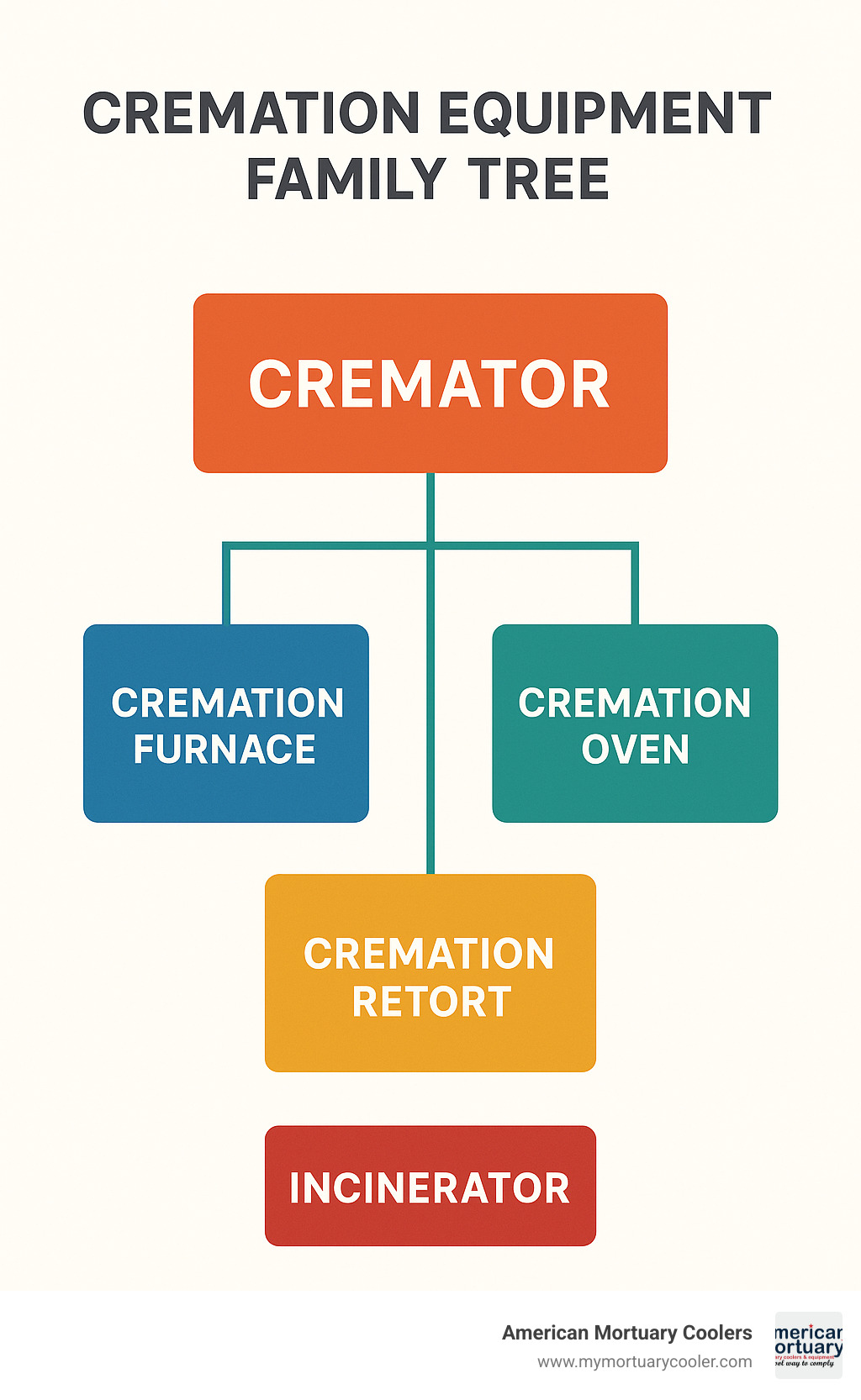

Understanding Cremation Equipment Terminology

When researching cremation machine name options, funeral professionals often encounter a variety of terms used interchangeably in the industry. Here's a quick reference guide to the most common terminology:

| Term | Definition |

|---|---|

| Cremator | The most technically accurate term for the machine that performs cremation |

| Cremation Furnace | Common industry term emphasizing the heating function |

| Cremation Oven | Frequently used colloquial term |

| Cremation Retort | Professional term referring to the chamber where cremation occurs |

| Incinerator | General term sometimes used, though less specific to human remains |

The world of cremation equipment can be confusing with its specialized vocabulary. Whether you're researching a cremation machine name for your funeral home or simply trying to understand industry terminology, knowing the difference between a retort and an oven matters - both practically and when communicating with manufacturers, regulators, and families.

Modern cremation equipment has evolved significantly from its historical origins. Today's machines operate at temperatures between 760°C to 1,650°C (1,400°F to 3,000°F), completing an average cremation in 90 minutes while incorporating advanced environmental controls and digital monitoring systems.

I'm Mortuary Cooler, a national-level supplier of mortuary cooling systems and cremation equipment with extensive experience helping funeral directors select the right cremation machine name for their specific operational needs. My team specializes in American-made cremation systems that combine reliability with cutting-edge technology.

Simple guide to cremation machine name terms:

What's in a Cremation Machine Name?

Have you ever noticed how we humans love giving things different names? In the funeral industry, what you call the equipment can vary widely depending on where you're from, your training, and even local traditions. The cremation machine name isn't just a label—it reflects our approach to this respectful service.

"I've been in funeral homes across 38 states," shares Tom Richards, a seasoned funeral director with 30 years of experience, "and I've heard these machines called everything from 'the processor' to 'Eleanor' at one family-owned funeral home in Maine. But proper terminology matters when ordering parts or discussing regulations."

Here at American Mortuary Coolers, we've noticed fascinating regional patterns. Our Northeast customers almost exclusively say "cremation retort" with formal precision, while folks in the Southwest tend to prefer the more straightforward "cremation oven." Our service teams have become quite skilled at translating these regional dialects when providing support across the country.

The Primary Keyword Defined: cremation machine name

The term cremation machine name works as a helpful umbrella category covering all equipment specifically designed for cremation purposes. While not a technical term you'd find in an operator's manual, it encompasses the entire family of specialized thermal processing equipment used throughout the funeral industry.

From a technical standpoint, "cremator" stands as the most precise term—derived from the Latin word "cremare," meaning "to burn." This etymology connects modern practice to ancient traditions that stretch back thousands of years, though today's technology would be unrecognizable to our ancestors.

When dealing with official paperwork, terminology becomes even more important. The Cremation Association of North America (CANA) consistently uses "cremator" in their standards documentation, while the EPA might refer to the same equipment as "human remains incinerator" in emissions guidelines. Understanding these distinctions becomes crucial when navigating permits and staying compliant with local regulations.

Other Popular Synonyms You'll Hear

The vocabulary around cremation equipment is surprisingly rich and varied, each term carrying slightly different shades of meaning.

Retort has fascinating historical roots in chemistry and metallurgy, where it originally described vessels used for distillation or decomposition by heat. In cremation contexts, this term specifically refers to the chamber where the actual cremation takes place. Many technical manuals describe it as: "The cremation retort consists of a primary chamber where the body is placed and a secondary chamber where gases are further combusted."

Chamber sometimes gets used interchangeably with retort, but can also specifically refer to either the primary area (where remains are placed) or the secondary area (where exhaust gases undergo further treatment). When someone mentions "checking the secondary chamber temperature," they're referring to a specific part of the overall system.

Hot Hearth refers to a specific design innovation where the floor of the cremation chamber is directly heated, significantly improving efficiency and reducing process time. B&L Cremation Systems proudly notes they were "first to market with the Hot Hearth System as a proprietary cremation technology"—a feature that many funeral homes now consider essential.

For those wanting to dive deeper into the technical specifics of cremation retorts, we've put together a comprehensive guide you can explore: More info about cremation retorts.

What's most important to remember is that behind all these names lies a commitment to providing dignified care. Whether you call it a cremator, a retort, or a furnace, the purpose remains the same: helping families honor their loved ones with respect and care.

Main Types of Cremation Machines on the Market

When you're exploring cremation equipment, you'll quickly find there's not a one-size-fits-all solution. The market offers several specialized machines, each designed with specific purposes in mind. Let me walk you through the main types of cremation machine name options you might consider for your facility.

Human & Pet Units Carrying the cremation machine name

Human cremation equipment represents the cornerstone of the market, and for good reason. These machines handle one of life's most solemn moments with both dignity and technical precision.

At our Tennessee headquarters, we often recommend the B&L N-20SA for mid-sized funeral homes. With its generous 63 cubic foot chamber and average cremation time of 150 minutes, it's perfect for facilities performing up to 5 cremations daily. One funeral director in Atlanta told me, "It's like the reliable family sedan of cremators—not flashy, but it shows up ready to work every single day."

For busier operations, the CFS2300 Human Chamber offers impressive throughput of about 150 pounds per hour. What really sets this model apart is its Quick Change hearth system—a feature our service team in Columbia absolutely loves. When a traditional hearth replacement might sideline your operation for days, this modular design allows for a complete swap in just one day.

The PowerPak series offers flexibility depending on your volume needs. The PowerPak I suits smaller operations handling four or fewer cremations daily, while the PowerPak II PLUS can comfortably manage up to 6 cremations per day. As one of our Johnson City customers put it, "It's like having equipment that grows with your business."

On the pet cremation side, machines like the PET-200 have become increasingly popular as more families seek dignified services for their animal companions. This compact but mighty unit processes up to 7 pet cremations daily, with a chamber capacity of 0.63 cubic meters and operating temperatures reaching 1,450°C.

"The biggest mistake I see is funeral homes trying to use human equipment for pet cremations," shares our technical advisor who supports clients across our service regions. "It's not just about size—pet cremation involves different workflows, with more frequent loading and unloading cycles that affect both your equipment choice and how you'll arrange your facility."

| Feature | Human Cremation Units | Pet Cremation Units |

|---|---|---|

| Average Capacity | 750-1200 lbs | 200-500 lbs |

| Chamber Size | 42-48" width | 24-36" width |

| Average Cycle Time | 90-150 minutes | 60-120 minutes |

| Temperature Range | 760-980°C | 760-1450°C |

| Typical Daily Throughput | 4-6 cremations | 7-12 cremations |

| Special Features | Weight-based automation | Multi-door/partitioned options |

Specialty & Eco-Friendly Alternatives

The cremation industry isn't standing still, and neither are the options for environmentally conscious facilities. We're seeing growing interest in alternative cremation machine name technologies, especially in our Pacific and Northeast service areas.

Electric retorts have gained traction in regions with lower electricity costs or stricter emissions regulations. Unlike their gas-fired cousins, these units eliminate direct combustion emissions and can be paired with renewable energy sources. One Oregon funeral director told us, "It aligned perfectly with our community's environmental values, and that's become a real differentiator for our business."

For those looking to reduce their carbon footprint while sticking with thermal processes, bio-oil burners offer an interesting middle ground. These systems use biological oils rather than fossil fuels, making them increasingly popular with environmentally conscious funeral homes. They're relatively new to the market, but we've seen growing adoption rates, particularly in coastal regions.

In sunnier climates, some pioneering facilities have experimented with solar cremators. While these typically require backup energy sources and longer processing times, they represent an innovative approach to sustainable end-of-life services. As one Arizona customer noted, "It perfectly matches our desert environment and our commitment to sustainability."

Perhaps the most radical departure from traditional cremation comes in the form of alkaline hydrolysis – sometimes called "aquamation" or "water cremation." This process uses water, alkali, heat, and pressure rather than fire. According to scientific research on environmental impact, it produces roughly one-tenth the carbon footprint of flame cremation. While not technically a traditional cremation machine name, it serves the same essential purpose with significantly reduced emissions.

"Ten years ago, these alternatives were considered fringe," observes our sustainability specialist who travels between our regional service areas. "Today, they're becoming mainstream options as families increasingly ask about environmental impact. The funeral homes that accept these technologies often find they've tapped into a growing market segment that values sustainability alongside tradition."

At American Mortuary Coolers, we're committed to helping you steer these choices with honest, practical advice custom to your specific needs, whether you're in Tennessee or any of the 48 contiguous states we serve.

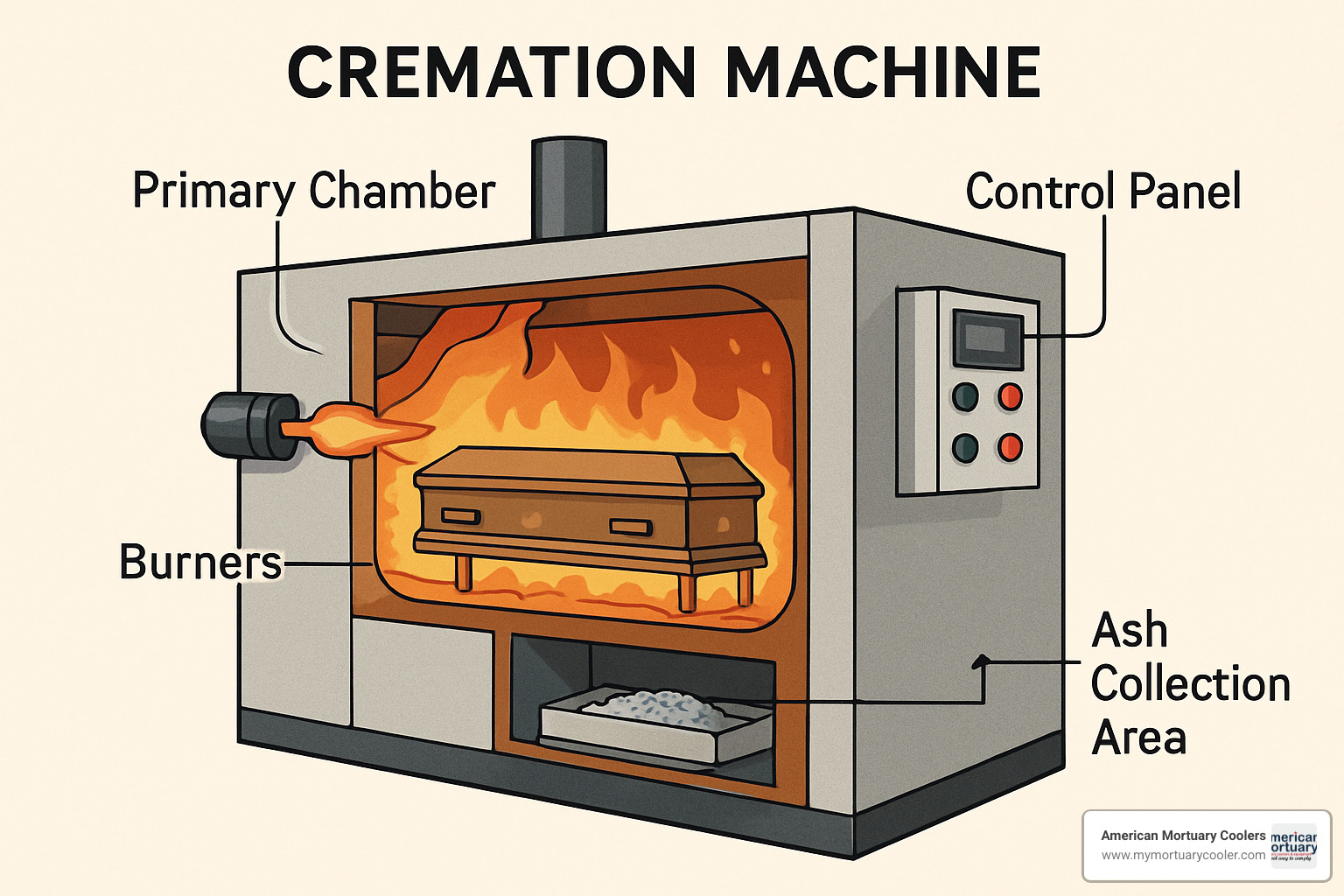

Anatomy & Operation: From Burner to Cremulator

Have you ever wondered what actually happens inside a cremation machine name after the doors close? Understanding these remarkable machines helps funeral professionals make smarter choices about their equipment – and gives families peace of mind about the care their loved ones receive.

Modern cremators aren't just simple fire chambers – they're sophisticated systems combining precise engineering with respectful design. Let me walk you through how these remarkable machines work.

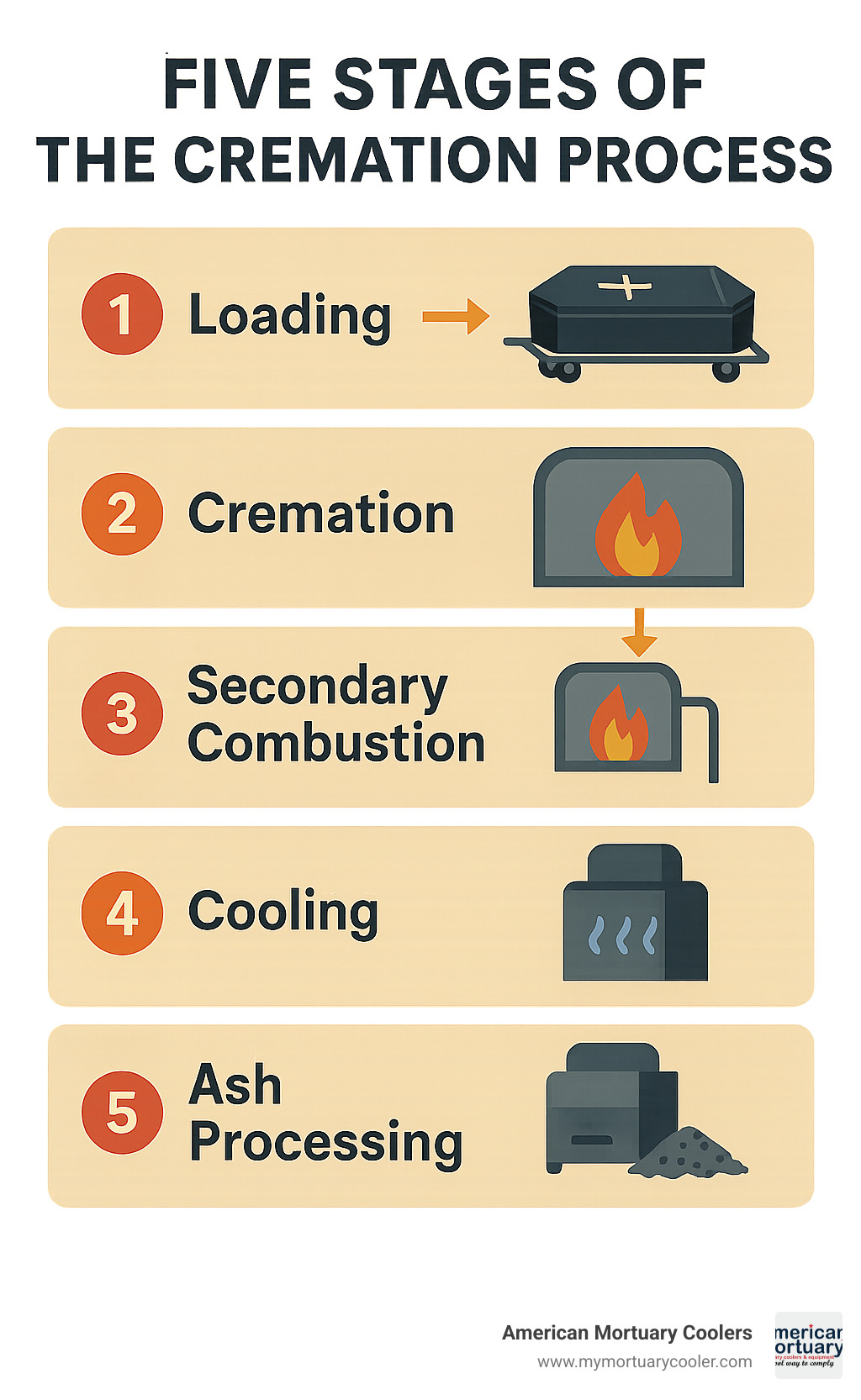

Step-by-Step Process Inside a "cremation machine name"

The journey begins with preheating. Before any remains enter the chamber, the system warms to approximately 800°C – creating the optimal environment for efficient, respectful processing. Think of it like preheating your oven before baking, except with much more precision and purpose.

"We always emphasize the importance of proper preheating," says Mark, one of our veteran technicians at American Mortuary Coolers. "It ensures consistency and dignity throughout the entire process."

Once ready, the coffin charging begins. Using a mechanized charging bier (essentially a specialized loading device), the container with remains is swiftly inserted into the primary chamber. This quick transfer minimizes heat loss while maintaining the sanctity of the moment.

Inside the primary chamber, primary combustion happens at temperatures between 760-980°C (1400-1800°F). During this gentle yet thorough phase, organic materials transform into gases and bone fragments. The DFW 6000 model, which we regularly service, maintains a precise range of 800°C - 850°C during this critical stage.

The process continues with secondary burn, where gases flow into an afterburner chamber and heat to over 900°C. This important step ensures complete combustion, eliminates odors, and helps funeral homes meet environmental standards. It's one reason why modern cremation is so much cleaner than historical methods.

After about 90-150 minutes (depending on several factors), the system begins cooling down. Modern cremators are smart – they don't just use timers but actually monitor temperature patterns to determine completion, ensuring thorough and respectful processing every time.

The final step involves ash processing. Many people don't realize that cremation doesn't directly produce fine ash. Instead, bone fragments remain that must be processed in a specialized machine called a cremulator. This gentle processor creates the fine, sand-like material families receive, typically about 2.4 kg (5.3 lb) for an average adult.

"When families ask me about the process," shares Jennifer, a funeral director we work with in Nashville, "I explain that cremation is really a change – from one physical state to another. Understanding the technology helps them see how carefully their loved one is being treated."

Environmental & Safety Features You Can't Ignore

Today's cremation machine name systems aren't just about efficiency – they're designed with both environmental responsibility and operator safety in mind.

Mercury abatement has become increasingly important as awareness grows about emissions from dental amalgams. Modern systems include specialized filtration that makes a real difference. The average cremation uses about 110 liters of fuel and releases approximately 240 kg of carbon dioxide, so efficient combustion and filtration aren't just good practice – they're essential.

I've watched opacity sensors save the day during installations across our service regions. These clever devices monitor smoke density in the exhaust stack, ensuring complete combustion and helping funeral homes stay compliant with increasingly strict regulations. The CFS 2300 model we supply includes sensors that continuously monitor emissions for EPA compliance.

Never overlook the importance of UL listing when selecting equipment. This independent safety certification tells you the machine has passed rigorous testing. At American Mortuary Coolers, we won't install equipment without proper certification – it's that important.

The human element matters too. Operator PPE (personal protective equipment) includes heat-resistant gloves, face shields, and appropriate respiratory protection when handling remains. Our training teams in Dallas and Chicago emphasize these safety practices during every installation.

Finally, automated controls have revolutionized cremation operations. Modern PLC systems (those are Programmable Logic Controllers) monitor and adjust parameters automatically, improving both safety and consistency. The days of purely manual controls are largely behind us, with intuitive touch-screens now guiding operators through the process.

"The technology has come so far since I started in this industry," reflects Tom, who's been with American Mortuary Coolers for 18 years. "Today's systems combine reverence with remarkable engineering – making the process gentler on the environment and more consistent for families."

For more information about the tools and accessories that complement these systems, check out our guide on cremation equipment tools.

Choosing the Right Cremation Machine: Cost, Capacity & Compliance

When it comes time to invest in a cremation machine name for your funeral home, you're making a decision that will impact your business for decades. I've helped hundreds of funeral directors through this process, and I always tell them the same thing: take your time and consider the full picture.

The price tag on cremation equipment can cause a bit of sticker shock at first. These sophisticated machines represent a significant investment, though specific pricing varies widely based on your needs. Don't worry though - most manufacturers understand this is a major purchase and offer financing solutions. As our friends at B&L Cremation Systems like to say, they "work with top financing companies to get you up and running."

"I always tell my clients to look beyond that initial price when evaluating cremation equipment," shares Maria, our financial specialist at American Mortuary Coolers. "The real story is in the total cost of ownership - how much fuel it uses, how often it needs maintenance, and how many years of reliable service you'll get."

Your daily operational needs should drive your capacity decisions. Are you a smaller funeral home handling just a few cremations weekly? The PowerPak I might be perfect for you, designed for facilities performing four or fewer cremations daily. Growing businesses might need something more robust like the PowerPak II PLUS that comfortably handles up to 6 cremations each day.

Modern families come in all sizes, and your equipment needs to accommodate everyone with dignity. Today's advanced systems like the CFS2300 can handle larger cases exceeding 750 pounds, which is increasingly important as average case weights continue to rise in America. Efficiency matters too - cycle times typically range from 60-150 minutes, with high-performance models like the Classic-XCEL processing at impressive rates up to 400 pounds per hour.

Let's talk about the regulatory side - not the most exciting topic, I know, but absolutely crucial. Your cremation machine name must meet EPA standards for emissions, which limit particulate matter, carbon monoxide, and mercury. The Cremation Association of North America (CANA) provides important industry guidelines that quality equipment should support. And don't forget local permitting - many areas require specific approvals before installation.

Our team at American Mortuary Coolers has steerd these regulatory mazes countless times, from the complex frameworks in New York City to the strict environmental requirements in Los Angeles. We'll stand beside you throughout the entire permitting process - that's a promise.

Future-Proofing Your Investment

Think of your cremation machine name purchase as a long-term relationship. You'll want features that help it adapt to changing times and technologies.

Modern automation is revolutionizing cremation operations. Advanced systems with computerized controls, like the DFW 6000 cremation oven, operate "fully automatically, requiring minimal operator intervention." This means your staff can focus on family care while the equipment handles the technical aspects precisely.

Remote diagnostic capabilities have been a game-changer for our clients. Systems equipped with technology like the Tek Marshal diagnostic package allow our technicians to troubleshoot issues remotely, often resolving problems without an on-site visit. As one relieved funeral director in our Pittsburgh service area told me, "That remote fix saved us from canceling three families' services during a holiday weekend."

With energy costs constantly rising, fuel efficiency matters more than ever. B&L Cremation Systems has made impressive strides with their "introduction of fuel-saving refractory materials such as ceramics." These innovations can significantly reduce your monthly operating expenses while also lowering your environmental impact.

Speaking of the environment, regulatory trends consistently move toward stricter emissions standards. Choosing equipment with advanced filtration capabilities or the ability to upgrade these systems will protect you from costly compliance issues down the road.

For more insights about where the industry is headed, check out our article on the cremation furnace market.

Maintaining Your Unit for Decades

With proper care, your cremation machine name can serve your business reliably for 20+ years. The key is consistent maintenance - think of it like caring for a high-performance vehicle.

Annual professional inspections are non-negotiable. These regular check-ups catch small issues before they become major problems. B&L Cremation Systems emphasizes the importance of "annual tune-ups and refractory inspections for cremation equipment," and they're absolutely right.

The refractory lining (the heat-resistant interior of the cremation chamber) works incredibly hard and will eventually need attention. Newer systems like the Quick Change modular hearth have revolutionized this maintenance aspect, allowing "full hearth replacement in just one day without on-site curing." This means minimal downtime for your business.

I always recommend keeping critical spare parts on hand. Nothing is worse than having to delay services for families because you're waiting on a simple replacement part to arrive. A small investment in spare components can prevent significant disruption.

Proper training extends equipment life dramatically. When operators understand the correct procedures and best practices, they naturally put less stress on the machinery. Many manufacturers offer "operator training and certification on all makes and models," and taking advantage of these programs pays dividends in equipment longevity.

Our maintenance teams at American Mortuary Coolers provide comprehensive support throughout our service regions. Our technicians based in Pittsburgh and across the Midwest are factory-trained on multiple equipment brands, ensuring expert service regardless of which manufacturer you choose.

For those interested in a deeper technical understanding of cremation processes, this scientific research on the cremation process provides excellent additional information.

Choosing the right cremation machine name is one of the most important decisions you'll make for your funeral home. We're here to help you steer the options with the care and attention your business deserves. After all, the equipment you select today will serve countless families in your community for decades to come.

Frequently Asked Questions about Cremation Machine Names

What makes a "cremation machine name" different from an incinerator?

Though they might seem similar at first glance, cremation machine names and standard incinerators are quite different beneath the surface. Think of it like the difference between a specialized kitchen oven and an industrial furnace – they both generate heat, but they're designed for entirely different purposes.

A cremation machine name is specifically engineered for the respectful processing of human or animal remains. These machines feature thoughtfully designed loading systems for caskets, carefully calibrated temperature controls to preserve bone fragments, and an overall design that honors the dignity of the deceased. They also comply with specific regulations governing the handling of human remains.

"When families ask me about the cremation process, I explain that our equipment is specifically designed for this sacred purpose," shares James Wilson, a funeral director from our Nashville service area. "It's not just about the technical function – it's about treating each person with dignity until the very end."

Standard incinerators, by contrast, are built primarily for waste disposal without these special considerations. As one of our engineers puts it: "A cremator is an incinerator, but an incinerator is not necessarily a cremator. The distinction goes beyond technical specs – it's about purpose, design philosophy, and regulatory framework."

How hot does a cremation machine run and for how long?

Modern cremation machine names operate at impressively high temperatures – ranging from 760°C to a scorching 1,650°C (1,400°F to 3,000°F), depending on the model and specific application.

The primary chamber, where the body is placed, typically maintains temperatures between 760-980°C (1400-1800°F). Meanwhile, the secondary chamber (the afterburner) runs even hotter at above 900°C (1650°F) to ensure complete combustion of gases and minimize environmental impact.

The time required for cremation varies based on several important factors. Body size and composition play a major role, as does the type of container or casket. The equipment's design efficiency and operating temperature also significantly affect timing.

On average, the process takes between 1 to 3 hours, with most adult cremations completed in about 90 minutes. High-efficiency models like the Classic-XCEL can process remains at impressive rates up to 400 lb/hr, potentially bringing cremation time down to as little as an hour for standard cases.

"The technology has come a long way," notes our technical specialist based in our Atlanta service region. "Today's systems are not only more efficient but also more environmentally responsible, with better temperature control and emissions management."

Can one cremation machine handle both humans and pets?

While it might seem practical to use one machine for both purposes, using the same equipment for human and pet cremation generally isn't recommended – and in many places, it's actually prohibited by regulations. There are several compelling reasons for this separation:

First, regulatory compliance is a major consideration. Many jurisdictions have entirely different permitting requirements for human versus animal cremation.

From an operational standpoint, human and pet cremations often benefit from different chamber sizes and cycle parameters. A machine optimized for human remains might be inefficient for smaller pets, while equipment designed for multiple small animals wouldn't be appropriate for human remains.

Public perception also matters tremendously in the funeral industry. Many families might have understandable concerns about equipment being used for both purposes, even if thoroughly cleaned between uses.

Finally, different service types typically require different workflows and facility designs. As we've observed across our service regions from Chicago to Miami, facilities that offer both services maintain separate dedicated equipment as the industry standard.

"When we help funeral homes design their cremation facilities," explains our operations consultant, "we recommend separate systems for those offering both human and pet services. It's not just about regulations – it's about providing the right experience for families during a difficult time."

At American Mortuary Coolers, we work with facilities throughout our service regions to design appropriate solutions for their specific service mix, whether they focus exclusively on human cremation, pet services, or both with properly separated systems.

Conclusion

Understanding cremation machine name terminology and technology is essential for funeral professionals making equipment decisions. From traditional terms like cremator, retort, and furnace to the specialized components like cremulators and afterburners, this technical vocabulary creates the foundation for clear communication within our industry.

The evolution of cremation equipment has been remarkable. Modern systems bear little resemblance to their historical predecessors, incorporating advanced refractory materials, sophisticated computerized controls, and comprehensive environmental safeguards. These improvements haven't just made the process more efficient – they've also made it more respectful and environmentally responsible.

"When we help funeral homes select the right equipment, we're really helping them create a dignified experience for families during their most difficult moments," shares our equipment specialist at American Mortuary Coolers. "The right system makes all the difference in operational efficiency, staff experience, and ultimately, family satisfaction."

Whether you're managing a high-volume human crematory or a specialized pet cremation service, your equipment choice should carefully balance several factors: immediate capacity needs, future growth projections, local regulatory requirements, and the long-term cost of ownership. The initial purchase price is just one piece of a much larger operational puzzle.

At American Mortuary Coolers, we've built our reputation on being true partners to funeral professionals, not just equipment suppliers. From our home base in Johnson City, TN, our teams travel across the contiguous 48 states, providing hands-on support throughout the entire equipment lifecycle. While we're known for our durable, custom mortuary coolers, our expertise extends to the complete funeral equipment ecosystem, including cremation systems.

The trends are clear – cremation continues to grow in popularity across America. Industry projections suggest the cremation rate will reach 78.8% by 2035, underscoring the importance of investing in quality equipment that can handle increasing demand while maintaining the highest standards of dignity and environmental responsibility.

For those facilities considering adding or upgrading pet cremation services specifically, we invite you to explore our detailed guide to pet cremation equipment for specialized insights custom to that growing market segment.

By developing a deeper understanding of cremation equipment terminology, technology options, and industry trends, funeral professionals can make truly informed decisions. These choices will not only serve today's families with dignity but also build sustainable, efficient operations that will thrive for decades to come.

We're here to help whenever you're ready to explore your options. After all, selecting the right cremation machine name isn't just a business decision – it's an investment in your ability to provide compassionate care when families need it most.