Maximizing Efficiency: The Power of Roller Rack Systems

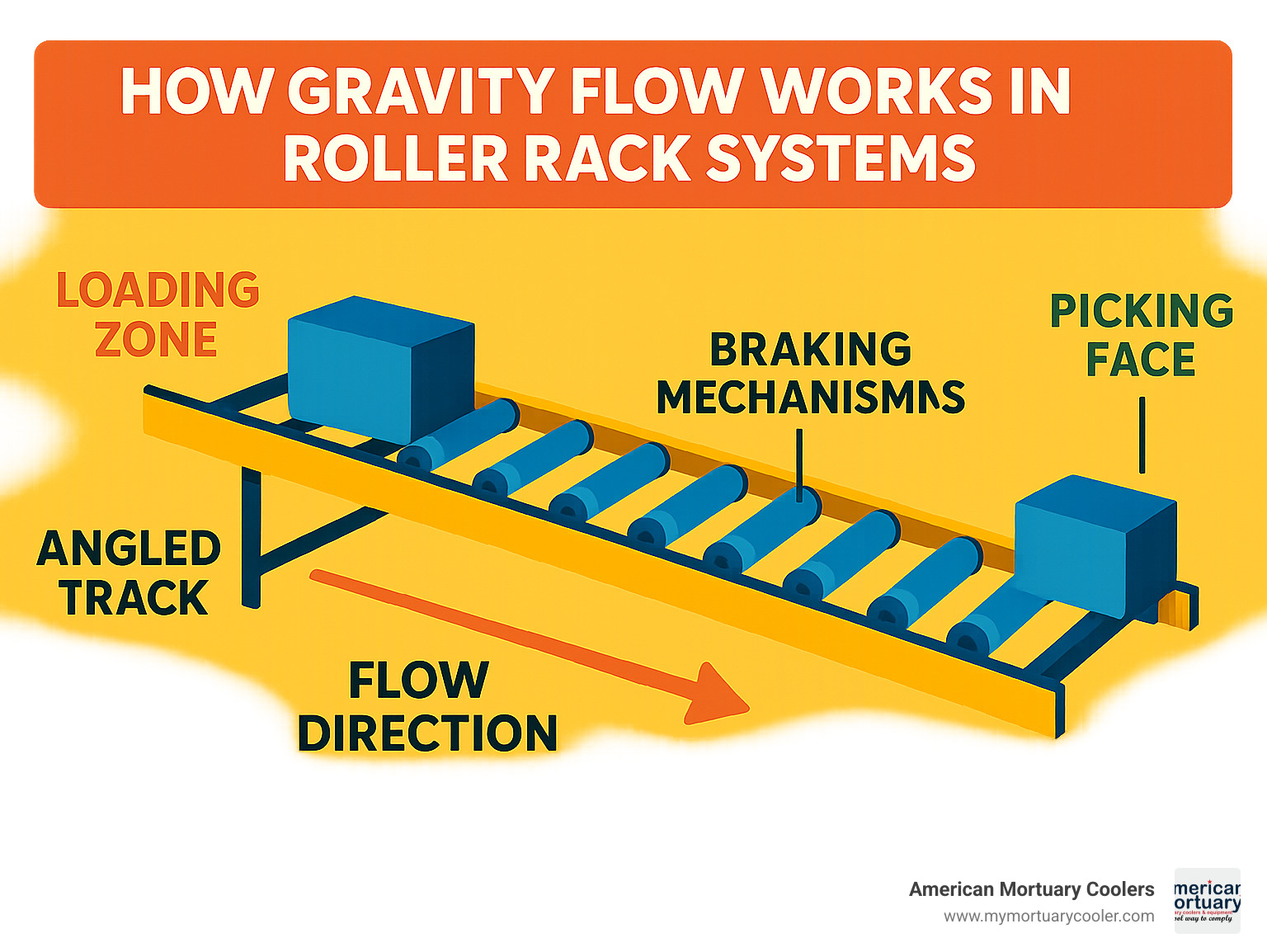

A roller rack is a gravity-powered storage system that uses inclined lanes with rollers to move products from the loading side to the picking side without motorized components.

What is a Roller Rack?

- A storage system with angled tracks featuring rollers or wheels

- Uses gravity to move items from back to front (or vice versa)

- Enables first-in, first-out (FIFO) or first-in, last-out (FILO) inventory management

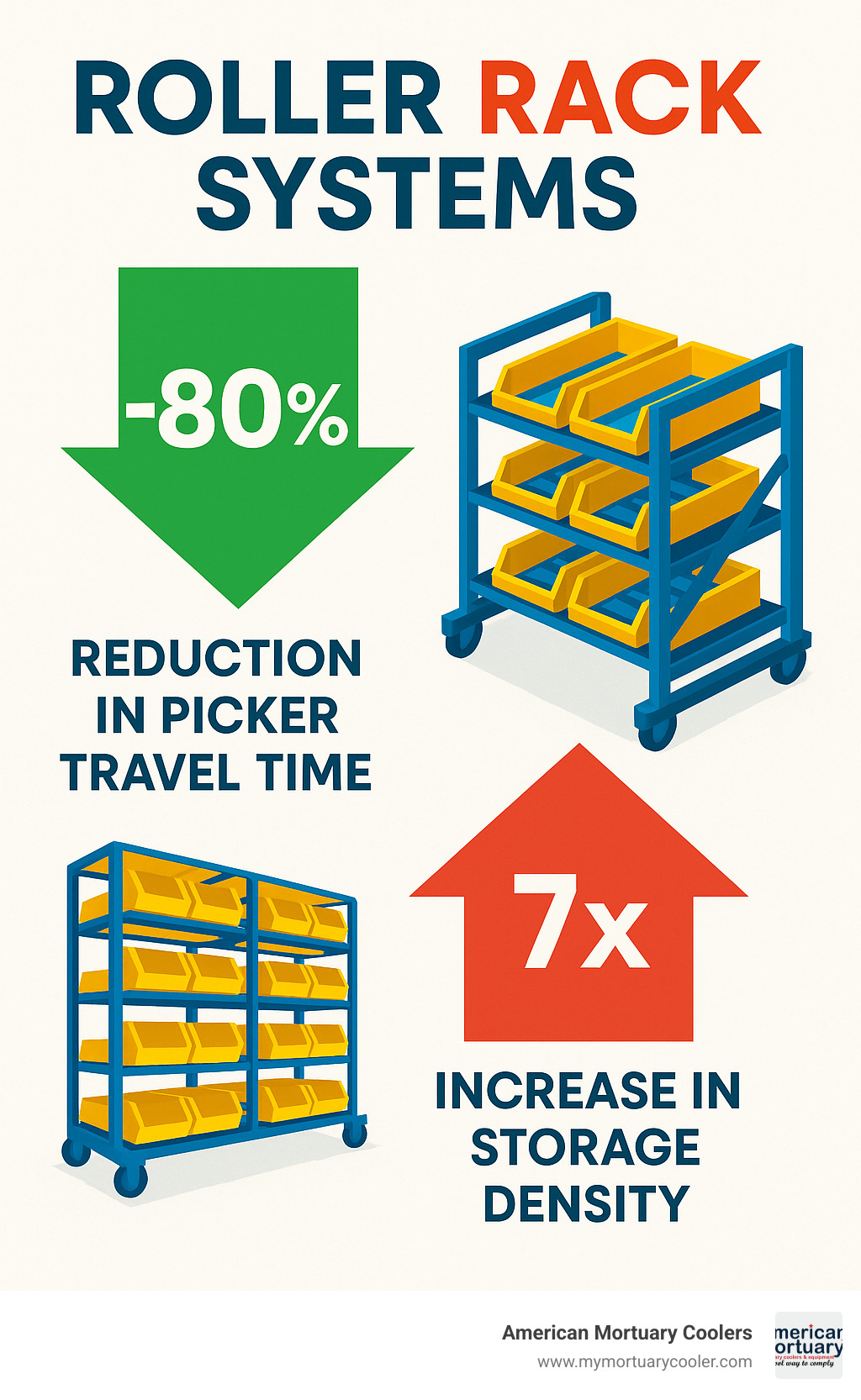

- Creates high-density storage that can be up to 7 times denser than static shelving

- Available in various types: carton flow, pallet flow, mortuary, medical, and more

roller rack systems revolutionize storage by combining simplicity with efficiency. These ingenious structures use gravity—not electricity or motors—to create a self-replenishing storage solution that automatically moves products forward as items are removed from the front. Whether you're managing a warehouse, funeral home, or medical facility, roller racks provide an neat answer to space constraints and workflow challenges.

In warehouse environments, these systems can reduce picker travel time by up to 80% while increasing storage density dramatically. For specialized applications like mortuary storage, roller racks offer dignified, space-efficient solutions that respect both the deceased and staff needs through ergonomic design.

I'm Mortuary Cooler, a national supplier of mortuary equipment with extensive experience designing and installing customized roller rack systems for funeral homes across America. My expertise in both standard and custom roller rack configurations ensures funeral directors receive storage solutions perfectly custom to their facility requirements and workflow needs.

Roller rack terms at a glance:

Roller Rack Fundamentals: How Gravity Makes Storage Move

The beauty of a roller rack lies in its neat simplicity. While other storage systems rely on complex mechanics, power sources, and frequent maintenance, roller racks harness one of nature's most dependable forces: gravity.

As one of our funeral home clients told us after switching from motorized systems to our gravity-flow racks: "Nothing else gives the warmth, beauty, and quietness of a well-designed roller rack system. The reduction in noise alone made the investment worthwhile, not to mention the energy savings."

How a Roller Rack Works

Think of a roller rack as a gentle downhill slope for your inventory. These systems feature lanes set at a slight incline—typically between 3-6 degrees—just enough for items to move forward on their own without picking up too much speed.

The magic happens on the roller bed. Whether your system uses full-width rollers spanning the entire lane or wheel beds (sometimes called split rollers), these components create a smooth surface that lets products glide effortlessly downward. When someone removes an item from the front, gravity naturally pulls the next item forward to take its place, creating what we call a "self-replenishing pick face."

For warehouse staff, this means no more reaching deep into shelves or moving products around to find what they need—items are always waiting at the front of the rack. In our mortuary applications, this thoughtful design allows bodies to be loaded from one side and retrieved from another, minimizing handling while creating a natural rotation system that respects both the deceased and the staff who care for them.

FIFO vs. FILO Processes in a Roller Rack

Your roller rack can be set up to support two different inventory approaches, depending on your specific needs:

First-In, First-Out (FIFO) works like a checkout line—whoever arrives first gets served first. Items are loaded from the back and picked from the front, ensuring the oldest inventory moves out before newer items. This approach shines for anything with an expiration date or time-sensitive processing needs.

A funeral director from Atlanta who recently installed our custom mortuary roller racks shared: "In our funeral home operations, FIFO is essential. It ensures dignified handling of the deceased while maintaining proper chronological processing for services."

First-In, Last-Out (FILO) works more like stacking plates—the last one placed on top is the first one you'll grab. With this approach, you load and pick from the same side, with new items gently pushing existing inventory deeper into the rack. It's perfect when you have limited access space or for non-perishable items where rotation is less critical.

The choice between these approaches comes down to your specific space, workflow, and the nature of what you're storing.

Key Components Every Roller Rack Needs

A quality roller rack isn't just a frame with wheels—it's a thoughtfully designed system with several essential parts working together:

The frame structure serves as the backbone, typically crafted from industrial-grade welded steel with a powder-coated finish that stands up to years of use. Within this frame, you'll find the roller beds, which come in two main varieties: full-width rollers that span the entire lane (great for various package sizes) or wheel beds arranged in tracks (more economical for uniform packages).

At entry points, impact plates protect the rollers from damage during loading—especially important when you're handling heavier items. Lane dividers and guides keep everything neatly aligned, while knuckled fronts at the picking end gently slow products as they approach the front, preventing them from rolling off the rack.

For heavier items, flow speed controls or brake modules regulate descent speed, and load separators maintain space between items to prevent pressure buildup down the lane.

In our mortuary applications at American Mortuary Coolers, we add several specialized features: high-impact castors with locking brakes for mobile units, stainless steel or specially coated rollers for improved hygiene, reinforced structures for heavier loads, and customized dimensions to perfectly fit standard 23-inch mortuary trays.

Want to learn more about optimizing your storage space? Check out our detailed guide on optimizing body cooler storage efficiency for insights specific to funeral facilities.

Types, Applications, Pros & Cons

The versatility of roller rack systems extends across numerous industries and applications. Each type is designed to address specific storage and handling challenges.

Mortuary Roller Rack: Specialized Storage for Funeral Facilities

Here at American Mortuary Coolers, we've spent years perfecting roller rack systems specifically for funeral homes. We understand the unique challenges you face daily, which is why our mortuary racks aren't just functional—they're thoughtfully designed with dignity and respect in mind.

Our mortuary roller racks come in both side-loading and end-loading configurations to fit seamlessly into your existing workflow. Many of our clients love our knock-down frames that can be easily assembled inside your facility—perfect for those historic funeral homes with narrow doorways that would otherwise make installation impossible.

"The multi-directional loading feature of our new roller rack has transformed our preparation room workflow," shared a funeral director from Dallas. "We've increased our capacity by 40% without expanding the physical footprint of our cooler."

We use stainless steel rollers in all our mortuary systems for superior hygiene in cooler environments, and our multi-tier options (available in 2, 3, or 4 tiers) help you make the most of your vertical space. While our standard dimensions include 28" end openings with 21" tier heights and 16.25" spacing between tiers, we're happy to customize measurements to fit your specific needs.

Curious about how different storage options compare? Check out our detailed guide on Everything You Need to Know About Comparing Roller Storage Racks.

Other Industry-Specific Variants

The beauty of roller rack technology extends well beyond the funeral industry. In e-commerce warehouses, carton flow racks with their full-width rollers create organized picking faces that can boost throughput by a remarkable 150% compared to traditional methods. The smiles on warehouse managers' faces when they see pickers grabbing items without walking miles each day tells us everything we need to know!

For heavier items, pallet flow racks can handle full pallets in warehouse settings, sometimes storing up to 20 pallets deep in a single lane. These workhorses of the industry are perfect for high-volume, fast-moving inventory.

Music schools love our instrument storage racks, which trade industrial steel for warm wood materials and plush padding. These specialized racks often include rubber casters for quiet movement—because nobody wants a squeaky rack interrupting orchestra practice!

In hospitals, medical equipment racks feature smooth-rolling capabilities and specialized mounting brackets, with materials chosen specifically for easy cleaning and infection control. Meanwhile, retail stores rely on mobile Z-racks with their distinctive shape to display clothing while maintaining the flexibility to rearrange floor layouts quickly.

Advantages vs. Drawbacks Across Use Cases

When it comes to the benefits of roller rack systems, the numbers speak volumes. Storage density increases up to seven times compared to conventional storage, while picker travel time drops by a whopping 80%. Your staff will thank you for the improved ergonomics—no more reaching deep into shelving or awkwardly maneuvering heavy items.

I remember visiting a client six months after installation, and the warehouse manager couldn't stop grinning: "The initial cost gave us pause, but our picking efficiency improved so dramatically that we've already recouped our investment. The maintenance has been minimal—just quarterly inspections and occasional roller replacements."

These systems also create automatic stock rotation in FIFO configurations, eliminating the extra handling that traditional storage requires. Since they're gravity-powered, you'll never worry about electricity costs or downtime from power failures. And as your needs grow, the modular design makes expansion straightforward.

Of course, no storage solution is perfect. Roller racks do require a higher initial investment than static shelving, though the ROI typically arrives quickly through operational efficiencies. The moving parts need periodic inspection and occasional replacement, and the necessary incline requires more depth than vertical storage systems.

Not every item is suited for roller movement—very small, oddly shaped, or extremely fragile items might need alternative storage solutions. And don't forget that your team will need training in proper loading and unloading techniques to get the most from your system.

Whether you're storing deceased loved ones with dignity or managing thousands of SKUs in a busy warehouse, roller rack systems offer a blend of simplicity and efficiency that's hard to beat. The right system, properly configured for your specific needs, can transform your operations while providing years of reliable service.

Choosing & Customizing the Right Roller Rack

Finding your perfect roller rack system shouldn't feel like solving a puzzle. At American Mortuary Coolers, we walk alongside our clients through a friendly, straightforward assessment that considers what really matters: your daily operations, available space, and budget realities.

When our Tennessee funeral home clients call us, their first question is often: "How do I know which system is right for my facility?" The answer always starts with understanding a few key factors: the weight of what you'll store, how uniform your containers are, how quickly items move through your system, your facility environment, your aisle width, and any future expansion plans.

Full-Width vs. Split Roller Rack Systems – Which Fits Your Operation?

One of the most important choices you'll make is between full-width and split roller designs. Think of it as choosing between a smooth highway and a track system – both get you there, but in different ways.

Full-width roller systems provide continuous support across the entire lane width. These workhorses support over 100% more surface area than other systems, making them perfect when you're handling various sized containers or pallets. They're gentle on your products and minimize system wear, though they do come with a higher price tag. Many of our mortuary clients choose full-width rollers because the smooth, stable movement shows respect for the deceased and provides peace of mind for staff.

As one Chicago funeral director told us, "We chose full-width rollers despite the higher cost. When you're handling mortuary trays, that added stability isn't just about efficiency – it's about dignity and care."

Split roller systems take a different approach with wheels arranged in tracks rather than continuous rollers. They're more budget-friendly when you don't need full support, and they work beautifully with uniform containers. You'll get similar capacity to full rollers while using less material, though they might need a bit more TLC in busy operations.

The right choice depends on whether your items are uniform, your budget constraints, how much flexibility you need, and your expected volume. Our team can help you weigh these factors to find your perfect fit.

Budgeting, ROI & Hidden Costs

Let's talk money – because while roller rack systems might have a higher upfront cost than static shelving, they often pay for themselves quickly.

When budgeting for your system, remember to include the rack structure itself, roller components and accessories, installation labor, and any facility modifications you might need. But don't stop there – also consider the ongoing (though typically minimal) maintenance, occasional roller replacement, and staff training.

Some costs aren't as obvious at first glance. You might experience downtime during installation, need to reorganize existing inventory, or adjust your workflows. But these temporary challenges lead to lasting benefits.

The ROI comes from multiple directions: labor savings from reduced travel time (up to 80% in many cases), dramatically improved space utilization (up to 7 times more storage in the same footprint), reduced product damage, better inventory accuracy, and improved worker safety and comfort. For our mortuary clients, there's also immeasurable value in providing dignified handling, reducing physical strain on staff, and creating a professional impression for visiting families.

"We were hesitant about the price tag," a Tennessee mortuary manager shared with us, "but within eight months, the efficiency gains and space savings more than justified the investment. Plus, our staff's backs are thanking us every day."

At American Mortuary Coolers, we don't just sell you equipment and disappear. We provide detailed ROI projections based on your specific operational needs, helping you make a confident decision and explain the value to other stakeholders. We've found that when our clients understand both the immediate costs and long-term benefits, the choice becomes much clearer.

Curious about the scientific research behind dynamic storage efficiency? Check out this detailed research on dynamic storage efficiency that confirms what our customers experience every day.

Installation, Maintenance, Safety & Real-World Insights

Setting up and caring for your roller rack system doesn't have to be complicated. With proper installation, a bit of regular TLC, and some common-sense safety practices, your investment will serve your facility beautifully for years to come.

Installation Process

When we install a roller rack at your facility, we handle everything with care and precision. Our process starts with a thorough site survey where we measure your space, check floor levelness, and note any potential obstacles. We know that every inch matters, especially in smaller funeral homes where space is at a premium.

Most of our roller rack systems arrive in a knock-down configuration—think of it as sophisticated furniture that needs assembly. This approach lets us steer through standard doorways and tight corridors without the headache of major renovations.

Our experienced technicians then build the frame structure according to your custom layout, installing the rollers at just the right angle to ensure smooth movement without excessive speed. We add all the necessary components—lane dividers, impact plates, and any specialized accessories your operation requires.

"The installation team worked around our schedule, even coming in after hours to avoid disrupting services," shared a funeral director from Memphis. "They were respectful of our space and understood the sensitive nature of our work."

Before we consider the job complete, we thoroughly test the system with actual weight to ensure everything flows properly. We'll never leave you hanging—our team provides hands-on training for your staff so everyone understands how to load, unload, and maintain your new roller rack system properly.

Maintenance Requirements

One of the beauties of a roller rack system is its mechanical simplicity. Without motors or complex electronics, maintenance is refreshingly straightforward. Think of it as caring for a quality bicycle rather than a complicated vehicle.

A quarterly once-over is usually sufficient for most facilities. During these check-ups, take a few minutes to inspect rollers for wear or damage, clear away any debris that might have accumulated, and verify that all connections remain tight and secure. Once a year, a light application of appropriate lubricant to roller bearings will keep everything running smoothly.

"I was worried maintenance would be a headache," confessed a funeral director from Virginia. "But honestly, it takes me about 20 minutes every three months to check everything over. In five years, we've only replaced three rollers, and that was after an accidental impact with equipment."

If your facility experiences heavy usage or operates in particularly demanding conditions, you might want to increase inspection frequency. Many of our clients incorporate quick visual checks into their weekly routines, looking for any signs of wear or performance issues before they become problems.

Safety Considerations

When it comes to safety around roller rack systems, common sense goes a long way. Always respect the weight limits we specify—they're calculated with safety margins, but exceeding them puts unnecessary stress on the system and creates hazards.

Proper loading techniques make a world of difference. We train your staff to distribute weight evenly and position items correctly to prevent jams or unexpected movements. For mortuary applications, this careful handling also preserves the dignity of the deceased in your care.

Keep the floors around your roller rack clear and clean. Not only does this prevent trips and falls, but it also ensures easy access during busy periods. And while it may seem obvious, make sure your system remains properly anchored to the floor—over time, even the most secure installations can loosen with regular use.

For our mortuary clients, we place special emphasis on ergonomic practices. The right techniques for loading and retrieving can prevent back strain and other injuries that come from improper lifting. These small adjustments in procedure can make a significant difference in staff well-being over time.

For more detailed guidance on selecting and safely operating the perfect morgue storage solution, check out our comprehensive guide: Rolling in Efficiency: Choosing the Right Morgue Storage Rack.

Real-World Success Stories

Numbers tell part of the story, but the real impact of a well-designed roller rack system comes through in the experiences of the people who use them every day.

Take Metropolitan Funeral Home in Chicago. Before working with us, their staff struggled with a cramped cooler that required constant repositioning of deceased individuals—a situation that was physically demanding and less than dignified. After installing our custom three-tier, side-loading roller rack system, the change was remarkable. Their capacity jumped by 40% without expanding their cooler footprint. Staff reported 65% less physical strain from reduced handling, and their overall processing time decreased by 30% thanks to improved workflow.

"The difference is night and day," their director told us. "Our staff no longer dreads cooler retrievals, and we can serve more families without the stress of space constraints."

In the commercial sector, we helped a regional distribution center in Atlanta replace their traditional shelving with carton flow roller racks throughout their picking area. Their order picking times plummeted by 75%, while storage density tripled. Perhaps most importantly, worker fatigue and injury reports dropped by half, and training new staff became much simpler.

"I was skeptical about the investment," their operations manager admitted. "But seeing our pickers go from walking miles each day to having product constantly available at their fingertips—it's been revolutionary. We recouped our costs in under 8 months."

FAQ: Roller Rack Selection and Use

Q: What clearances do I need for a roller rack system?

A: For mortuary applications, we generally recommend at least 3 feet of clearance on both loading and unloading sides. This gives staff comfortable room to maneuver. For warehouse applications, clearances depend on your equipment—forklifts need more space than hand-picking operations. We'll help you plan the perfect layout during our initial consultation.

Q: Can roller racks be retrofitted into existing shelving?

A: Often, yes! Our drop-in roller tracks can transform static shelving into dynamic flow racks in many cases. The key factors are the strength of your existing shelving and whether the dimensions are compatible. During our site survey, we can assess your current setup and recommend the most cost-effective approach.

Q: What warranty comes with your roller rack systems?

A: At American Mortuary Coolers, we stand behind our work with a solid 5-year warranty on frame structures and a 2-year warranty on roller components. We also offer extended warranties for facilities with particularly high usage or special requirements. We build these systems to last, and our warranty reflects that confidence.

Q: How do I determine the appropriate load ratings for my application?

A: We handle the heavy lifting here—literally and figuratively! Our team analyzes your specific needs, considering individual item weights, how many items will typically be in each lane, and the total system load. For mortuary applications, we design systems that comfortably accommodate standard mortuary trays with plenty of safety margin to spare.

Q: Can roller racks be used in refrigerated environments?

A: Absolutely! In fact, our mortuary roller racks are specifically engineered for cooler environments. We select materials and finishes that perform beautifully in cold, potentially humid conditions without corrosion or performance issues. This specialized design ensures your system will function flawlessly for years, even in the challenging environment of a mortuary cooler.

Conclusion

Choosing the perfect roller rack system isn't just about buying storage equipment—it's about changing how your business operates. The right system can breathe new life into your funeral home, warehouse, or specialized facility by dramatically improving your workflow, maximizing your available space, and creating a more dignified environment for both the deceased and their families.

We've worked with hundreds of funeral directors across America, and I've seen how the right storage solution can make all the difference. One director in Tennessee told me, "I never thought a storage rack could change our whole operation, but it's like night and day compared to what we had before."

Before you make your decision, take a moment to consider these essential questions:

- What types of items will your rack need to hold? (Bodies, caskets, or supplies?)

- Would FIFO or FILO inventory management better suit your facility's layout?

- What are your specific space limitations and traffic flow needs?

- How many items do you typically need to store at peak times?

- What's your budget, both for initial purchase and long-term maintenance?

- Which safety features are non-negotiable for your team's wellbeing?

At American Mortuary Coolers, we believe that listening is the first step in creating the perfect solution. Every funeral home has unique needs, and what works brilliantly for a large urban facility might not be ideal for a smaller rural operation. That's why we take the time to understand your specific challenges before recommending any system.

Our customers consistently tell us that the investment in a quality roller rack system pays for itself through improved efficiency, reduced physical strain on staff, and the professional impression it creates for families visiting your facility. As one Florida funeral director shared, "Families notice the difference—everything feels more organized and respectful."

For a deeper dive into our complete equipment offerings, including our specialized roller racks, check out our Detailed guide to MOBI Medical Supply equipment.

Ready to see how a custom roller rack system could transform your facility? We're just a phone call away. Our team serves funeral homes across all 48 contiguous states from our locations in Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, Pennsylvania, and our regional offices nationwide. We'd be happy to provide a no-pressure consultation and quote custom to your specific needs.

The right storage solution isn't just about organization—it's about honoring the sacred work you do every day. Let us help you create a more efficient, dignified environment that serves both the living and the deceased with equal respect.