The Essential Guide to Walk In Cold Rooms

A walk in cold room is an insulated, refrigerated chamber designed for storing large quantities of temperature-sensitive items. These specialized rooms maintain precise temperatures and are essential for businesses handling perishable goods.

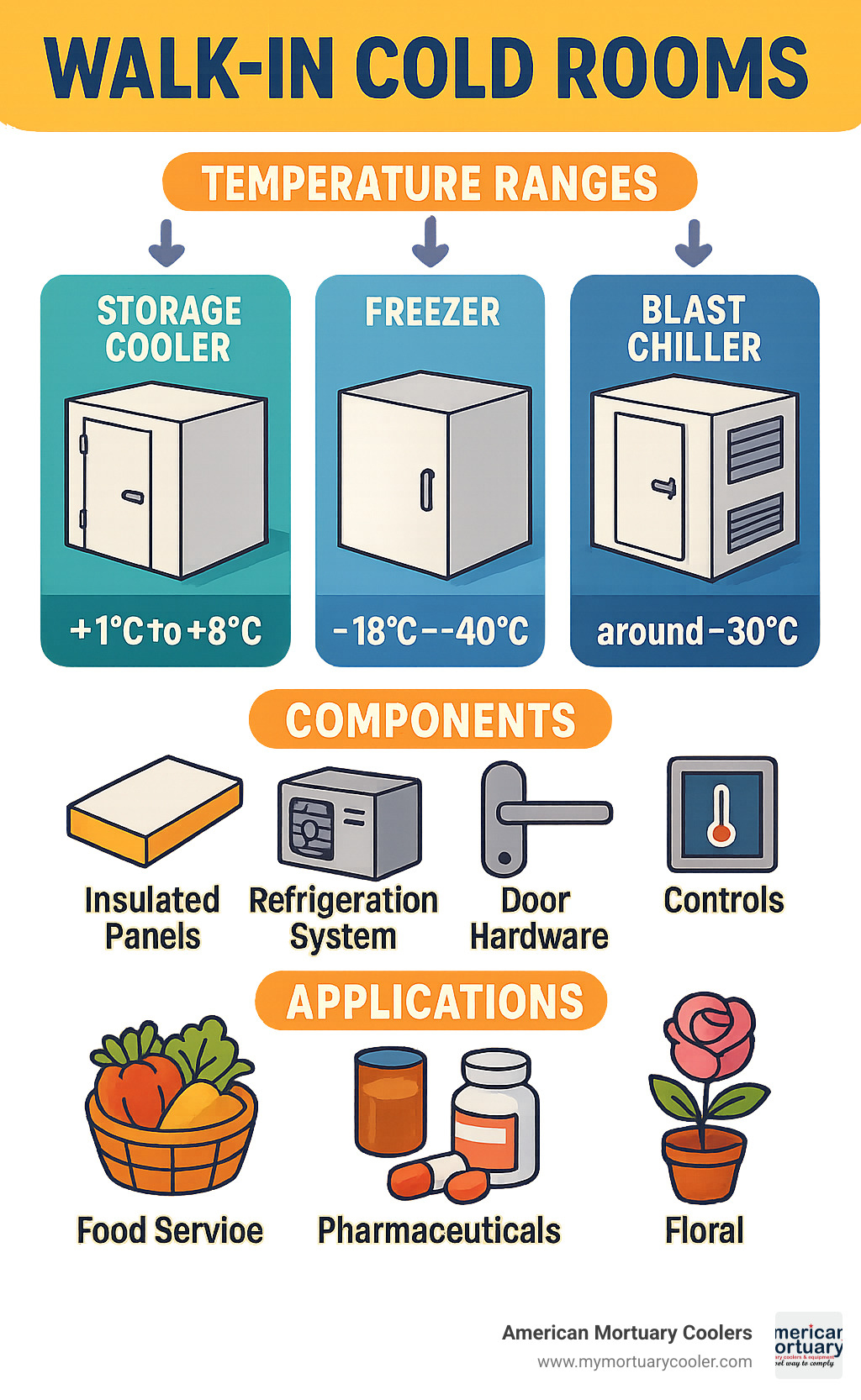

Quick Guide to Walk In Cold Rooms:

| Feature | Description |

|---|---|

| Purpose | Temperature-controlled storage for perishable goods |

| Temperature Range | +1°C to +8°C (coolers), -18°C to -40°C (freezers) |

| Key Components | Insulated panels, refrigeration system, door hardware, controls |

| Main Benefits | Large storage capacity, energy efficiency, consistent temperature |

| Common Applications | Food service, pharmaceuticals, floral, mortuary, laboratories |

Walk in cold rooms function through a refrigeration cycle that includes a compressor, condenser, evaporator, and thermostat working together to maintain consistent temperatures. Unlike standard refrigerators, they offer significant space for bulk storage and organization, making them invaluable for businesses that need to store large quantities of temperature-sensitive products.

These specialized chambers come in various configurations including storage coolers (+1°C to +8°C), freezers (-18°C to -40°C), deep-freezers (around -30°C), and blast chillers for rapid cooling. The right choice depends on your specific storage needs and the items being preserved.

With proper insulation and energy-efficient refrigeration systems, walk in cold rooms help reduce waste, maintain product quality, and ultimately save money through improved organization and preservation capabilities.

I'm Mortuary Cooler, a national-level supplier of walk in cold room solutions with specialized expertise in mortuary applications and US cooler systems. My experience spans designing and implementing walk in cold room solutions for diverse industries, focusing on reliability and temperature precision.

Walk in cold room terms to know:

Understanding Walk In Cold Rooms

Ever walked into a giant refrigerator? That's essentially what a walk in cold room is – a spacious refrigerated environment large enough for people to enter and move around in. Unlike your kitchen fridge, these rooms offer massive storage capacity while keeping temperatures just right for whatever you're storing.

Think of "cold room" as the family name for these spaces. The family has two main branches: walk-in fridges (the ones that stay above freezing, usually between +1°C and +8°C) and walk-in freezers (the chilly relatives that operate below 0°C).

The key difference is pretty straightforward – cold rooms keep things cool but not frozen, perfect for fresh foods, flowers, or certain medications. Freezer rooms, on the other hand, maintain everything in a frozen state, ideal for long-term preservation.

What makes these rooms special is their construction. Walk in cold rooms are built with sophisticated insulated panels – imagine a sandwich with polyurethane filling between metal or fiberglass bread slices. Quality matters here – our panels exceed Department of Energy standards with R-values of R-29 for coolers and R-32 for freezers (the minimum requirement is R-25). This superior insulation keeps temperatures stable and energy bills lower.

At American Mortuary Coolers, we take this a step further. Our walk in cold rooms feature seamless fiberglass panels with rounded interior corners. This might seem like a small detail, but it makes cleaning much easier and creates a more sanitary environment – absolutely crucial when you're working in sensitive settings like mortuaries.

Want to learn more? Check out our Ultimate Guide to Walk-In Coolers.

How a Walk In Cold Room Works

A walk in cold room operates on a surprisingly simple principle that involves four main components working together in harmony:

The compressor acts as the heart of the system. It squeezes refrigerant gas, raising both its temperature and pressure – kind of like how a bicycle pump gets hot when you're inflating a tire.

Next, the condenser (typically located outside) releases this heat into the surrounding air, cooling the refrigerant and turning it from gas to liquid.

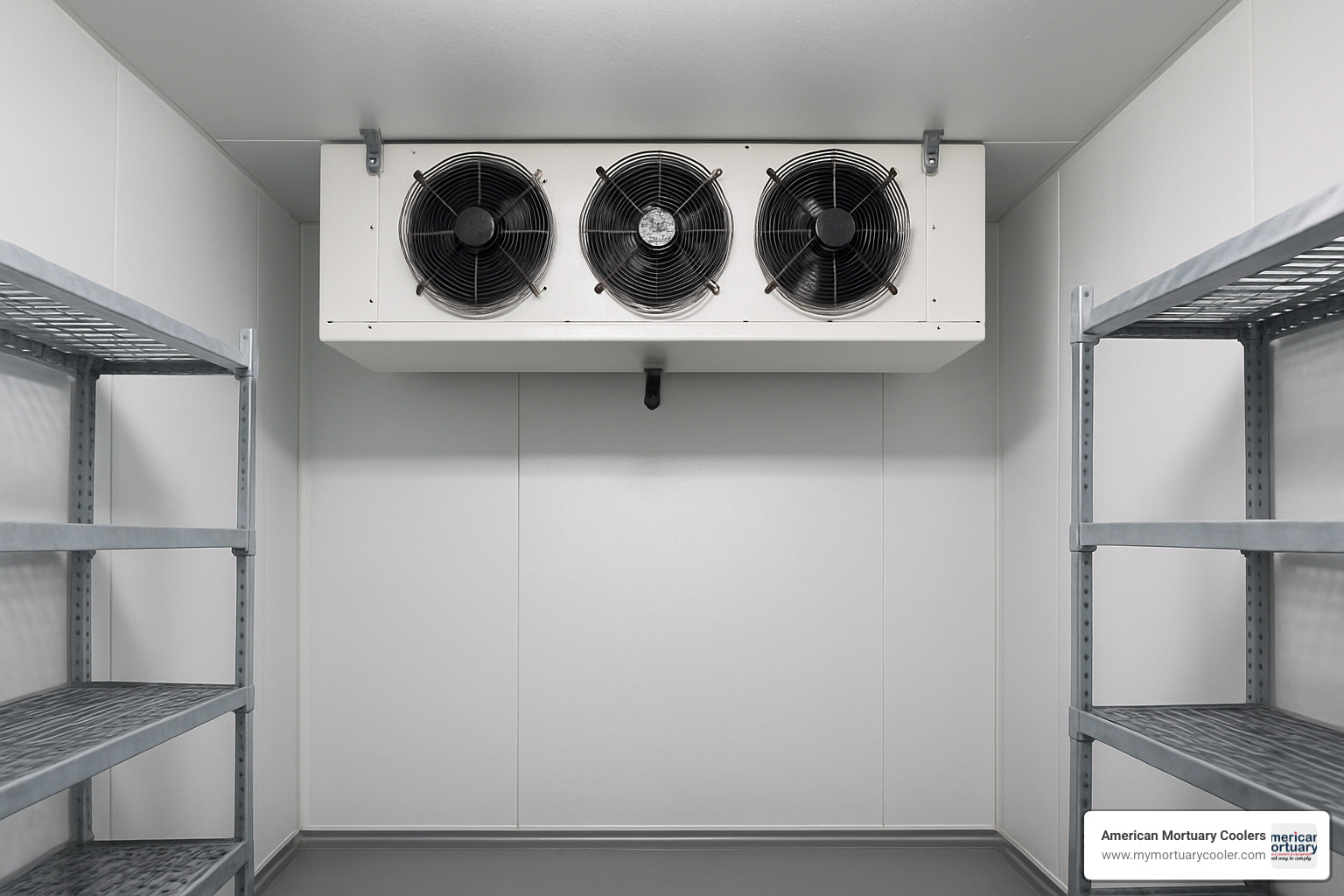

Inside the cold room, the evaporator does the opposite job. As the refrigerant expands and changes back to gas, it absorbs heat from inside the room – leaving behind that nice cool air we want.

The thermostat serves as the brain, constantly monitoring the temperature and telling the system when to kick on or off to maintain your perfect setting.

This cycle repeats continuously, essentially moving heat from inside to outside. Modern walk in cold rooms feature digital thermostats that allow for incredibly precise control – often down to 0.1°C increments.

Good airflow is absolutely essential for these systems to work properly. Evaporator fans push the cooled air throughout the space, while smart shelving arrangements ensure nothing blocks this circulation. Safety features like emergency release mechanisms (so nobody gets accidentally locked in) and strip curtains (those plastic strips that hang in doorways) help maintain temperatures while keeping people safe.

Types of Walk In Cold Rooms

Walk in cold rooms come in several flavors, each designed for specific temperature needs:

Storage Cold Rooms are the most common type, operating between +1°C and +8°C. These are perfect for fresh produce, dairy products, prepared foods, and flowers. At American Mortuary Coolers, our mortuary-specific cold rooms typically maintain temperatures between +2°C and +4°C – the ideal range for respectful preservation.

Freezer Rooms maintain temperatures between -18°C and -22°C. These colder environments are ideal for long-term storage of frozen foods, certain medical supplies, and other items requiring sub-zero conditions. The colder temperature significantly extends preservation times.

Deep-Freeze Rooms take things even further, operating at approximately -30°C or lower. These specialized environments support applications like certain pharmaceutical storage, scientific research specimens, or specialized food preservation techniques that require ultra-low temperatures.

Blast Chiller Rooms serve a different purpose entirely. Rather than long-term storage, these rooms rapidly cool hot food to prevent bacterial growth and preserve quality. Think of them as the sprinters of the cold room world – they're all about speed rather than endurance.

Your choice depends entirely on what you're storing and for how long. At American Mortuary Coolers, we understand that different facilities have different needs, which is why we work closely with each client to determine the perfect solution for their specific requirements.

Components, Temperature & Refrigerants

Ever wondered what makes a walk in cold room tick? It's all about quality components working together in perfect harmony. Let's peek behind the panels and see what's really keeping things cool!

The heart of any cold room starts with its insulated panels. These aren't your average walls—they feature clever tongue-and-groove joints that snap together to create an airtight seal. Think of them as giant puzzle pieces that, when assembled correctly, prevent precious cold air from escaping and warm air from sneaking in.

Don't underestimate the importance of good door hardware! Those heavy-duty hinges and magnetic gaskets aren't just for show—they ensure your door closes with a satisfying thud and stays sealed tight. Many of our customers love the added strip curtains that act like a transparent shield against temperature loss when staff are going in and out.

The refrigeration system is where the real magic happens. The evaporator inside pulls heat from the room, while the condensing unit (usually mounted outside) releases that heat elsewhere. It's basically playing an endless game of "hot potato" with the heat in your cold room!

Modern walk in cold rooms have come a long way from the old manual thermostats. Today's digital controls give you pinpoint temperature management down to a tenth of a degree. At American Mortuary Coolers, we've seen how these smart systems provide peace of mind through real-time monitoring and automatic alerts if temperatures drift.

When it comes to refrigerants, there's a green revolution happening in the industry. The old standby R404A (with its whopping GWP of 3,922) is being shown the door in favor of more earth-friendly alternatives:

| Refrigerant | GWP Value | Efficiency vs. R404A | Safety Class | Common Applications |

|---|---|---|---|---|

| R404A | 3,922 | Baseline | A1 (non-flammable) | Traditional cold rooms (being phased out) |

| R448A | 1,387 | +10% | A1 (non-flammable) | Retrofit and new medium/low temp |

| R449A | 1,397 | +12% | A1 (non-flammable) | Retrofit and new medium/low temp |

| R290 (Propane) | 3 | +10-15% | A3 (highly flammable) | Self-contained units with charge limits |

| CO₂ (R744) | 1 | Variable | A1 (non-flammable) | New installations, especially in cool climates |

We design all our systems with the future in mind, making sure they're ready for the transition to these lower-GWP options. It's not just good for the planet—it's good business sense as regulations continue to tighten.

Temperature Bands & Controls

Not all cold is created equal! Walk in cold rooms operate in specific temperature ranges custom to what you're storing:

For fresh items like produce, dairy, and prepared foods, the chiller range of +1°C to +8°C keeps everything perfectly preserved without freezing. Our mortuary coolers typically run between +2°C and +4°C—the sweet spot for respectful preservation.

Need to keep things frozen? The freezer range of -18°C to -22°C is standard for frozen foods and long-term storage. And for those special applications requiring arctic-like conditions, deep freezers plunge temperatures down to -30°C or even -40°C.

I love showing clients how today's digital control systems put precise temperature management at their fingertips. With bright LCD displays and intuitive interfaces, you can monitor conditions in real-time and receive alerts if anything starts to drift off course.

For businesses juggling different storage needs, dual-zone walk in cold rooms are a game-changer. These clever systems use insulated divider panels to create separate compartments within a single unit—like having two cold rooms for the price of one! Each zone gets its own evaporator and temperature control, so your ice cream can stay frozen while your fresh produce stays crisp.

Low-GWP Refrigerants & Sustainability

The refrigeration world is going green, and fast! Regulations like the European F-Gas Regulation and the U.S. EPA's SNAP program are pushing the industry toward refrigerants that won't contribute to climate change.

R448A and R449A are the current stars of the show. These blends slash GWP by about 65% compared to old-school R404A while actually improving energy efficiency by 10-12%. Best of all, they're non-flammable and relatively easy to retrofit into existing systems. It's like getting a greener system with better performance—win-win!

For the ultimate in environmental credentials, CO₂ (R744) is hard to beat with its GWP of just 1. The catch? It operates at much higher pressures (up to 140 bar) and works best in cooler climates. When the mercury rises above 31°C, CO₂ systems need special design considerations to maintain efficiency.

R290 (Propane) is another super-green option with a tiny GWP of 3. It's highly efficient but comes with a catch—it's classified as highly flammable (A3). This usually limits its use to systems with small refrigerant charges or requires additional safety measures. Not a deal-breaker, just something to plan for!

Understanding refrigerant safety classifications helps make sense of your options:

A1 refrigerants (like R448A, R449A, and CO₂) are non-flammable and non-toxic—the safest bet for most applications.

A2L options (like R454C and R455A) are mildly flammable but still non-toxic, requiring some safety precautions.

A3 refrigerants (like propane) are highly flammable but non-toxic, calling for specific safety systems and charge limitations.

At American Mortuary Coolers, we help clients look beyond just GWP to consider the whole picture—what experts call Lifecycle Climate Performance (LCCP). This accounts for both direct emissions from refrigerant leaks and indirect emissions from energy use. After all, an inefficient system with a low-GWP refrigerant might actually have a bigger carbon footprint than an efficient system with a moderate-GWP refrigerant.

Scientific research on thermal conductivity

Planning, Installation & Maintenance

Getting a walk in cold room right starts with thoughtful planning. Think of it as building a home - you wouldn't start without a blueprint, right? The journey begins with a detailed site survey that looks at your available space, how people will access the room, whether your floor can handle the weight, and if your electrical system is up to the task.

When it comes to sizing, the Goldilocks principle applies - not too big, not too small, but just right. An undersized cold room will struggle like an overworked air conditioner on the hottest day of summer, while an oversized one is like heating a mansion when you only use one room. I always recommend adding a 15-20% buffer to your current storage needs - businesses tend to grow, and your cold storage needs likely will too.

Today's walk in cold rooms are typically built using modular panels - think of them as sophisticated building blocks that snap together. This approach is brilliant because it allows for flexible layouts and makes future expansion much easier. Plus, these panels can fit through standard doorways, so installation doesn't require knocking down walls!

Deciding between indoor and outdoor installation? Each has its merits. Indoor installations offer convenient access and protection from the elements but do claim valuable floor space. Outdoor units free up your interior but need weatherproofing and might face zoning problems. It's worth checking local regulations before making this decision.

Don't overlook ventilation - it's crucial both inside the cold room (to prevent that musty smell and mold growth) and around the condensing unit (so it can efficiently release heat). For outdoor units, imagine your condenser needs room to breathe - crowding it against walls or other equipment is like trying to cool down while wrapped in a blanket.

If you already have a walk in cold room that's showing its age, consider retrofitting rather than replacing. Upgrading to newer refrigeration systems or switching to environmentally friendlier refrigerants can breathe new life into your unit while cutting energy costs.

How to Master Walk-In Cooler Design in 5 Simple Steps

Choosing the Right Walk In Cold Room Size

Finding the perfect size for your walk in cold room is a bit like choosing the right vehicle - it needs to fit everything you plan to store while not wasting resources on unused space.

Floor space is your starting point. A handy rule of thumb is allowing about 28-30 cubic feet of storage for every 1,000 pounds of product. Think about how you'll arrange items inside - will you need space for people to walk around comfortably? Will you be using shelving systems?

If you'll be storing goods on pallets, plan accordingly. A standard 8ft x 36ft walk in cold room can comfortably house about 18 pallets. Visualize your workflow - how will items move in and out? Will you need room for a pallet jack to maneuver?

Don't forget about height! Standard ceiling heights range from 7'6" to 8'6", but evaporator units hang down from the ceiling and will reduce your usable height. If you're storing tall items or using high shelving, you might need to go with a custom height.

Future-proofing your investment is smart business. While modular systems can be expanded later, it's typically more cost-effective to build with growth in mind from the start. I've seen too many businesses outgrow their cold rooms within a year or two, wishing they'd gone just a bit larger initially.

Doorways deserve special attention too. Standard doors are 34" to 36" wide, but if you'll be moving large items or equipment through them, you might need something bigger. Nothing's more frustrating than realizing your door is too narrow for your needs!

At American Mortuary Coolers, we offer walk in cold rooms from cozy 6' x 6' units to expansive custom installations. We're happy to help you determine the perfect size based on your specific needs and space constraints - just reach out and let's talk through your requirements.

Installation Best Practices

Installing a walk in cold room is precision work that affects everything from energy efficiency to food safety. Getting it right pays dividends for years to come.

Seal integrity is absolutely critical. Every joint between panels needs proper sealing with gaskets and appropriate caulking. Even tiny air leaks can lead to significant energy waste and temperature fluctuations. It's like leaving a window cracked open in your air-conditioned home - those small gaps add up to big energy bills.

Before installation day, verify your electrical system can handle the load. Most standard units need 115/230 volt power, while larger systems might require 3-phase power. Having an electrician check this beforehand can save headaches later - nothing delays a project like finding you need electrical upgrades!

Drainage might not be glamorous, but it's essential. Condensate drain lines need the right slope and must lead to appropriate drain points. For freezers, drain line heaters are necessary to prevent freezing - a frozen drain line can lead to water backing up and creating dangerous ice patches.

For freezer installations, floor considerations are particularly important. Insulated floors with subfloor heating systems prevent frost heave that could damage your building's foundation. Coolers may not need insulated floors but should have water-resistant, non-slip surfaces for safety.

Emergency release mechanisms inside the door aren't just a good idea - they're often required by law. These safety features prevent the nightmare scenario of someone being accidentally trapped inside. We take this very seriously at American Mortuary Coolers - safety is never optional.

Lighting should be energy-efficient LED fixtures with appropriate IP ratings for cold, moist environments. Position lights thoughtfully to minimize shadows on shelving areas, making it easier to identify and access stored items.

Our installation teams follow detailed protocols to ensure every walk in cold room we install meets both regulatory requirements and our own high standards. We don't just want your cold room to work - we want it to work perfectly for years to come.

Maintenance Checklist

Think of your walk in cold room as you would your car - regular maintenance prevents breakdowns and extends its lifespan. Here's what needs attention:

Door gaskets and hardware deserve monthly inspections. These rubber seals are the frontline defense against temperature loss. Clean them regularly with mild detergent to remove any buildup that could prevent a proper seal. While you're at it, check hinges and closers to ensure doors shut properly every time. If you have strip curtains, make sure they're intact and hanging correctly.

Evaporator and condenser coils need regular cleaning to maintain efficiency. Dust and debris on these coils act like a blanket, making your system work harder. Clean evaporator coils quarterly and condenser coils monthly (more often in dusty environments). Also keep an eye out for ice buildup on evaporator coils - excessive ice suggests defrost issues that need addressing.

Your refrigeration system is the heart of your cold room. Monitor refrigerant pressure and temperature regularly, and listen for unusual noises or vibrations from the compressor - these often signal problems developing. Check refrigerant lines for oil stains, which might indicate leaks, and verify defrost cycles are operating correctly.

Temperature monitoring is critical, especially for sensitive applications. Calibrate thermometers and sensors annually and occasionally verify readings with independent thermometers. Test alarm systems to ensure you'll be notified if temperatures drift outside acceptable ranges - this is particularly important for mortuary applications where precise temperatures are essential.

General maintenance includes cleaning interior surfaces with appropriate food-safe sanitizers, checking for moisture or condensation issues, inspecting electrical connections for corrosion, and keeping condensate drain lines clear to prevent clogs.

We recommend professional maintenance visits at least twice yearly, with more frequent service for critical applications. At American Mortuary Coolers, our comprehensive maintenance plans include regular inspections, preventive maintenance, and priority response when you need emergency service. We've found that regular maintenance not only prevents costly breakdowns but also significantly extends the life of your equipment.

Applications, Customisation & Future Trends

Walk in cold rooms aren't one-size-fits-all solutions – they're as diverse as the industries they serve. Let me walk you through how these versatile spaces are changing businesses across different sectors.

In food service, these cooling powerhouses have become the backbone of restaurants and catering companies. Imagine walking into a perfectly organized cold room where fresh ingredients are neatly arranged on specialized shelving, making inventory management a breeze rather than a headache. Chefs love the ability to store bulk ingredients while maintaining that farm-fresh quality customers expect.

The hospitality industry has acceptd cold rooms with open arms too. Hotels and resorts often feature multi-zone systems that keep everything from breakfast buffet ingredients to evening cocktail garnishes at their perfect temperatures. I've seen some beautiful glass-fronted display cold rooms that turn wine and craft beer storage into a visual centerpiece – practical and impressive!

For florists, temperature and humidity control isn't just nice to have – it's essential. Their specialized cold rooms maintain that sweet spot between 2°C and 5°C with higher humidity levels that keep roses perky and lilies looking lovely for days longer than conventional storage.

In the pharmaceutical world, precision is paramount. These aren't just cold rooms; they're guardians of potentially life-saving medications. With redundant refrigeration systems and round-the-clock monitoring, pharmaceutical cold rooms ensure temperature-sensitive vaccines and medications maintain their efficacy from production to patient.

And then there's our specialty at American Mortuary Coolers – mortuary cold rooms. These require a unique blend of technical precision and respectful design. We maintain temperatures between 2°C and 4°C, with specialized racks, reinforced flooring for ease of movement, and designs that blend discretion with dignity. It's a delicate balance, but one we've perfected over years of focused experience.

The world of walk in cold rooms continues to evolve with exciting innovations. Modular designs now allow businesses to create custom configurations that maximize every inch of available space. For outdoor installations, our fiberglass-reinforced panels stand strong against whatever Mother Nature throws their way – from scorching summer heat to winter blizzards.

Technology is changing these spaces too. IoT-enabled monitoring systems now offer peace of mind through real-time temperature alerts sent straight to your smartphone. These smart systems don't just report problems – they help predict and prevent them before your inventory is at risk.

Looking ahead, regulatory changes continue pushing the industry toward greener solutions. The global refrigerant phase-down will reach significant milestones by 2025, making energy efficiency and environmental responsibility not just nice-to-have features but essential requirements.

8 Benefits of Cold Rooms for Commercial Kitchens

Custom Features for Specific Sectors

What makes a walk in cold room truly shine is how it's custom to your specific needs. Let me share some of the custom touches that make all the difference across various industries.

In food service and retail, it's all about accessibility and food safety. Heavy-duty shelving systems transform these spaces from simple storage to organizational wonders. I've helped restaurants install glass display doors that let customers see the freshness – a simple addition that boosts sales and confidence. Strip curtains and air curtains are practical additions that maintain temperatures even during the constant in-and-out of busy service times. And those antimicrobial interior surfaces? They're not just a selling point – they're peace of mind for food safety inspections.

The beverage industry has its own unique needs. Breweries and bars love our specialized keg racks and dispensing systems that maximize space while keeping everything accessible. "Beer caves" with glass fronts have become popular retail features that turn storage into a selling point. And don't forget about floor reinforcement – those liquid-filled kegs and cases add up quickly in weight!

For pharmaceutical and laboratory applications, precision isn't just important – it's everything. These specialized cold rooms maintain temperatures within a tight ±0.5°C range, with redundant refrigeration systems standing by just in case. The monitoring systems comply with strict 21 CFR Part 11 regulations, and controlled access systems ensure only authorized personnel can enter sensitive storage areas.

In mortuary services – our specialty at American Mortuary Coolers – we've developed features specifically for funeral homes and medical examiners. Our specialized body racks and trays are designed for dignified, respectful care. We reinforce flooring to support heavy-duty carts, and our improved ventilation systems maintain appropriate conditions. We even focus on quiet operation and discreet exterior designs that blend seamlessly with funeral home aesthetics – because some things shouldn't draw attention.

Future-Proofing Your Investment

A walk in cold room represents a significant investment, and you'll want it serving your business for many years to come. Here's how to ensure your cold room won't become obsolete as technology and regulations evolve.

First, consider low-GWP readiness. The refrigerants that keep your cold room cool today might not be available or permitted in the future. We design our systems to accommodate tomorrow's environmentally friendly refrigerants – even if you're using traditional options now. This adaptability extends the useful life of your investment and keeps you ahead of regulatory changes.

Think about scalable design from day one. Your business isn't static, and your cold room shouldn't be either. Modular systems can grow with you – whether that means provisions for additional panels, oversized condensing units with room to expand, or multiple evaporators. I've seen too many businesses outgrow their cold rooms within a few years – a little forward thinking prevents this costly mistake.

Smart controls aren't just fancy add-ons – they're the future of efficient operation. Remote monitoring lets you check temperatures from anywhere, while predictive maintenance alerts you to potential issues before they become problems. These systems improve day-to-day efficiency and can be updated with new features as technology evolves.

Energy efficiency pays dividends every month on your utility bill. EC motors, LED lighting, and optimized defrost cycles might cost a bit more upfront, but they significantly reduce operating costs over time. Plus, energy-efficient designs are less likely to be affected by future regulations targeting power consumption.

Finally, maintain detailed compliance documentation including equipment specifications, refrigerant information, and maintenance history. This paperwork might seem tedious, but it becomes invaluable as regulatory requirements evolve – and absolutely essential if you ever need service or parts.

At American Mortuary Coolers, we design our walk in cold rooms with these future considerations built in. Our nationwide presence – with locations across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, and Pennsylvania – means we're always close by to provide ongoing support as your needs evolve. We're not just selling you a cold room; we're building a long-term relationship to keep your business running smoothly for years to come.

Frequently Asked Questions about Walk In Cold Rooms

What is the typical temperature range of a walk in cold room?

When folks ask me about temperatures for walk in cold rooms, I always explain that it really depends on what you're storing. Think of it as different comfort zones for different products:

For regular cold rooms (what we call chillers), you're looking at a gentle cool between +1°C and +8°C (+34°F to +46°F). This is perfect for keeping your fresh produce crisp, dairy products fresh, prepared foods safe, and flowers blooming longer.

Freezer rooms take things much colder, typically running between -18°C and -22°C (0°F to -8°F). These are your go-to for anything that needs to stay frozen solid.

For specialized needs like certain scientific applications, we can go extremely cold – down to -30°C to -40°C or even colder. But that's pretty specialized territory!

In our mortuary coolers (our specialty at American Mortuary Coolers), we typically recommend temperatures between +2°C and +4°C. This sweet spot provides optimal preservation conditions while avoiding freezing, which is critical for respectful care.

The good news is that modern digital controls let you dial in temperatures with amazing precision – often down to 0.1°C increments – so you can create the perfect environment for whatever you're storing.

Can I retrofit my existing walk in cold room to a low-GWP refrigerant?

Yes, you absolutely can retrofit your walk in cold room to use more environmentally friendly refrigerants! It's like giving your cooling system an eco-upgrade, though it does require some professional help.

First, you'll need a qualified technician to check out your current setup. They'll look at your compressor, expansion devices, and other components to see what's compatible with newer refrigerants.

For most systems currently using R404A or R507, the easiest path forward is switching to non-flammable alternatives like R448A or R449A. These can reduce your system's global warming impact by about 65% while requiring minimal modifications – a win-win!

Some parts might need replacing during the retrofit – typically expansion valves, filter driers, and possibly the compressor oil. The actual process involves safely recovering your old refrigerant, swapping out necessary components, thoroughly vacuuming the system, and charging it with the new refrigerant. Your technician will then fine-tune everything to ensure optimal performance.

One important note: retrofitting to flammable refrigerants like propane (R290) usually isn't recommended for existing systems. These require specific safety features that need to be designed in from the start.

Here at American Mortuary Coolers, we're happy to assess your current system and guide you through the best options for your specific equipment. Going green doesn't have to be complicated!

How often should a walk in cold room be serviced?

Taking care of your walk in cold room is a lot like maintaining your car – regular check-ups prevent breakdowns and keep everything running smoothly. Here's what I typically recommend to our customers:

Every three months, have someone on your team do a quick check-up. Look at how well the unit is maintaining temperature, inspect door seals for wear or damage, and give everything a general once-over. These simple checks can catch small issues before they become big problems.

Twice a year, bring in the professionals for a more thorough service. Our technicians will clean the evaporator and condenser coils (which collect dust and debris over time), check refrigerant levels and system pressures, inspect all electrical components, verify that the defrost cycle is working properly, check door alignment and seals, and make sure all temperature controls are properly calibrated.

Once a year, schedule a comprehensive inspection. This deeper dive includes refrigerant leak testing, a thorough evaluation of compressor performance, verification of all control systems, testing of safety features like emergency releases and alarms, and a review of all documentation.

For critical applications – particularly mortuary coolers or pharmaceutical storage where temperature stability is absolutely essential – you might want to consider more frequent professional service, perhaps quarterly, to ensure uninterrupted operation.

Regular maintenance isn't just about preventing unexpected breakdowns (though it definitely helps with that!). It also optimizes energy efficiency and extends the life of your equipment. At American Mortuary Coolers, we offer customized maintenance plans custom to your specific equipment and needs, with service available nationwide across our regional centers.

Think of it this way: a little preventive care today saves a lot of headaches (and expense) tomorrow!

Conclusion

Investing in a walk in cold room is a significant decision for any business. But when you choose the right system, install it properly, and maintain it regularly, the returns are substantial. You'll enjoy expanded storage capacity, lower energy bills, and better preservation of your temperature-sensitive items. As regulations around refrigerants and energy efficiency continue to evolve, having a knowledgeable partner by your side becomes more valuable than ever.

Here at American Mortuary Coolers, we've dedicated ourselves to crafting walk in cold room solutions that truly understand the unique needs of the funeral industry. We combine the highest standards of quality with a deep respect for the sensitive nature of mortuary operations. Our decades of experience have taught us that attention to detail makes all the difference in this specialized field.

While our roots are in mortuary applications, our expertise extends to any industry where precise temperature control matters. We're proud to serve customers nationwide with locations spanning from Johnson City, Tennessee to Los Angeles, California, and many points in between including Atlanta, Chicago, Columbia, Dallas, New York, and Pittsburgh. This national footprint ensures you receive prompt, knowledgeable service wherever you're located.

What sets us apart? It's our commitment to energy efficiency without compromising performance. It's our ability to design custom solutions that fit your exact space and operational requirements. And it's our understanding that your walk in cold room isn't just equipment—it's essential infrastructure for your business.

We've simplified the process of acquiring your new cold room from start to finish. Our comprehensive approach begins with a thorough site assessment, moves through custom design and professional installation, and continues with reliable maintenance support for years to come. And with direct delivery available across the lower 48 states, getting your system in place is hassle-free.

Whether you're preserving the dignity of the deceased in a funeral home or storing other temperature-sensitive items, we invite you to experience the American Mortuary Coolers difference. It's where quality craftsmanship, thoughtful customization, and genuine customer care come together to create cold storage solutions you can truly rely on—what we like to call "cold comfort."