American Mortuary Equipment: Definition, Categories & U.S. Market Snapshot

When you step into funeral service, you quickly learn that quality equipment isn't just a preference—it's essential. American Mortuary Equipment stands as the gold standard in our industry, combining craftsmanship with reliability in ways imported alternatives simply can't match.

As someone who's helped hundreds of funeral homes find their perfect cooling solutions, I've seen how the right equipment transforms a facility's operations. American-made mortuary products offer that perfect blend of durability and thoughtful design that comes from decades of understanding what funeral professionals truly need.

What makes our domestic manufacturing special? It starts with superior materials and exacting quality control. Most American Mortuary Equipment comes with extended warranties—up to 15 years on cooler panels—because manufacturers stand confidently behind their work. The self-contained cooling systems plug into standard 110V outlets, making installation straightforward even in older facilities. And when you need support, you're talking directly to the people who built your equipment, not navigating through layers of overseas customer service.

The mortuary market has seen steady growth in recent years, with a notable surge during the pandemic that highlighted the critical importance of reliable preservation systems. This challenging period revealed the strength of American supply chains, as domestic manufacturers quickly adapted to meet unprecedented demand.

Core Categories of American Mortuary Equipment

The backbone of any funeral home or morgue facility includes several essential equipment categories. American Mortuary Equipment encompasses everything from refrigeration systems to preparation tools:

Body storage solutions form the foundation, including walk-in coolers, roll-in units, and specialized rack systems that maximize capacity while ensuring respectful handling. Preparation room equipment like embalming tables, fluid injection systems, and ventilation units create a safe, efficient workspace for preparation professionals. Transport systems including stretchers, cots, and church trucks provide dignified movement throughout the facility and beyond.

Innovation continues to drive the industry forward, with digital temperature controls, energy-efficient systems, and modular designs that can adapt to changing needs and spaces.

Leading American Mortuary Equipment Manufacturers

Several companies have established themselves as leaders in American Mortuary Equipment manufacturing:

AWIC (American Walk-In Coolers) specializes in customized walk-in refrigeration systems built to exacting specifications. Their panel systems are renowned for longevity and temperature stability.

Mobi Medical has revolutionized the portable cooler market with their roll-in, self-contained units that require minimal installation—perfect for facilities with limited space or temporary needs.

Mortech offers innovative direct-contact cooling technology, with systems designed for rapid deployment during mass casualty events or pandemic response.

American Mortuary Coolers—that's us—focuses on creating custom cooling solutions delivered directly to funeral homes across the contiguous 48 states. Our Tennessee-based team takes pride in crafting systems perfectly custom to each client's unique requirements.

The terminology in our field can sometimes be confusing. Here's a quick reference to common American Mortuary Equipment terms:

- Mortuary refrigeration systems encompass all cooling technologies used for preservation

- Morgue drawers refer to the sliding storage units common in medical examiner facilities

- Mortuary chamber describes the enclosed space where bodies are stored under controlled conditions

The pandemic certainly taught our industry many lessons, but perhaps the most important was the value of equipment you can truly rely on. When families are counting on you during their most difficult moments, you need equipment that won't let you down. That's the promise of American Mortuary Equipment—quality you can trust when it matters most.

American Mortuary Equipment: Definition, Categories & U.S. Market Snapshot

When we talk about American Mortuary Equipment, we're referring to the specialized tools and systems designed specifically for caring for the deceased. These essential items help funeral homes, morgues, and medical facilities provide dignified death care while ensuring proper preservation and handling of human remains.

The U.S. market for mortuary equipment continues to grow steadily, thanks to new technologies, increased focus on worker safety, and funeral homes seeking more efficient ways to operate. American manufacturers have stepped up to the challenge by creating innovative, energy-efficient products that can be customized to meet the unique needs of death care professionals.

A funeral director from Columbus, Ohio named Paula recently shared: "We are thrilled with our A-200 purchase and after 400+ cases in our first 8 months we still have not had any service issues and we have averaged $12 gas cost over the first 400 cases."

Stories like Paula's highlight why American-made equipment has earned a reputation for reliability and cost-effectiveness. During recent global supply chain disruptions, U.S. manufacturers proved particularly valuable by maintaining production and delivery when imported alternatives faced significant delays.

Core Categories of American Mortuary Equipment

The world of American Mortuary Equipment includes several essential types of products that serve different purposes in the death care process.

Body storage systems form the backbone of any funeral operation, including mortuary coolers (available in walk-in, roll-in, and upright styles), refrigeration units, and specialized storage racks. These systems maintain the perfect preservation conditions for remains awaiting preparation or final disposition.

Preparation room equipment helps funeral professionals perform their technical work with dignity and precision. This includes embalming tables, aspirating machines, proper ventilation systems, and specialized lighting designed for detail-oriented tasks.

Transport systems ensure the respectful movement of remains between locations. From mortuary cots and stretchers to body lifts and vehicle equipment, these tools help maintain dignity throughout the transportation process.

For safe handling of remains of all sizes, specialized handling equipment like hydraulic lifts, body hoists, and bariatric-rated equipment proves essential for staff safety and respectful care.

Cremation equipment rounds out the major categories, with crematory retorts, processing stations, and cooling systems specifically designed for facilities offering cremation services.

Leading American Mortuary Equipment Manufacturers

Several standout companies have established themselves as leaders in the American Mortuary Equipment industry by focusing on quality, innovation, and customer service.

American Walk In Coolers (AWIC) has earned a reputation for excellence with their high-quality mortuary coolers featuring 4-inch no-wood insulated PPS panels. Their 100% Made in the USA products comply with federal energy standards and range from compact 2-body units to larger systems for busier facilities.

Mobi Medical specializes in user-friendly, self-contained mortuary coolers that plug into standard 110V outlets. Their industry-leading warranties (15 years on panels/doors and 5 years on mechanical parts) reflect their confidence in their roll-in, upright, and side-load cooling systems.

Mortech Manufacturing stands out as an innovator with their patented MERC System—the first direct contact cooling system using liquid cooling technology. Their solutions have proven particularly valuable during disaster response situations and pandemic preparedness planning.

American Mortuary Coolers, based in Tennessee with locations nationwide, focuses on creating custom-built solutions delivered directly to funeral homes across the contiguous 48 states. Their ability to craft equipment for unique spaces makes them particularly valuable for facilities with challenging layout constraints.

American Crematory Equipment Company has served the industry since 1974, making them one of the longest-standing manufacturers in North American death care. Their focus on cremation equipment and related systems has established them as specialists in this growing segment of final disposition.

How Mortuary Coolers & Refrigeration Systems Work

Ever wondered what keeps a mortuary cooler running efficiently? It's actually a fascinating blend of engineering and specialized design that makes these systems unique in the refrigeration world.

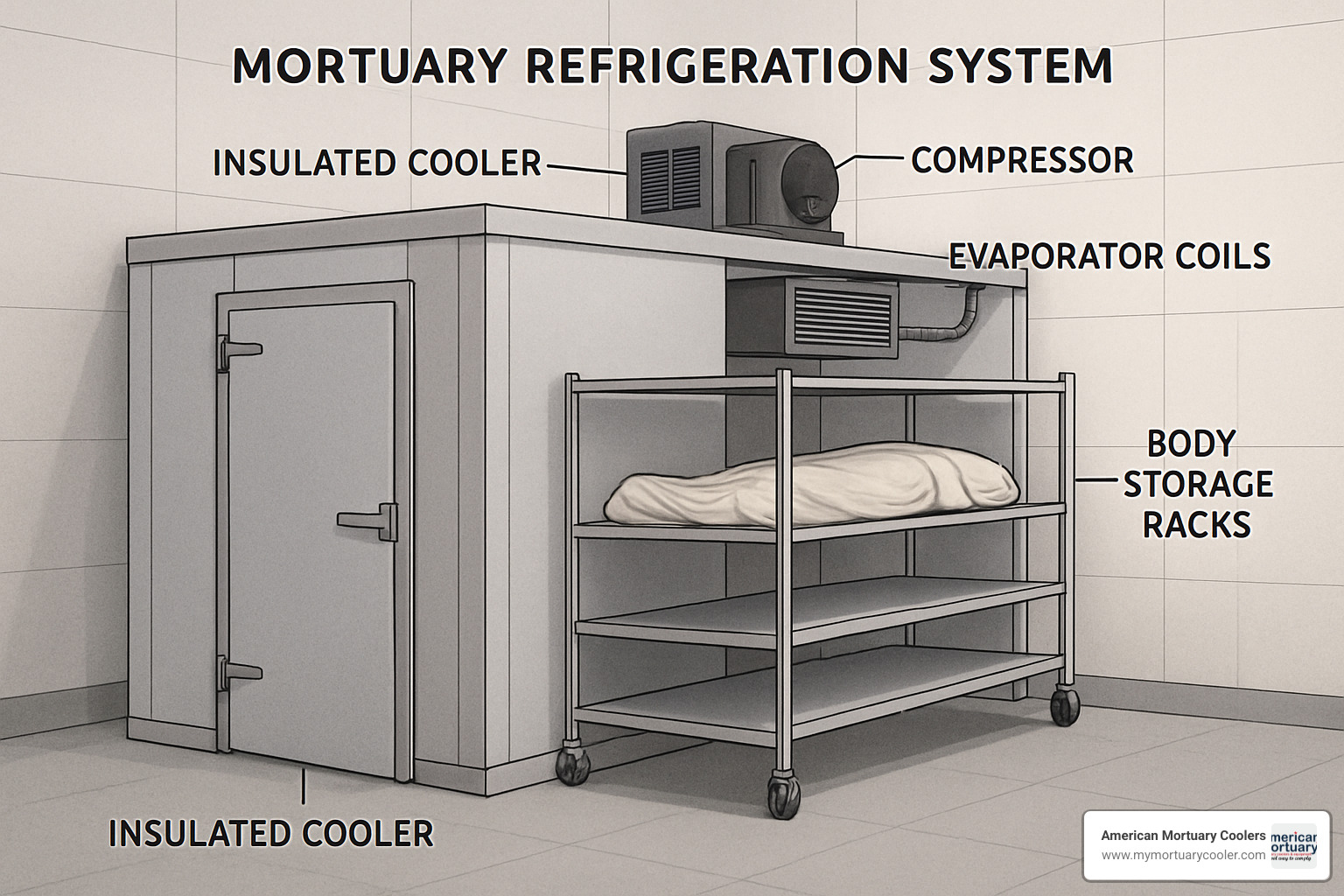

The magic happens through a carefully orchestrated refrigeration cycle. First, the compressor (think of it as the heart of the system) pressurizes refrigerant gas, heating it up in the process. This hot gas then flows through condenser coils, where it releases heat and transforms into liquid form. Next, this liquid passes through an expansion valve that dramatically reduces both its pressure and temperature. Finally, the now-cold refrigerant absorbs heat from inside the cooler as it moves through evaporator coils, returning to gas form and starting the whole dance again.

American Mortuary Equipment stands apart from standard commercial refrigeration because of its precision requirements. Most systems maintain a sweet spot between 35-40°F (1.7-4.4°C) – carefully calibrated to preserve remains without freezing tissues, which could compromise their condition.

"When we installed our new digital control system, the peace of mind was immediate," shares James, a funeral director from Oregon. "Knowing the temperature is consistently perfect lets us focus on serving families rather than worrying about equipment."

Today's modern mortuary coolers feature sophisticated digital controls that provide precise temperature management with built-in alarm systems. These alerts notify staff immediately if temperatures drift outside acceptable ranges – a critical safeguard when preservation is paramount. The specialized air handling systems are designed to maintain consistent temperatures throughout the storage area while minimizing odors.

Many funeral homes also invest in backup systems with redundant components or emergency power connections. This ensures continuous operation even during equipment failures or those inevitable power outages that seem to happen at the worst possible times.

The innovation doesn't stop there. The Mortech MERC System takes refrigeration in a different direction with direct-contact cooling technology. Rather than cooling air (which is less efficient), this system uses liquid cooling technology for more precise temperature control and greater portability – particularly valuable during disaster response situations.

Walk-in vs. Roll-in: Choosing the Right Configuration

When it comes to mortuary cooler designs, funeral homes have several options to match their specific needs:

Walk-in coolers feature insulated panel construction with doorways large enough for staff to enter. These provide maximum capacity and flexibility for larger operations. Most walk-ins use split cooling systems with the condenser unit located outside the cooler, requiring professional HVAC installation but offering quieter operation and better heat management.

Roll-in coolers are designed with convenience in mind. They accommodate standard mortuary cots or body trays on rollers, allowing for easy loading and unloading. One of their biggest advantages is the self-contained refrigeration system that plugs into standard 110V outlets – truly plug-and-play solutions that don't require specialized installation.

For facilities where space is at a premium, upright coolers offer vertical storage with telescoping trays for easy access. These space-saving designs maximize capacity while minimizing the footprint on your facility's floor plan.

Energy Efficiency That Pays For Itself

All new walk-in coolers must comply with the Federal Energy Independence & Security Act of 2007 (EISA), which sets minimum efficiency standards. American Mortuary Equipment manufacturers like AWIC have acceptd these requirements as an opportunity to innovate, using 4-inch high-density insulated PPS panels without wood components to exceed these standards.

The investment in energy-efficient equipment pays dividends quickly. A funeral director from the Midwest recently told us, "After switching to an EISA-compliant cooler, we saw our electricity costs drop by nearly 20%. The investment paid for itself faster than we expected."

These efficiency improvements aren't just good for your bottom line – they also reduce your facility's environmental footprint while ensuring reliable performance for decades to come.

Scientific research confirms that maintaining proper temperatures is essential for preservation. Studies show that cooling to appropriate temperatures significantly slows bacterial growth and tissue degradation, maintaining dignity and safety throughout the preparation process.

More info about mortuary refrigeration requirements

Scientific research on body preservation temperatures

1. AWIC Walk-In Mortuary Coolers

American Walk In Coolers (AWIC) has established itself as a premier provider of walk-in mortuary coolers with a focus on quality American manufacturing and energy compliance.

Key Features:

- 100% Made in USA construction

- 4-inch high-density insulated PPS panels (no wood)

- Compliance with EISA 2007 Title III, Section 312

- Department of Energy Certification

- UL-NSF approval and ASTM E84 testing for smoke and flame spread

- Super-Door package with chrome Kason hinges

- UL-approved vapor-proof LED lighting with exterior switch

- Digital temperature display and controller

- Magnetic door seal gaskets and self-actuating door closures

- Diamond tread kick plates for durability

AWIC offers several standard configurations, including 2-body, 3-body, and 4-body boxes, with options for standard or wide designs and with or without insulated floors.

Their pricing starts at $6,095 for a basic 2-body box (no floor) and ranges up to $9,431 for a 4-body wide box with floor. Accessories include casters ($885), locking handles ($220), alarms ($775), and exterior ramps ($575).

A funeral director from the Southeast shared: "All is well here. I couldn't be happier with the retort. What a great job and I cannot say enough about your technician who put our machine back to its original functioning."

AWIC's 15-year warranty on panels and doors provides exceptional peace of mind for funeral homes making this significant investment. Their customization options allow facilities to design coolers that perfectly fit their available space and workflow requirements.

For facilities with unique requirements, AWIC provides personalized design assistance: "We will be happy to assist you in designing your walk in body box unit of any size... Our knowledgeable and experienced staff will be happy to answer any and all questions."

More info about mortuary refrigeration requirements

2. Mobi Medical Roll-In Self-Contained Coolers

When it comes to convenience without compromising quality, Mobi Medical's roll-in coolers truly shine in the American Mortuary Equipment landscape. These ingenious units have transformed how funeral homes think about refrigeration installation and operation.

What makes these coolers special? It's their true plug-and-play design. Simply wheel the unit into your desired location, plug it into any standard 110V outlet, and you're ready to go. No specialized electrical work, no complex installation process—just immediate functionality when you need it most.

"The day our Mobi Medical cooler arrived changed everything," shares James, a funeral director from Atlanta. "We literally wheeled it in, plugged it in, and were operational within hours. No contractors, no waiting, no hassle."

These versatile units come in several configurations to suit different facility needs. Whether you prefer roll-in styles for direct cot access, upright models to maximize floor space, or side-load designs for easier body access, Mobi Medical has thoughtfully engineered solutions for every situation. Capacity options range from compact 2-body units all the way up to 12-body systems for larger operations.

The attention to practical details is evident throughout their design. Telescoping trays make body access smooth and dignified, while heavy-duty chrome-plated hardware ensures these units can withstand years of daily use. The digital temperature control system maintains precise preservation conditions with minimal oversight required.

For smaller funeral homes where space is at a premium, the roll-in models offer the perfect balance. Staff can wheel a standard mortuary cot directly into the cooler, eliminating the need to transfer remains between surfaces—reducing both physical strain and the potential for accidents during handling.

Perhaps most impressive is Mobi Medical's commitment to standing behind their products. Their warranty coverage sets an industry standard: 15 years on panels and doors and 5 years on mechanical components. This exceptional coverage reflects their confidence in their American Mortuary Equipment and provides valuable peace of mind for funeral homes making this significant investment.

Customization options abound, including casters for improved mobility, energy-efficient LED lighting, insulated floors for improved efficiency, and removable ramps for easier access. Each unit can be custom to fit your facility's specific needs and workflow requirements.

Many hospital morgues and larger funeral operations particularly appreciate the side-load models with their telescoping stainless steel trays. This design allows staff to access specific remains without disturbing others, improving workflow efficiency in busy environments.

Ready to explore how Mobi Medical's self-contained coolers might transform your operation? More info about comparing systems is available to help you make an informed decision for your facility's unique needs.

3. Mortech MERC Portable Direct-Contact Cooling System

When disaster strikes or facilities face unexpected surges, the Mortech MERC System stands ready as a game-changing solution in the mortuary world. This innovative system—whose name stands for Mortuary Improved Remains Cooling—has revolutionized how we think about emergency preservation.

Unlike traditional coolers that chill the air around remains, the MERC System uses a completely different approach. It employs direct contact liquid cooling technology that touches the remains themselves, creating more efficient temperature management while using less space and power. It's like the difference between cooling your entire kitchen versus just keeping the food in your refrigerator cold!

"We deployed the MERC System during our COVID surge, and it was operational within hours," shared one hospital administrator from a major urban center. "When our standard capacity was overwhelmed, these units literally saved us from an impossible situation."

What makes the MERC System particularly valuable is its incredible flexibility. The system is completely portable, allowing it to be transported in standard vehicles to wherever it's needed most. Whether it's a natural disaster site, a remote location, or a facility experiencing unexpected demand, the MERC can be there quickly.

The modular design means you can start with the capacity you need today and expand it tomorrow. Components work together or independently, giving emergency managers unprecedented flexibility during crisis response. This interoperability proved invaluable during the pandemic when many facilities faced rapidly changing circumstances.

Digital temperature controls ensure precise preservation conditions, even in challenging environments. The system plugs into standard electrical systems, eliminating the need for specialized power infrastructure—a critical advantage when responding to disaster areas.

The MERC System has found particular value in three challenging scenarios:

- Pandemic response situations where facilities face unprecedented case volumes

- Natural disaster recovery efforts where infrastructure may be compromised

- Opioid epidemic hotspots where communities experience unexpected surges

For emergency management professionals, the MERC represents a reliable solution that can be deployed with minimal training and maximum impact. Its American-made quality ensures dependability when it matters most, while its innovative approach solves problems that traditional cooling systems simply cannot address.

When dignity and preservation can't wait for permanent infrastructure, the Mortech MERC System delivers immediate, effective cooling capability wherever and whenever it's needed.

4. American Mortuary Coolers Custom Walk-In & Roll-In Systems

When it comes to mortuary refrigeration, one size definitely doesn't fit all. That's why we at American Mortuary Coolers take such pride in our custom approach. Based in Tennessee with friendly faces in regional offices across the country, we've built our reputation on creating refrigeration solutions that feel like they were made just for you—because they actually were!

Custom sizing is at the heart of what we do. We understand that every prep room is different, and those precious square feet matter. Whether you're working with an oddly shaped corner or trying to maximize a compact space, we measure carefully and design thoughtfully to give you the perfect fit.

"I was convinced we'd need to knock down a wall to fit a decent cooler," shares James, a funeral director from Oregon. "The team at American Mortuary Coolers proved me wrong. They designed a unit that fits our unusual space perfectly and actually improved our workflow. It's like it was always meant to be there."

Our 100% Made in USA construction isn't just a point of pride—it's your guarantee of quality and craftsmanship that stands the test of time. We use modular panel designs that allow for truly flexible configurations, whether you need a standard rectangle or something more creative like an L-shape to work around existing fixtures.

Energy efficiency isn't optional anymore, and we've acceptd that reality. All our systems comply with EISA standards, helping you keep operational costs in check while doing your part for the environment. The digital temperature controls with alarm capabilities give you peace of mind, especially during those rare times when you're not at the funeral home.

From intimate family operations needing a 2-body system to busy urban facilities requiring 12-body capacity, we scale to your needs. And you've got options—roll-in designs for easy loading, walk-in configurations for maximum capacity, or hybrid solutions that give you the best of both worlds.

What truly sets us apart is what happens after installation. Our nationwide presence means we're never too far away if you need us. When Maria from Miami had questions about her digital control system, we had someone on site the next day—not weeks later.

The funeral profession is built on personal relationships and trust. We bring that same approach to equipment design. Instead of just shipping standard units, we start with a conversation. We want to understand your specific challenges, your workflow patterns, and even your plans for the future. That way, the solution we create doesn't just meet today's needs—it grows with your business.

For historic funeral homes in older buildings, we've become something of specialists. These beautiful, character-filled spaces often present unique challenges, but there's something deeply satisfying about designing a modern refrigeration system that respects the building's heritage while providing all the benefits of current technology.

From initial design to final installation and beyond, we're with you every step of the way. Because in this profession, details matter. And so does having partners you can count on.

More info about custom mortuary coolers

5. Essential Accessories: Body Storage Racks & Transport Stretchers

When you're equipping your mortuary facility, the coolers are just part of the equation. The accessories that help you move and store remains with dignity are equally important to your daily operations. Let's look at how American manufacturers have created thoughtful solutions for these critical components.

Body storage racks are the unsung heroes of any well-organized mortuary. Made from heavy-duty stainless steel, these workhorses do more than just maximize your space – they make your entire workflow smoother and safer.

I recently spoke with a funeral director in Oregon who told me, "Our new adjustable racks have been a game-changer. We can configure them differently depending on our needs that week, and the roller system makes loading so much easier on my back."

That's exactly what makes American Mortuary Equipment stand out – the thoughtful engineering that considers both the deceased and the caregivers. These racks feature telescoping slide rails that give you easy access even in tight spaces, and most can handle weights up to 650 pounds per shelf. The stainless steel construction isn't just about durability (though they'll last for decades) – it's also essential for thorough sanitization between uses.

When it comes to transport stretchers and cots, American manufacturers have focused on creating equipment that's both functional and compassionate. The anodized aluminum construction prevents oxidation while keeping the weight manageable – most weigh around 58 pounds, yet can safely transport individuals up to 650 pounds.

What funeral professionals appreciate most are the smart design features. Automatic locking mechanisms on the reinforced legs provide security during transport. The height adjustment range (typically 10" to 32½") means you can align perfectly with both vehicles and preparation tables. Heat-sealed mattresses resist fluids while providing a dignified surface.

"The single-person operation capability of our American-made cot has been invaluable," shared a funeral director from Chicago. "It's dramatically reduced the physical strain of removals, especially for our older team members."

These transport systems shine in their versatility. The locking swivel wheels make navigating tight hallways and doorways much easier, while integrated restraint straps ensure secure transport over uneven surfaces or during vehicle transport.

Many forward-thinking funeral homes keep extra racks and stretchers on hand for disaster preparedness. The exceptional durability of American Mortuary Equipment means these reserve units remain fully functional even after extended storage periods – ready when you need them most.

The investment in quality accessories pays dividends in both operational efficiency and staff wellbeing. When your team has the right tools, they can focus on providing compassionate care rather than struggling with inadequate equipment.

More info about buying funeral equipment

Buying Guide: Pricing, Warranty, Compliance & Custom Ordering

Shopping for mortuary equipment is a significant investment for any funeral home. Whether you're upgrading your existing setup or equipping a new facility, understanding what to expect regarding costs, warranties, and the ordering process will help you make confident decisions.

Pricing: What to Expect

Let's talk dollars and cents - what should you budget for quality American Mortuary Equipment?

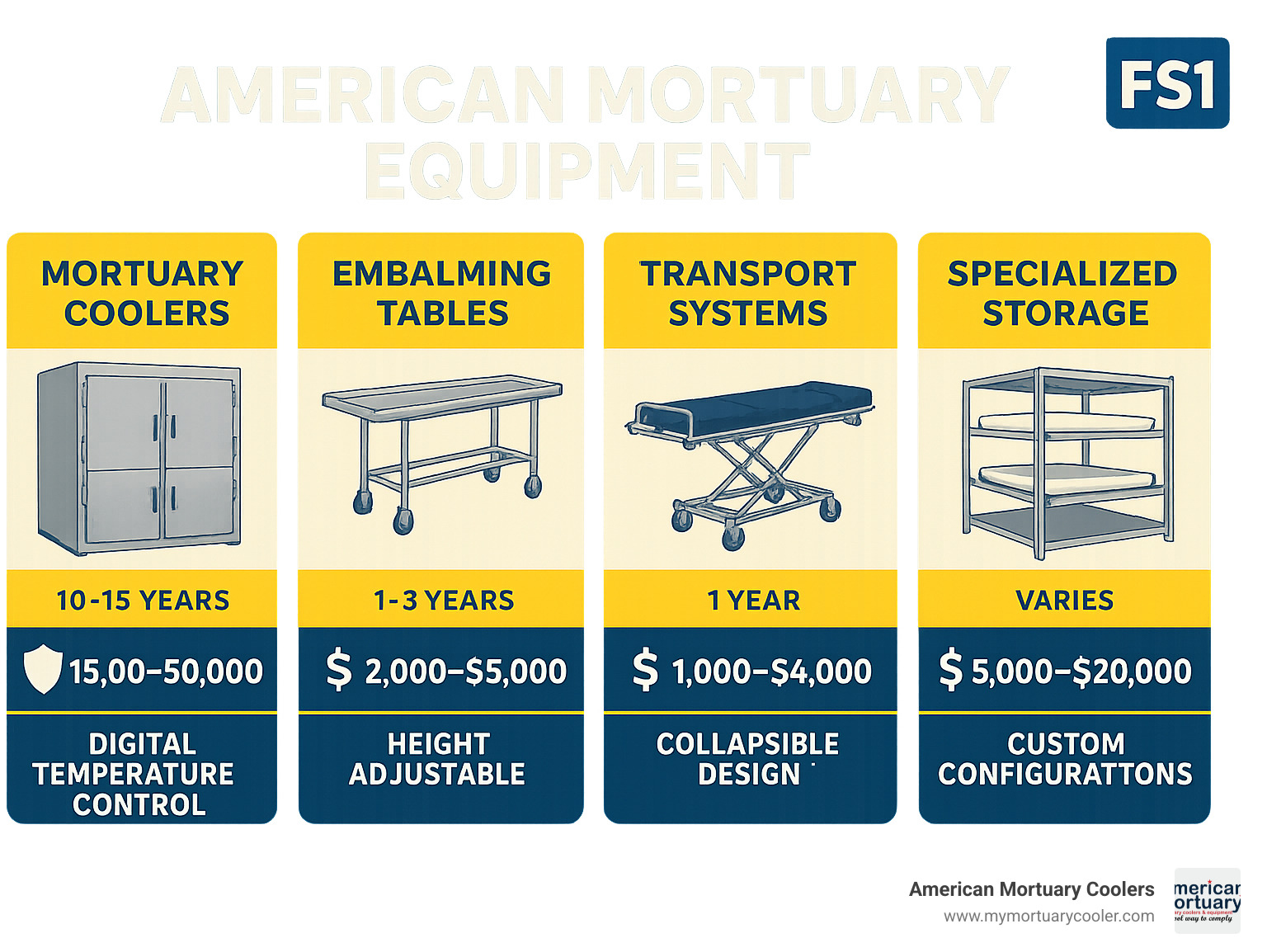

For mortuary coolers, prices typically start around $6,095 for a basic 2-body unit and can reach $25,000+ for larger custom walk-ins with all the bells and whistles. A standard 3-body unit generally falls between $7,611 and $8,952, while a 4-body wide unit with floors runs approximately $9,431.

Body storage racks are considerably more affordable, with complete systems ranging from $1,000 to $4,000 depending on capacity and materials. If you just need individual roller assemblies, expect to pay around $200-$300 each.

Embalming tables start around $3,000 for basic fixed-height models, while hydraulic options with advanced features can cost between $4,000 and $6,000.

For transport equipment, standard mortuary cots begin at about $1,500, with advanced hydraulic models reaching up to $3,500.

"We initially balked at the price difference between American-made and imported options," shares Mark, a funeral director from Oregon. "But after our imported cooler failed twice in the first year, we switched to American-made. Five years later, we haven't had a single issue - the peace of mind alone was worth every penny."

Warranties That Actually Protect You

One of the major advantages of choosing American Mortuary Equipment is the comprehensive warranty coverage. Most American manufacturers stand firmly behind their products with warranties that significantly outshine imported alternatives:

Cooler panels and doors typically carry impressive 15-year warranties, while mechanical components are usually covered for 5 years. Digital controls generally come with 1-3 year protection, transport equipment with 3-5 years, and embalming tables with 5-10 years of coverage.

Always ask exactly what's included in the warranty. Does it cover parts only, or does it include labor for repairs? Is on-site service available, or will components need to be shipped back to the manufacturer? These details can make a significant difference when you need service.

Navigating Regulatory Requirements

Compliance isn't optional in our industry, and quality American Mortuary Equipment is designed with these requirements in mind:

The Energy Independence & Security Act (EISA) sets mandatory efficiency standards for all walk-in coolers under federal law 110-140 Title III Section 312. OSHA standards govern worker safety features and ventilation requirements, while the National Funeral Directors Association (NFDA) provides important best practices.

Don't forget that state regulations vary considerably, particularly regarding required refrigeration capacity. American manufacturers are typically well-versed in these requirements and can help ensure your purchase meets all applicable standards.

The Custom Ordering Experience

For many funeral homes, custom equipment provides the perfect balance of functionality and space efficiency. Here's what the typical ordering process looks like:

The journey begins with an initial consultation to discuss your specific needs, space constraints, and capacity requirements. This is followed by precise site measurements to ensure a perfect fit. You'll then receive a detailed design proposal with drawings and specifications for your approval.

Manufacturing generally takes 4-8 weeks for custom units, followed by coordinated delivery with optional professional installation. The process concludes with thorough system testing and staff training on proper operation.

"The design team really listened to our concerns about our oddly-shaped preparation room," explains Sarah, a funeral home manager from Texas. "They created a custom L-shaped cooler that maximized our capacity while still allowing comfortable workspace. It's like it was built specifically for our building – because it was!"

Many manufacturers understand the financial impact of these purchases and offer financing options to help manage the investment. For example, some companies provide three-payment plans of approximately $995 each for larger purchases, making quality equipment more accessible.

More info about buying funeral home equipment

Frequently Asked Questions about American Mortuary Equipment

What distinguishes American-made mortuary equipment from imports?

When it comes to quality and reliability, American Mortuary Equipment stands head and shoulders above imported alternatives. The difference isn't just about patriotism – it's about tangible benefits that matter in daily operations.

American manufacturers use higher-grade materials throughout their products. You'll find superior stainless steel that resists corrosion, more durable plastics that won't crack under pressure, and better insulation that maintains temperatures more efficiently. This attention to materials translates directly to equipment longevity.

The quality control process for American-made equipment is notably more rigorous. With production happening on U.S. soil, manufacturers can implement stricter testing protocols and more thorough inspections before anything leaves the factory floor.

Perhaps most reassuring for funeral directors is the warranty difference. While imported units might offer 1-2 year coverage, American manufacturers typically stand behind their products with warranties extending up to 15 years on certain components. This confidence speaks volumes about expected durability.

"After struggling with an imported cooler that failed twice in three years, we switched to an American-made unit," shared a funeral director from New York. "The difference in build quality was immediately apparent, and five years later, we haven't had a single issue."

When something does need attention, the advantages continue. Parts for American-made equipment are typically available within days rather than weeks or months, and you'll get support from people who understand both the equipment and the unique needs of funeral professionals.

How has pandemic demand affected equipment lead-times?

The unprecedented challenges of COVID-19 created ripple effects throughout the mortuary equipment industry that we're still feeling today, though the situation has largely stabilized.

For standard, catalog-type equipment, lead times have mostly returned to their pre-pandemic norms of 2-4 weeks from order to delivery. However, if you're looking for custom-designed coolers or specialized solutions, you should still plan for somewhat extended timelines – typically 8-12 weeks instead of the pre-pandemic 4-8 weeks.

The pandemic highlighted another advantage of domestic manufacturing. While international supply chains faced severe disruptions, American manufacturers generally maintained more consistent production capabilities, even during the height of the crisis.

Some electronic components and specialized parts continue to experience occasional availability issues. This is why we always recommend planning your equipment purchases with as much lead time as possible, especially for custom configurations or larger systems.

Many funeral homes learned valuable lessons about capacity planning during the pandemic. Having adequate refrigeration capacity – perhaps even slightly more than your typical needs – provides crucial flexibility during unexpected surges.

What should I measure before ordering a walk-in cooler?

Getting the right fit for your mortuary cooler starts with accurate measurements, and there's more to consider than you might initially think.

Floor space dimensions are the obvious starting point – measure the exact width and depth of your available area. Don't forget to account for any obstructions like columns, existing equipment, or utility connections that might impact the usable space.

Ceiling height is equally important, especially for walk-in units. Measure from the floor to the lowest point of the ceiling, noting any overhead obstacles like light fixtures, sprinkler heads, or ductwork that might limit your vertical space.

Access is a consideration that's easy to overlook. Measure all doorways, hallways, and corners that equipment will need to steer during delivery. Many a funeral director has had the unpleasant surprise of equipment that won't fit through their building's entrance!

"We thought we had measured correctly, but forgot to account for the swing radius of our prep room door," admitted a funeral home owner from Los Angeles. "The manufacturer caught this during their site verification and adjusted the design accordingly, saving us from a major headache."

Don't forget practical considerations like your floor's load capacity (especially important for upper floors), the location of electrical outlets, proximity to floor drains for condensate removal, and adequate ventilation space around the unit.

Most reputable manufacturers, including American Mortuary Coolers, offer measurement assistance or verification services to ensure everything is accurate before production begins. Taking advantage of this expertise can prevent costly mistakes and ensure your new equipment integrates perfectly with your existing space.

At American Mortuary Coolers, we understand that every funeral home has unique needs and space constraints. That's why we specialize in custom solutions that fit your specific requirements – because one-size-fits-all rarely does.

More info about buying funeral equipment

Conclusion

When it comes to American Mortuary Equipment, investing in quality, reliability, and domestic craftsmanship truly pays dividends through years of trouble-free operation. Here at American Mortuary Coolers, we're genuinely proud of our Tennessee roots and our ability to deliver thoughtfully designed solutions to funeral homes throughout the lower 48 states.

The equipment choices you make today will be with you for decades to come. That's not just a statement – it's a reality our customers experience every day. American-made mortuary coolers, stretchers, tables, and accessories give you something invaluable: the confidence that your equipment will perform flawlessly during those moments when families need your services most.

I've seen how quality equipment allows funeral professionals to focus on what truly matters – providing compassionate care to grieving families rather than troubleshooting equipment failures.

Key things to remember when selecting your equipment:

Quality matters tremendously in this field. The difference between premium American-made equipment and budget imports becomes crystal clear over years of daily use – often at the most inconvenient possible moments.

While American equipment might have a higher price tag initially, the extended warranties, improved energy efficiency, and remarkable durability typically result in significantly lower costs over the equipment's lifetime. Many of our customers tell us their units are still performing beautifully after 15+ years of service.

When selecting equipment capacity, think beyond today. Consider not just your current volume but what your needs might be 10-15 years down the road. The funeral industry evolves, and communities grow and change.

Always verify that your equipment meets current EISA standards and other relevant regulations. Non-compliant equipment can lead to headaches down the road, from higher energy bills to potential regulatory issues.

Remember the value of reliable support. When an unexpected equipment issue arises (and eventually, something always does), having prompt access to service and parts makes all the difference.

As one family in Columbus, Ohio, shared about their American-made cooler: "We are thrilled with our purchase and after 400+ cases in our first 8 months we still have not had any service issues and we have averaged $12 gas cost over the first 400 cases."

This wonderful combination of reliability and efficiency perfectly illustrates why American Mortuary Equipment continues to be the gold standard for funeral professionals who simply won't compromise on quality. When you're caring for families during their most vulnerable moments, your equipment should be the last thing you need to worry about.