The Heart of Your Cooling System: Understanding Walk-In Cooler Compressors

A walk in cooler compressor is the heart of any refrigeration system, pumping refrigerant through the system to maintain proper temperatures. Without a properly functioning compressor, your walk-in cooler cannot maintain the critical temperatures needed for preservation.

Quick Guide to Walk-In Cooler Compressors:

- Purpose: Compresses refrigerant gas to initiate the cooling cycle

- Types: Hermetic, semi-hermetic, scroll, and screw compressors

- Capacity Range: Available from 0.75 HP to 100 HP depending on cooler size

- Operating Temperature: Should not feel hot to touch during normal operation

- Lifespan: 8-12 years with proper maintenance

- Maintenance: Annual professional inspection recommended

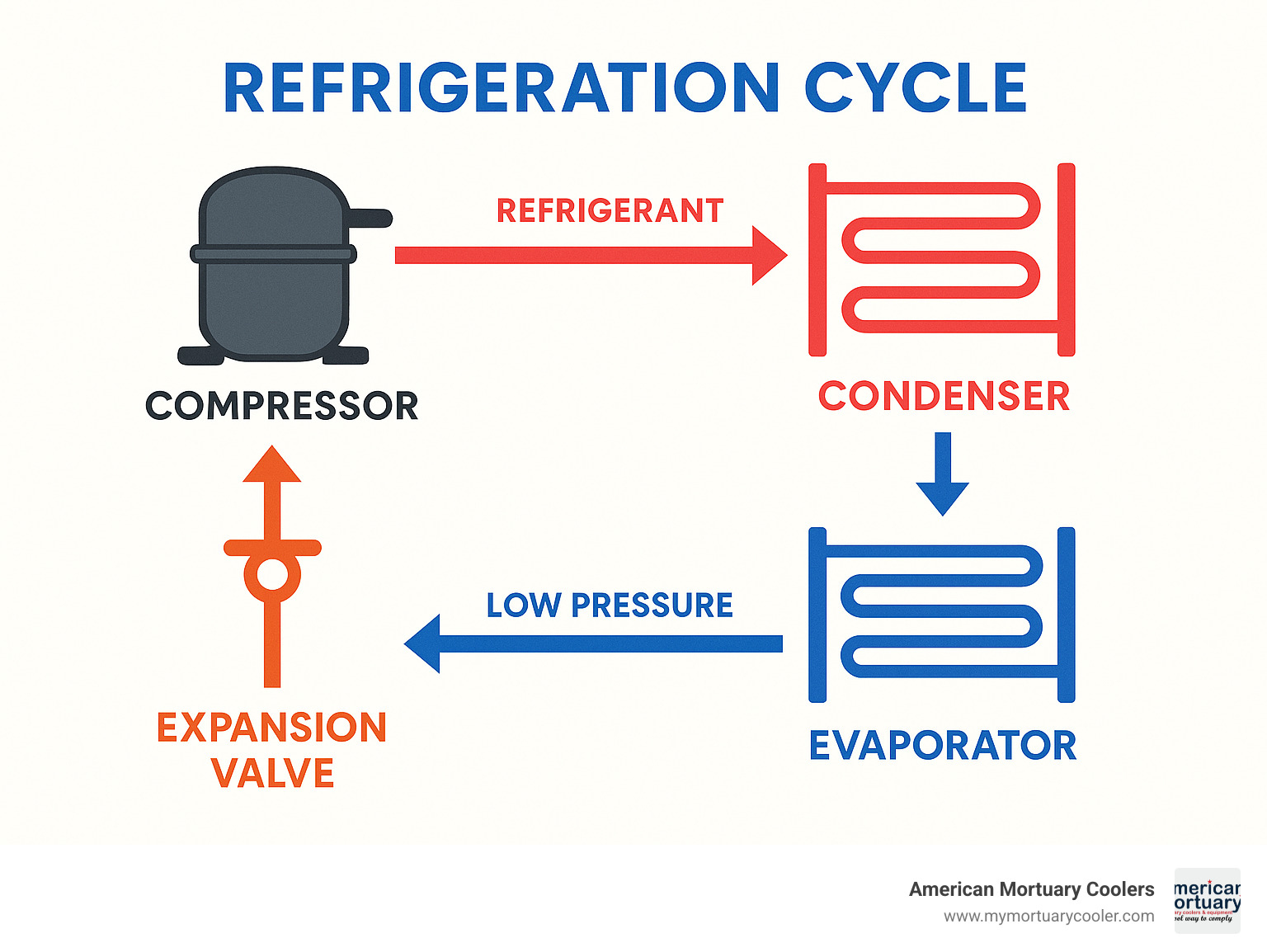

The compressor works by compressing refrigerant gas, raising its temperature and pressure before it moves through the condenser coil where heat is released. This process is crucial for maintaining the cooling cycle that keeps your walk-in at the proper temperature.

A properly functioning compressor is not just about keeping things cold—it's about efficiency and cost savings. According to industry data, a walk-in cooler compressor that runs hot can increase energy costs by up to 20%, potentially adding $1,440 annually to your utility bills. Beyond energy waste, compressor failure can lead to approximately $3,000 in repair costs and potentially thousands more in product loss.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select and maintain reliable walk in cooler compressors for their preservation needs.

Walk In Cooler Compressor Anatomy & Operation

The walk in cooler compressor is like the heart of your cooling system, with several key components working in harmony to create refrigeration magic.

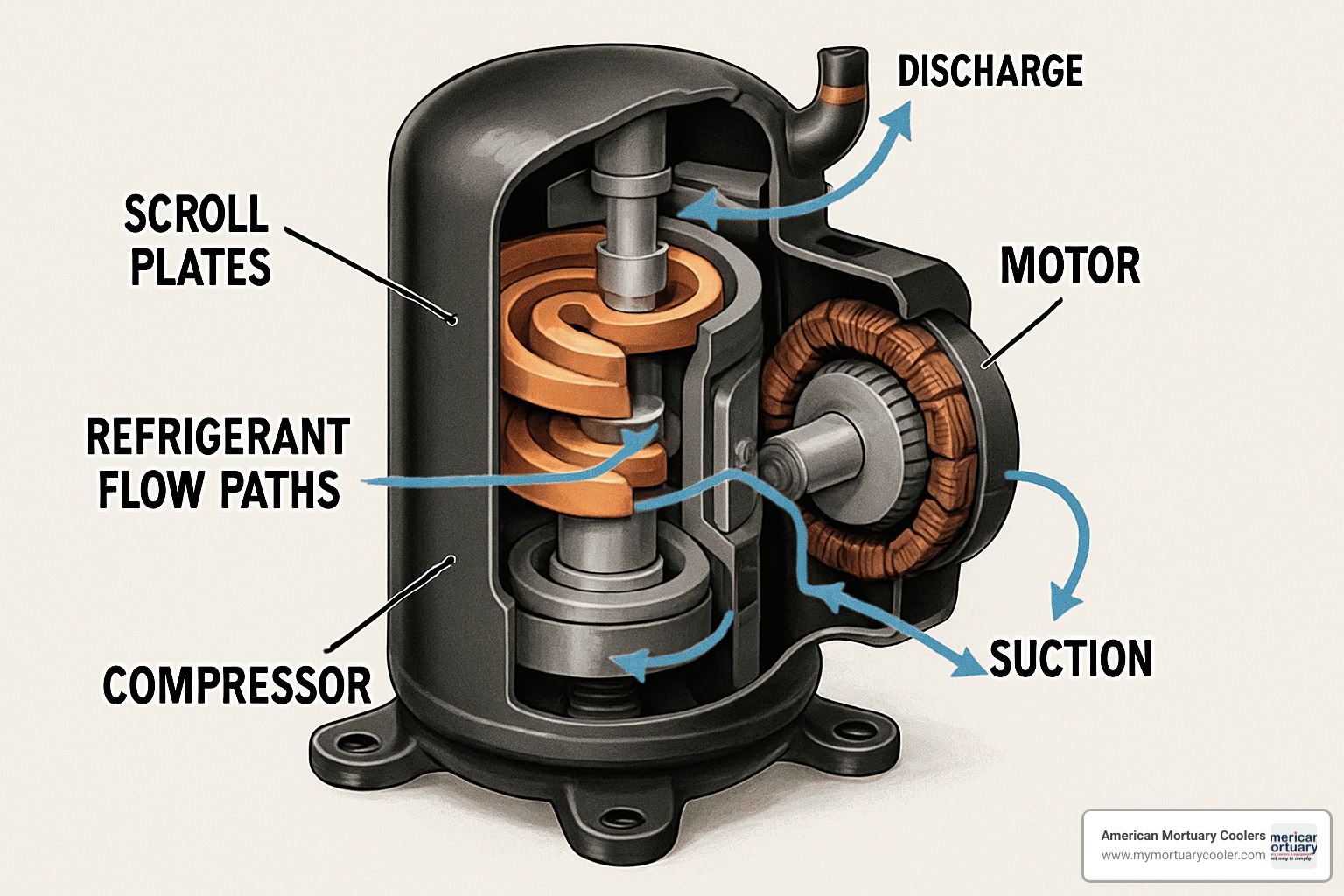

The motor provides mechanical power to drive the compression. This motor connects to the compression mechanism that physically squeezes the refrigerant gas. The suction line serves as the entrance where low-pressure, cool gas enters, while the discharge line works as the exit where high-pressure, hot gas leaves. All of this is protected by a sturdy metal housing that both contains pressure and dissipates heat. Inside, valves direct the refrigerant flow in the right direction.

The housing is crafted from durable metal designed to handle significant pressure while effectively transferring heat away from the system.

How a Walk In Cooler Compressor Works

The cooling cycle begins with the suction phase, where low-pressure, cool refrigerant vapor gets drawn into the compressor. Next comes the compression stroke – the compressor mechanically squeezes this vapor, dramatically boosting both its pressure and temperature.

This newly hot, high-pressure gas rushes out through the discharge line to the condenser. As it flows through the condenser coils, the gas releases heat to the surrounding air and transforms into a high-pressure liquid. This liquid passes through an expansion device that reduces its pressure before entering the evaporator inside your walk-in cooler.

Inside the evaporator, the refrigerant absorbs heat from your cooler's interior, causing it to evaporate back into a gas. This low-pressure gas returns to the compressor, and the cycle begins again.

This continuous cycle efficiently removes heat from inside your walk-in cooler, maintaining critical temperatures needed for proper preservation.

The Main Types of Walk-In Cooler Compressors

When choosing a walk in cooler compressor for your mortuary facility, you have several options:

Hermetic compressors have the motor and compressor permanently sealed within the same housing, making them leak-proof and compact. They're typically more affordable upfront but can't be repaired if something goes wrong internally. These work well for smaller walk-ins with moderate usage.

Semi-hermetic compressors have bolted construction that allows access to internal components. This makes them serviceable and repairable, often extending their lifespan. They cost more initially but are ideal for medium to large walk-in coolers with heavy use.

Scroll compressors use an innovative spiral-shaped scroll design to compress refrigerant, resulting in higher efficiency, fewer moving parts, and quieter operation – something funeral homes particularly appreciate. While they cost more upfront, their reliability and efficiency often make them worth it.

For larger operations, screw compressors offer tremendous capacity for continuous operation, though they come with a higher price tag and more complex maintenance requirements.

| Compressor Type | Horsepower Range | Efficiency | Noise Level | Best Application |

|---|---|---|---|---|

| Hermetic | 0.75-5 HP | Good | Moderate | Small coolers |

| Semi-Hermetic | 1-30 HP | Very Good | Moderate | Medium-large coolers |

| Scroll | 1.5-15 HP | Excellent | Low | Most modern installations |

| Screw | 20-100 HP | Very Good | High | Large industrial coolers |

Selecting the Right Walk In Cooler Compressor

When it comes to preserving dignity in mortuary care, few things matter more than a reliable cooling system. Think of your compressor as the heart of your cooling system – you want something that works efficiently without drawing attention to itself.

Capacity & Horsepower Matching for Your Walk In Cooler Compressor

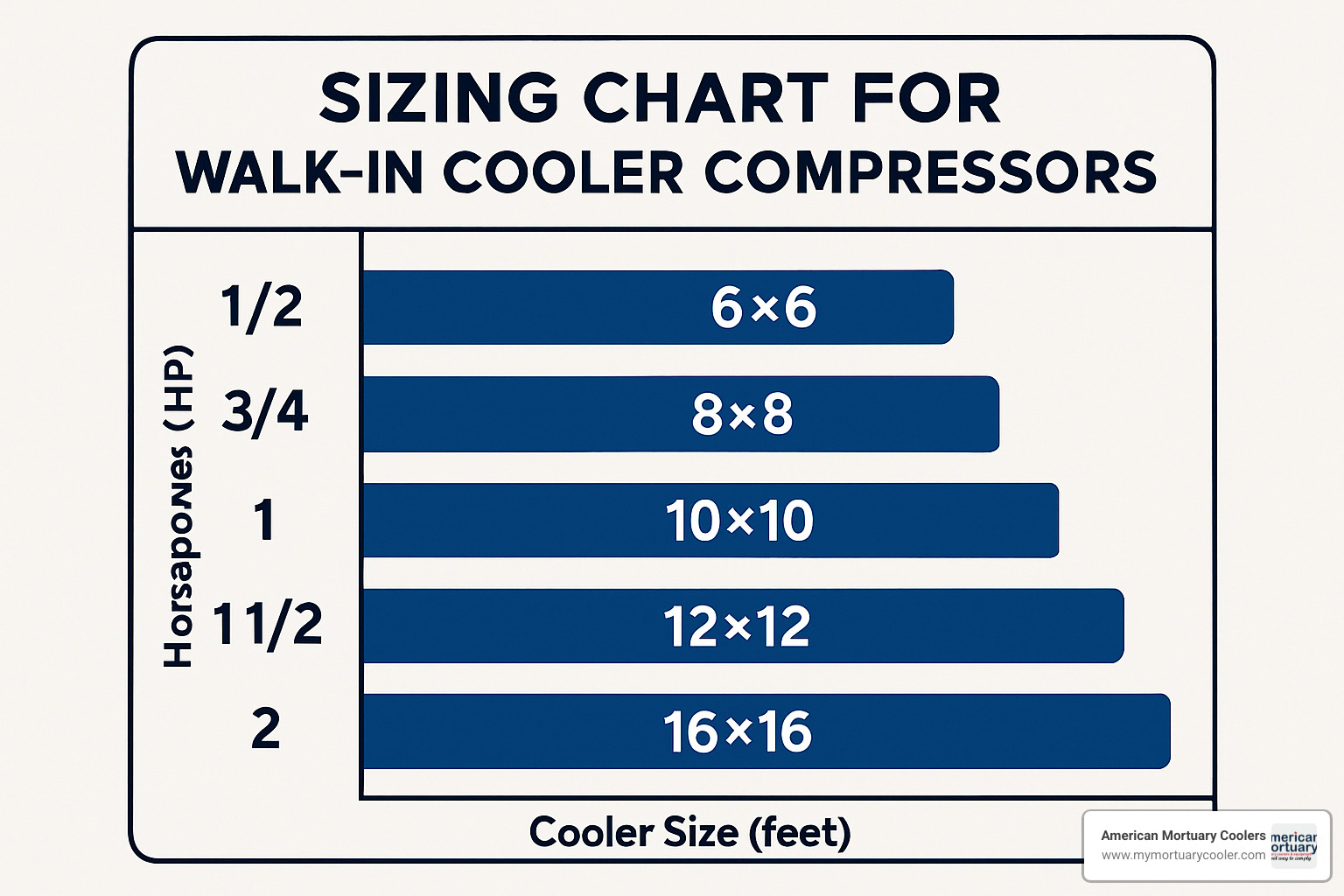

The first step is understanding your space by calculating your walk-in's volume. Each body adds roughly 250-350 BTU/hr of heat load, and every door opening introduces warm air.

For most mortuary coolers, we recommend between 1,200-2,500 BTU/hr at a 10°F temperature differential. This needs adjustment based on your specific situation – insulation quality, ambient temperature, access frequency, and capacity needs.

Converting this to horsepower is straightforward: about 12,000 BTU/hr equals 1 HP. So if your calculations show you need 18,000 BTU/hr, you're looking at approximately a 1.5 HP compressor. Adding a 10-15% safety factor is recommended.

A common mistake is thinking bigger is always better. An oversized walk in cooler compressor will short-cycle – turning on and off frequently. This is hard on components, reduces dehumidification, wastes energy, and creates temperature fluctuations.

An undersized unit will run continuously, wear out quickly, and fail to maintain proper temperature, potentially failing in just 2-3 years instead of the expected 8-12 year lifespan.

For most mortuary coolers storing 3-6 bodies, a 1/3 HP to 1 HP compressor is typically sufficient.

Environmental & Efficiency Factors

Modern walk in cooler compressors now use refrigerants like R-448A and R-449A, which have significantly lower environmental impact while maintaining or improving efficiency. These refrigerants also help future-proof your investment as regulations evolve.

When comparing units, look for the Annual Walk-In Energy Factor (AWEF) rating. The higher this number, the more efficient the system.

Technology has brought other efficiency improvements too. Microchannel condensers improve heat transfer while using less refrigerant. Variable speed drives adjust output to match cooling demand rather than just turning on and off. Digital scroll technology provides more precise temperature control.

Noise matters in a funeral home setting – families need a peaceful environment. Scroll compressors typically run quieter (around 63 dBA) than older technologies, and proper mounting can reduce vibration and noise even further.

Want to explore this topic further? Check out our detailed guide on how to master walk-in cooler design for more insights.

Troubleshooting, Maintenance & Repair Decisions

Even the most reliable walk in cooler compressor will eventually run into issues. Identifying problems early can save thousands in repair costs and prevent middle-of-the-night emergencies.

Signs Your Walk In Cooler Compressor Is Failing

Your compressor will usually give warning signs before it completely fails:

- Unusual sounds: A healthy compressor has a steady, consistent hum. Grinding or metallic sounds often indicate bearing issues. Clicking noises typically point to electrical problems.

- Temperature problems: If your walk-in isn't holding steady at around 35°F, or if temperature gradually creeps up despite continuous operation, something's wrong.

- Overheating: The compressor should be warm but never hot to touch.

- Short cycling: Frequent on/off cycles are not normal behavior.

- Physical signs: Oil spots around the compressor, frost or ice buildup on the suction line, or excessive vibration.

- Pressure issues: High head pressure (above 240 psi) or low suction pressure (below 34 psi) in a medium-temperature application.

In a mortuary setting, these warnings deserve immediate attention.

Diagnosing Compressor Issues in a Walk In Cooler

When a walk in cooler compressor starts acting up, a systematic approach to diagnosis will save time and money:

- Check power: Verify the power switch is on and the circuit breaker hasn't tripped.

- Inspect electrical components: Check terminals for proper voltage and look for loose connections.

- Test starting components: Use a multimeter to check the start capacitor, start relay, and overload protector.

- Check the run capacitor: Measure its capacitance and look for physical damage.

- Evaluate motor windings: Measure resistance between terminals.

- Check refrigerant charge: Connect a gauge set to measure system pressures.

If your walk-in temperature rises above 38°F, you need to act quickly.

More info about compressor function

Repair vs Replace: Making the Call

When deciding whether to repair or replace a failing walk in cooler compressor, consider these factors:

- Age: If a compressor is less than 5 years old and the issue is a minor component, repair often makes sense. For compressors over 10 years old, replacement is usually smarter.

- Cost ratio: If repair costs are less than 30% of replacement and the system has been reliable, fixing it is usually best. When repair costs exceed 50% of replacement, replacement makes more sense.

- Financial impact: A typical compressor replacement runs between $2,200-$3,000. Consider not just the repair bill but potential inventory loss.

- Warranty: New compressors typically come with a 12-month warranty, while rebuilt units often carry just 90 days of coverage.

In mortuary applications, preventive replacement of aging compressors is often the wisest approach. When you're responsible for preserving remains, the peace of mind from reliable equipment is priceless.

Installation & Best Practices to Maximize Lifespan

Proper setup makes all the difference in keeping your walk in cooler compressor running smoothly for years.

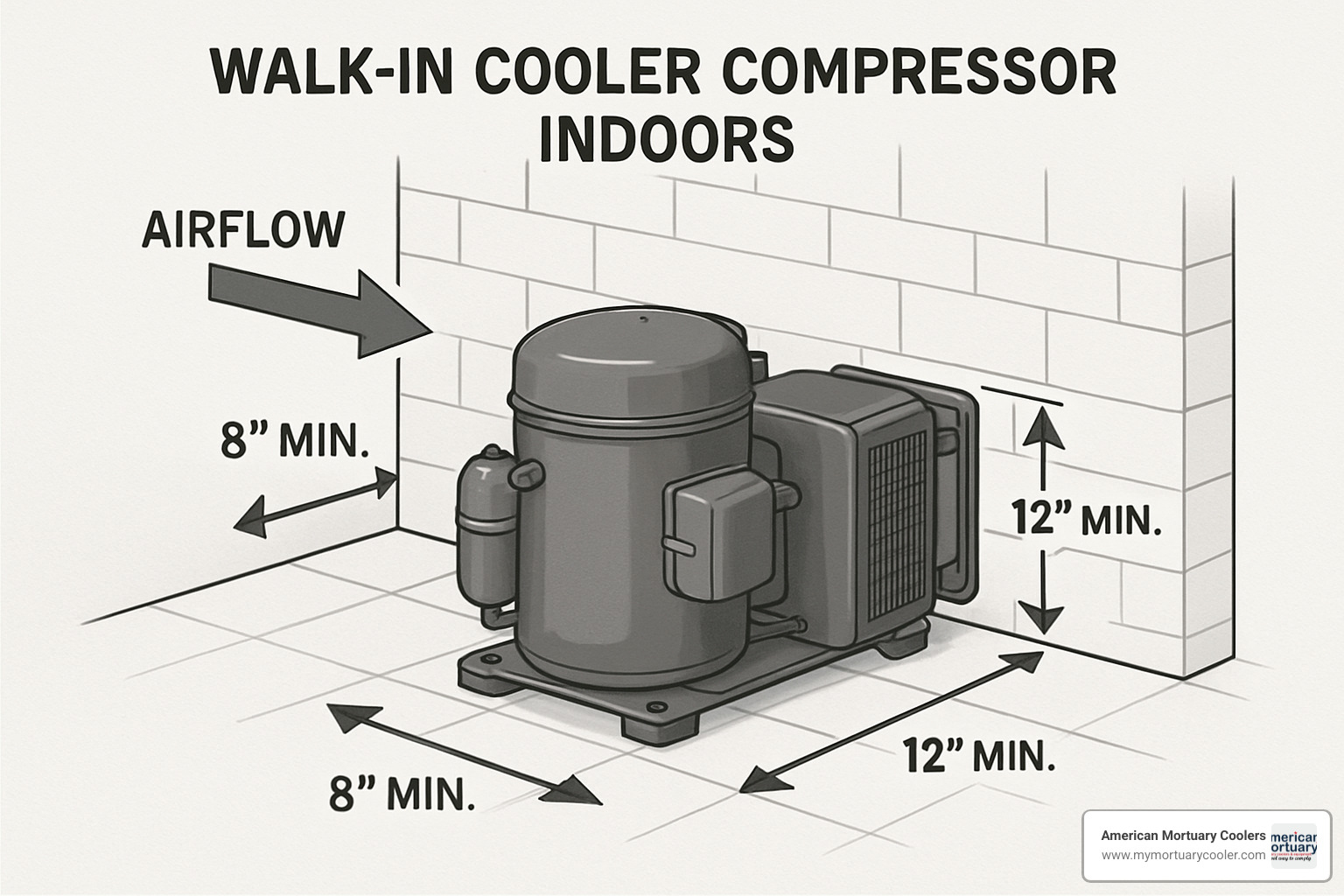

When installing your compressor, ensure at least 24 inches of clearance around the condensing unit for proper airflow. Position it away from other heat sources to prevent it from working harder than necessary.

Size refrigerant lines according to manufacturer specs and avoid unnecessary bends or excessive lengths. Properly insulate suction lines to prevent condensation issues.

Your walk in cooler compressor deserves its own dedicated circuit with appropriate overcurrent protection. Always verify the voltage and phase at the terminals matches what your compressor expects.

For system charging, evacuate the system to at least 500 microns before charging with the correct refrigerant type and amount. After charging, check superheat and subcooling values.

For mortuary coolers, set defrost cycles four times daily for about 24 minutes each. Temperature controls should be configured for optimal operation—usually around 35°F for coolers.

Preventing Compressor Strain

The secret to a long-lived walk in cooler compressor is regular maintenance. Monthly condenser coil cleaning is essential. Dirty coils are perhaps the number one killer of compressors – when coils get clogged, your compressor works harder, runs hotter, and dies younger.

Don't ignore fan blades either. Clean, balanced blades running at the correct speed are essential for proper heat rejection.

Door gaskets and closers might seem unrelated to your compressor, but they're crucial allies. Every time warm air enters your cooler, your compressor works harder. Check gaskets monthly and install automatic closers on frequently used doors. For busy areas, vinyl strip curtains pay for themselves in energy savings and reduced compressor strain.

Keep evaporator coils clean and frost-free, with clear drain lines. Maintain at least 5 feet of clearance in front of evaporator fans to ensure proper air circulation.

Address humidity control and water leaks promptly, as excessive moisture can significantly impact compressor lifespan.

When to Call a Professional for Walk In Cooler Compressor Service

While DIY maintenance is appropriate in some cases, call professionals when:

- Your compressor won't start, trips breakers, or produces burning smells

- You suspect refrigerant problems (insufficient cooling despite the compressor running, ice buildup, visible oil spots)

- The compressor makes unusual noises like grinding, knocking, or squealing

- You notice excessive vibration or overheating

- Your cooler can't maintain proper temperature or the compressor is short-cycling

When selecting a service provider, look for EPA certification for refrigerant handling and NATE certification or equivalent experience. Verify they have specific experience with commercial refrigeration, particularly walk-in coolers.

More info about refrigeration units

Frequently Asked Questions about Walk In Cooler Compressors

What causes a walk in cooler compressor to overheat?

When your walk in cooler compressor runs hot, it's potentially a costly emergency. Common causes include:

- Low refrigerant charge: When your system doesn't have enough refrigerant, your compressor works overtime.

- Dirty condenser coils: Dust on a condenser traps heat instead of releasing it.

- Poor ventilation: Your unit needs at least 24 inches of clearance on all sides for proper airflow.

- Electrical problems: Voltage issues can make motors work harder than designed.

- Defective fan motors: These prevent proper heat removal.

- High head pressure from various system issues.

- Faulty start components that stress the system during startup.

An overheating compressor typically increases energy costs by about 20%, potentially adding $1,440 annually to utility bills. It also dramatically shortens equipment lifespan, potentially leading to a premature $3,000 replacement.

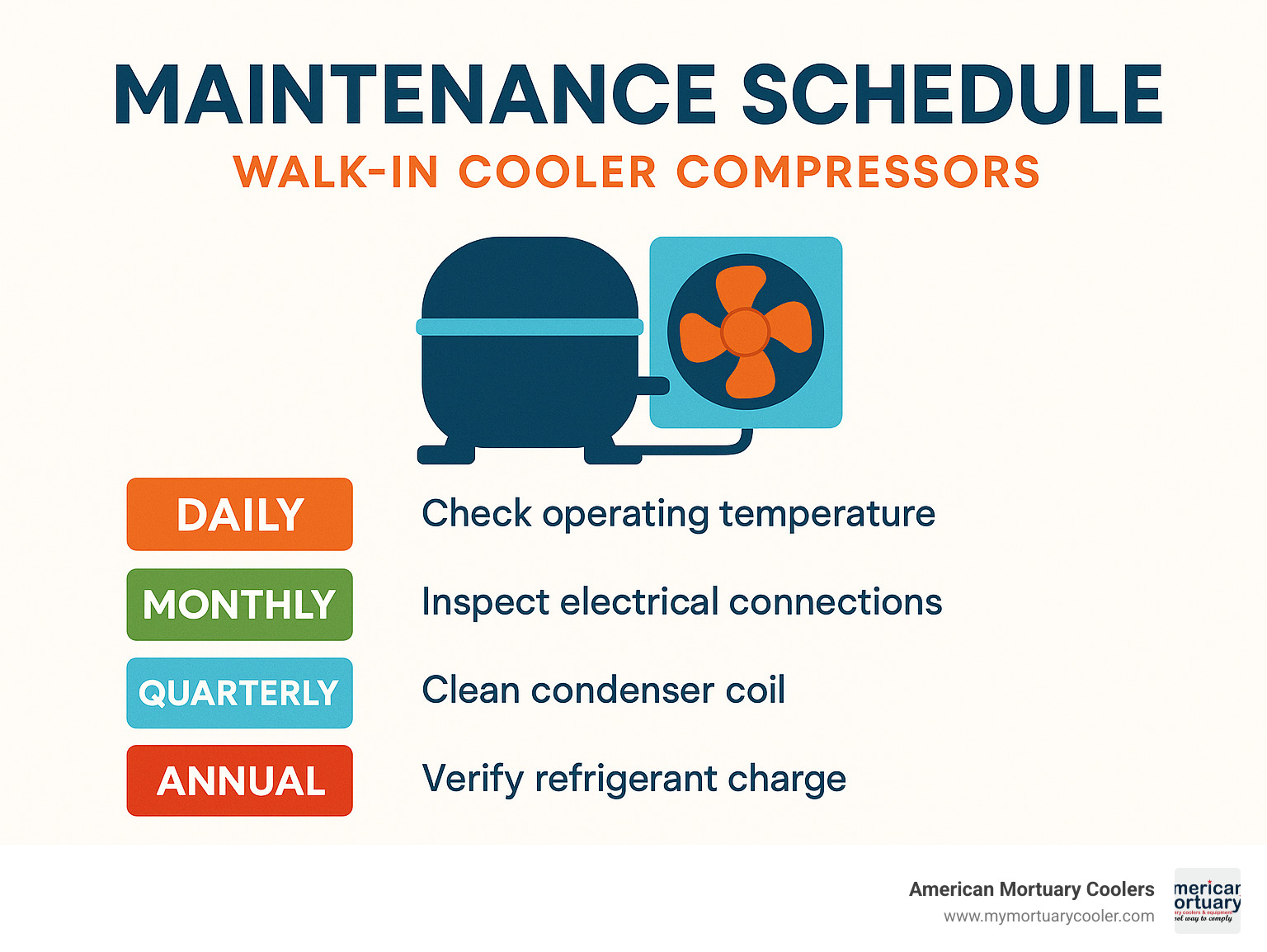

How often should a walk in cooler compressor be serviced?

Maintaining your walk in cooler compressor requires consistent attention:

- Monthly maintenance: Visual inspection, condenser coil cleaning, checking for unusual noises/vibrations, verifying temperature settings, and checking door gaskets/seals.

- Quarterly maintenance: Verifying refrigerant levels/pressures, inspecting electrical connections, cleaning evaporator coils, checking defrost cycle operation, and testing safety controls.

- Annual professional service: Complete performance evaluation, electrical inspection, leak detection, oil assessment, control system calibration, and vibration analysis.

For mortuary clients, where temperature stability directly impacts dignified care, at least one annual professional inspection is strongly recommended.

When should I replace instead of repair my compressor?

Consider these factors when deciding whether to repair or replace a failing walk in cooler compressor:

- Age: For compressors over 10 years old, replacement is typically more economical.

- Patterns of failure: Multiple repairs within a short timeframe indicate underlying issues.

- Component failure: When motor windings or internal mechanical damage occurs, replacement is usually necessary.

- Outdated refrigerants: Systems using phased-out refrigerants often make more sense to replace.

- Energy costs: A sudden spike often indicates your compressor is struggling.

- Cost comparison: If repair estimates exceed 50% of replacement cost, replacement is typically wiser.

A new compressor installation typically runs $2,200-$3,000 for medium-sized walk-ins. For mortuary applications, a more conservative approach is recommended, as temperature stability is about providing dignified care.

More info about refrigeration units

Conclusion

The walk in cooler compressor truly is the heart of your refrigeration system. Like the human heart pumping life-sustaining blood, your compressor circulates refrigerant that keeps your walk-in at the proper temperature.

Let's recap what we've learned:

Choosing the right compressor type and size matters enormously. Scroll compressors are popular in funeral homes due to their quiet operation and reliability—exactly what you need when maintaining a respectful environment.

Implementing a regular maintenance schedule is crucial. Monthly condenser coil cleanings might seem tedious, but they can add years to your compressor's life and save thousands in emergency repairs.

Address problems early. That unusual noise or slight temperature fluctuation is your system trying to tell you something. Early intervention can prevent major failures.

Today's refrigeration technology offers exciting advancements in environmental and efficiency factors. Modern refrigerants and energy-efficient designs not only reduce utility bills but also ensure compliance with evolving regulations.

Knowing when to repair and when to replace is essential. Sometimes, continuing to repair an aging unit is like putting premium gas in an old car with a failing transmission—you're investing in something that can't deliver the performance you need.

At American Mortuary Coolers, we understand that refrigeration isn't just about keeping things cold—it's about maintaining dignity in preservation. Our custom solutions are designed specifically for funeral homes across all 48 contiguous states, with particular expertise in Tennessee, Georgia, and our other service regions.

We take pride in crafting durable, custom walk-in coolers that maintain precise temperatures consistently. When you work with us, you're gaining a partner who understands the unique challenges of mortuary operations and the importance of uninterrupted service.

For more information about our custom mortuary coolers or to discuss your specific refrigeration needs, please reach out to our team. We're committed to providing the expertise and support you need to make informed decisions about your walk in cooler compressor and overall refrigeration system.