Understanding the Critical Role of Morgue Refrigeration

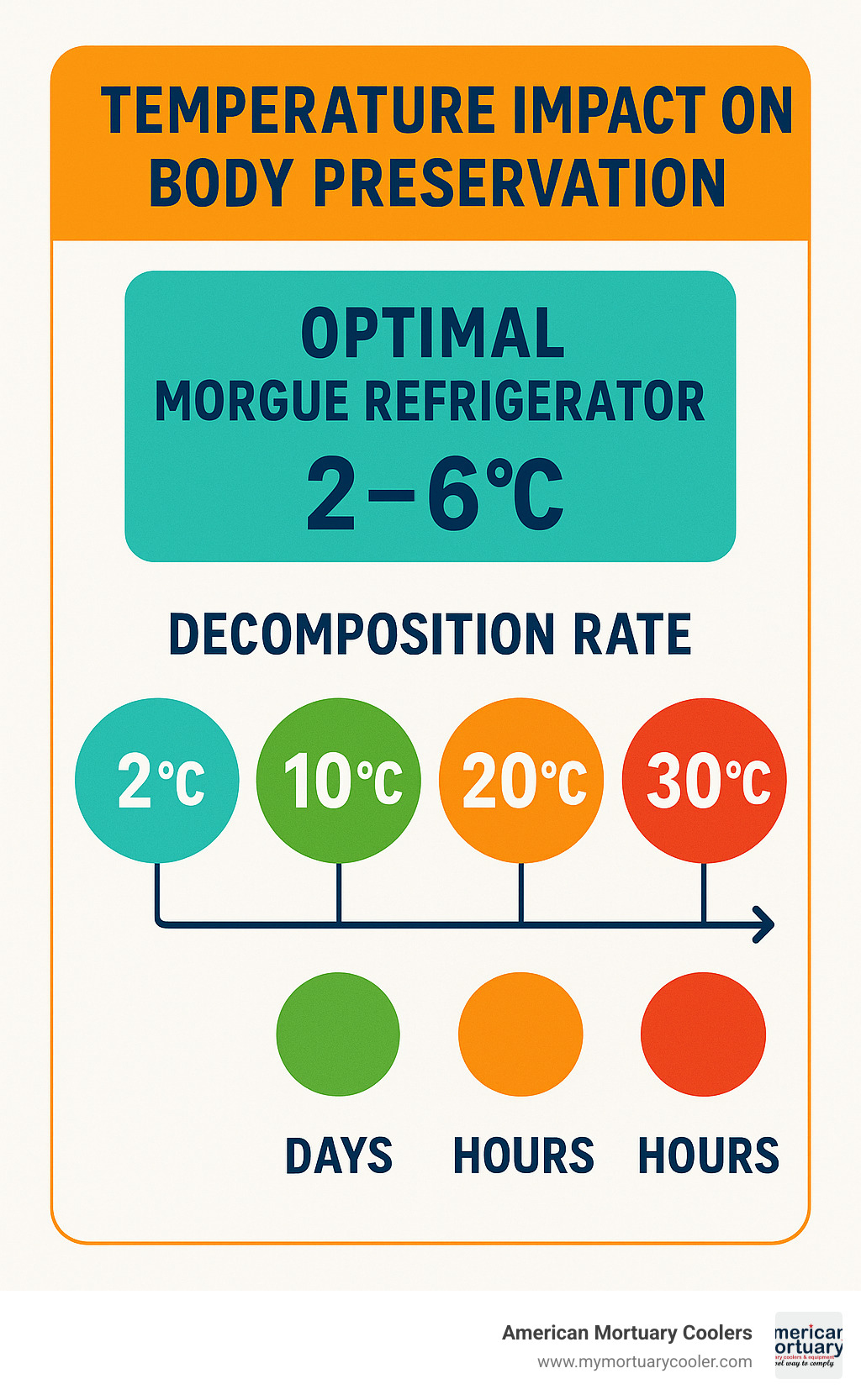

A morgue refrigerator is specialized cold storage equipment designed to preserve human remains by maintaining temperatures between 2°C and 6°C (36°F to 43°F). These units are essential for slowing decomposition and maintaining dignity in death care settings.

| Quick Facts About Morgue Refrigerators |

|---|

| Temperature Range: 2-6°C (36-43°F) |

| Common Names: Mortuary cabinet, mortuary refrigerator, cadaver locker, morgue cooler |

| Primary Purpose: Preserve human remains and slow decomposition |

| Main Types: Single-door, multi-drawer, walk-in, roll-in, side-load, bariatric |

| Typical Capacity: Single body to 50+ bodies depending on configuration |

| Construction: Stainless steel (typically Type 304, 18-gauge) with 4-inch insulated panels |

The preservation of human remains requires precise temperature control. Without proper refrigeration, natural decomposition processes begin immediately after death, accelerating significantly within the first 24 hours. Modern morgue refrigeration systems not only address this biological reality but do so while maintaining the dignity and respect owed to the deceased.

For funeral homes, hospitals, and forensic facilities, reliable morgue refrigeration is non-negotiable. These specialized units differ significantly from commercial refrigeration in their construction, temperature precision, and interior design features like body trays and telescoping racks that can support up to 500 pounds.

Today's morgue refrigerators incorporate advanced features like digital temperature controllers, high/low temperature alarms, antimicrobial surfaces, and energy-efficient cooling systems using environmentally friendly refrigerants. Many units can be customized to fit specific facility needs, from compact single-body cabinets to expansive walk-in systems capable of storing dozens of remains.

I'm Mortuary Cooler, a national-level supplier of morgue refrigerators with extensive experience helping funeral directors select the right morgue refrigerator solutions for their specific facility needs. My expertise includes customizing morgue refrigerator specifications to optimize workflow efficiency while maintaining strict temperature control for proper preservation.

Common morgue refrigerator vocab:

What Is a Morgue Refrigerator?

A morgue refrigerator is much more than just a cold storage unit – it's specialized equipment designed with the solemn purpose of preserving human remains with dignity. These units create a stable, cool environment (typically between 2°C and 6°C or 36°F to 43°F) that significantly slows the natural decomposition process that begins immediately after death. This temperature control provides respectful temporary storage while families make arrangements, medical examiners complete their work, or funeral directors prepare for services.

You might hear these essential units called by several different names across the funeral industry:

- Mortuary cabinet

- Mortuary refrigerator

- Morgue cooler

- Cadaver locker

- Body box refrigerator

- Mortuary freezer (when referring to negative temperature units)

Here at American Mortuary Coolers, we've been handcrafting these specialized units for decades in our Tennessee manufacturing center. We're proud to serve facilities throughout all 48 contiguous states through our regional distribution points in Atlanta, Chicago, Dallas, New York, and Los Angeles.

How a Morgue Refrigerator Works

The science behind a morgue refrigerator follows the same basic principles as your kitchen refrigerator, but with crucial modifications specifically designed for the dignified preservation of human remains.

The refrigeration cycle is neatly simple: a hermetically sealed compressor pressurizes refrigerant gas, which then releases heat as it condenses to liquid. This liquid expands and cools rapidly before absorbing heat from the cabinet interior as it evaporates, starting the cycle again.

What sets our morgue units apart is how we implement these principles:

Our systems use forced-air circulation with coaxial blowers to ensure the temperature remains perfectly uniform throughout the cabinet. This eliminates hot spots that could compromise preservation in certain areas. Digital microprocessor-based PID thermostats maintain incredibly precise temperatures (within ±1°C) while humidity control mechanisms prevent the condensation that could affect the deceased.

The 4-inch thick polyurethane foam insulation panels (with an impressive R-value of 32) create an exceptional thermal barrier that keeps the cold in and the heat out. And of course, we use only environmentally friendly, CFC-free refrigerants like R134a that comply with current regulations.

We design the entire system for optimal preservation with minimal energy use and maximum reliability. Many of our units feature redundant systems – because when it comes to caring for the deceased, backup plans aren't optional.

Positive vs Negative Morgue Refrigerator Temperatures

When it comes to morgue refrigerators, temperature isn't one-size-fits-all. We offer two primary configurations to meet different needs in death care:

Positive Temperature Refrigerators (2°C to 4°C) are the standard choice for most funeral homes and hospitals. They effectively slow decomposition without freezing tissues, which makes them ideal for preserving bodies that will be viewed or embalmed. They consume less energy, require simpler maintenance, and are perfect for the typical storage duration of hours to days.

Negative Temperature Refrigerators (-10°C to -50°C) serve a different purpose, primarily in forensic settings and long-term storage situations. By freezing tissues, they nearly halt decomposition completely, preserving forensic evidence for extended periods. While they demand more energy and require more robust cooling systems, they're invaluable when bodies need to be stored for weeks or even months.

| Feature | Positive Temperature Units | Negative Temperature Units |

|---|---|---|

| Temperature | 2°C to 4°C (36°F to 39°F) | -10°C to -50°C (14°F to -58°F) |

| Primary Use | Hospitals, Funeral Homes | Forensic Labs, Long-term Storage |

| Decomposition | Slowed significantly | Nearly halted |

| Energy Use | Lower | Higher |

| Body Impact | Minimal tissue change | Freezing may alter tissues |

| Cost | Lower initial and operating costs | Higher initial and operating costs |

| Typical Duration | Hours to days | Weeks to months |

When helping our clients choose between these options, we consider their specific needs, budget constraints, and how long they typically store remains. Every facility is unique, and at American Mortuary Coolers, we take pride in finding the perfect balance of functionality, efficiency, and respect for each situation.

Types & Configurations to Fit Every Facility

When it comes to morgue refrigerators, one size definitely doesn't fit all. We've seen how different facilities have unique needs, space limitations, and varying case volumes. That's why we offer such a diverse range of options to ensure you find the perfect fit.

Our single-door units are perfect for smaller operations like rural hospitals or boutique funeral homes. They hold 1-2 bodies while taking up minimal floor space—about the same footprint as your home refrigerator. These units plug into standard 110V outlets and come with self-contained refrigeration systems that make installation a breeze.

For mid-sized facilities handling more cases, our multi-drawer units offer an neat solution. These stack bodies horizontally in individual drawers (holding anywhere from 2-15 remains) and allow you to access each compartment separately. This means you can retrieve one body without exposing others to warm air—a huge advantage for busy facilities where multiple staff members might need access throughout the day.

When capacity needs grow beyond a handful of bodies, walk-in coolers become the gold standard. These room-sized refrigerated spaces can accommodate 5 to 50+ bodies using specialized rack systems. The interior configuration can be customized to your workflow, making them ideal for county morgues, large hospitals, and facilities that need to be prepared for mass casualty events.

"The staff at American Mortuary Coolers helped us design a walk-in system that doubled our capacity without increasing our footprint," a customer from a metropolitan hospital recently told us. "They understood our workflow needs from the start."

For facilities concerned with minimizing staff lifting and transfer requirements, our roll-in units are a game-changer. These accommodate gurneys or body carts directly, reducing the physical strain on your team while maintaining proper refrigeration for 1-6 bodies.

Working with a challenging space? Our side-load configurations might be your answer. Instead of loading from the end (which requires more clearance space), these units allow bodies to be inserted from the side—perfect for narrow rooms or awkward layouts where every inch matters.

We also understand the importance of accommodating all body types with dignity. Our bariatric morgue refrigerators feature reinforced trays, wider compartments, and higher weight capacities to properly care for larger individuals. These specialized units ensure every person in your care receives the same level of respect and proper handling.

The modular panel construction we use allows us to create custom configurations for virtually any space or requirement. During the COVID-19 pandemic, this flexibility proved invaluable as facilities scrambled to increase capacity. Many turned to mobile trailer solutions and overflow storage when their permanent installations reached capacity.

Choosing the Right Morgue Refrigerator Size

Selecting the appropriate morgue refrigerator size isn't just about counting how many bodies you handle today—it's about planning for tomorrow too. We typically work through five key considerations with our clients:

First, analyze your current case volume, looking at both average and peak periods. Next, consider your typical turnover rate—how quickly bodies move through your facility affects how much storage you need at any given time. Don't forget to factor in future growth projections based on population trends in your service area.

Your available space matters too—we'll need precise measurements of your available footprint, including clearance for doors and service access. Finally, think about workflow efficiency and how the unit will integrate with your existing processes.

Based on decades of experience, we recommend adding at least 25% capacity beyond your current peak needs. This buffer accommodates unexpected surges and future growth without requiring another major investment down the road.

Specialty Morgue Refrigerator Solutions

Beyond our standard offerings, we've developed several specialized morgue refrigerator solutions for unique circumstances.

Our bariatric storage solutions feature extra-wide compartments (up to 44" width) with reinforced trays supporting over 750 pounds. We can also recommend compatible lifting and transfer equipment to ensure staff safety when handling larger remains.

For facilities with specific workflow needs, our passthrough designs include doors on opposite sides of the unit. This creates a natural separation between "clean" and "dirty" areas—ideal for medical examiners' offices where bodies move from autopsy to storage areas through a logical progression.

When disaster strikes or temporary capacity is needed, our portable and pop-up units provide rapidly deployable refrigeration with self-contained operation. These units have proven invaluable during natural disasters, pandemic surges, and other emergency situations.

Military and disaster response teams often rely on our field deployment systems, which are ruggedized for non-traditional environments and compatible with generator power. These units are built to withstand harsh conditions while maintaining proper preservation temperatures.

For facilities focused on emergency preparedness, we offer modular expansion systems with quick-connect utilities designed for rapid capacity scaling during mass casualty events. These can be stored compactly and deployed quickly when needed.

From our regional distribution centers across the country—Southeast, Southwest, Midwest, Northeast, Rocky Mountain, and Pacific regions—American Mortuary Coolers can quickly deliver these specialized solutions nationwide. We understand that when you need additional capacity, you often need it immediately, not weeks down the road.

Critical Features & Construction Details

When it comes to morgue refrigerators, the details truly matter. These aren't just cold boxes – they're sophisticated systems designed to preserve dignity while maintaining perfect preservation conditions.

At American Mortuary Coolers, we've spent decades perfecting the construction of these essential units. The foundation starts with 304 stainless steel – the gold standard in the industry. This isn't just any stainless steel; it's an 18-gauge construction with a #4 satin finish that resists fingerprints and makes cleaning remarkably simple. When you run your hand across one of our units, you'll feel the quality difference immediately.

Insulation is where the real magic happens. Our 4-inch polyurethane panels create an exceptional thermal barrier with tongue-and-groove connections that lock tightly together. This design eliminates those pesky thermal bridges that can compromise efficiency. We've also integrated vapor barriers throughout, preventing the moisture infiltration that can degrade insulation over time.

Inside our morgue refrigerators, you'll find thoughtfully designed components that make daily operations smoother. Our telescopic rack systems glide out effortlessly, providing full access without strain. The heavy-duty trays support up to 500 pounds, ensuring safe handling for all individuals. We've designed adjustable shelving options too, because we understand that flexibility matters in your facility.

The brains of our units – the control systems – maintain that critical temperature sweet spot within ±1°C. Digital controllers provide precise readings, while high/low temperature alarms offer peace of mind. Many facilities appreciate our optional data logging features, which simplify compliance documentation and provide a complete temperature history.

We've thoughtfully incorporated LED lighting throughout – vapor-proof fixtures that provide excellent visibility without generating heat. Safety release mechanisms are standard in our walk-in units (nobody wants to get accidentally locked inside!), and our antimicrobial SmartProtec® finishes create an environment that actively resists bacterial growth.

Even our door systems reflect our attention to detail. Chrome-plated hardware maintains its appearance year after year, while magnetic gaskets create tight seals that are easy to replace during maintenance. In larger units, heated door frames prevent that frustrating condensation and frost buildup that can compromise efficiency.

Every morgue refrigerator we build comes from our Tennessee manufacturing facility, crafted from American steel by skilled technicians who understand the importance of their work. It's not just about building refrigeration units – it's about creating systems that honor the deceased and serve the living.

Hygiene and Safety Considerations

Let's talk cleanliness – because in this industry, it's non-negotiable. Our morgue refrigerators feature seamless interior construction that eliminates hiding places for contaminants. Those rounded corners aren't just for looks; they make thorough cleaning significantly easier. And our removable trays? They allow for complete sanitization, reaching areas that might otherwise be inaccessible.

The surfaces inside our units are completely non-porous, standing up to frequent disinfection with hospital-grade cleaners. The chemical-resistant finishes won't degrade or discolor over time, maintaining both function and appearance. Even the door gaskets are removable for cleaning or replacement – a small detail that makes a big difference in maintaining hygiene standards.

We've given careful thought to condensation management too. Proper insulation prevents that annoying "sweating" on exterior surfaces, while our condensate management systems prevent water accumulation. In walk-in units, we incorporate slightly sloped floors to direct any moisture toward drains, keeping the environment dry and safe.

Staff protection is built into every design. We recommend comprehensive PPE protocols when accessing refrigerated remains, and our ventilation systems minimize odors and airborne contaminants. We're happy to provide training resources on proper body handling techniques for your team.

Temperature integrity isn't just about preservation – it's about safety too. Consistent cooling prevents accelerated decomposition, while our alarm systems provide immediate alerts to any temperature deviations. Many facilities opt for our backup systems to ensure continuity during power interruptions – because some situations simply can't wait for the power company.

We strongly recommend developing clear SOPs for cleaning and maintenance, with scheduled deep cleaning quarterly and immediate attention to any contamination events. Your facility's reputation depends on these standards, and we're here to help you maintain them.

Regulatory & Certification Standards

Navigating the regulatory landscape can be challenging, but your morgue refrigerator shouldn't add to that burden. Our units comply with all relevant standards to ensure safety, reliability, and environmental responsibility.

OSHA requirements are fully addressed in our designs, with safety release mechanisms standard on walk-in units, proper lighting throughout, and non-slip flooring options for larger installations. These aren't just "nice-to-haves" – they're essential protections for your staff.

We pursue NSF certification for our units, ensuring food-grade quality materials and sanitary design principles. Regular testing and verification maintain these standards throughout our production process. When inspectors visit your facility, you can confidently show them equipment that meets the highest standards.

UL listing provides peace of mind regarding electrical safety. Every component undergoes rigorous testing, and our comprehensive approach to fire safety compliance exceeds minimum requirements. We believe safety isn't an area for cutting corners.

On the environmental front, we exclusively use CFC-free refrigerants (typically R134a) and design for energy efficiency that exceeds current standards. We can even help with proper disposal protocols when you're replacing older units, ensuring environmental compliance throughout the equipment lifecycle.

Local health codes vary widely, but our experience across all 48 contiguous states means we understand the nuances of regional requirements. Whether your jurisdiction specifies particular temperature ranges or requires specific alarm systems, we've likely already addressed similar needs for other clients.

Documentation requirements are simplified with our systems. Temperature logs, maintenance records, and staff training documentation are all supported by our designs and accompanying materials. We provide the tools you need to demonstrate compliance during inspections.

At American Mortuary Coolers, we don't just build equipment – we build partnerships. Our team stays current with evolving regulations to ensure our products remain compliant throughout their service life, giving you one less thing to worry about in your already demanding profession.

Buying Guide: Specs, Customization & Cost Control

Choosing the right morgue refrigerator isn't just about finding a cold box – it's about making a thoughtful investment that serves your facility's unique needs while respecting your budget. Let me walk you through what matters most when making this important decision.

Before you even think about placing an order, start with a proper site survey. We've seen too many facilities rush this step only to find installation challenges later. Our team can visit your location to evaluate your available space, existing utilities, and workflow patterns. This on-site assessment helps us understand not just where your unit will go, but how your staff will interact with it daily.

When it comes to system configuration, you'll face an important choice between self-contained and remote units. Self-contained morgue refrigerators house all components within the cabinet itself – simple to install but they do release heat into your space. Remote systems place the condensing unit elsewhere (typically outdoors or in a mechanical room), keeping your workspace cooler and quieter but requiring additional installation work. For facilities concerned about system failures, we offer redundancy options with backup cooling systems that provide peace of mind.

Morgue refrigerators aren't one-size-fits-all, and we take pride in our customization capabilities. Need a unit with specific dimensions to fit an awkward space? No problem. Want a particular door configuration to improve workflow? We can do that. From specialized rack systems to advanced control interfaces, we build each unit to match your specific requirements.

Let's talk dollars and cents. A quality morgue refrigerator represents a significant investment, with small units typically ranging from $8,000-$15,000 and walk-in systems running $20,000-$100,000+. But remember – this equipment will serve your facility for decades when properly maintained. We stand behind our products with one of the industry's best warranties: 15 years on panels/doors and 5 years on mechanical components. And if budget constraints are a concern, ask about our financing options including leasing and installment plans.

When your unit arrives, you have installation options. Many of our systems can be shipped "knocked-down" for easier transport to remote locations, then assembled on-site. Our factory-trained technicians ensure proper setup and provide comprehensive training for your staff on operation and maintenance procedures.

For a deeper dive into comparing different refrigeration systems, check out our detailed guide on comparing mortuary refrigeration systems.

When to Choose a Walk-In Morgue Refrigerator

"Should we go with a walk-in?" It's one of the most common questions we hear, and the answer depends on your specific situation. Walk-in morgue refrigerators make the most sense for facilities regularly storing eight or more bodies simultaneously, organizations with fluctuating capacity needs, or institutions planning for future growth.

The space efficiency of walk-ins often surprises people. Rather than having multiple individual units scattered throughout your facility, a single walk-in centralizes your storage while making better use of vertical space. Our multi-tier rack systems can dramatically increase your capacity within the same footprint.

The interior flexibility of walk-ins is another major advantage. Our cantilever storage racks can be adjusted to accommodate different body sizes, and the open floor plan allows for mixed-use configurations. Need to store supplies alongside remains? We can design a solution that meets both needs efficiently.

Perhaps most importantly, walk-ins offer room to grow. Their modular panel construction means you can expand later as your needs increase. We've helped hundreds of funeral homes and hospitals transition from multiple small units to more efficient walk-in systems, often with significant long-term cost savings. The per-body storage cost is typically lower with walk-ins, and maintaining a single cooling system is generally simpler than servicing multiple units.

Tech Innovations to Watch

The world of morgue refrigeration continues to evolve, and staying informed about emerging technologies can help you make forward-thinking decisions. Here are some innovations we're particularly excited about:

Smart monitoring systems have transformed how facilities manage their refrigeration. IoT-enabled morgue refrigerators now offer real-time temperature tracking with remote access to performance data. Imagine getting an alert on your phone the moment temperatures begin to drift, potentially preventing a serious problem before it develops.

Cloud-based alert systems take this further by creating escalating notification protocols – first alerting on-site staff, then supervisors, and finally emergency contacts if issues remain unresolved. These systems also maintain digital logs for compliance documentation, eliminating the need for manual temperature checks and paper records.

User interfaces have become remarkably more intuitive. Today's touch-screen dashboards make operation simpler while allowing for user-specific access controls. This means staff members only see the functions relevant to their responsibilities, reducing the risk of accidental setting changes.

Environmental improvements continue to be a focus across the industry. We've acceptd eco-friendly refrigerants and energy-efficient designs that reduce both environmental impact and operating costs. Some facilities are even exploring solar power options for critical functions or smart battery systems to maintain temperature during brief power interruptions.

Body tracking technology represents perhaps the most significant advance in morgue management. RFID integration for remains identification helps maintain proper chain of custody while reducing the risk of misidentification. Digital inventory systems can track exactly where each body is stored within your facility – particularly valuable for larger institutions.

At American Mortuary Coolers, we carefully evaluate these emerging technologies, incorporating those that provide meaningful benefits while maintaining our commitment to reliability. After all, the best technology is the kind that works so seamlessly you hardly notice it's there.

Maintenance & Cleaning Essentials

Keeping your morgue refrigerator in top condition isn't just about performance—it's about respect for the deceased and the health of your staff. At American Mortuary Coolers, we've seen how proper maintenance can extend equipment life while ensuring dignified preservation.

Think of your morgue cooler maintenance as following a natural rhythm, from daily attention to annual care:

Start each day with a quick temperature check and documentation—this simple habit can catch problems before they become emergencies. While you're there, give exterior surfaces and handles a thorough wipe-down and scan for any unusual condensation or frost that might signal developing issues.

Once a week, set aside time for a more thorough disinfection of accessible interior surfaces. This is also the perfect time to run your fingers along door gaskets checking for cracks or wear—these rubber seals are your first defense against temperature fluctuations. For self-contained units, a weekly cleaning of condenser coils prevents dust buildup that can strain your system.

Monthly deep cleaning should include removing and sanitizing all trays and racks. This not only maintains hygiene but gives you a chance to inspect these components for any damage. While the unit is empty, check refrigerant pressure gauges and give all mechanical components a visual inspection.

Quarterly is when the professionals should step in. Our service technicians can perform a comprehensive inspection of the cooling system, replace any worn gaskets, and recalibrate temperature controls to ensure precise preservation conditions.

Your annual service appointment is non-negotiable for long-term reliability. This comprehensive visit includes compressor maintenance, electrical safety checks, and evaluation of insulation integrity—essentially giving your entire system a thorough physical.

When it comes to cleaning products, not just any cleaner will do. Hospital-grade disinfectants specifically approved for morgue use provide the right balance of sanitizing power without damaging sensitive components. For those beautiful stainless steel surfaces, non-abrasive cleaners prevent scratching while maintaining that professional shine.

Documentation might seem tedious, but those maintenance logs and temperature records are invaluable for regulatory compliance and tracking performance patterns over time. Create a simple system for recording each service visit, daily temperature readings, and any unusual incidents.

Staff training completes your maintenance program. Even the newest team members should understand proper cleaning techniques, know how to recognize developing problems, and be prepared to follow emergency procedures if equipment fails unexpectedly.

For a deeper dive into specific maintenance requirements for different refrigeration options, check out our guide on morgue fridge options.

Troubleshooting Common Morgue Refrigerator Issues

Even the best morgue refrigerators occasionally need some troubleshooting love. Knowing how to respond to common issues can prevent minor hiccups from becoming major headaches.

When temperature alarms sound (and they will eventually), don't panic. First, check the obvious—is a door slightly ajar or has a gasket come loose? Verify the ambient room temperature hasn't spiked, which can strain your system. If temperatures don't normalize within 30 minutes after addressing these basics, it's time to call in the professionals.

Frost build-up tells a story about your unit's environment. Excessive humidity or compromised door seals often invite this icy visitor. Try reducing how frequently doors are opened and check all seals for proper contact. Rapid frost accumulation despite your best efforts suggests a defrost system failure requiring professional attention.

Door seals are the unsung heroes of your morgue refrigerator. These gaskets work tirelessly to maintain temperature integrity but eventually show wear. Inspect them regularly for tears or hardening, and clean gently with mild soap to remove residue that can compromise their effectiveness. When a seal is visibly damaged or no longer forms a tight connection, replacement can't wait.

Unusual noises from your unit are like it's way of whispering "help me." Different sounds point to different issues—rattling might indicate a loose component while grinding could signal compressor problems. First, try to identify the source and check for any obvious obstructions. Any persistent or loud mechanical noises deserve prompt professional attention.

Power outages create special challenges for morgue refrigeration. Your immediate response should focus on minimizing door openings to preserve cold air. If you have backup systems, activate them immediately. Throughout the outage, monitor and document the internal temperature rise rate—this information helps determine if remains have been compromised when power returns.

Unwelcome odors have no place in a properly maintained morgue refrigerator. When they appear, immediately identify the source—often it's improper cleaning, body fluid leakage, or bacterial growth in hidden corners. Increase ventilation while addressing the specific cause, and if thorough cleaning doesn't resolve the issue, service technicians can help identify hidden problems.

Our team at American Mortuary Coolers provides 24/7 technical support for emergencies, with service professionals available throughout our regional service network spanning the Southeast, Southwest, Midwest, Northeast, Rocky Mountain, and Pacific areas.

Extending Service Life

A quality morgue refrigerator represents a significant investment in your facility's capabilities—one that should serve you reliably for decades with proper care. We've helped hundreds of clients maximize their equipment lifespan through these proven strategies.

Preventive maintenance contracts provide peace of mind through scheduled professional inspections that catch small issues before they become costly repairs. These agreements typically include priority service response when problems do arise and generate documentation that simplifies regulatory compliance.

Smart facilities maintain a strategic inventory of critical spare parts on-site. Having replacement gaskets, filters, and other commonly needed components readily available can transform a potential multi-day downtime into a quick fix. We can help you identify which parts make sense to keep on hand based on your specific equipment.

Performance monitoring provides early warning of developing issues. Watch for changes in energy consumption, temperature stability, or compressor run-time—these metrics often reveal problems before they affect performance. Many modern units include built-in monitoring capabilities that simplify this process.

Staff training might be the most underappreciated factor in equipment longevity. When your team understands proper operation procedures, basic troubleshooting, and correct cleaning protocols, they become your first line of defense against premature equipment failure. We offer training sessions for new staff and refresher courses that can be conducted right at your facility.

Don't overlook upgrade opportunities as technology evolves. Control system modernization, energy efficiency improvements, and refrigerant updates can extend useful life while improving performance and environmental compliance. Many of these upgrades can be implemented without replacing the entire unit.

Finally, pay attention to the environment surrounding your morgue refrigerator. Proper room ventilation allows heat to dissipate efficiently, stable ambient temperatures reduce system strain, and regular cleaning prevents dust and debris from affecting mechanical components.

At American Mortuary Coolers, our comprehensive service contracts include all necessary maintenance, priority emergency response, and documentation for regulatory compliance. Many of our earliest customers are still using systems we installed decades ago—testament to the power of quality equipment paired with proper maintenance.

Frequently Asked Questions about Morgue Refrigerators

What temperature should a morgue refrigerator maintain?

If there's one thing I've learned in my years at American Mortuary Coolers, it's that temperature precision isn't just a technical detail—it's the foundation of respectful preservation. A standard morgue refrigerator needs to maintain temperatures between 2°C and 6°C (36°F to 43°F). This sweet spot effectively slows decomposition while preserving the natural condition of tissues, which is crucial for both viewing and embalming.

Some facilities, particularly those handling forensic cases or requiring long-term storage, opt for negative temperature units that operate between -10°C and -50°C. These freezer units practically halt decomposition entirely, though we typically recommend them only for specific circumstances. They consume more energy and the freezing process can alter tissues in ways that might affect later procedures.

Modern morgue refrigerators feature digital temperature controllers that maintain stability within ±1°C of your set point. The best units include high/low temperature alarms that alert staff immediately if temperatures drift outside the acceptable range. We always remind our clients that consistent temperature monitoring isn't just good practice—it's often required for regulatory compliance, so maintaining proper documentation is essential.

How many bodies can a walk-in morgue refrigerator hold?

I'm often asked this question during initial consultations, and my answer always starts with "it depends"—but let me break it down more helpfully. The capacity of a walk-in morgue refrigerator varies based on its dimensions and the rack system you choose.

A small 8' x 10' walk-in typically accommodates 8-10 bodies with standard racks, while a medium 10' x 12' unit usually holds 16-20. Larger facilities measuring 12' x 20' can comfortably store 24-30 bodies, and our custom extra-large units can be designed for 50+ bodies when needed.

Many of our clients have significantly increased their capacity by upgrading to multi-tier cantilever rack systems or high-density sliding arrangements. These configurations make better use of vertical space while maintaining proper circulation around each body.

It's worth noting that your actual capacity might be lower if you regularly handle bariatric cases or need to maintain extra space for staff movement. At American Mortuary Coolers, we work closely with each facility to create detailed capacity plans based on your specific space constraints and daily workflow patterns. We've helped hundreds of facilities maximize their storage capacity without compromising staff comfort or dignity in handling.

How often should a morgue refrigerator be cleaned?

Maintaining proper cleanliness in your morgue refrigerator isn't just about appearances—it's about respect, safety, and equipment longevity. Based on our experience serving facilities nationwide, here's the cleaning rhythm that works best:

Daily attention is essential—wipe down exterior surfaces and handles with an appropriate disinfectant, paying special attention to touch points where staff contact is frequent. This simple habit prevents cross-contamination and odor buildup.

On a weekly basis, take time for a more thorough disinfection of all accessible interior surfaces. Don't forget the door gaskets—they need gentle cleaning with mild soap to maintain their seal integrity while preventing mold growth.

Once a month, schedule time for a deep clean where all contents are temporarily relocated so you can thoroughly disinfect every interior surface, rack, and tray. This is also the perfect time to check your condensate drainage system to prevent water accumulation.

Quarterly professional cleaning is something we strongly recommend. This involves complete disassembly of removable components, cleaning of refrigeration coils, and inspection of less accessible areas that might otherwise be overlooked.

Of course, any body fluid leakage requires immediate attention, following proper bloodborne pathogen protocols. Always document these incidents and your response for your records.

Remember to use hospital-grade disinfectants appropriate for morgue environments, and ensure staff wear proper PPE including gloves, masks, and eye protection. The few extra minutes spent on proper cleaning can add years to your equipment's life while maintaining the dignified environment your facility and the families you serve deserve.

Conclusion

The morgue refrigerator represents far more than just a piece of equipment—it's a crucial tool in providing dignified care for those who have passed. Whether in a small-town funeral home or a busy metropolitan morgue, these specialized units create the controlled environment necessary to preserve remains with the respect and care families deserve.

Here at American Mortuary Coolers, we see beyond the stainless steel and refrigeration components. We understand that behind every technical specification lies a commitment to honoring the deceased and supporting the dedicated professionals who care for them during life's most difficult moments.

Our Tennessee manufacturing facility isn't just assembling refrigeration units—we're crafting custom-built, durable solutions specifically designed for the unique challenges of the funeral industry. We take pride in building equipment that stands the test of time, just as the memories of loved ones endure in the hearts of those they leave behind.

Nationwide presence means we're always close by when you need us. With delivery across all 48 contiguous states and regional support centers in Atlanta, Chicago, Dallas, Los Angeles, New York, and Pittsburgh, we provide not just equipment but ongoing service and support. Our team brings decades of combined experience to every installation, offering comprehensive solutions custom to each facility's specific needs.

Selecting the right morgue refrigerator impacts your operations for years to come. The perfect combination of temperature control, durable construction, appropriate capacity, and regular maintenance creates the foundation for respectful, efficient, and compliant body storage. We understand that your reputation depends on providing dignified care, and we take that responsibility seriously.

For those considering an upgrade, replacement, or expansion of their facilities, we invite you to learn more about how American Mortuary Coolers has become the leading supplier of morgue coolers across the country.

Our commitment to quality, reliability, and respect guides everything we do. When you choose American Mortuary Coolers, you're not just purchasing equipment—you're partnering with a team dedicated to supporting your mission of providing dignified care at life's most challenging moments. Because in this industry, we understand that what we build serves a purpose higher than mere functionality—it helps you honor lives with the dignity they deserve.