The Strategic Value of Commercial Cooling Systems

Commercial cooling refers to specialized refrigeration and HVAC systems designed for business applications that require precise temperature control, energy efficiency, and reliable operation. Unlike residential systems, commercial cooling solutions are built for continuous operation in demanding environments.

Quick Guide to Commercial Cooling Solutions:

- Walk-in Coolers/Freezers: For restaurants, grocery stores, mortuaries ($5,000-$30,000)

- Data Center Cooling: Precision air or liquid cooling for servers ($15,000-$100,000+)

- VRF Systems: Flexible zone-based cooling for office buildings ($20,000-$80,000)

- Process Chillers: For manufacturing and industrial applications ($10,000-$200,000)

- Rooftop Units: For retail and commercial spaces ($8,000-$50,000)

In the busy world of commerce, maintaining optimal temperatures isn't just about comfort—it's about protecting inventory, ensuring food safety, preserving sensitive materials, and maximizing equipment lifespan. A properly designed commercial cooling system can reduce energy costs by up to 80% compared to makeshift solutions, while providing the reliability demanded by regulations and business operations.

Regular maintenance can extend the life of commercial cooling systems by years, helping businesses avoid costly replacements. Smart systems with advanced controls are increasingly popular because they significantly reduce operating costs in both large and small commercial settings.

I'm Mortuary Cooler, and I've spent over two decades specializing in commercial cooling solutions for a variety of industries, with particular expertise in custom mortuary refrigeration systems that meet the unique needs of funeral homes while adhering to the highest standards of commercial cooling technology.

Terms related to commercial cooling:

What Is Commercial Cooling & Why It Pays Off

Commercial cooling goes far beyond your home refrigerator or window AC unit. These specialized systems are the workhorses of temperature control in business settings—built tough for around-the-clock operation, designed to handle serious cooling demands, and engineered to keep running when the pressure's on.

When businesses invest in proper commercial cooling equipment, they're not just buying a machine—they're securing peace of mind. For restaurants, grocery stores, and mortuaries, maintaining precise temperatures isn't optional—it's required by law. The FDA Food Code, for instance, demands refrigerated food storage at 41°F or below, a standard that only commercial-grade equipment can consistently deliver.

Today's cooling systems also address growing environmental concerns. With regulations phasing out harmful refrigerants, forward-thinking businesses are choosing equipment like the STULZ CyberCool WaterTec liquid chiller, which uses refrigerant with a Global Warming Potential under 750—already meeting the EU's 2027 requirements.

For tech companies, reliable cooling directly impacts the bottom line. Each degree above optimal temperature in a server room not only shortens equipment life but increases the risk of costly downtime that can run into thousands of dollars per minute.

As one restaurant owner told us, "In my kitchen, the walk-in cooler isn't just another appliance—it's as essential as my head chef." This sentiment rings true across industries—whether you're preserving food, protecting servers, or maintaining dignity in mortuary care, proper cooling is absolutely fundamental to your operation.

The bottom-line benefits of commercial cooling

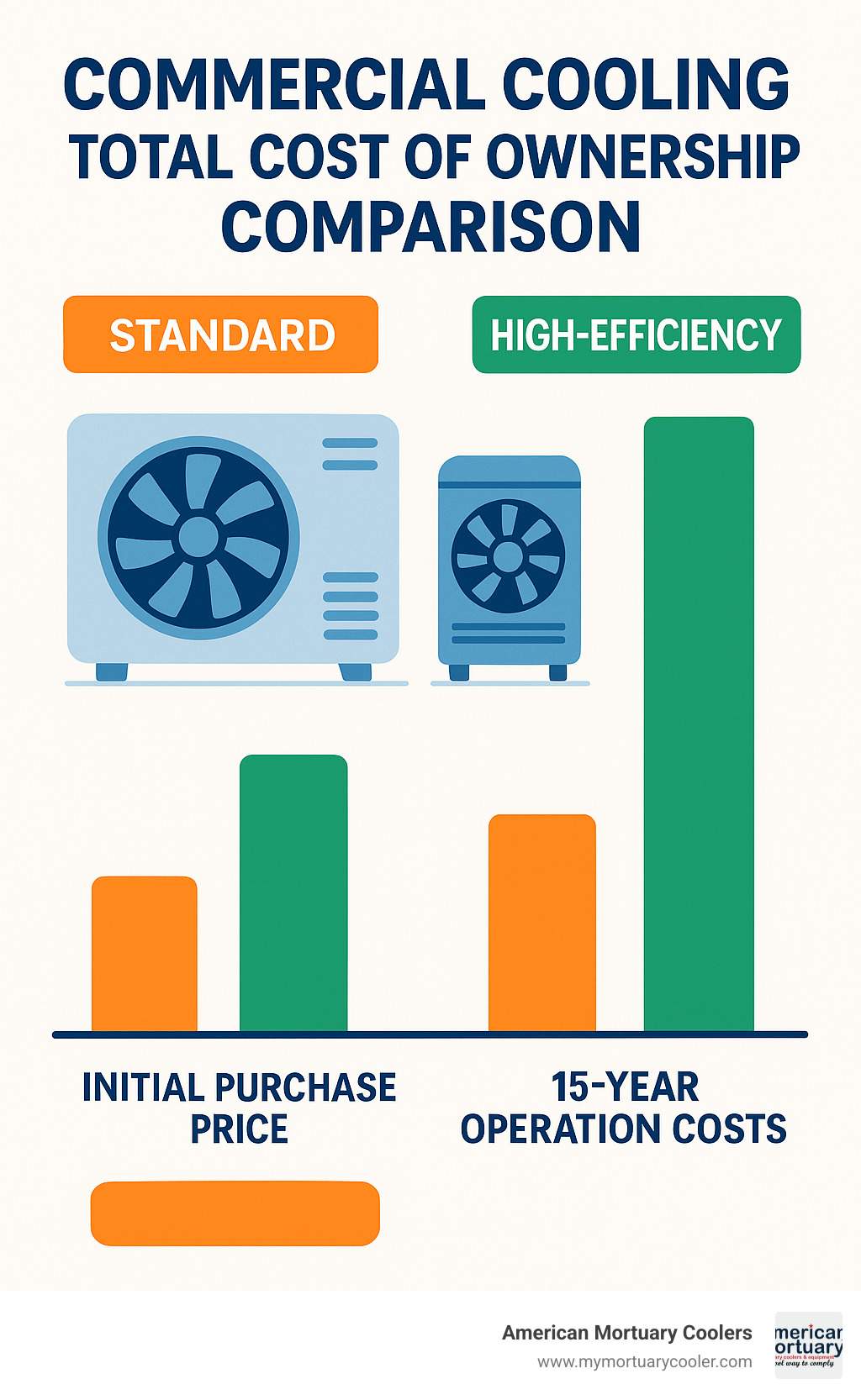

The financial wisdom of investing in quality commercial cooling becomes crystal clear when you look beyond the price tag to the total ownership cost. Yes, commercial systems cost more upfront than DIY solutions like Cool Bot setups, but the long-term math strongly favors professional equipment.

Energy bills drop significantly with efficient commercial systems. Companies using ISOCOOL technology report slashing energy consumption by up to 80% compared to conventional cooling. One grocery client of ours cut their monthly utility bills by nearly a third after upgrading.

Product loss plummets too. Consistent temperatures mean less spoilage in food service—one of our restaurant clients reduced their food waste by over 20% in the first year after installation. For our mortuary customers, reliable cooling preserves dignity and prevents the need for embarrassing and costly emergency measures.

Your equipment also lasts longer. Commercial systems are built for the long haul, with components designed to withstand constant use. As Patrick, one of our manufacturing clients, put it: "We replaced our makeshift cooling system three times in five years. Our commercial unit has been running flawlessly for seven years now."

Staff productivity improves in properly cooled environments too. Research shows that for every degree above comfortable working temperature, productivity drops by about 2%—a hidden cost many businesses overlook.

Perhaps most importantly, you'll face fewer emergency repair calls. Those middle-of-the-night service calls for failing equipment rarely come cheap, and they always seem to happen during your busiest times.

Key industries relying on commercial cooling

Commercial cooling serves as the backbone for numerous industries, each with unique requirements:

In restaurants and food service, walk-in coolers need to recover temperature quickly after dozens of door openings during busy service periods. The difference between consumer and commercial equipment becomes painfully obvious during a Saturday night rush.

Grocery stores depend on display coolers that not only maintain food safety but also showcase products attractively. The right lighting and glass door technology can significantly impact sales while keeping energy costs manageable.

Data centers face ever-increasing heat loads as computing power grows. Many facilities are transitioning from traditional air cooling to liquid cooling solutions that can handle the intense heat generated by AI and high-performance computing applications.

The pharmaceutical industry requires ultra-precise temperature control where even a half-degree fluctuation can ruin expensive compounds. As one lab director told us, "Temperature precision isn't just about compliance—it's about protecting research that took years to develop."

Manufacturing operations, especially plastics processing, rely on industrial chillers to cool equipment and materials during production. Without proper cooling, production lines grind to a halt and product quality suffers dramatically.

In mortuary science—our specialty at American Mortuary Coolers—purpose-built systems provide the dignity and preservation families deserve. Our mortuary clients appreciate features like quiet operation and specialized body-tray configurations that respect both the deceased and those who care for them.

As Medhat Gorgy from Pyramid Laboratories perfectly summarized: "Our Bio-pharmaceutical industry demands Quality, Precision and Accuracy... Commercial Cooling Units are capable to handle our sophisticated requirements and conditions." We couldn't have said it better ourselves.

How to Evaluate Your Cooling Requirements

Finding the perfect commercial cooling system starts with understanding what you really need. It's like buying shoes – you want the right fit, not just something that looks good but pinches your toes!

When we help customers at American Mortuary Coolers, we always begin with a proper heat-gain calculation. This isn't just technical jargon – it's a practical way to figure out exactly how much cooling power your space requires. We look at your building's walls and roof, the heat from equipment and lighting, how many people typically occupy the space, how often doors open, and what you're actually cooling.

"I once had a customer who insisted on a massive cooler system because 'bigger is better,'" shares one of our cooling specialists. "Six months later, they called back complaining about high energy bills and temperature fluctuations. The system was working too hard for the space!"

Space constraints matter too. Not everyone has a warehouse-sized area to work with. Sometimes you're fitting cooling equipment into tight spaces, which might mean considering a rooftop penthouse unit to save valuable floor space inside your building.

The indoor versus outdoor placement decision is another crucial factor. Remote systems that put heat-generating condensers outside can keep your interior spaces more comfortable and reduce your overall cooling costs. However, they require professional installation and longer refrigerant lines.

Your local utility rates should influence your choice too. In areas with high electricity costs, investing in a more efficient system often pays for itself surprisingly quickly. Some areas even offer rebates for energy-efficient commercial cooling equipment, putting money back in your pocket.

Don't forget to think ahead! If your business is growing, consider systems that can expand with you. It might cost a bit more upfront, but it's usually cheaper than a complete replacement later.

Sizing commercial cooling correctly

Getting the size right is perhaps the most important decision you'll make about your commercial cooling system. It's a bit like Goldilocks – not too big, not too small, but just right.

For walk-in coolers, industry standards suggest about 70-80 BTUs per cubic foot. Freezers need more power – typically 120-130 BTUs per cubic foot. But these numbers aren't set in stone. If your facility is in Phoenix where temperatures regularly exceed 90°F, you'll need to add about 15% more capacity compared to a similar facility in a cooler climate.

Modern insulation makes a big difference too. Today's polyurethane foam panels typically provide R-29 to R-32 insulation value, dramatically improving efficiency compared to older systems.

How you use your cooler matters just as much as its size. A restaurant that constantly opens and closes the cooler door during busy service periods needs more cooling capacity than a facility where the door opens only a few times daily.

"We've seen many businesses struggle with improperly sized cooling systems," notes one of our engineers at American Mortuary Coolers. "A mortuary cooler that's too small can't maintain proper temperature during busy periods, while an oversized unit costs more to purchase and operate while providing suboptimal performance."

HVAC systems require even more careful sizing, considering your square footage (roughly 25 BTUs per square foot for basic cooling), ceiling height, windows, occupancy, and equipment heat output. It's a balancing act that pays dividends in comfort and efficiency when done right.

Maintenance plans for commercial cooling

Even the best commercial cooling equipment needs regular TLC to keep running smoothly. Think of it like changing the oil in your car – skip it, and you're asking for trouble down the road.

A good quarterly maintenance routine includes cleaning or replacing air filters, checking belts and bearings for wear, verifying refrigerant levels, cleaning those all-important coils, and making sure your thermostat is telling the truth about the temperature. Safety controls should be tested regularly too – they're your early warning system for potential problems.

Once a year, your system deserves a more thorough check-up. This includes inspecting the entire system, checking motor amperage, tightening electrical connections (they can loosen with vibration over time), cleaning the condensate drain to prevent water damage, and using specialized equipment to detect even tiny refrigerant leaks.

Many modern systems now include smart monitoring features that send alerts before small issues become big problems. These might notify you if a door is left open, if temperatures drift outside acceptable ranges, or if the system's power consumption suddenly changes – often a sign that something's not right.

The payoff for this attention is substantial. Well-maintained commercial cooling systems typically last 15-20 years, while neglected ones might fail in half that time. When you're running a business where temperature control is critical – whether it's preserving food, protecting server equipment, or maintaining dignity in mortuary services – that reliability is priceless.

Walk-In Coolers & Freezers: Durable Workhorses

Walk-in coolers and freezers are truly the unsung heroes of commercial cooling. These versatile temperature-controlled rooms adapt to almost any business need, providing reliable cooling day in and day out without complaint.

Think of walk-ins as the reliable employee who never calls in sick—they just keep working, protecting your inventory around the clock. What makes these cooling workhorses so dependable? It all comes down to quality construction.

The best walk-ins feature modular panel construction, allowing you to create a custom-sized space that fits your exact needs. Commercial Cooling, one of the industry leaders, offers impressive panels spanning up to 26 feet in a single piece—perfect for businesses needing larger installations without seams.

Inside these panels, you'll find foamed-in-place polyurethane insulation that outperforms alternatives like polystyrene or fiberglass. Modern walk-in panels achieve impressive R-29 to R-32 insulation values, which not only exceeds federal EISA requirements but also keeps your energy bills manageable.

The panels connect using clever cam-lock fastening systems that create tight, secure connections while still allowing for disassembly if you ever need to relocate. It's like a giant, temperature-controlled puzzle that's built to last for decades.

Flooring options range from standard to heavy-duty reinforced floors that can handle pallet jacks and weighty equipment without breaking a sweat. And for food-related businesses, NSF #7 certification ensures your unit meets strict food safety standards for materials, construction, and performance.

California businesses should note that Title 20 compliance from the California Energy Commission is required for walk-in sales in the state, guaranteeing energy efficiency standards are met.

Quality manufacturers like Commercial Cooling take the extra step of pre-assembling units before shipping. This attention to detail catches and fixes potential issues before your walk-in ever arrives at your doorstep, saving you headaches during installation.

Top Pick: Pre-Assembled Remote Walk-In

If you're looking for the Cadillac of walk-ins, our top recommendation is the Commercial Cooling Pre-Assembled Remote Walk-In system. With over five decades in the business and a management team boasting more than 320 years of combined experience, these folks know their cooling.

What sets them apart? Every unit undergoes a meticulous 7-point inspection before leaving their facility. Their field-ready panels feature a clever tongue-and-groove design with secure cam-lock fasteners that make assembly a breeze while maintaining that critical thermal seal.

The remote refrigeration system is particularly brilliant—it moves the heat-generating components outside your building, keeping your indoor spaces more comfortable and often reducing your overall energy costs.

As one happy restaurant owner in Atlanta told us, "We've had our Commercial Cooling walk-in for eight years with zero issues. The pre-assembly meant installation took half the time we expected, and the remote system keeps our kitchen comfortable even in summer."

Budget Pick: Quick-Ship American Walk-In

When time and budget constraints are pressing concerns, American Walk-In Coolers offers a fantastic middle ground. Their quick-ship program can have a quality walk-in cooler or freezer ready in just 14 days—a lifesaver when you're dealing with equipment failure.

These 100% USA-made units don't skimp on quality despite their competitive pricing. The UL-listed panels meet rigorous standards for burning characteristics, smoke index, and flame spread ratings, while still maintaining NSF #7 compliance for food safety.

Perhaps most impressive is their warranty coverage—20 years on panels and 5 years on doors and compressors. That's confidence you can count on.

Michael, a customer who needed a quick solution, shared: "You have been most helpful and your quick response has been recognized. I will tell all who enquire about walk-in fridges & freezer suppliers that you're the only guy to deal with."

Specialty Pick: Mortuary Walk-Ins

At American Mortuary Coolers, we've specialized in addressing the unique requirements of funeral homes and medical facilities. We understand that mortuary refrigeration isn't just about temperature control—it's about dignity, respect, and reliability when it matters most.

Our mortuary coolers incorporate specialized features like body-tray shelving systems in various configurations to maximize capacity while ensuring respectful handling. We've selected low-noise compressors that operate quietly—essential for maintaining a peaceful atmosphere during services or viewings in nearby rooms.

The interiors feature antimicrobial finishes for proper sanitation, and our specialized door configurations ensure dignified access. Comprehensive temperature monitoring and alarm systems provide peace of mind for facilities that simply cannot experience cooling failures.

Based in Tennessee, we proudly deliver our specialized commercial cooling solutions directly to funeral homes across all 48 contiguous states. We've built our reputation on understanding the unique needs of the funeral industry and creating solutions that blend technical excellence with compassionate design.

A funeral director from Chicago recently told us, "The quiet operation of our American Mortuary Cooler makes a significant difference during viewings in adjacent rooms. The reliability gives us peace of mind, and the custom configuration maximizes our available space."

Want to learn more about what makes a great walk-in cooler? Check out our complete guide to walk-in cooler features and prices or find how to choose the perfect commercial cooler for your specific needs.

Precision Cooling for Data Centers & Edge Sites

When your servers are running hot, regular air conditioning just won't cut it. Today's data centers and edge computing sites generate incredible amounts of heat—especially with the rise of AI workloads that push hardware to its limits. This is where specialized commercial cooling solutions become absolutely essential.

Liquid cooling has become the star player for high-density computing environments. Think of it as the difference between splashing your face with water versus standing in front of a fan when you're overheated—liquid simply transfers heat more efficiently.

Systems like the STULZ CyberCool WaterTec liquid chiller represent the cutting edge of this technology. These advanced systems use environmentally friendly refrigerants like R1234ze with a Global Warming Potential under 750, which means they're already meeting the EU's 2027 requirements for larger chillers.

What makes precision cooling so valuable for data environments? For starters, the cooling capacity is impressive. The CyberCool CMU Coolant Distribution Unit can handle up to 1380kW of heat exchange—enough for the most demanding computing setups. Liquid cooling is also 5-10 times more efficient than air cooling at removing heat from servers, takes up less space, runs more quietly, and eliminates those dangerous hot spots that can fry your equipment.

As Malintha Gamarachchi noted about an edge installation near Vienna: "Our partner IT Klima has done an excellent job in understanding the customer need for low latency and speed of deployment... We can sense that the industrial Edge is becoming more common as the need for data-driven, efficient manufacturing is helping our clients reach their sustainability targets."

When to move from air to liquid

Wondering if it's time to upgrade your data center's cooling system? There are some clear signals that it's time to make the leap from traditional air cooling to liquid-based commercial cooling:

When your rack densities push beyond 10 kW, traditional air cooling starts to struggle. If your facility is in a warm climate, liquid cooling's efficiency becomes even more valuable. Are you running AI or High-Performance Computing workloads? Those generate intense heat that demands superior cooling capacity.

Space constraints are another consideration—liquid cooling's smaller footprint preserves valuable data center real estate. And if sustainability matters to your organization (as it should!), the superior efficiency of liquid cooling significantly reduces both energy consumption and carbon footprint.

OptiCool Technologies, a leader in this space, points out that their refrigerant-based systems are "five times more efficient at moving heat than water," and their CDU-M15 provides an impressive 1.5 MW cooling capacity—perfect for those demanding AI and HPC environments.

One data center manager in Dallas shared his experience: "After switching to liquid cooling for our AI cluster, we saw a 250-amp reduction in energy draw. The ROI was achieved in just 14 months through energy savings alone." That's the kind of real-world impact that makes financial officers smile.

Smart monitoring must-haves

Today's commercial cooling systems for data centers are smarter than ever, with sophisticated monitoring capabilities that ensure reliability while optimizing performance. If you're investing in cooling for critical infrastructure, make sure your system includes:

BMS integration that allows your cooling systems to work harmoniously with other facility systems. Leak detection is absolutely critical for liquid cooling systems to prevent costly damage to IT equipment. Power Usage Effectiveness (PUE) dashboards provide real-time monitoring of cooling efficiency, helping you spot opportunities to improve.

Predictive maintenance alerts powered by AI can detect potential failures before they happen, dramatically reducing downtime risks. Remote management through cloud-based controls lets your team monitor and adjust settings from anywhere. And comprehensive environmental sensors tracking temperature, humidity, and airflow provide the complete picture of your facility's conditions.

As IT KLIMA Service Kft., an exclusive STULZ precision cooling distributor, emphasizes: "Precíziós hűtés, kompromisszumok nélkül" (Precision cooling without compromises). When it comes to mission-critical cooling applications, this philosophy says it all—you simply can't afford to compromise.

At American Mortuary Coolers, we understand the importance of reliable cooling for critical applications. While our specialty is the funeral industry, the principles of dependable, efficient commercial cooling apply across all sectors where temperature control is non-negotiable.

VRF & Rooftop HVAC Systems for Large Buildings

When it comes to keeping larger commercial spaces comfortable, Variable Refrigerant Flow (VRF) systems and rooftop package units stand out as the champions of commercial cooling technology.

Carrier VRF HVAC systems have become increasingly popular for good reason. These sophisticated systems tackle common challenges like unpredictable energy costs and those annoying temperature inconsistencies that plague many commercial buildings.

What makes these systems special? For starters, they use variable speed compressors that adjust their output to match exactly what your building needs – unlike traditional systems that simply turn on full blast or shut off completely. This smart approach dramatically improves energy efficiency while maintaining consistent comfort.

The zoning capabilities are another game-changer. Different areas of your building can enjoy different temperatures simultaneously – keeping server rooms cool while reception areas stay comfortable. This targeted approach not only improves comfort but also prevents wasting energy on spaces that don't need it.

Some VRF systems even feature heat recovery, which is almost like magic – they can take heat from areas being cooled and transfer it to areas that need warming. Talk about making the most of your energy dollars!

Your employees and customers will appreciate the quiet operation too. With outdoor condensing units and small, whisper-quiet indoor fan coils, VRF systems won't disrupt conversations or concentration. And building owners love the flexible installation options, with smaller refrigerant lines and modular components that make these systems perfect for retrofits and buildings where mechanical space comes at a premium.

For retail spaces and larger single-zone applications, rooftop package units offer an all-in-one solution that keeps the mechanical equipment outside where it belongs. These workhorses deliver simple installation since all components come in a single package. Placing equipment on the roof preserves valuable interior space that can be used for merchandise or customer seating instead.

Maintenance becomes much easier too, with easy service access that allows technicians to perform regular maintenance without disrupting your business operations. Many units include economizer capability, using outside air for "free cooling" when weather conditions permit. And utility companies often offer rebates for systems with demand-response compatibility that can reduce load during peak demand periods – putting money back in your pocket.

Retrofits that slash energy bills

Not ready for a complete system replacement? Good news! Strategic retrofits can deliver substantial energy savings for buildings with existing but inefficient commercial cooling systems.

Wi-Fi enabled thermostats have become incredibly popular in commercial settings because they learn your usage patterns and optimize operation accordingly. These smart devices can significantly reduce heating and cooling costs while giving you remote control capabilities.

Upgrading to ECM fan motors makes a surprising difference too. These Electronically Commutated Motors use 60-70% less electricity than traditional PSC motors while providing variable speed capability – a win-win for comfort and your utility bills.

Indoor air quality and energy efficiency can both improve with sensor-based ventilation. CO2 sensors can adjust fresh air intake based on how many people are actually in your building rather than assuming maximum occupancy at all times. This smart approach reduces the energy needed to condition outside air while maintaining healthy indoor environments.

Even your refrigerant can make a difference. Refrigerant upgrades to newer, more efficient formulations can improve system performance while often being more environmentally friendly. And control system updates to modern building automation systems optimize operation across multiple parameters, not just temperature.

The results speak for themselves. As one retail chain in the Southeast Region told us: "After retrofitting our stores with smart thermostats and ECM motors, we saw a 23% reduction in cooling-related energy costs. The payback period was less than two years."

At American Mortuary Coolers, we understand that while our specialty is mortuary refrigeration, many of our clients also need efficient building cooling solutions. That's why we stay up-to-date on the latest commercial cooling technologies for all applications – helping you make informed decisions for your complete facility needs.

Process & Industrial Chillers for Manufacturing

Manufacturing and industrial processes generate enormous amounts of heat that must be managed with precision and reliability. In these demanding environments, commercial cooling takes the form of process chillers – specialized workhorses designed to maintain exact temperatures for machinery, materials, and critical processes.

These industrial cooling champions come in several distinct varieties, each bringing unique strengths to the factory floor:

Air-cooled chillers reject heat directly to the atmosphere through condensers with powerful fans. They win points for simpler installation since they don't require cooling towers or complex water systems. The trade-off? They typically run less efficiently than their water-loving cousins, especially in hot climates.

Water-cooled chillers partner with cooling towers to reject heat, achieving impressive efficiency gains. While they deliver superior performance in most conditions, they do require more complex installation and ongoing water treatment to prevent scale and biological growth. For many manufacturers, the efficiency benefits easily justify this added complexity.

Adiabatic chillers offer a clever hybrid approach. By pre-cooling air before it reaches the condenser, they boost efficiency in hot weather while using significantly less water than traditional cooling towers. It's the best of both worlds for many applications.

Industry leader ISOCOOL has demonstrated energy savings up to an astonishing 80% with their high-efficiency chillers. Their systems have proven particularly valuable in plastics extrusion, where precise cooling is essential not just for product quality but for protecting expensive equipment from overheating.

Today's cutting-edge process chillers often incorporate smart energy recovery features that capture waste heat for useful purposes rather than simply dumping it outside. This reclaimed thermal energy can warm facilities, pre-heat process water, or serve other functions – effectively delivering "free" energy that further improves the ROI of quality commercial cooling investments.

Choosing the right chiller type

Finding your perfect process chilling match involves weighing several crucial factors that will impact performance and costs for years to come.

Cooling capacity requirements form the foundation of your decision. Process chillers typically range from compact 5-ton units to massive 500-ton systems. Getting the size right is absolutely critical – too small, and your chiller will struggle constantly, unable to maintain temperature and wearing out prematurely. Too large, and you'll waste money on both purchase and operation as the system inefficiently cycles on and off.

The ambient conditions at your facility play a major role too. In hot, humid climates, water-cooled or adiabatic systems typically deliver better performance than air-cooled units, which lose efficiency as outdoor temperatures climb. A Georgia plastics manufacturer told us, "Our air-cooled chiller struggled in summer until we switched to an adiabatic system. Now we maintain perfect temperatures year-round while using less energy."

Water availability and quality can't be overlooked if you're considering water-cooled options. These systems need reliable water sources and may require treatment systems to prevent scale buildup and biological growth that can hamper efficiency.

Your process's temperature stability needs might dictate more sophisticated controls. While some applications can tolerate minor temperature fluctuations, others (like precision pharmaceuticals or specialty plastics) may require extremely tight control within ±0.5°F or better. These demanding applications typically justify more advanced control systems.

Don't forget to consider your team's maintenance capabilities. More complex systems deliver better performance but require more skilled maintenance. Be honest about your facility's maintenance resources when selecting a chiller type. The most efficient system won't save money if it frequently sits idle awaiting specialized service.

Space constraints matter too. Air-cooled chillers need adequate clearance around the unit for proper airflow, while water-cooled systems require space for cooling towers but can have smaller footprints for the chiller itself.

One manufacturing client summed it up perfectly: "We switched from an outdated air-cooled to a modern adiabatic chiller and saw a 32% reduction in energy costs while improving temperature stability. The initial cost difference was recovered in under 18 months – and that's not counting the improved product quality and reduced scrap rate we've enjoyed."

Smart Controls, IoT & Energy Management Add-Ons

Remember when managing your commercial cooling system meant walking around with a clipboard? Those days are long gone. Today's smart controls and IoT technologies are changing how businesses monitor and optimize their cooling equipment – and the savings can be substantial.

Modern commercial cooling systems now come with cloud-based dashboards that let you check performance from anywhere with internet access. Imagine adjusting your mortuary cooler's settings while at a conference or getting an alert about a temperature fluctuation before it becomes a problem. This remote capability isn't just convenient – it's changing how businesses approach maintenance and operation.

"The ability to monitor our walk-in cooler from my phone has given me peace of mind I never thought possible," shares a restaurant owner in Nashville. "Last month, I got an alert at 2 AM about a temperature spike and was able to call for service before our inventory was compromised."

Occupancy sensors have also revolutionized energy management by automatically adjusting cooling based on whether spaces are actually being used. Why cool an empty room to perfection? These smart sensors eliminate wasted energy and reduce wear on your equipment.

Variable-frequency drives (VFDs) represent another game-changer in the commercial cooling world. Instead of motors simply running at full speed or completely off, VFDs allow precise speed control, dramatically cutting energy consumption. Many of our customers report 20-30% energy savings after installation.

Remote diagnostics capabilities mean service technicians can often troubleshoot issues before stepping foot on your property. This improves first-time fix rates and minimizes downtime – crucial for businesses where temperature control is non-negotiable.

Perhaps most impressive are the predictive maintenance systems that use AI algorithms to analyze performance data and predict failures before they happen. These systems learn your equipment's normal patterns and can detect subtle changes that might signal an impending problem. It's like having a crystal ball for your cooling system!

Quick wins for small businesses

Not every business needs (or can afford) enterprise-level smart systems. The good news? Even small operations can benefit from affordable commercial cooling upgrades that deliver impressive returns.

Night setback controls offer one of the simplest ways to save energy. These affordable devices automatically adjust temperature setpoints during closed hours, reducing energy consumption when precise cooling isn't as critical. For funeral homes, this can mean significant savings without compromising dignity or preservation during viewing hours.

Door-ajar alarms are another simple yet effective addition. These sensors alert staff when refrigerator or freezer doors are left open, preventing both product loss and energy waste. In a busy environment where staff are juggling multiple responsibilities, these gentle reminders can save thousands in energy costs and prevent catastrophic inventory losses.

Lighting upgrades often get overlooked, but replacing fluorescent lights with LEDs in display cases or walk-in coolers reduces heat load and energy consumption simultaneously. LEDs generate less heat, meaning your cooling system doesn't have to work as hard, and they use a fraction of the electricity.

Many utility companies offer free or subsidized energy audits that can identify these opportunities. As our energy consultant partner in Memphis tells clients, "The lowest-hanging fruit in commercial energy savings is often in refrigeration and cooling systems, where simple upgrades can yield 15-30% energy savings."

Don't forget to check for utility program incentives in your area. Many electric utilities offer substantial rebates for energy-efficient cooling upgrades, reducing payback periods from years to months. We've helped several funeral homes connect with local programs that covered up to 50% of their energy efficiency upgrades.

At American Mortuary Coolers, we understand that every dollar saved on energy is a dollar that can be invested back into your business. That's why we design our mortuary coolers with energy efficiency in mind and offer a range of smart control options that can be custom to your specific needs and budget.

Frequently Asked Questions about Commercial Cooling Equipment

How often should my system be serviced?

One question we hear all the time is about maintenance schedules. The truth is, your commercial cooling system is a lot like your car—regular check-ups prevent breakdowns at the worst possible times.

For most businesses, quarterly preventive maintenance is the sweet spot. But there's no one-size-fits-all answer here. If your system runs around the clock (like many of our mortuary coolers do), you'll want more frequent attention than a system that only runs during business hours.

Your environment matters too. Restaurant kitchens with their grease-laden air need more frequent coil cleaning than clean office environments. And if you're cooling critical inventory—whether that's food, medications, or deceased loved ones—monthly inspections provide extra peace of mind.

Here's what a typical maintenance calendar might look like:

- Monthly: A quick visual check and fresh filters

- Quarterly: Deeper cleaning of coils, checking refrigerant levels, and calibrating controls

- Annually: A comprehensive inspection, including electrical components and leak detection

As one of our contractor partners puts it, "The systems that get regular TLC often last 5-7 years longer than neglected ones." When you consider that a new system can cost tens of thousands of dollars, those maintenance visits suddenly look like a bargain.

Which certifications prove food-safe performance?

When it comes to food safety, certifications aren't just paperwork—they're your assurance that equipment will perform as promised.

The gold standard is NSF Standard #7. This certification from NSF International means your commercial cooling equipment has been thoroughly tested for food safety, from the materials used in construction to its ability to maintain safe temperatures under stress.

Look for the UL Listing too. While this focuses on electrical safety rather than food safety, it's an important piece of the puzzle. After all, a system that shorts out can't keep anything cold!

If energy efficiency matters to you (and your utility bill suggests it should), Energy Star certification identifies equipment that maintains proper temperatures while sipping electricity instead of guzzling it.

For our California customers, the California Energy Commission Title 20 compliance is not just recommended—it's required for sales in the state.

At American Mortuary Coolers, we ensure our systems meet these standards because we understand that reliability isn't optional—whether you're preserving food or caring for the deceased with dignity.

How do upcoming refrigerant bans affect new purchases?

The refrigerant landscape is changing faster than a teenager's social media habits, and it matters for your next purchase.

Global agreements like the Kigali Amendment to the Montreal Protocol are phasing down HFCs (hydrofluorocarbons) with high Global Warming Potential. In practical terms, this means refrigerants that were industry standards just a few years ago are now on their way out.

The European Union's F-Gas Regulation requires that by 2027, liquid chillers above 12 kW can't use refrigerants with a GWP over 750. While that might seem far away (and far away geographically for US businesses), the US AIM Act is bringing similar restrictions stateside.

So what does this mean for your next commercial cooling purchase? Look for systems using future-friendly refrigerants like:

R-290 (propane), R-600a (isobutane), R-744 (CO2), or R-1234yf/R-1234ze (hydrofluoroolefins).

These refrigerants have significantly lower environmental impact. For example, the STULZ CyberCool WaterTec liquid chiller uses R1234ze refrigerant, which meets upcoming requirements with room to spare.

As one of our refrigeration specialists bluntly puts it, "Buying a system with R-404A or R-507 today is like buying a gas-guzzling SUV when gas prices are about to triple." You might save a little upfront, but you'll pay later when regulations force expensive retrofits or early replacement.

At American Mortuary Coolers, we stay ahead of these changes so our customers don't have to become refrigerant experts themselves. We're happy to explain the implications for your specific situation—just ask!

Conclusion

Choosing the right commercial cooling system isn't just a technical decision—it's a strategic business move that affects everything from your daily operations to your long-term profitability. Whether you're keeping restaurant ingredients fresh, maintaining optimal server temperatures, or preserving dignity in a mortuary setting, the fundamentals don't change: quality equipment that's properly sized, regularly maintained, and energy-efficient will always deliver the best value over time.

Here at American Mortuary Coolers, we've taken these universal cooling principles and applied them to our specialized corner of the industry. From our home base in Tennessee, we craft custom, dependable coolers that we ship directly to funeral homes across all 48 contiguous states. Our deep understanding of both commercial cooling technology and the unique requirements of funeral professionals allows us to create solutions that respect both the technical and the human aspects of mortuary science.

The cooling industry keeps evolving, and we're evolving right alongside it. Smart control systems, eco-friendly refrigerants, and energy-saving innovations are changing what modern cooling systems can do. By working with specialists who truly understand your specific needs, you can steer these changes confidently and make cooling investments that will serve your business faithfully for years.

I've learned over my years in this business that the cheapest option upfront almost never turns out to be the most affordable in the long run. Quality commercial cooling equipment pays you back many times over—through lower energy bills, reduced maintenance headaches, longer equipment life, and the kind of reliability that lets you sleep soundly at night. These aren't just technical benefits; they're business advantages that directly impact your bottom line and your peace of mind.

For specialized fields like mortuary science, partnering with a focused provider ensures you get equipment designed specifically for your unique challenges. At American Mortuary Coolers, we understand that when a cooling system fails in a funeral home setting, it's not just an inconvenience—it's a situation that can affect families during an already difficult time. That's why reliability isn't just a technical specification for us—it's a commitment to the dignity of those you serve.

More info about our mortuary coolers

Whether your funeral home is in a small town in Tennessee, the busy streets of Chicago, or anywhere in between, we're here to help you make cooling decisions that honor both your business needs and the families who depend on your services. Because at the end of the day, that's what commercial cooling in our industry is really about—supporting the important work you do with equipment that's as dependable as you are.