Why Rollerbed Floors Are Changing Loading Operations

A rollerbed floor is a pneumatic or mechanical system that uses retractable rollers to move heavy cargo without forklifts. Here's what you need to know:

Key Features:

- Pneumatic rollers that rise and fall on command

- Single-operator control from a pendant or control box

- Load capacity up to 30 tonnes or 250 lbs per roller

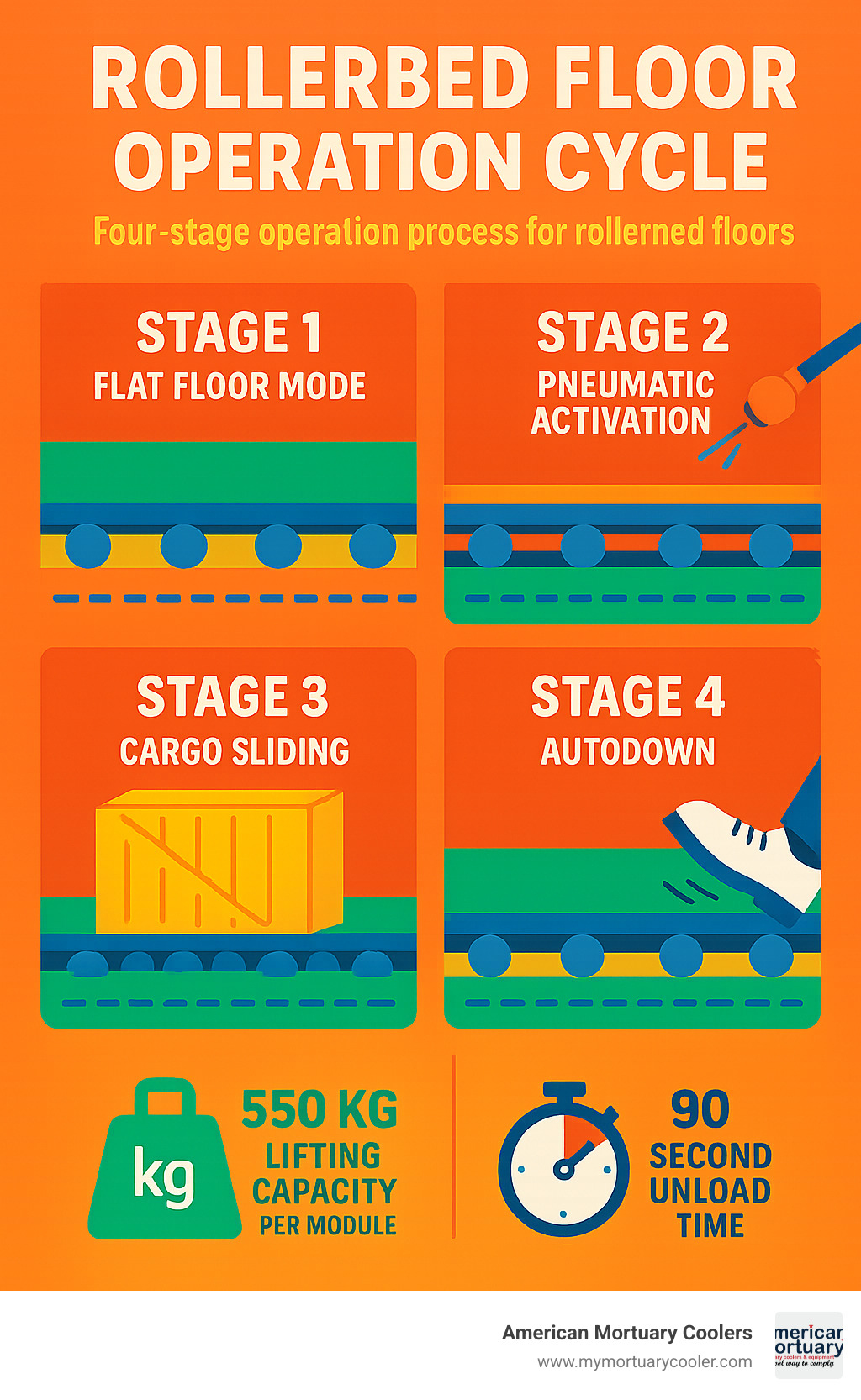

- 90-second unloads in high-volume applications

- Autodown safety that lowers rollers when brakes are applied

Main Types:

- Built-in systems (permanent installation)

- Modular systems (removable, transferable)

- Portable systems (temporary conversion)

If you've ever watched a forklift operator spend 30-60 minutes unloading a trailer, you'll understand why rollerbed floors are gaining popularity. These systems can unload a full trailer in as little as 90 seconds - changing what used to be an hour-long process into a quick, safe operation.

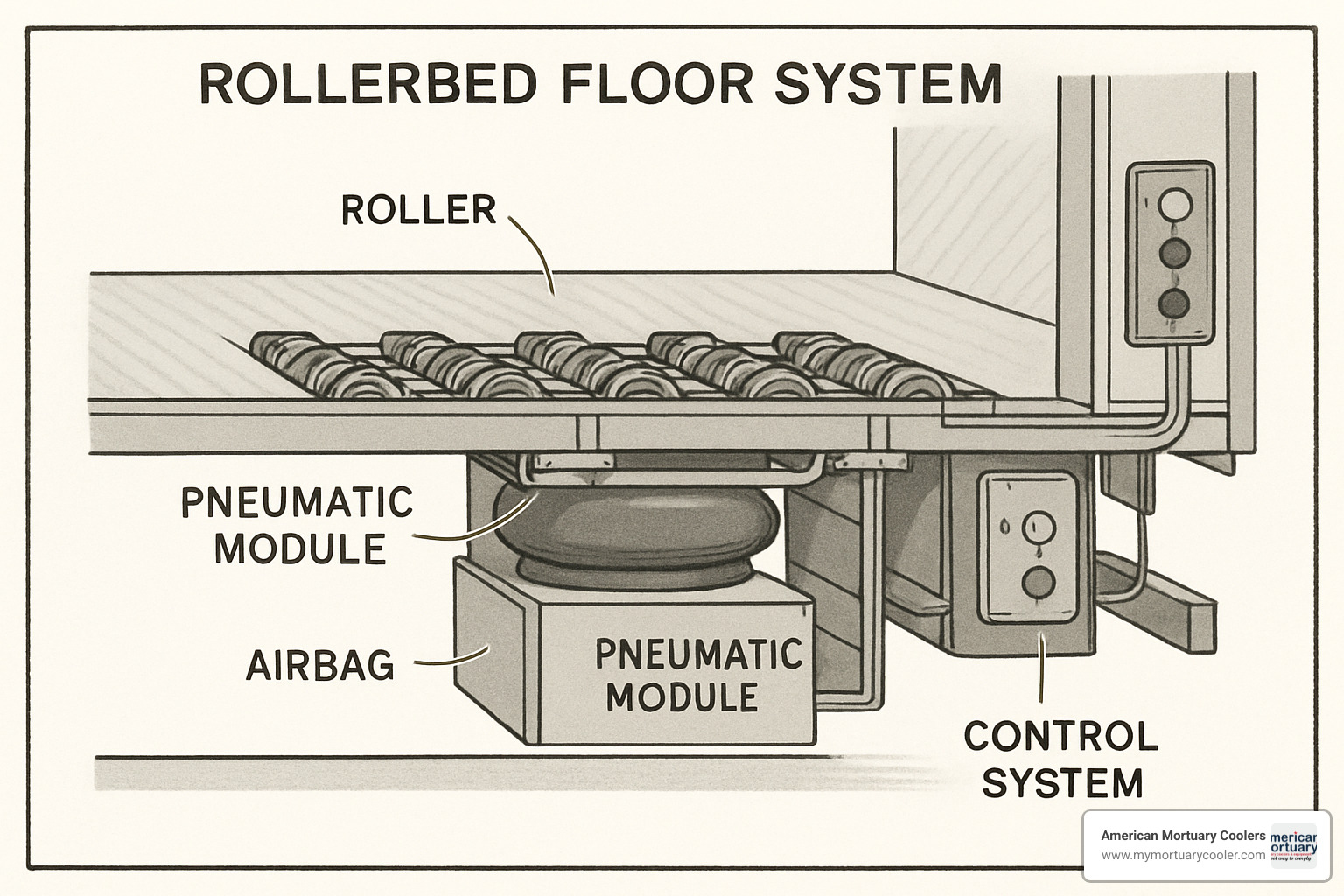

The technology works by using pneumatic airbags connected to your truck's air supply. When activated, the rollers rise above the floor surface, creating a smooth path for pallets and cargo containers. When loading is complete, the rollers retract flush with the floor for secure transit.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with experience in specialized loading and storage systems. My background includes working with funeral homes to optimize their rollerbed floor configurations for efficient body transport and storage operations. This guide will walk you through everything you need to know about these game-changing systems.

What Is a Rollerbed Floor and How Does It Work?

Picture this: you're watching a trailer unload that normally takes 45 minutes with a forklift. Instead, one person walks to a control panel, presses a button, and suddenly the floor comes alive. Rollerbed floors turn ordinary trailer floors into sophisticated cargo-handling systems that can move thousands of pounds with the push of a hand.

The system works through pneumatic modules that sit either built into your trailer floor or as removable units on top. Each module contains precision rollers connected to airbags underneath. When you need to move cargo, compressed air from your truck's air supply inflates these airbags, pushing the rollers up about an inch above the floor surface.

What makes this technology impressive is its single-operator control. One person with a pendant switch can activate the entire system in seconds. The rollers handle serious weight - most systems support 250 pounds per roller, with some heavy-duty versions handling even more. That means a 30-tonne capacity trailer can be unloaded by one person in under two minutes.

The safety features are equally impressive. Pallet stops prevent cargo from rolling too far during loading. The pressure protection valve ensures your truck's brake system always has enough air pressure. And the autodown brake interlock automatically lowers all rollers when you press your brake pedal, securing everything for transport.

Pneumatic Rise-and-Fall Mechanics

The beauty of pneumatic rollerbed floors lies in their simplicity. They tap directly into your truck's existing air system - the same one that powers your brakes. No additional compressors, no extra maintenance headaches.

When you activate the system, airbags beneath each roller inflate with compressed air from your truck air supply. The rollers rise through carefully engineered openings in the floor, creating smooth lanes for cargo movement. The whole process takes seconds.

The autodown brake interlock is genius from a safety standpoint. Every time you hit your brakes, an electric valve automatically vents air from the system. This means your rollers drop flush with the floor before you can drive away.

Manual & Mechanical Alternatives

Not everyone needs the high-tech pneumatic approach. Roller cubes with mechanical activation offer a straightforward alternative. These systems use step-loc locks that engage with steel pins along the trailer floor.

Lever actuation systems give you manual control over each section of rollers. While they require more physical effort than pneumatic systems, they're incredibly reliable. No air pressure to worry about, no electrical connections to fail.

Main Types of Rollerbed Floor Systems

When it comes to rollerbed floor systems, there's no one-size-fits-all solution. After working with funeral homes and logistics companies across the country, I've seen how different operations need different approaches.

Built-in systems are the premium choice - they're permanently installed right into your trailer floor during manufacturing or a major retrofit. These systems give you the lowest profile and keep every precious inch of internal height. Joloda's built-in systems can handle up to 550 kg per module per meter and work with everything from standard wooden pallets to specialized air cargo containers.

Modular systems offer something built-in systems don't - flexibility. These "floor-on-floor" solutions sit on top of your existing trailer floor with minimal fuss. The real beauty is that when your trailer reaches end-of-life, you can pull out these aluminum frame modules and install them in your next vehicle. Most installations take just 8-12 hours with two people.

Portable systems are perfect for operations that need maximum flexibility. The Portable Roller Bed System (PBS) lets you link sections together to create a full 53-foot rollerbed floor, then break it down and move it to different trailers as needed.

Powered systems take things to the next level with slipchain and moving floor technologies. These systems can handle massive loads - up to 60,000 pounds in some configurations.

| System Type | Installation | Capacity | Best For | Price Range |

|---|---|---|---|---|

| Built-in | Permanent | 550kg/module | High-volume, height-critical | $25k-$45k |

| Modular | Removable | 250-300 lbs/roller | Fleet flexibility | $15k-$35k |

| Portable | Temporary | Standard pallet loads | Multi-trailer operations | $12k-$25k |

| Powered | Permanent | Up to 60,000 lbs | Heavy freight | $35k-$60k |

Choosing the Right Rollerbed Floor Variant

Picking the right rollerbed floor system isn't just about budget. Trailer size and configuration is where you start. A 53-foot trailer handling standard CHEP pallets has completely different needs than a shorter trailer designed for air cargo containers.

Cargo type makes a huge difference in system selection. Air cargo operations love the low-profile twin roller configurations, which give you the absolute lowest height specifically for air cargo applications.

How often you'll use it affects your return on investment calculations. High-volume operations with dedicated loading lanes can justify the more expensive automated systems because they'll pay for themselves in under two years through reduced truck and driver requirements.

For specialized applications like our mortuary operations, understanding how different systems integrate with your overall workflow is crucial. More info about modular rack systems can help you think through how rollerbed floors might work with your existing storage and transport setup.

Rollerbed Floor vs Traditional Forklift Loading

The difference between rollerbed floor systems and traditional forklift loading is like comparing a sports car to a horse and buggy.

Traditional forklift unloading is a 30-60 minute process on a good day. The operator has to carefully drive into the trailer, position the forks, lift each pallet, back out without hitting anything, and repeat the whole process over and over.

Rollerbed floor systems flip this entire process on its head. In high-volume applications, you can unload a full trailer in as little as 90 seconds. The operator just hits the activation switch and starts pulling cargo out by hand or with minimal mechanical help. We're talking about a 95% time savings in optimal conditions.

The safety improvements are just as impressive. By keeping forklifts out of trailer interiors, you eliminate the biggest source of cargo and vehicle damage. Labor costs drop dramatically too - one person can handle loads that used to require multiple workers and heavy equipment.

Benefits and Industry Applications

The versatility of rollerbed floor systems has led to adoption across numerous industries, each finding unique advantages in the technology.

Air cargo operations were among the early adopters of this technology. Thousands of tons of air cargo move daily on retractable roller systems in airports worldwide. These systems handle air cargo pallets and ULD containers weighing up to 30 tonnes while maintaining the precise positioning that air freight operations demand.

The beverage industry showcases how dramatic the speed advantages can be. In high-volume beverage distribution centers, rollerbed floor systems make those impressive 90-second unloads possible. Beyond speed, the gentler handling significantly reduces product damage.

Automotive parts distribution operations have found how the precision and reliability of roller systems keep production lines humming. When parts need to move quickly between manufacturing plants and assembly lines, you can't afford delays.

Logistics and warehousing operations particularly appreciate the flexibility these systems offer. The ability to switch between roller mode for quick unloads and flat floor operation for mixed cargo loads means a single trailer can handle diverse shipments without compromising efficiency.

Efficiency & ROI Drivers

The financial case for rollerbed floor systems becomes compelling when you dig into the real numbers. Payback periods typically fall into that sweet spot of 1-2 years for operations with dedicated lanes and high turnover.

System costs vary depending on what level of sophistication you need. A basic pneumatic roller floor system runs about $12,000-$14,000, while fully automated systems can reach $45,000. Those automated systems often pay for themselves through labor savings and the sheer volume of additional loads they can handle.

The labor cost reductions really add up over time. When one operator can handle what previously required multiple people plus heavy equipment, those savings multiply across every single load.

Perhaps the most significant long-term benefit is increased asset utilization. When your trailers spend minutes instead of hours at loading docks, they can complete more runs per day.

Safety Improvements Built Into Rollerbed Floor Systems

Safety features in modern rollerbed floor systems go far beyond just making the rollers work properly. Pallet stop locks prevent that heart-stopping moment when cargo starts rolling away during loading operations.

The autodown systems represent what might be the most important safety innovation. When the driver presses the brake pedal, an electric valve automatically sends a signal to quickly release air from the rollers. This prevents the dangerous situation of driving away with raised rollers.

Pressure Protection Valves (PPV) ensure your vehicle's primary air systems never get compromised by rollerbed operation. The PPV maintains minimum air pressure for your brakes and other critical systems.

The ability to achieve forklift exclusion from trailer interiors eliminates a major source of accidents and damage. Rollerbed floor systems allow all the cargo handling to happen from outside the trailer, dramatically reducing accident risk.

For additional insights into safety considerations when selecting specialized equipment, More info about roller rack selection provides detailed guidance on choosing appropriate systems that meet your specific safety requirements.

Buying, Customizing & Maintaining Your Rollerbed Floor

Getting a rollerbed floor system up and running isn't just about writing a check and hoping for the best. After working with clients from coast to coast, I've learned that the most successful installations start with honest conversations about what you really need.

Load specifications matter more than you might think. Everyone knows their maximum weight, but do you know how that weight sits on your pallets? Your rollerbed floor system needs to handle both the weight and the way that weight moves across the rollers.

Lane count depends on your trailer width and cargo mix. Most operators find that aluminum construction gives them the best balance of weight savings and durability, though steel construction makes sense if you're dealing with particularly rough handling.

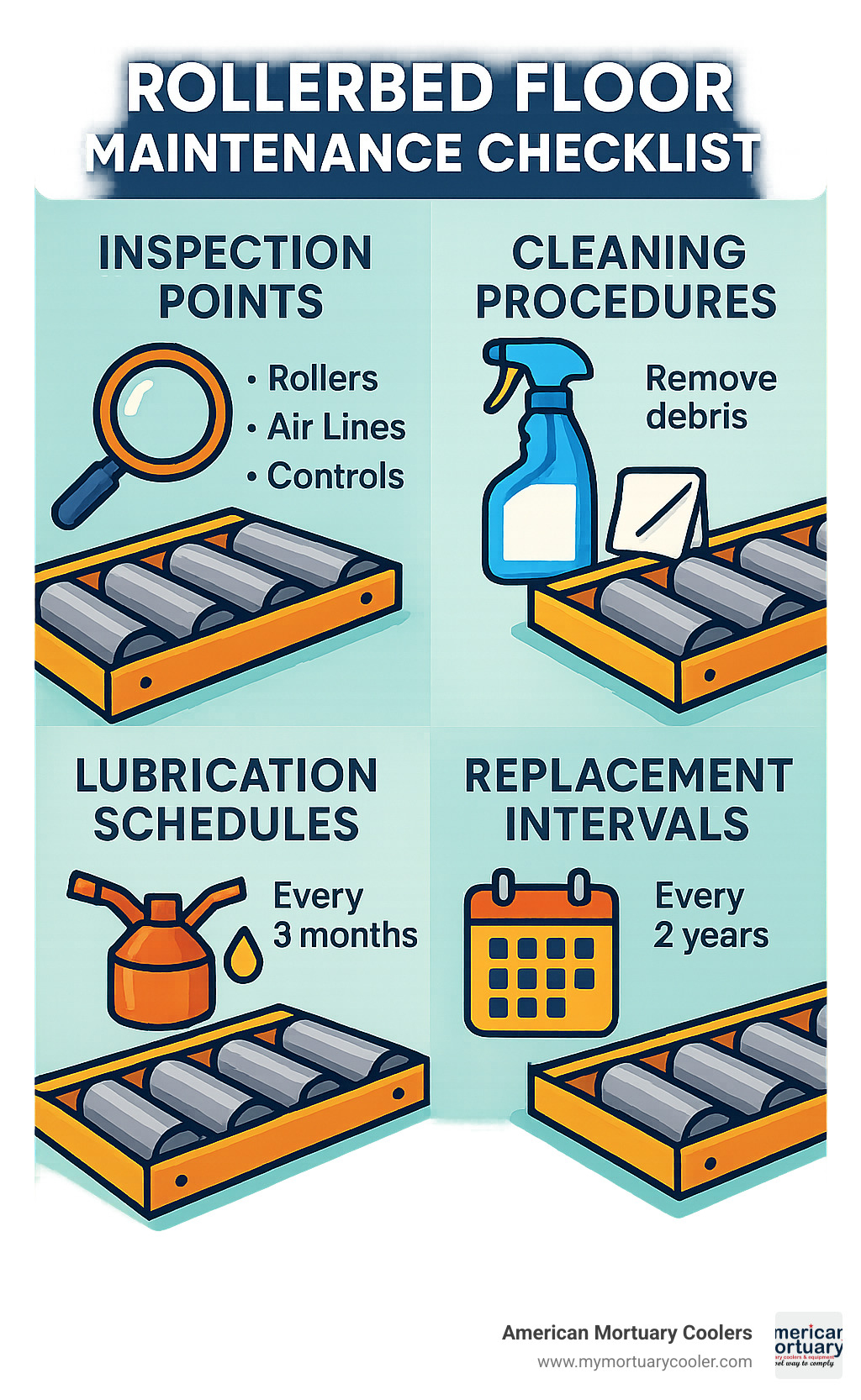

The top plate options might seem like a minor detail, but they're not. Quick-release plates make your maintenance team's life much easier when it's time for deep cleaning. Limited-opening plates can reduce debris problems by about 30%.

Installation typically takes 8-12 working hours for a two-person crew, assuming you're dealing with a straightforward modular system. The 24-month warranty that comes with quality systems reflects real confidence in the engineering.

Cost Breakdown and Financing Options

Manual systems start around $12,000 and work well if you don't need the bells and whistles. Automated systems can run up to $45,000, which sounds like a lot until you start calculating what you're spending on labor and dock time.

Financing plans are available for qualified buyers, which can make the decision easier. ROI calculators help you understand whether these systems make financial sense for your specific situation.

For operations that need specialized cooling integration alongside their loading systems, More info about effective mortuary coolers can show you how to approach comprehensive solutions that work together seamlessly.

Longevity & Upkeep Tips for Your Rollerbed Floor

Here's the truth about maintenance: the companies that treat their rollerbed floor systems well get years of trouble-free service.

Debris control is your biggest ongoing battle. Those limited-opening top plates really do help, but you still need to keep things clean.

Quick-release plates are worth their weight in gold when maintenance time comes. Routine inspection doesn't have to be complicated. Check that rollers move smoothly, air lines aren't cracked, and the control system responds properly.

Roller replacement intervals vary wildly depending on what you're hauling and how often. Keep records of your usage patterns so you can predict when replacements will be needed rather than waiting for failures.

Frequently Asked Questions about Rollerbed Floor Technology

When we talk with funeral directors and fleet operators across our service areas, certain questions about rollerbed floor systems come up repeatedly.

What load capacities can a rollerbed floor handle?

The load capacity depends on both individual roller strength and overall system design. Individual rollers handle 250 pounds per 2-inch roller in standard systems, while advanced designs increase this to 300 pounds per roller.

For total system capacity, modern pneumatic rollerbed floor systems can safely load and unload cargo up to 30 tonnes - approximately 66,000 pounds. Joloda's built-in systems offer 550 kg lifting capacity per module per meter.

The key insight is that capacity isn't just about individual roller strength - it's about proper load distribution across multiple rollers. For our mortuary cooler applications, these capacities are more than adequate for even the heaviest transport requirements.

How does the autodown feature keep cargo safe?

The autodown safety feature is one of the smartest innovations in rollerbed floor technology. An electric valve connects directly to your vehicle's brake pedal. When you press the brake, the system automatically sends an electrical signal to a quick exhaust valve, immediately venting air from the pneumatic rollers.

This prevents several potentially serious problems: cargo shifting during transit, damage to loading dock equipment, and arriving at destinations with inoperable roller systems. The autodown function works with pressure protection valves to ensure your vehicle's primary air systems maintain adequate pressure for safe operation.

Can I retrofit a rollerbed floor into my existing fleet?

Absolutely. Modular systems provide the easiest retrofit path, installing right over your existing trailer floor with minimal modifications. Installation typically takes just 8-12 working hours for a two-person team.

Built-in systems require more extensive modification but deliver the lowest profile and maximum internal height retention. Portable systems offer maximum flexibility, linking together to create partial or full roller-bed floors that can be removed and reused.

According to industry data from the Federal Motor Carrier Safety Administration, retrofit installations often exceed expectations for both performance improvement and return on investment when properly planned and executed.

Conclusion

After diving deep into rollerbed floor technology, it's clear that these systems are more than just a loading dock upgrade - they're a complete game-changer for cargo handling. The numbers don't lie: 90-second unloads versus hour-long forklift operations, 50% labor reductions, and 1-2 year payback periods make the business case compelling.

What really strikes me is how versatile these systems have become. Whether you're moving air cargo containers, handling beverage distribution, or managing specialized transport like our mortuary operations, rollerbed floor systems adapt to meet unique operational needs.

The safety improvements alone justify serious consideration. When you can eliminate forklifts from trailer interiors, reduce cargo damage, and implement autodown features that automatically secure loads, you're protecting your people and your reputation.

At American Mortuary Coolers, we've seen how the right equipment transforms operations. From our Tennessee headquarters, we serve clients across the contiguous 48 states, and we understand that customized loading solutions are essential for competitive operations. Whether you're considering a basic $12,000 manual system or investing in $45,000 automated solutions, the key is matching the technology to your specific needs.

The choice between built-in systems for maximum space efficiency, modular systems for fleet flexibility, or portable systems for ultimate adaptability comes down to understanding your operational priorities.

Improved efficiency and improved safety aren't just marketing buzzwords - they're measurable outcomes that show up in your bottom line. When you can handle more loads with fewer people and reduce dock time from hours to minutes, the financial impact compounds quickly.

For operations requiring specialized cooling and transport solutions, More info about morgue cooler storage efficiency provides additional insights into maximizing operational efficiency.

The transportation industry is evolving rapidly, and rollerbed floor systems represent practical innovation that helps companies stay competitive. They're smart solutions that solve real problems while delivering measurable results.