The Versatile World of Hammers with Hooks

A hammer with hook is a specialized tool that combines striking power with pulling capability, featuring a curved hook opposite the striking face. These versatile tools serve numerous functions across different industries and applications.

Types of Hammers with Hooks:

- Carpentry Claw Hammer - For driving and removing nails

- Climbing Hammer - Used for placing and removing pitons and hooks

- War Hammer (Bec de Corbin) - Historical weapon with armor-piercing capabilities

- Butchery Hook Hammer - For handling meat safely during processing

- Dissection/Mortuary Hammer - Precision tool for anatomical work

The hook component provides essential leverage, allowing users to pull, grip, or manipulate objects that would be difficult to handle with a standard hammer. This dual functionality makes hammers with hooks indispensable in their respective fields.

The design of a hammer with hook varies significantly based on its intended purpose. Carpentry hammers typically feature a curved claw for nail extraction, while climbing hammers may have specialized hooks for removing protection from rock. Butchery and mortuary hammers often include sharpened hooks for precise manipulation of tissues.

I'm Mortuary Cooler, with extensive experience evaluating and recommending specialized tools including the hammer with hook variants used in mortuary and forensic settings. My background in mortuary equipment supplies has given me unique insight into the durability and functionality requirements these specialized tools demand.

Hammer with hook terms at a glance:

What Is a Hammer with Hook? Key Types and Functions

A hammer with hook combines striking power with pulling capability. This clever pairing means you can work continuously without switching between tools.

The world of hammers with hooks is diverse! While they all share the basic design principle of a striking head opposite some form of hook, the hook's shape varies dramatically depending on its purpose.

What makes a hammer with hook valuable? The hook provides leverage for pulling or prying, eliminates tool switches, allows precise control in technical work, and improves efficiency.

Carpentry Claw Hammer with Hook – Everyday Construction Essential

The claw hammer is the most recognizable hammer with hook. That curved claw opposite the striking face is designed for pulling out nails with minimal effort.

The Estwing 24 oz hammer with its "shark fin" hook is a favorite among construction professionals for nail extraction and bending twisted lumber during framing. These hammers typically come in 15 oz versions for precision work and 24 oz versions for heavy construction.

War-Era Hammer with Hook – The Bec de Corbin Example

The medieval Bec de Corbin (French for "crow's beak") was a multi-tool of combat. Developed by Swiss and German weaponsmiths, it featured a spike opposite a hammer face, with a distinctive side hook for catching armor, yanking cavalry riders from horses, and penetrating plate armor at vulnerable joints.

Climbing Hammer with Hook Basics – Big-Wall Must-Have

For rock climbers, a hammer with hook is essential for placing and removing protection. The Grivel Thor climbing hammer weighs 500 g (17.6 oz) – ideal for effectively working with pitons. Its ergonomic handle and integrated spring leash prevent dropping the tool while hundreds of feet off the ground.

Meat & Butchery Hammer with Hook for Safe Handling

In butchery, the T325 PRHC 4" Right Hand Center Hook represents specialized tools focused on safety and efficiency. This lightweight tool (0.28 lb) features a right-center handle design for precise control during detailed cutting work. Its NSF Certification ensures it meets food safety standards.

Dissection & Mortuary Hammer with Hook

In anatomical and mortuary work, precision tools make all the difference. The standard dissection hammer with hook typically weighs around 12 ounces and measures 8.25 inches – substantial enough to be effective but controlled enough for delicate work. The hammer end separates bone during dissection, while the hook end manipulates small specimens without causing damage.

History and Evolution Across Trades

The journey of the hammer with hook through history shows remarkable adaptation. From simple beginnings to specialized modern tools, these implements have evolved alongside the trades they serve.

Timeline Highlights

- 10th century: Simple wooden mallets found in York, England (artifact no. 8188)

- 15th century: Early claw hammers appear in European illustrations, including the Mendelschen Hausbuch (1444)

- Medieval period: The Bec de Corbin war hammer emerges, combining striking power with a hook for grabbing armor

- 19th century: Factory production brings "farmer's billhooks" and specialized designs in Birmingham tool catalogues

- World Wars: Military-pattern billhooks with hooks, many still bearing government contract date stamps

- 1970s: Climbing community adopts "clean climbing" philosophy, developing specialized designs that minimize rock damage

- Today: Modern hammers feature ergonomic grips, composite materials, and specialized designs

The carpenter's claw hammer illustrates this evolution perfectly. What began as a wooden handle with simple metal reinforcement evolved into today's perfectly balanced tools with shock-absorbing grips. The hook component started as a basic curve for pulling nails but developed into specialized shapes for various woodworking challenges.

At American Mortuary Coolers, we appreciate tools that evolve to meet specific needs - just like our custom-designed mortuary solutions.

Design Variations and Functional Advantages

The design of a hammer with hook varies dramatically based on its intended application, reflecting the specific requirements of different trades.

Handle materials transform the tool's feel and performance. Ash wood handles offer natural flex that absorbs shock. Steel handles provide durability but transmit more vibration. Fiberglass handles strike a balance between weight and vibration dampening. Composite handles deliver optimal weight-to-strength ratio for comfortable extended use.

Head weight is another crucial design element. Carpentry hammers typically range from 15-24 oz, with heavier versions for framing and lighter models for finish work. Climbing hammers need at least 500 g (17.6 oz) to effectively work with pitons. Anatomical hammers are often lighter (around 12 oz) for precise control.

A well-balanced hammer with hook places the center of mass close to the striking face while maintaining comfortable handling, reducing fatigue and improving accuracy.

Why Add a Hook?

The hook transforms the tool's functionality in meaningful ways:

- For carpenters: Enables efficient nail removal

- For construction workers: Allows pulling, positioning, or bending materials

- For climbers: Helps manipulate protection devices in challenging positions

- In anatomical settings: Provides precise specimen manipulation without direct contact

- For storage: Allows the tool to be hung when not in use

The termination of the hook—how it ends—defines much of its function. Safety-focused terminations feature rounded ends to prevent injury, while utility terminations often incorporate sharp points for maximum performance.

Modern Innovations

Today's designs incorporate thoughtful innovations that improve functionality, safety, and comfort:

- Ergonomic grips with contoured handles reduce fatigue

- Spring leashes prevent dropping tools from height

- Magnetic nail starters hold nails in place for one-handed starting

- Shock reduction systems minimize impact transmission to the user

The Grivel Thor climbing hammer exemplifies modern innovation, combining traditional functionality with contemporary materials and design.

Selecting, Using & Maintaining Your Hammer with Hook

Finding the perfect hammer with hook requires matching the tool to your specific tasks.

Selection Criteria

For everyday carpentry, a 15-24 oz claw hammer provides versatility. The Estwing models with one-piece steel construction are particularly durable. Choose 15 oz for delicate finish work or 24 oz for framing and heavier jobs.

Rock climbers need a heavier head (at least 500 grams/17.6 oz) to effectively work with pitons. The Grivel Thor combines ideal weight with smart ergonomics and built-in safety features.

For mortuary and anatomical professionals, stainless steel construction is essential for proper sterilization. The standard 12 oz anatomical hammer balances force with precision for delicate procedures.

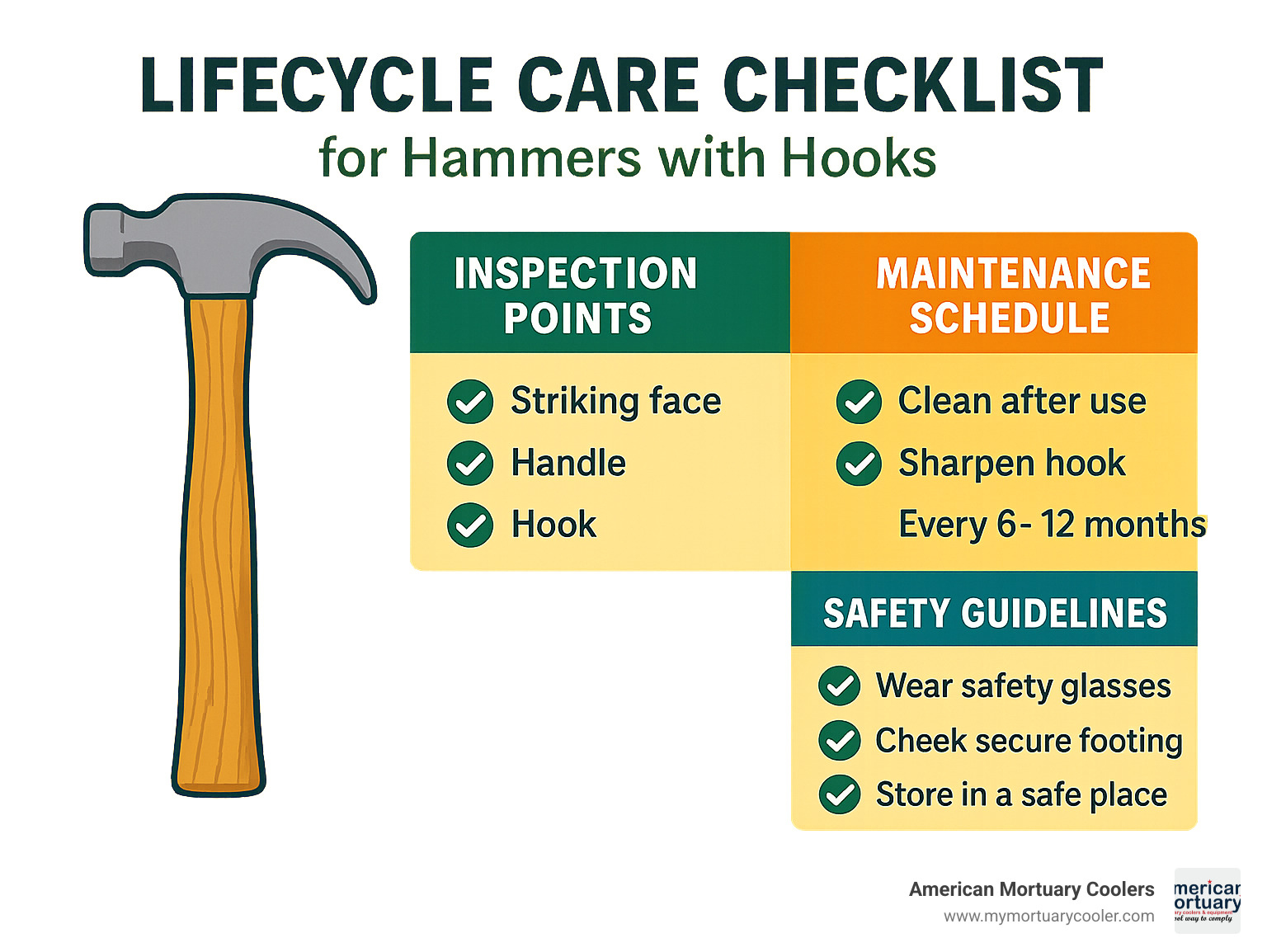

Safety Considerations When Swinging a Hammer with Hook

The hook requires extra safety awareness:

- Eye protection is non-negotiable

- Tether your tool when working at height

- Choose gloves that provide grip without sacrificing feel

- Be mindful of your fall zone

For climbers, the integrated spring leash isn't just a feature—it's a lifesaver. Butchers benefit from tools with slip-resistant handles and finger guards to prevent accidents when working with slippery materials.

Care & Maintenance Tips

A well-maintained hammer with hook will serve you for years. After use, wipe down metal components and apply a light coat of oil to prevent rust. Check your hook's shape regularly and reshape if needed using appropriate files.

For wooden handles, an occasional application of linseed oil prevents drying and cracking. Inspect leashes and tethers for wear and replace at the first sign of damage. Store your tool properly to prevent damage to the hook component.

In mortuary settings, thorough cleaning and sterilization between uses is an essential professional standard.

Common Misconceptions & Mistakes

Avoid these common errors:

- Using the claw as a crowbar (use a proper pry bar instead)

- Over-driving pitons (listen for the ring pitch)

- Choosing the heaviest hammer available (match weight to your specific task)

- Ignoring leash requirements, especially in climbing situations

Specialized Applications Spotlight

The hammer with hook design has been adapted for remarkably different uses across various fields.

Aid-Climbing Techniques with a Hammer with Hook

In aid climbing, your hammer with hook becomes a lifeline. Climbers progress by placing and weighting artificial protection rather than relying solely on natural holds.

Experienced climbers file skyhook tips to a blunt 60° point for improved placement security. When a stubborn piton refuses to budge, many use a "Funkness Device"—a thick wire loop for shock-loading and removing obstinate protection.

Most skyhooks have a breaking strength of around 2-3kN (similar to a small micro nut)—sufficient for body weight but not for dynamic falls. A well-balanced hammer allows for more precise placements, which is crucial when hanging from tiny metal hooks on vertical rock.

The climbing community has developed strong ethical considerations around hammer use, reflecting their commitment to minimizing environmental impact while preserving challenge.

Blacksmithing: Hook Termination Philosophy

Blacksmiths approach hook-making as the difference between "workmanship of risk" versus "workmanship of certainty"—a philosophy perfectly embodied in creating hooks.

The way a hook ends—its termination—reveals both purpose and skill:

- Safety terminations: Rounded ends that prevent injury

- Decorative terminations: Scrollwork or artistic elements

- Utility terminations: Purely functional, often pointed for specific tasks

Traditional blacksmiths insist on learning to make hooks freehand—using only hot cutting and bending—before relying on fixtures. This builds the hand-eye coordination and judgment that separate true craftsmen from mere technicians.

Food Processing & Meat Locker Use

In butchery and food processing, a specialized hammer with hook is essential for food safety and efficient handling. The T325 PRHC 4" Right Hand Center Hook features NSF Certification, a slip-resistant handle with integrated finger guard, and a right-hand center design optimized for balance.

Butchers use these specialized tools for quartering beef, hanging poultry, and general meat handling. The sharp hook provides a secure grip without causing excessive tissue damage, while the hammer component delivers controlled force exactly where needed.

Frequently Asked Questions about Hammers with Hooks

How do I choose the right head weight for my task?

For general carpentry, a 16 oz hammer hits the sweet spot between power and precision. For framing or heavy construction, step up to a 20-24 oz model. For delicate finish work, a lighter 12-16 oz hammer gives better control.

Climbers need at least 500 g (17.6 oz) of head weight when placing or removing pitons. Any lighter and you'll be tapping ineffectively; any heavier and you'll quickly tire on vertical terrain.

For anatomical and mortuary work, a 12 oz hammer provides controlled force without sacrificing accuracy for delicate procedures.

Can I retrofit a hook onto an existing hammer?

While technically possible, I generally advise against this DIY approach. Adding a hook requires welding or significant modifications that can compromise your hammer's heat treatment and structural integrity. The balance will almost certainly be affected, making the tool less effective and potentially more tiring to use.

Safety concerns also arise with retrofitted hooks. DIY modifications often create stress points or sharp edges that can lead to injuries. Instead, invest in a purpose-built hammer with hook designed specifically for your needs.

What is the breaking strength of climbing skyhooks and how does it relate to hammer choice?

Most climbing skyhooks have a breaking strength of approximately 2-3kN - comparable to a small micro nut. This means they're strong enough to support body weight or an extremely short fall, but won't hold up to dynamic loading or significant falls.

Your hammer with hook choice directly affects how you place and use these skyhooks. A well-balanced hammer allows for more precise placements, which is crucial when you're hanging from tiny metal hooks on vertical rock. Experienced climbers recommend hammers weighing at least 500 g (17.6 oz) because they provide better feedback - you can literally feel when a placement is solid.

When relying on skyhooks, redundancy is your friend. Always equalize marginal skyhook placements with a sliding-X or fall arrester to distribute weight across multiple points.

Conclusion

The hammer with hook isn't just a tool – it's a testament to human ingenuity and adaptation. From the carpenter's claw to the climber's tool, this simple yet brilliant design has evolved to meet countless needs while maintaining its fundamental purpose.

What makes these tools remarkable is how they embody both tradition and innovation. The basic concept has remained relevant for centuries, yet modern materials and ergonomic designs continue to improve functionality.

Safety, selection, and care remain the cornerstones of working with any hammer with hook. Choosing the right weight and design for your specific task improves efficiency, prevents injury, and extends the tool's life.

At American Mortuary Coolers, we understand specialized tools because specialization is our business. Just as a mortuary hammer is crafted for precise anatomical work, our custom coolers are designed with the specific needs of funeral professionals in mind.

We're proud to serve funeral professionals across Tennessee, Georgia, Illinois, South Carolina, Texas, California, New York, Pennsylvania, and throughout the contiguous United States. Our direct delivery service ensures that quality equipment reaches the professionals who need it, when they need it.

Whether you're driving nails, placing pitons, processing food, or performing delicate anatomical procedures, the right hammer with hook becomes an extension of your skill and intention. With proper selection and care, these remarkably versatile tools will serve faithfully through countless tasks.