Why Understanding the Order Process Transforms Your Operations

What is the order process—it’s the end-to-end workflow that turns a customer’s decision to buy into a product delivered to their door, covering everything from payment validation to post-delivery support.

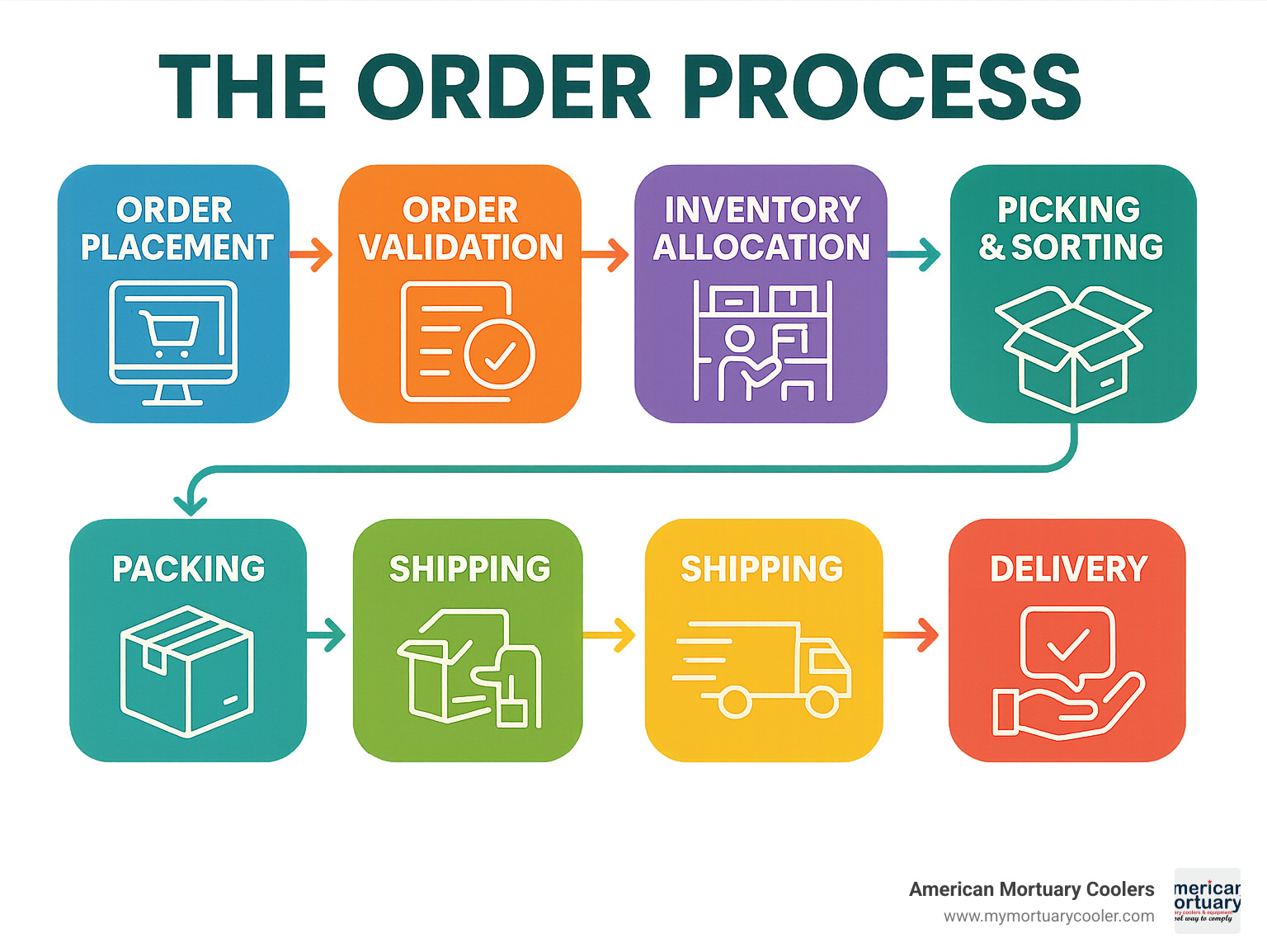

Quick Answer: The Order Process Includes:

- Order Placement – Customer submits purchase request

- Order Validation – Payment verification and fraud checks

- Inventory Allocation – Stock reservation and availability confirmation

- Picking & Sorting – Warehouse staff locate and organize items

- Packing – Products secured for safe transport

- Shipping – Carrier pickup and transit tracking

- Delivery – Final customer receipt and confirmation

- Post-Order Support – Returns, exchanges, and feedback collection

Ecommerce growth has pushed expectations sky-high: shoppers want fast, flawless fulfillment every time. One misstep can cause delays, extra costs, and lost loyalty, while a streamlined workflow delivers faster shipping, lower expenses, and happier customers.

For funeral homes, the impact is even greater. Delays in receiving mortuary coolers or related equipment affect your ability to serve families during difficult moments. At American Mortuary Coolers, we know a clear, reliable order process keeps your operation running smoothly when it matters most.

What Is the Order Process?

When someone asks what is the order process, they're really asking about the complete journey from "I want to buy this" to "It's at my door." It's the systematic workflow that transforms a customer's purchase decision into a delivered product.

What is the order process goes far beyond just moving boxes around a warehouse. It's the careful coordination of people, technology, and logistics to ensure every customer receives exactly what they ordered, when they need it, in perfect condition.

Think of it as a well-choreographed dance. Sales teams capture what customers actually need, customer service representatives handle questions and changes, warehouse staff locate and prepare items for shipment, logistics coordinators manage the shipping puzzle, and finance teams ensure payments flow smoothly.

At American Mortuary Coolers, this coordination becomes especially meaningful. When a funeral home places an order for a custom mortuary cooler, we're not just processing another transaction. We're ensuring that facility can continue serving families during their most difficult moments without interruption.

The order process delivers real competitive advantages that directly impact your bottom line. Better inventory management reduces both warehouse costs and expensive stock-outs. Faster, more accurate fulfillment leads to happier customers who order again and recommend you to others. Reliable, predictable service builds trust that competitors struggle to match. Plus, valuable data collection throughout the process informs smarter operational and marketing decisions.

What is the order process in ecommerce?

In the digital world, what is the order process kicks off the moment someone clicks "add to cart." The ecommerce order process seamlessly blends technology with human coordination.

Shopping cart management maintains everything customers select - products, quantities, special options - even if they leave and come back later. The system automatically calculates totals including taxes and shipping costs based on their location.

Payment authorization happens when customers hit checkout. The system verifies their payment information, runs fraud detection checks, and authorizes the transaction amount. Here's an interesting detail: Amazon actually holds all orders for a 30-minute window, giving buyers a chance to cancel before payment finalizes.

Once payment confirms, the order flows into the Order Management System (OMS) where it receives a unique identifier and begins its fulfillment journey. This is where the digital handoff to physical operations happens.

Multi-channel coordination adds another layer of complexity. Modern businesses receive orders from their website, mobile apps, marketplaces like Amazon, phone calls, and even in-person visits. The order process must seamlessly weave all these channels together so nothing falls through the cracks.

What is the order process vs order fulfillment?

Many people use these terms interchangeably, but understanding the difference helps optimize your entire operation.

Order processing handles all the administrative coordination from the moment an order arrives. This includes verifying payment details, updating inventory systems, confirming customer information, and coordinating the workflow between departments. It's the behind-the-scenes work that sets up everything for success.

Order fulfillment focuses specifically on the physical tasks - picking items from shelves, packing them securely, and shipping them to customers. It's the hands-on warehouse work that gets products moving toward their destination.

Think of order processing as the brain that coordinates everything, while order fulfillment is the muscle that executes the physical work. You need both working smoothly together, but they serve distinct functions in your overall workflow.

| Aspect | Order Processing | Order Fulfillment |

|---|---|---|

| Focus | Administrative coordination | Physical execution |

| Activities | Payment verification, inventory updates, workflow management | Picking, packing, shipping |

| Systems | OMS, ERP, payment gateways | WMS, shipping software, warehouse equipment |

| Timeline | Immediate upon order placement | After order processing is complete |

| Success Metrics | Accuracy, processing time, error rates | Pick accuracy, pack quality, shipping speed |

Key Steps in the Order Processing Workflow

Understanding what is the order process means breaking down each step that happens from the moment a customer hits "buy" until their order arrives at their door. While every business has slight variations, the core workflow follows a predictable pattern that, when executed well, creates happy customers and smooth operations.

The beauty of a well-designed order process is that it handles complexity behind the scenes while appearing effortless to customers. Let's walk through each critical stage and see how they work together.

Order placement & validation

Everything starts when customers provide their information during checkout. This isn't just about collecting a name and address - it's about gathering all the details needed to fulfill their order perfectly. Customer data collection includes contact information, shipping addresses, payment methods, and specific product requirements.

For businesses like ours at American Mortuary Coolers, this step gets more detailed. When funeral homes order custom equipment, we need precise specifications - cooler dimensions, temperature requirements, electrical needs, and installation preferences. Getting these details right from the start prevents costly mistakes later.

Fraud prevention happens automatically in the background. Modern payment systems run sophisticated checks, comparing billing addresses with credit card records, analyzing purchase patterns, and flagging anything suspicious. While most orders sail through quickly, some payment verification processes can extend processing times up to 21 days when additional security checks are needed.

Once everything checks out, the system creates a sales order - essentially the master document that guides everything that follows. This formal record gets a unique identifier and becomes the single source of truth for fulfillment teams, customer service, and tracking systems.

At American Mortuary Coolers, we take extra care during validation because custom mortuary equipment leaves no room for error. A mistake in dimensions or electrical specifications could mean weeks of delays for a funeral home that needs equipment to serve families.

Picking & sorting best practices

The warehouse is where what is the order process becomes physical work. Picking strategies vary based on order volume, product types, and warehouse layout, but the goal is always the same - get the right items efficiently and accurately.

Piece picking works well for businesses handling unique orders one at a time. Workers focus on individual orders, gathering everything needed before moving to the next. It's personal but can be slower for high-volume operations.

Zone picking divides warehouses into specialized areas where workers become experts in their section. Batch picking takes multiple orders and picks them together, improving efficiency when many customers order similar items. Wave picking combines zone and batch approaches for operations handling hundreds of orders daily.

Barcode scanning has revolutionized picking accuracy. Workers scan item codes to confirm they're grabbing the correct product and quantity. This simple step catches most picking errors before they become shipping problems.

Quality control happens during sorting, where items get one final verification before packing. Experienced warehouse staff can spot damaged products, quantity errors, or items that don't match order specifications. This checkpoint prevents most customer complaints and returns.

Packing, shipping & last-mile tracking

Packing teams face a balancing act - protecting products during shipping while controlling material costs and keeping packages as light as possible. Cost-effective materials selection depends on what's being shipped, how far it's traveling, and how fragile it is.

Carrier integration streamlines the shipping process through direct connections with UPS, FedEx, and regional carriers. Systems automatically generate shipping labels, schedule pickups, and provide tracking numbers without manual data entry.

Real-time updates keep customers informed throughout delivery. Automated notifications go out at key moments - order confirmation, shipment, out for delivery, and final delivery confirmation. Customers appreciate knowing where their order stands without having to call and ask.

For specialized equipment like mortuary coolers, we coordinate white-glove delivery services that bring equipment inside facilities and provide basic setup assistance. Heavy, sensitive equipment needs this extra care, and funeral homes appreciate not having to wrestle with installation themselves.

The entire workflow creates a seamless experience that makes complex logistics look simple. When done right, customers barely think about what is the order process - they just know their orders arrive quickly and correctly.

For more detailed insights into optimizing your order workflow, check out our comprehensive guide on How Does Order Processing Work? A Step-by-Step Guide.

Challenges, Metrics & Influencing Factors

Let's be honest - understanding what is the order process is one thing, but actually running it smoothly? That's where things get interesting (and sometimes frustrating).

Every business faces problems when processing orders, and the funeral industry has its own unique challenges. Human errors remain one of the biggest culprits - a mistyped address here, a wrong quantity there, and suddenly you're dealing with delayed deliveries and unhappy customers. When we're talking about mortuary equipment, these mistakes aren't just inconvenient - they can impact a funeral home's ability to serve families.

Inventory inaccuracies create another headache. Your computer says you have five units in stock, but when someone goes to pick the order, there are only three. This problem gets amplified with custom equipment where lead times stretch for weeks, not days.

Then there's the seasonality factor. Just like retail sees spikes during holidays, mortuary equipment suppliers face increased demand during flu season and other periods when mortality rates climb. Your standard processes that work fine in July might buckle under December's pressure.

System silos cause their own brand of chaos. When your order management system doesn't talk to your inventory system, which doesn't sync with your shipping software, information falls through the cracks. Orders get lost, inventory gets oversold, and customers get frustrated.

Labor shortages add another layer of complexity. Finding workers who can safely handle heavy mortuary equipment isn't like hiring seasonal retail help. These folks need training, experience, and the physical capability to move substantial equipment safely.

Factors that shape the order process

Several key factors influence how what is the order process unfolds in your specific operation, and understanding these helps you design better workflows.

Product nature plays a huge role. Shipping small parts versus delivering a full-size mortuary cooler requires completely different approaches. Our coolers need specialized handling equipment, custom crating, and coordinated delivery scheduling - you can't just toss them in a standard shipping box.

Packaging requirements vary dramatically based on what you're shipping. Some products need climate control during transit, others require hazmat handling protocols, and heavy equipment like mortuary coolers often needs custom wooden crates and specialized loading equipment.

Workforce capacity directly impacts your processing speed and picking strategies. Having enough trained staff means you can batch orders efficiently and maintain quality standards. Cross-training workers helps maintain flexibility when someone calls in sick or demand spikes unexpectedly.

Demand variability shapes your entire approach. Predictable, steady demand allows for efficient scheduling and resource planning. Volatile demand requires more flexible processes and often higher inventory buffers to avoid stockouts.

Core KPIs to monitor what is the order process performance

Tracking the right metrics helps you spot problems before they become disasters and identify opportunities for improvement.

Order cycle time measures how long it takes from order placement to shipment. While same-day shipping has become common for consumer goods, specialized equipment often requires longer processing times for custom manufacturing and quality checks.

Order accuracy rate tracks the percentage of orders shipped without errors. Top-performing operations achieve 99%+ accuracy through systematic quality controls and barcode scanning. Even small improvements here can dramatically reduce customer service calls and return costs.

On-time delivery rate measures whether orders arrive when promised. This metric directly impacts customer satisfaction and repeat business. For funeral homes, reliable delivery timing is especially critical since they're often working with tight schedules for services.

Cost per order includes all fulfillment expenses - labor, materials, shipping, and overhead costs. Understanding this number helps you price services appropriately and identify cost reduction opportunities.

Customer satisfaction scores provide direct feedback on the order experience. While operational metrics tell you what happened, customer feedback tells you how it felt from their perspective. This qualitative data often predicts future business better than purely operational metrics.

For deeper insights into optimizing inventory efficiency and turnover ratios, this latest research on inventory efficiency provides valuable benchmarking data across different industries.

Optimizing & Automating Your Order Process

Making what is the order process work better for your business doesn't have to be overwhelming. The smartest operations start with understanding exactly what they're doing now, then make targeted improvements that deliver real results.

Process mapping is your first step - and it's simpler than it sounds. Walk through your current workflow from the moment an order arrives until it's delivered. Write down every step, no matter how small. You'll be surprised at how many unnecessary handoffs and bottlenecks you find just by mapping things out.

Once you see the full picture, continuous improvement becomes much easier. Set aside time each month to review your performance data with your team. What's working well? Where are orders getting stuck? Your frontline staff often have the best insights about what's really happening.

Demand forecasting might sound fancy, but it's really about paying attention to patterns. When do your busiest periods happen? How do seasonal changes affect your orders? For funeral homes, this might mean tracking flu season impacts or regional demographic trends.

The real game-changer comes from ERP and order management system integration. When your systems talk to each other automatically, you eliminate those manual steps where errors creep in. No more updating inventory in three different places or wondering if accounting got the latest order changes.

For high-volume operations, robotics and automation can transform efficiency. Automated conveyor systems and robotic picking aren't just for Amazon - they're becoming accessible for mid-sized operations too. Even simple mobile picking solutions with barcode scanners can cut errors dramatically.

At American Mortuary Coolers, we've learned that even small improvements compound over time. When we standardized how we handle custom cooler specifications, our error rate dropped by 60%. It wasn't a massive technology investment - just better processes and training.

Quick wins to streamline workflows

The fastest improvements often come from the simplest changes. Standardized operating procedures might not sound exciting, but they're incredibly powerful. When everyone follows the same steps, quality becomes predictable and training new staff gets much easier.

Staff training deserves more attention than most operations give it. Your team wants to do good work - they just need clear guidance on how. Regular training sessions don't have to be formal. Sometimes the best learning happens when experienced workers mentor newer team members.

Internal dashboards create magic when everyone can see the same real-time information. When your picking team knows which orders are urgent and your customer service team can see actual shipment status, coordination happens naturally.

Choosing order processing software

Picking the right software feels overwhelming with so many options available. Focus on the features that matter most for your specific operation.

Real-time inventory tracking isn't negotiable anymore. Your system needs to show accurate stock levels across all locations, updated instantly when items are picked or received. Nothing frustrates customers more than ordering something that's actually out of stock.

Multi-warehouse support becomes critical as you grow. Even if you only have one location now, choose software that can handle multiple warehouses. Expanding your operation shouldn't mean replacing your entire system.

Analytics and reporting help you make smarter decisions. Look for systems that show you patterns in your order data - which products sell together, when your busiest times occur, where delays typically happen.

Integration capabilities determine how well your new software plays with existing systems. Your order processing software should connect seamlessly with your accounting system, shipping carriers, and any ecommerce platforms you use.

We've invested heavily in integrated systems that track our custom mortuary coolers from initial customer consultation through final installation. This visibility lets us proactively communicate with funeral homes and solve potential issues before they cause delays.

For broader inventory management strategies, explore these inventory management insights. And if you're dealing with specialized equipment maintenance, check out our guide on More info about walk-in cooler repair tips.

Frequently Asked Questions about the Order Process

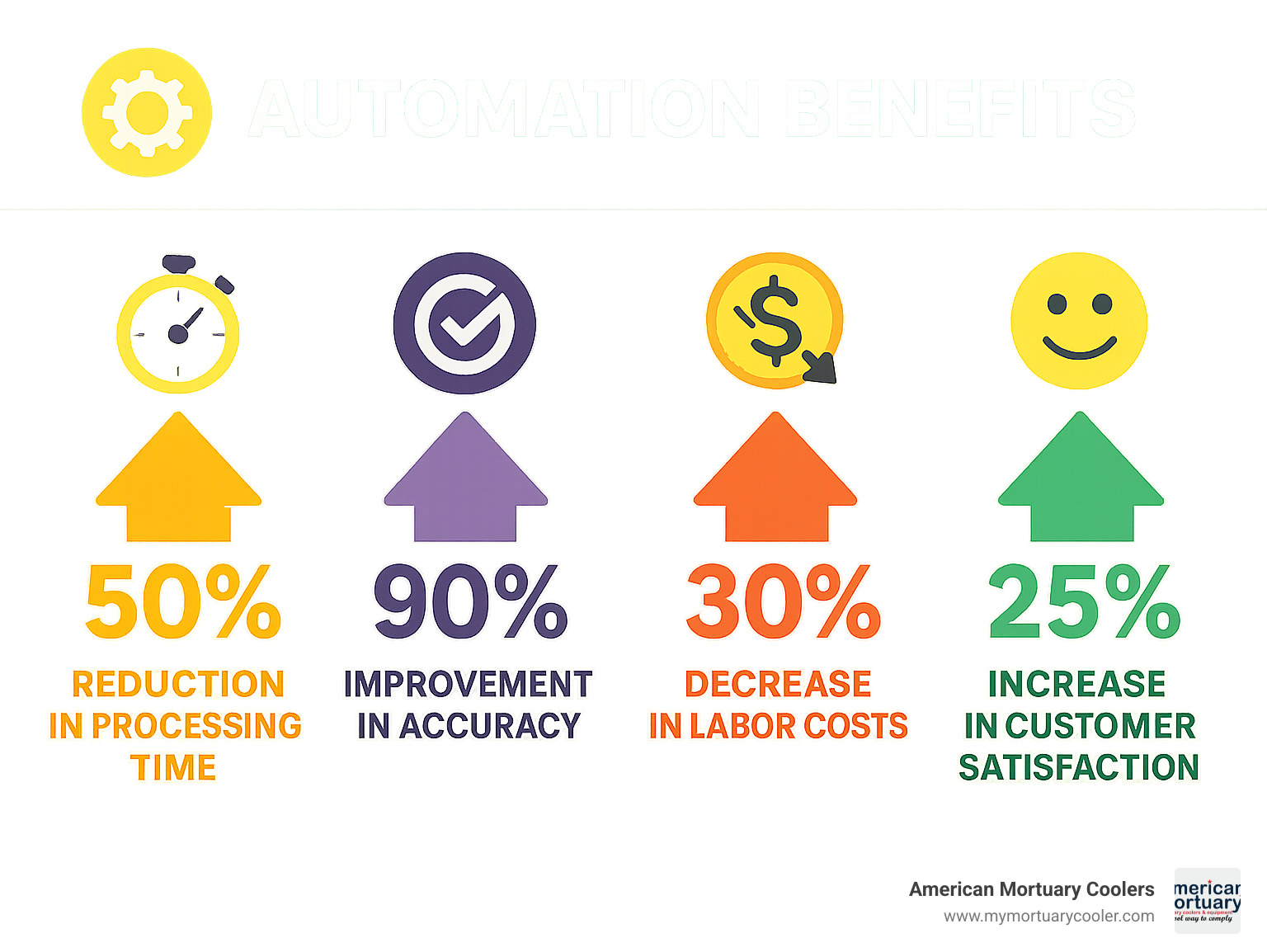

How does automation affect what is the order process?

Automation is revolutionizing what is the order process looks like in modern operations. Instead of staff manually entering data and updating spreadsheets, automated systems handle routine tasks instantly and accurately.

The change is dramatic. Error reduction happens naturally when systems eliminate human data entry mistakes. Speed improvements are immediate - computers don't need coffee breaks or lunch hours. Scalability becomes effortless since automated processes handle sudden order spikes without hiring temporary staff.

But here's the reality check: automation isn't magic. You'll need significant upfront investment, ongoing system maintenance, and comprehensive staff training. The sweet spot is finding the right balance between automation efficiency and human judgment.

At American Mortuary Coolers, we've automated our order confirmation and inventory tracking, but we still rely on experienced team members for custom specifications and installation coordination. Some conversations just need a human touch.

Which metrics matter most to prove ROI?

When you're justifying order processing improvements to management, focus on metrics that directly impact the bottom line.

Cost per order is your golden metric. Track everything - labor hours, packaging materials, shipping costs, and system expenses. When this number drops, profits rise immediately.

Order cycle time matters because speed creates competitive advantage. Customers will pay premium prices for faster delivery, and shorter cycles mean happier customers who become repeat buyers.

Error rates have hidden costs that add up quickly. Every picking mistake, wrong address, or damaged shipment costs money in returns, replacements, and frustrated customers calling your support team.

Customer satisfaction scores predict future revenue better than most financial metrics. Happy customers buy again, refer friends, and cost less to serve over time.

Inventory turnover shows how efficiently you're managing working capital. Faster turnover means less money tied up in stock and reduced risk of obsolescence.

How is order processing linked to inventory & supply-chain management?

Understanding what is the order process means recognizing it's just one piece of a larger puzzle. Your order processing system needs to talk constantly with inventory management and supply chain partners.

Inventory reservation happens the moment customers click "buy." The system must immediately flag those items as unavailable to prevent overselling disasters.

Replenishment triggers activate automatically as stock levels drop. Smart systems generate purchase orders or production requests before you run out completely.

Supplier coordination becomes critical for custom products. When a funeral home orders a specialized mortuary cooler, our system immediately communicates specifications to our manufacturing team and schedules production slots.

Lead time management affects every delivery promise you make. The system must know supplier schedules, manufacturing capacity, and shipping timeframes to give customers accurate delivery dates.

Substitution handling saves orders when primary items aren't available. Rather than disappointing customers, the system can offer alternatives or partial shipments.

At American Mortuary Coolers, our integrated approach means when you order a custom cooler, our system automatically reserves stainless steel, schedules manufacturing time, and coordinates delivery logistics across Tennessee and beyond. Everything connects seamlessly so your funeral home gets exactly what it needs, when promised.

Conclusion & Next Steps

Mastering what is the order process transforms how you serve customers and run your business. It's not just about moving boxes from warehouse shelves to doorsteps - it's about creating a seamless experience that builds trust, reduces costs, and sets you apart from competitors.

When you get order processing right, the benefits ripple through your entire operation. Customer delight happens naturally when orders arrive quickly and accurately. Cost reduction follows as streamlined workflows eliminate waste and reduce handling time. Your business gains a competitive advantage because reliable fulfillment becomes a reason customers choose you over alternatives.

Perhaps most importantly, well-designed order processes scale with your growth. The systems and workflows you build today can handle tomorrow's increased volume without dramatically increasing your costs or complexity.

At American Mortuary Coolers, we've learned these lessons through years of serving funeral homes across the country. Our commitment to durable, custom solutions extends beyond just building quality equipment - it includes how we process and fulfill every order.

We understand that when a funeral home places an order with us, they're not just buying a mortuary cooler. They're trusting us to deliver equipment that helps them serve families during their most difficult moments. There's no room for delays, errors, or confusion in what is the order process when it comes to mortuary equipment.

That's why we've invested in integrated systems that track every custom order from initial specifications through final installation. Every step is designed to ensure funeral directors get exactly what they need, when they need it.

Your next step is taking an honest look at your current order processing capabilities. Start by walking through your existing workflow from a customer's perspective. Where do orders get stuck? What causes the most errors? Which steps take longer than they should?

Map out your current process, measure your key performance indicators, and ask your team where they see opportunities for improvement. Your staff often have the best insights into what's working and what isn't.

Don't try to fix everything at once. Pick one or two areas that will have the biggest impact and focus your efforts there. Maybe it's implementing barcode scanning to reduce picking errors, or integrating your inventory system with your order management platform.

For comprehensive insights into building and optimizing your order workflow, dive into our detailed resource: How Does Order Processing Work? A Step-by-Step Guide.

Understanding what is the order process isn't a destination - it's an ongoing journey. The businesses that thrive are the ones that continuously refine their processes, adapt to changing customer expectations, and invest in systems that support long-term growth.

The effort you put into perfecting your order process today will pay dividends in customer satisfaction, operational efficiency, and business success for years to come.