintain cleaning documentation alongside temperature records for health inspections. Use mild detergent solutions on panels – never harsh abrasives that could damage protective finishes.

Warranty Coverage & Support Options

Quality systems include 20-year panel coverage, 5-year compressor protection, comprehensive door warranties, and one-year parts and labor coverage. Extended warranties and service contracts provide additional peace of mind.

Keep warranty documentation organized – proper records can mean the difference between covered repairs and expensive out-of-pocket expenses. Remote diagnostics in newer systems allow technicians to troubleshoot problems without expensive service calls.

Buying Tips, Financing & Common Mistakes

Purchasing an indoor walk in cooler requires careful planning beyond current needs. Consider projected growth over 3-5 years – upgrading later costs more than buying the right size initially.

Space planning involves more than measurements. Consider door swing radius (need 3 feet clearance), workflow patterns, and heat load calculations that factor ambient temperature, door openings, and product loads.

Don't forget permitting requirements – building permits, electrical permits, and health department approvals take time and money. Factor these into your timeline and budget.

Common expensive mistakes include undersizing to save money upfront, ignoring growth projections, skipping permits, attempting DIY installation, and failing to plan for maintenance needs.

New vs. Used Indoor Walk-In Coolers

Used units save 40-60% but require careful evaluation. Inspect panel condition, refrigeration systems, door hardware, and electrical components. Request maintenance records and warranty information.

Reconditioned units from reputable dealers cost 20-30% less than new while providing greater reliability than unserviced used equipment. Consider resale value if you might relocate or upgrade.

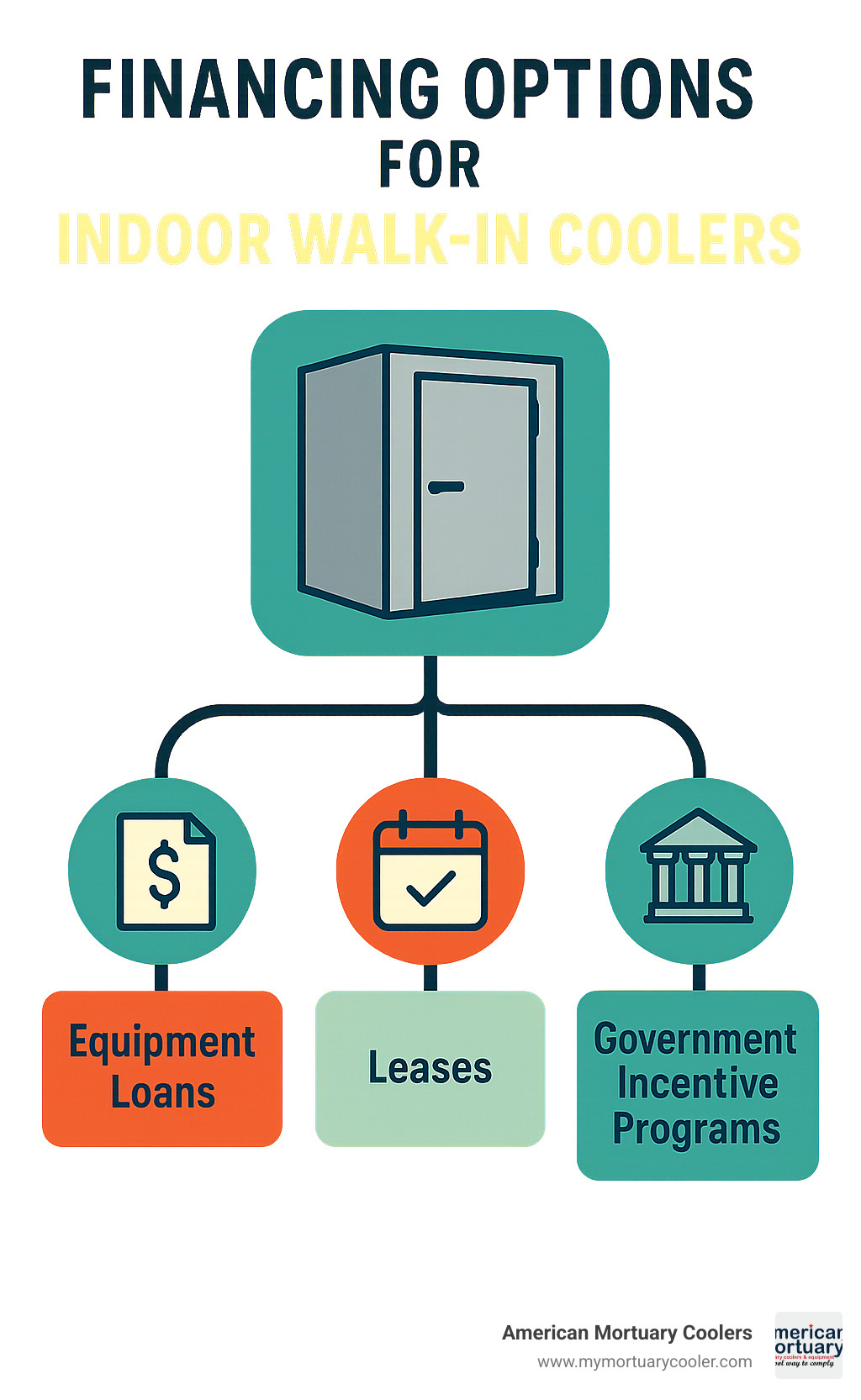

Financing & Incentive Programs

Equipment financing often offers better terms than general business loans. Options include equipment loans, leasing with upgrade flexibility, and SBA loans for qualified small businesses.

The Section 179 tax deduction allows full purchase price deduction in the year of purchase. Don't overlook utility rebates for ENERGY STAR equipment and state grants for energy-efficient refrigeration.

Evaluate total cost of ownership including purchase price, financing costs, energy consumption, and maintenance expenses over the unit's 15-20 year lifespan.

Frequently Asked Questions about Indoor Walk-In Coolers

What is the standard temperature for an indoor walk in cooler?

38°F is your target temperature for most applications, providing the perfect balance between food safety and preventing accidental freezing. The FDA sets the legal maximum at 41°F for commercial refrigeration, but staying a few degrees below gives you a crucial safety buffer for normal temperature fluctuations.

Most indoor walk in cooler systems cycle between 35°F and 40°F automatically. Have temperature sensors checked annually – sensors off by 2-3 degrees can put inventory at risk or cause energy waste.

How much space do I need for an indoor walk in cooler?

The minimum practical footprint is 8' x 8' (64 square feet). Plan for 18 inches of ceiling clearance above your cooler and 3 feet of clearance around indoor condensing units for adequate airflow.

Don't forget the door swing radius – a standard 36-inch door needs about 4 feet of clear space to open fully. Position your cooler where staff can access it efficiently without creating workflow bottlenecks.

Can I install an indoor walk in cooler myself or do I need a pro?

Professional installation by a licensed refrigeration contractor is essential. Warranty validity often depends on professional installation, and mistakes can void coverage worth thousands of dollars.

Installation involves electrical connections meeting local codes, refrigerant handling requiring EPA certification, and building code compliance. Licensed contractors have proper tools, experience, and insurance to handle complications. Professional installation typically costs 10-15% of the total project – a small price for proper operation and peace of mind.

Conclusion

Finding the perfect indoor walk in cooler becomes straightforward when you understand the key factors: proper sizing, quality components, professional installation, and regular maintenance. Modern walk-in coolers offer exceptional long-term value with 20-year panel warranties and 5-year compressor coverage, plus energy-saving features that keep operating costs low.

Every business has unique needs, and that's something we understand at American Mortuary Coolers. Our experience serving clients from Tennessee to Atlanta, Chicago, and beyond has taught us that the right cooler makes all the difference – whether you're running a restaurant kitchen, managing laboratory samples, or operating a funeral home requiring specialized storage solutions.

Success comes from matching the right equipment to your specific situation. Your indoor walk in cooler isn't just equipment – it's the foundation of your food safety program, protector of valuable inventory, and often key to passing health inspections. When you invest in quality and plan carefully, you're setting your business up for years of trouble-free operation.

For more detailed information about indoor solutions and custom equipment for your specific needs, visit mymortuarycooler.com. Our team provides custom solutions with direct delivery across all 48 contiguous states, because your business deserves equipment that fits perfectly.

The right walk-in cooler represents an investment in your business's future, compliance with safety regulations, and daily operational efficiency. Take time with planning, work with experienced professionals, and choose components built to last.