Understanding Hydraulic Lifts: The Foundation of Modern Material Handling

Hydraulic lifts are powerful mechanical devices that use pressurized fluid to raise and lower heavy loads with precision and safety. These systems operate on Pascal's law, which states that pressure applied to an incompressible fluid is transmitted equally in all directions - allowing a small force to lift much larger weights through force multiplication.

Quick Answer for Hydraulic Lifts:

- What they are: Lifting devices powered by pressurized hydraulic fluid (usually oil)

- How they work: Electric pump pushes oil into cylinder, forcing piston up to lift load

- Main types: Holed, hole-less, scissor, platform, vehicle, and specialized lifts

- Best for: Buildings up to 7 stories, heavy loads up to 6,000+ lbs, cost-effective installations

- Speed limit: Maximum 150 feet per minute

- Key advantage: No risk of free-fall due to trapped oil system

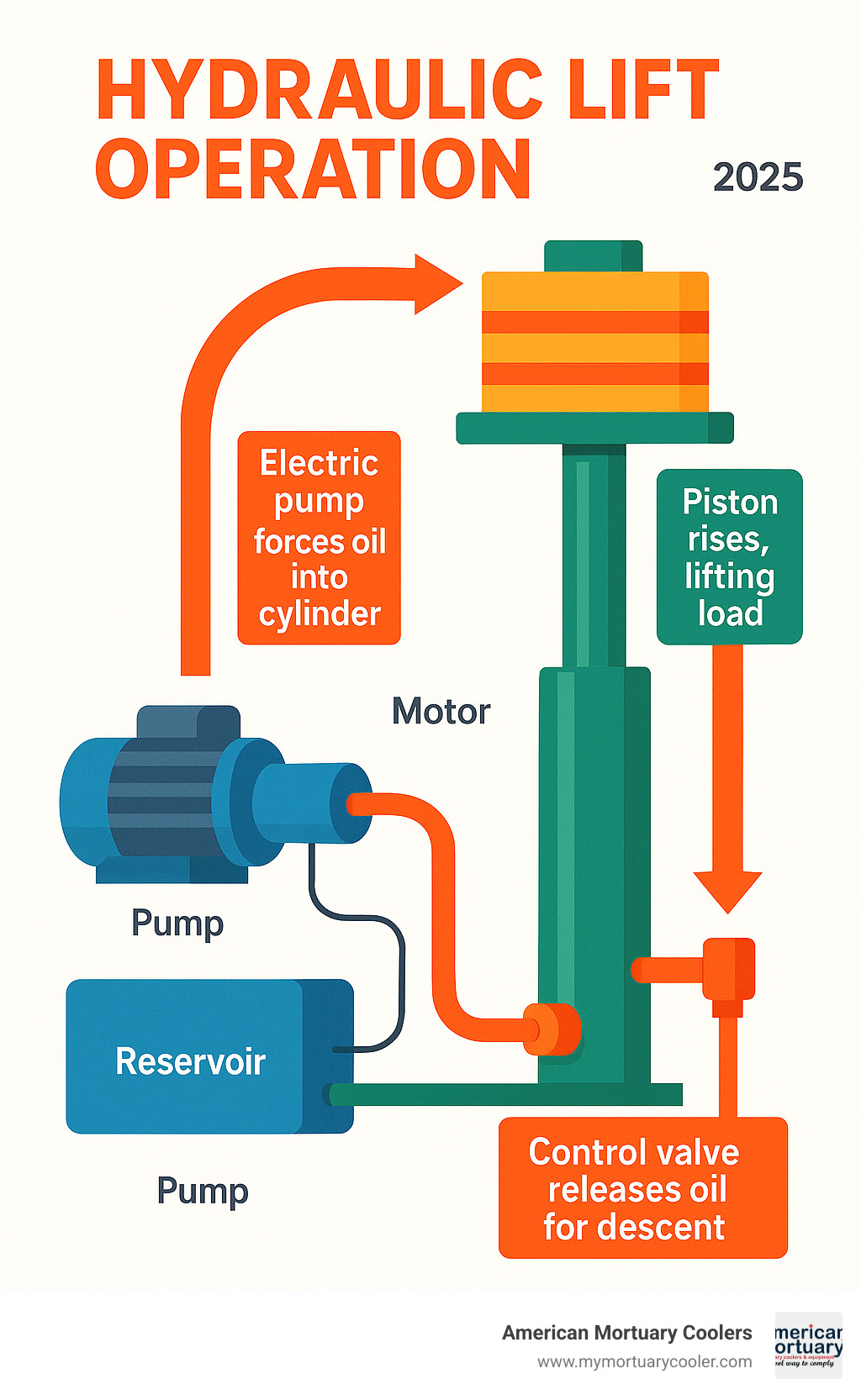

The basic operation involves an electric motor powering a pump that forces hydraulic oil into a cylinder. This pressurized oil pushes a piston upward, lifting the load. When descending, a control valve releases the oil back to a reservoir, allowing gravity to lower the load in a controlled manner.

Hydraulic lifts are found everywhere - from passenger elevators in low-rise buildings to forklifts in warehouses, vehicle lifts in auto shops, and specialized equipment in funeral homes and mortuaries. They're particularly valued for their ability to handle heavy loads safely while requiring less installation space than other lift types.

Hydraulic lifts terms at a glance:

Why Learn About Hydraulic Lifts?

Understanding hydraulic lifts is crucial for facility management and specialized applications like mortuary services. These systems offer superior efficiency in material handling, dramatically reducing manual labor and injury risks. The ergonomic benefits alone make them indispensable - workers no longer need to strain their backs lifting heavy items.

Industry adoption continues to grow across sectors. From manufacturing plants using scissor lifts for assembly work to funeral homes implementing specialized cadaver lifts, hydraulic systems have become the backbone of modern material handling.

How Hydraulic Lifts Work (Primary Keyword)

Hydraulic lifts operate on simple principles - they're essentially giant syringes that can lift thousands of pounds with ease. At the core of every system, you'll find a pump and motor working together, pressurizing hydraulic oil and sending it into a cylinder where a piston does the heavy lifting.

The electric motor spins up the pump, which grabs oil from a reservoir and squeezes it under tremendous pressure into the hydraulic cylinder. As that pressurized oil rushes in, it forces the piston upward with incredible force.

The real magic happens through force multiplication - this is where Pascal's principle shines. A relatively small pump can generate enormous lifting power because hydraulic pressure spreads equally throughout the system.

Valve control keeps everything running smoothly. Modern hydraulic lifts use sophisticated control valves that regulate oil flow, ensuring smooth operation instead of jerky movements. These valves can be operated manually or controlled electronically for pinpoint positioning.

You'll encounter two main setups: traditional machine-room systems and newer Machine Room-Less (MRL) designs. Traditional systems keep the pump, motor, and controls in a separate room, while MRL systems tuck everything right into the hoistway to save space.

Pressure sensors act like the system's nervous system, constantly monitoring performance and ready to trigger safety shutoffs if something goes wrong.

Here's something really cool about hydraulic lifts - they're incredibly safe during power failures. Unlike cable elevators that might suddenly drop, hydraulic systems provide controlled descent. The oil trapped in the cylinder acts like a solid support column, and a special valve can slowly release pressure to bring the lift down safely.

For the science-minded folks, you can dive deeper into Pascal's principle to understand exactly how force multiplication works in hydraulic systems.

Upward Movement Cycle

When it's time to go up, the electric motor kicks the hydraulic pump into action. The pump creates suction at its inlet, drawing oil from the reservoir. Then it pressurizes that oil and forces it through supply lines straight into the hydraulic cylinder.

As the pressurized oil enters the cylinder, it pushes against the piston with tremendous force. The force multiplication is impressive - imagine a 2-inch piston paired with a 6-inch piston giving you ninefold force multiplication. That means 100 pounds of force on the small piston can lift 900 pounds on the larger one.

Check valves work like one-way doors in the system, preventing oil from flowing backward and keeping your lift exactly where you want it.

Downward & Emergency Descent

Coming down is where gravity becomes your friend. The system opens a control valve that lets the pressurized oil flow back to the reservoir. The weight of the load helps push the oil out of the cylinder, but the valve carefully controls the flow rate to ensure smooth, controlled descent.

The trapped oil safety feature is one of the best things about hydraulic lifts. Even if the power goes out completely, that oil stays trapped in the cylinder, preventing any chance of free-fall. There's even a special emergency valve that can be operated manually to slowly release pressure.

Main Components Explained

Every hydraulic lift system has several key components working together. The reservoir serves as home base for the hydraulic fluid when it's not busy lifting things. It often includes filters to keep the oil clean.

Hydraulic fluid selection can make or break your system's performance. Most setups use mineral oil because it's reliable and cost-effective, but environmental concerns have pushed many operators toward biodegradable alternatives like vegetable oils and synthetic polyalphaolefin (PAO) fluids.

Safety components work behind the scenes. Velocity fuses automatically stop oil flow if the lift starts descending too quickly. Guide rails keep everything aligned and prevent platform swaying. Pressure relief valves protect against dangerous over-pressurization.

Types and Applications of Hydraulic Lifts

The world of hydraulic lifts is surprisingly diverse, with specialized designs created to solve specific lifting challenges across countless industries. From simple platform lifts to massive vehicle lifts, these systems have adapted to meet virtually every lifting need.

Holed hydraulic lifts represent the traditional approach that's been around for decades. These systems require digging a deep pit - called a jackhole - that extends into the ground by the same distance the lift travels upward. While this means more excavation work during installation, it allows these lifts to reach impressive heights of up to 60 feet.

Hole-less systems took a different approach to solve the excavation problem. Instead of burying the hydraulic cylinder underground, these designs use telescopic jacks mounted above ground. This design makes installation much simpler and eliminates worry about underground oil leaks, though it typically limits travel to around 20-30 meters.

Roped hydraulic lifts offer an interesting hybrid solution. They combine cables with hydraulic pistons to extend travel beyond what hole-less systems can achieve - up to 60 feet like holed systems but without requiring that deep pit.

Scissor lifts work on a completely different principle, using hydraulic cylinders to extend crossed support arms that raise the platform. These workhorses are everywhere in warehouses, construction sites, and maintenance operations. Platform lifts serve the important purpose of helping people with mobility challenges steer height differences safely.

In automotive shops, vehicle lifts use hydraulic power to raise everything from compact cars to massive commercial trucks. Mortuary lifts represent a specialized application that helps funeral home staff safely handle bodies and caskets, dramatically reducing workplace injury risks.

The applications seem endless: aerial work platforms for construction work, forklifts moving materials in warehouses, vertical reciprocating conveyors (VRCs) transporting goods between floors, and even theme park rides that rely on hydraulic systems for smooth, controlled movements.

Holed vs Hole-less Hydraulic Lifts (Primary Keyword)

Choosing between holed and hole-less hydraulic lifts often feels like choosing between a basement and a ground-floor installation - each has distinct advantages depending on your situation.

Holed systems require excavating a jackhole that extends below ground level to house the hydraulic cylinder. This deep jack design has been the industry gold standard for decades because it allows for maximum travel height and provides excellent stability.

But that excavation requirement can turn into a real headache. Urban installations often run into underground utilities, solid rock formations, or high water tables that make deep drilling expensive or sometimes impossible. There's also the long-term concern about soil leakage risk.

Hole-less systems solve these problems by using telescopic jacks installed entirely above ground. Since all components remain accessible, inspection and maintenance become much easier.

The main trade-off comes down to travel limits. While holed systems can reach up to 60 feet of travel, hole-less systems typically max out around 20-30 meters.

Scissor & Table Lifts in Material Handling

Scissor lifts have become the unsung heroes of workplace safety, changing how we think about material handling. These ergonomic tables can position materials at the perfect height for workers, eliminating the repetitive bending and lifting that leads to so many back injuries.

Dock lifts represent a specialized scissor application that solves a common logistics headache. These systems bridge the gap between truck beds and loading docks, accommodating trucks of varying heights.

For operations looking to eliminate electrical connections while maintaining full lifting capabilities, battery-powered options offer excellent flexibility. We've detailed these advantages in our comprehensive guide to battery lift tables.

Specialized Mortuary & Cadaver Lifts

In the funeral industry, hydraulic lifts serve a critical dual purpose: protecting workers while maintaining dignity in body handling. Mortuary lifts help transfer bodies between preparation tables, storage racks, and transport vehicles without requiring multiple staff members to manually lift heavy loads.

Crematory scissor lifts face unique challenges, requiring heat-resistant materials and precise positioning capabilities. Body transport systems feature specialized stretcher interfaces and precise height adjustment to align with various equipment heights.

The selection process for these specialized systems involves many considerations beyond basic lifting capacity. We've covered this complex selection process thoroughly in our guide to mortuary lifts, helping funeral directors steer these important decisions with confidence.

Advantages vs. Disadvantages of Hydraulic Lifts

Hydraulic lifts aren't perfect, but they're pretty close for many applications. After years of helping funeral homes and businesses choose the right lifting equipment, I've seen how these systems can transform operations when matched correctly to their intended use.

The cost-effectiveness of hydraulic systems is their biggest selling point, especially for buildings up to five floors. You're looking at significantly lower installation and maintenance costs compared to traction elevators.

Heavy load capacity is where these systems really shine. We're talking about lifting 6,000 pounds or more - that's serious capability. The compact shaft requirement is a game-changer for many facilities. Hydraulic lifts need about 10% less shaft area than other elevator types, which means more usable space for your building.

Simple evacuation procedures make these systems particularly appealing for funeral homes where dignity and calm are essential. There's no dangerous counterweight overhead, and the trapped oil system means no sudden drops during power outages. In earthquake-prone areas, this seismic safety advantage becomes even more important.

But let's talk about the limitations honestly. Slower speed is the big one - you're capped at 150 feet per minute. Heat build-up can occur during heavy use cycles, though modern systems handle this well with proper maintenance.

Oil leaks are the environmental concern that keeps some facility managers up at night. While rare with proper installation and maintenance, underground leaks can contaminate soil and groundwater. The good news? Modern hole-less systems and biodegradable fluids have largely solved this problem.

Energy usage tends to run higher than traction systems, particularly if you're cycling frequently. Each lift operation requires pressurizing the entire system, which adds up on your electric bill over time.

Key Benefits at a Glance

The lower install cost makes hydraulic lifts accessible for facilities that couldn't otherwise afford lifting equipment. Flexible machine room placement is pure gold for retrofit projects. Seismic safety gives everyone peace of mind, especially in earthquake country.

Common Limitations to Consider

The 150 fpm speed cap isn't just a number on a spec sheet - it's a real operational consideration. ≤7 floors represents the practical height limit for most hydraulic installations. 10 cycles/hr and 100 cycles per day limitations matter more than you might think. Energy usage considerations become important for high-frequency operations.

Safety, Maintenance & Environmental Best Practices

Working with hydraulic lifts safely starts with proper training. Your operators need to understand not just the basics of running the equipment, but what to do when things go wrong.

OSHA and ANSI standards aren't just bureaucratic paperwork - they're your roadmap to keeping people safe. OSHA Standard 1926.451 covers the guardrail systems and fall protection that can save lives, while ANSI A92 spells out everything from design requirements to daily operation procedures.

One of the smartest safety features in modern hydraulic lifts is the velocity fuse. Think of it as an automatic emergency brake that kicks in if your lift starts dropping too fast. Regular inspections are like going to the doctor for checkups - boring but essential.

Oil quality matters more than you might think. Dirty or degraded hydraulic fluid is like putting sludge in your car's engine - it's going to cause expensive damage. Here's something that keeps me up at night: pinhole leaks in hydraulic lines. These create nearly invisible high-pressure streams that can punch right through skin and cause serious injury. Never use your bare hands to check for leaks - always use cardboard or wood to safely detect those dangerous fluid jets.

Essential Safety Features

Modern hydraulic lifts come packed with safety features that work behind the scenes to protect everyone. Interlocks are like digital bouncers - they won't let the system operate unless all safety conditions are met. Pressure relief valves act as safety pop-offs, automatically releasing excess pressure before it can burst hydraulic lines. Dead-man controls require constant operator attention to keep things running.

Preventive Maintenance Schedule

Monthly visual checks should become as routine as checking your oil. Look for leaks, listen for unusual noises, and watch for jerky or erratic operation. Annual fluid changes keep your system running smoothly and extend its life. Five-year hose replacement might seem excessive, but hydraulic hoses deteriorate from the inside out.

For additional safety resources and training materials, check out the Business Safety Portal - it's packed with practical guidance for keeping your workplace safe.

Greener Hydraulic Fluids & Spill Response

Environmental responsibility doesn't have to hurt your bottom line. Vegetable-based hydraulic oils offer excellent biodegradability and come from renewable sources. Polyalphaolefin (PAO) synthetic fluids represent the cutting edge of environmentally conscious hydraulic technology.

Spill response planning is like having a fire extinguisher - you hope you'll never need it, but you'll be grateful it's there if you do. Keep absorbent kits designed specifically for hydraulic fluids wherever your equipment operates.

Choosing the Right Hydraulic Lift for Your Facility

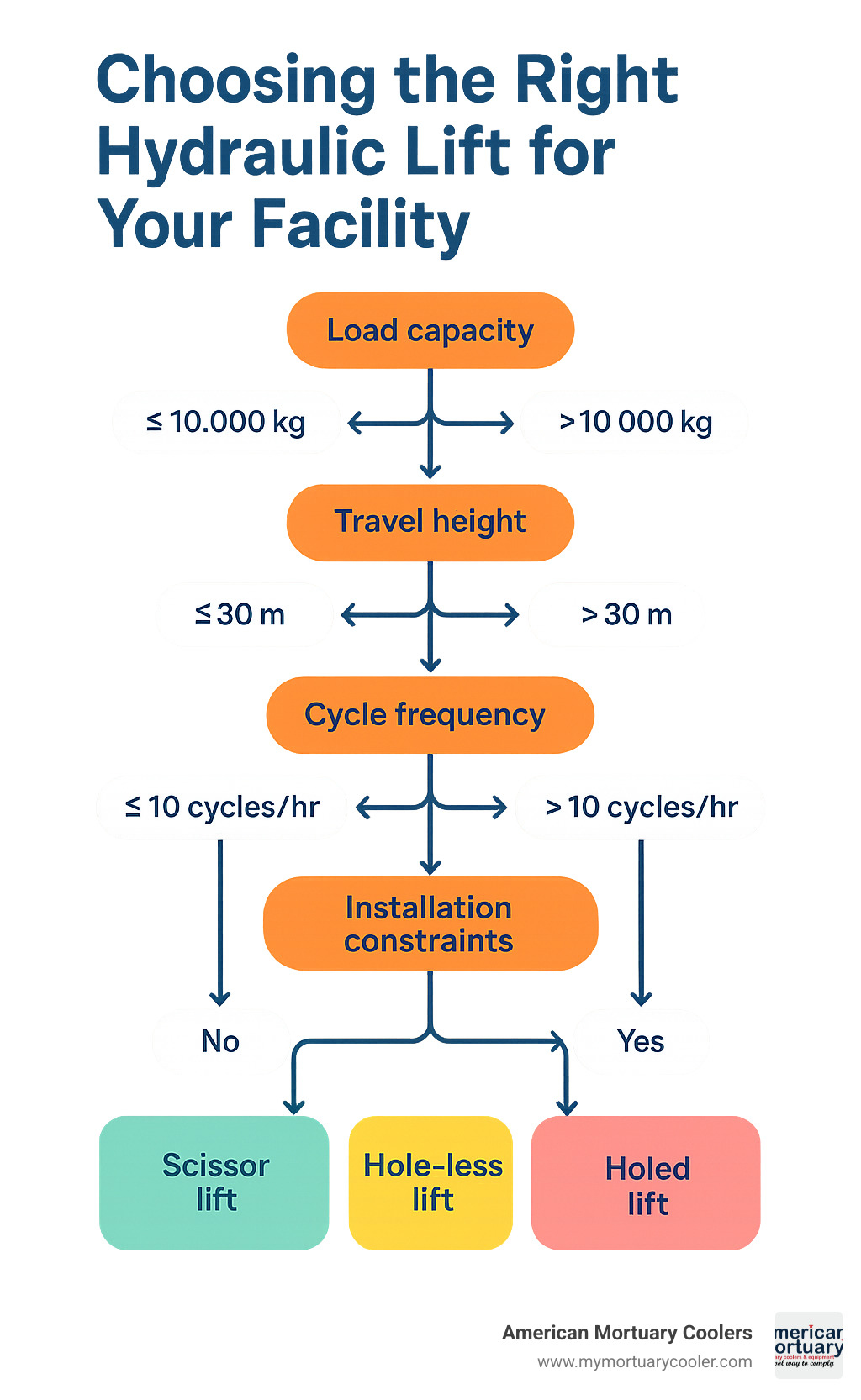

Finding the perfect hydraulic lift for your facility doesn't have to feel overwhelming. Think of it like buying a truck - you need to know what you're hauling, how far you're going, and how often you'll use it.

Load capacity is your starting point. Don't just consider the weight you're lifting today - think about future needs too. Always build in a safety margin for dynamic forces during movement.

Travel height quickly narrows your options. If you need less than 30 meters of lift, hole-less systems offer simpler installation and lower leak risks. Need to go higher? You'll likely need a holed system, despite the extra excavation costs.

Cycle frequency is where many buyers stumble. Hydraulic lifts shine for intermittent use but struggle with constant operation. If you're planning more than 10 cycles per hour, mechanical systems might serve you better.

Indoor versus outdoor installation affects everything from component materials to control systems. Budget planning goes beyond the sticker price. Compliance codes can make or break your project.

Your vendor selection checklist should prioritize local service availability over rock-bottom pricing. The best hydraulic lift in the world becomes worthless if you can't get parts or service when problems arise.

Decision Matrix for Building Owners

The holed vs hole-less debate often comes down to your specific site conditions. Got rocky soil or high water tables? Hole-less systems eliminate excavation headaches. Need maximum travel height? Holed systems deliver the performance despite installation complexity.

Hydraulic versus mechanical systems each have their sweet spots. Retrofit limitations often favor hydraulic systems. Older buildings rarely have the overhead space or structural support needed for traction elevators.

Mortuary-Specific Considerations

Funeral homes have unique needs that standard industrial lifts simply can't address. Rack alignment must be absolutely precise. Stretcher interface compatibility matters enormously. Ceiling height restrictions in older funeral homes often eliminate standard lift options.

At American Mortuary Coolers, we've seen how properly selected hydraulic lifts transform funeral home operations. We've documented this impact extensively in our analysis of how mortuary scissor lifts reduce workers' comp claims, showing real-world results from funeral homes across the country.

Frequently Asked Questions about Hydraulic Lifts

When I talk with facility managers and funeral directors about hydraulic lifts, the same questions come up again and again. Let me share the answers to the most common concerns I hear.

What hydraulic fluid should I use?

The hydraulic fluid you choose can make or break your system's performance. Mineral oil remains the gold standard for most hydraulic lifts because it lubricates beautifully and won't break your budget. You'll want to stick with ISO 32 or ISO 46 viscosity grades for most applications.

Environmental considerations have pushed many facilities toward greener options. Vegetable-based oils and synthetic esters break down naturally if they leak. Polyalphaolefin (PAO) synthetics represent the premium option. They handle temperature extremes better and last longer between changes.

Temperature range matters more than most people realize. If your lift operates in an unheated warehouse that drops below freezing, you'll need a low-temperature fluid. Hot environments like crematoriums require thermally stable formulations.

How do hydraulic lifts compare to mechanical lifts in cost?

Installation costs definitely favor hydraulic lifts, especially for buildings under seven stories. The simpler installation process means fewer headaches and a smaller upfront investment.

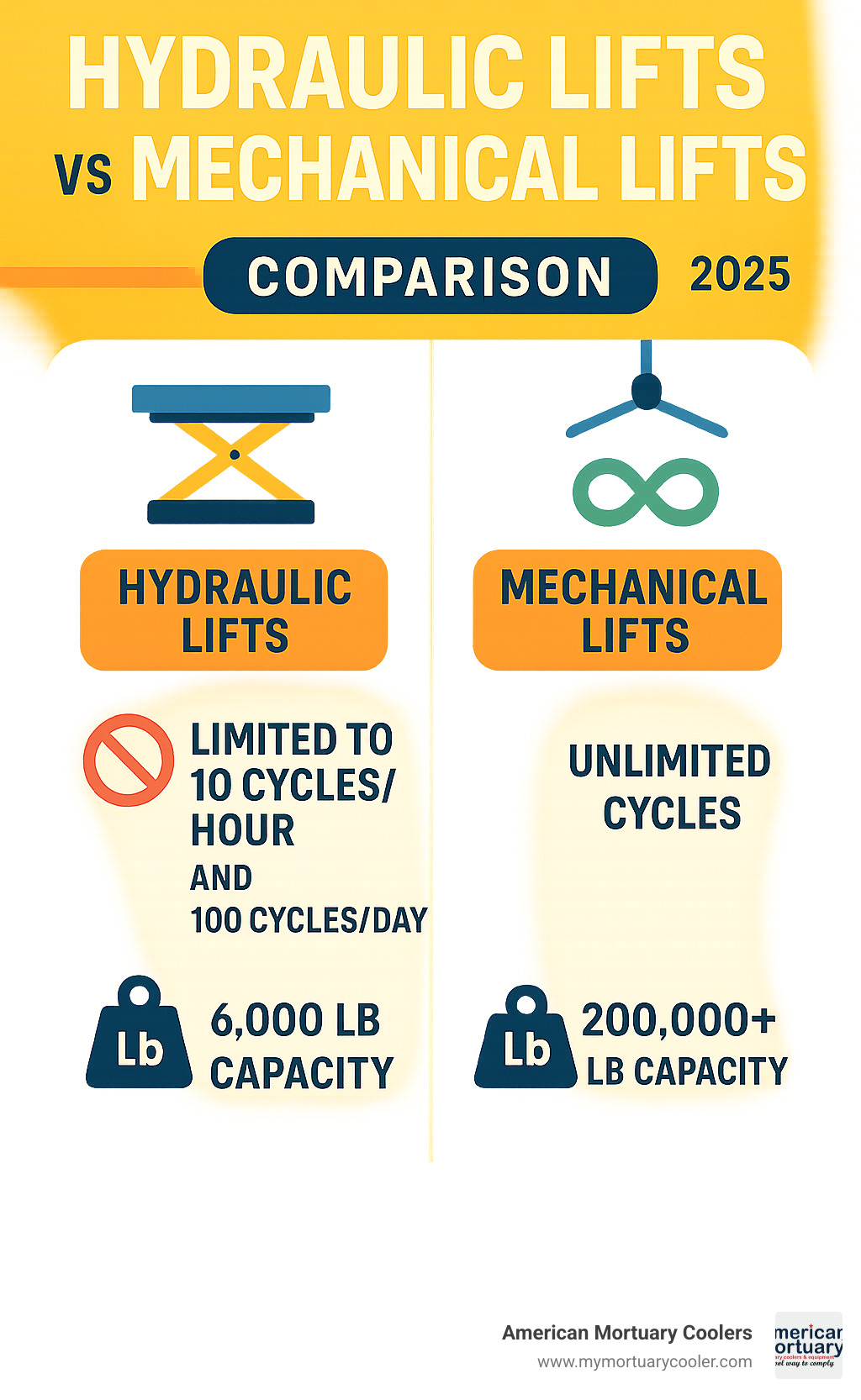

But lifetime costs tell a different story. Hydraulic lifts have built-in limitations that mechanical systems don't face. We're talking about 10 cycles per hour and 100 cycles per day maximums for most hydraulic systems.

Mechanical lifts can run continuously, handle loads over 200,000 pounds (compared to about 6,000 pounds for most hydraulic systems), and keep going day after day.

The sweet spot for hydraulic lifts is intermittent use with moderate loads - exactly what most funeral homes and smaller facilities need.

What codes govern hydraulic lift safety?

ASME A17.1 covers the big picture for passenger and freight elevators, including hydraulic systems. ASME B20.1 steps in for specialized equipment like vertical reciprocating conveyors (VRCs) and material lifts. European installations follow EN-81.2 standards.

OSHA regulations add another layer, particularly OSHA 1926.451 for guardrail systems and OSHA 1910.29 for personal protective equipment requirements. The key is working with qualified installers who know these codes inside and out.

Conclusion

Hydraulic lifts have earned their place as workhorses of modern material handling. After decades of proven performance, these systems continue to solve lifting challenges across countless industries - from busy warehouses to quiet funeral homes.

The beauty of hydraulic technology lies in its reliability. When you understand Pascal's law and how pressurized oil creates lifting force, you gain confidence in operating these systems safely. That trapped oil isn't just sitting there - it's your safety net, preventing the free-fall accidents that can happen with other lift types.

Safe operation starts with choosing the right system for your needs. A hydraulic lift handling 50 cycles per day will serve you well for years. Try to push it to 200 cycles daily, and you'll face premature wear and costly repairs.

Informed selection means looking beyond the attractive upfront costs. Yes, hydraulic lifts often cost less to install than mechanical systems. But factor in your usage patterns, maintenance requirements, and energy costs over 10-15 years.

The future looks bright for hydraulic technology. Smarter pump controls are reducing energy consumption, while biodegradable fluids address environmental concerns. Predictive maintenance systems now monitor oil quality and component wear, preventing failures before they happen.

Here at American Mortuary Coolers, we've seen how the right hydraulic lift transforms funeral home operations. Instead of three staff members straining to move a casket, one person operates a lift safely and efficiently. Workers' compensation claims drop. Staff retention improves.

Our custom mortuary hydraulic solutions reflect 15+ years of understanding funeral industry needs. Whether you're in Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, or Pennsylvania, we deliver systems designed specifically for your space and workflow.

The key is matching the technology to your reality. Standard material handling lifts work great for pallets and boxes. Mortuary applications need different considerations - precise alignment, sanitary surfaces, quiet operation, and integration with existing equipment.

Every funeral home director we work with has unique challenges. Limited ceiling height in older buildings. Tight budgets after recent renovations. Staff concerns about learning new equipment. We address these concerns with custom solutions that fit your specific situation.

Ready to explore how hydraulic lifts can improve your operations? Visit our website to see our full range of mortuary equipment and cooling solutions. We're here to help you find the perfect balance of safety, efficiency, and cost-effectiveness for your facility.