Understanding Walk-In Cooler Quotes: What You Need to Know

If you're searching for a walk in cooler quote, here's what you need to know:

- Average Cost: $15,000 (ranging from $8,000-$40,000 depending on size and features)

- Timeline: 1-6 weeks for quick-ship models, 10-12 weeks for custom units

- Required Information: Size dimensions, indoor/outdoor location, refrigeration type, door configuration

- Key Cost Factors: Size, insulation type, finish material, floor inclusion, refrigeration unit (30-40% of total cost)

- Getting a Quote: Call directly, submit online form, or email specifications

A walk in cooler quote is much like pricing a home in a new development—the final cost depends on size, finishes, features, and customization options. Whether you're running a restaurant, convenience store, or funeral home, understanding the quoting process is essential for making an informed purchasing decision.

Walk-in coolers represent a significant investment for any business that needs to store perishable items at controlled temperatures. Getting an accurate quote requires gathering specific information about your space constraints, usage patterns, and technical requirements.

Most suppliers offer both standard "quick-ship" models (available in 1-6 weeks) and fully customized units (typically requiring 10-12 weeks for delivery). The price difference between these options can be substantial, with standard units ranging from $8,000-$30,000 and custom configurations from $10,000-$40,000.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral directors secure accurate walk in cooler quotes that meet their specific needs and budget constraints. My team specializes in guiding customers through the quoting process to ensure the final installation perfectly matches their requirements.

Must-know walk in cooler quote terms:

Walk-In Cooler Fundamentals: Sizes, Users, Certifications

Before you start hunting for a walk in cooler quote, let's get comfortable with the basics. Think of a walk-in cooler as a refrigerated room built from insulated panels that create the walls, ceiling, and sometimes the floor. Add in doors, a refrigeration system, and a few accessories, and you've got yourself a complete unit.

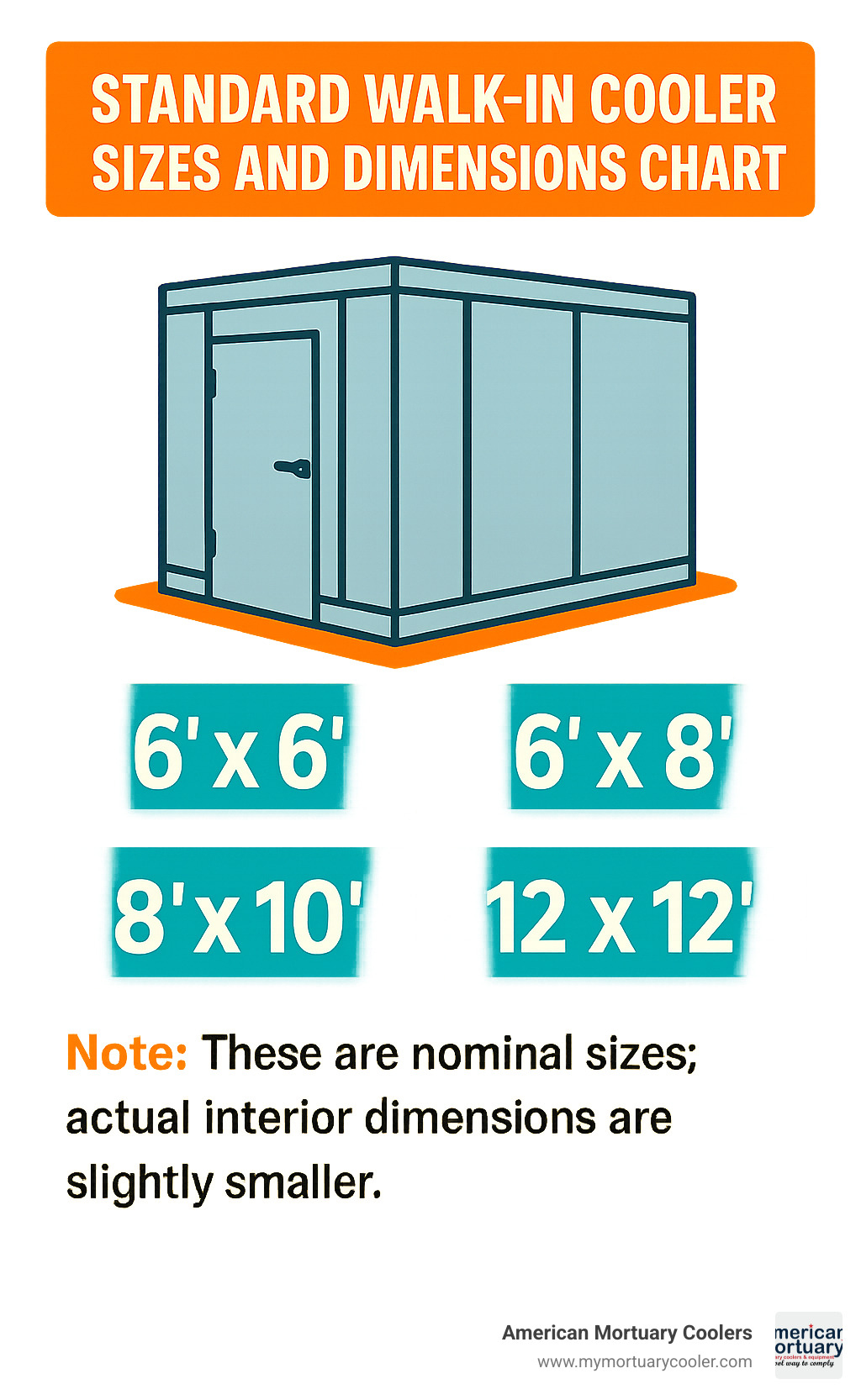

Most folks start with standard sizes, which typically range from cozy 6'×6' units to spacious 12'×12' models. The 8'×10' size is particularly popular – it's the Goldilocks option for many businesses. Just remember that these are nominal dimensions, meaning the actual interior space will be a bit smaller once you account for those thick insulation panels. For example, if you order an 8'×8'×8' cooler, your actual usable space inside might be closer to 7'6"×7'6"×7'6".

When you receive your walk in cooler quote, you'll see several key components broken down:

- Panel System: These are typically 4" thick with insulation values of R-29 for coolers and R-32 for freezers

- Door Package: Usually includes a 34"×76" or 36"×78" door with self-closing hinges and safety releases (so nobody gets trapped inside!)

- Floor: This is optional and adds about 10-20% to your total cost. Some installations can use existing concrete floors instead.

- Refrigeration System: This is the heart of your cooler and represents 30-40% of the total cost. It's sized based on how you'll use the cooler and what temperature you need.

- Accessories: These are the finishing touches – strip curtains to keep cold air in when the door opens, thermometers, shelving, ramps, and lighting.

Common Applications and Industry Needs

Here at American Mortuary Coolers, we work with many industries beyond funeral homes. Each business has unique needs that affect their walk in cooler quote:

Restaurants and food service operations need floors that can handle heavy carts rolling in and out all day. They also need to meet NSF certification for food safety – no compromises there!

Convenience stores often want those attractive glass display doors so customers can see products without opening the cooler. They typically prefer self-contained refrigeration systems because they're easier to install.

Our brewery clients need extra-strong floors to support heavy kegs and often request wider door openings to move those kegs in and out easily.

Floral shops are all about precise humidity control and gentle cooling – flowers are delicate, after all. Many request glass display doors to showcase their beautiful arrangements.

For our laboratory and medical facility clients, precision is everything. They need exact temperature control, backup systems in case of power failure, and specialized finishes that are easy to clean and sanitize.

And of course, our core clients – mortuaries and funeral homes – have very specific needs. They require dimensions that accommodate respectful body storage, completely sanitary surfaces, and whisper-quiet operation.

Our experience with mortuary applications has given us a unique perspective on specialized cooling needs across all industries. Whether you're opening a restaurant in Chicago or a funeral home in Dallas, we understand the subtle requirements that will affect your walk in cooler quote.

Standard vs. Custom Dimensions

When you're ready to request a walk in cooler quote, one of your first big decisions will be whether to go with standard sizes or custom dimensions.

Standard quick-ship sizes include 6'×6'×8' (perfect for tight spaces), 8'×8'×8' (great starter size for small businesses), 8'×10'×8' (our most popular middle-ground option), 10'×10'×8' (ideal for larger storage needs), 10'×12'×8' (for high-volume operations), and 12'×12'×8' (suited for large commercial needs).

Going with a standard size has two big advantages: they're more affordable and they arrive much faster. Many manufacturers keep these sizes in stock, ready to ship.

Custom dimensions let you maximize your available space but typically add 20-30% to your walk in cooler quote and can significantly extend delivery times. If you're considering custom dimensions, keep these factors in mind:

The standard ceiling height is 8'3" on the exterior, which gives you about 7'6" of clearance inside – enough for most people to walk comfortably without ducking.

Door placement isn't just about convenience – it affects how efficiently you can use the interior space and how smoothly your team can work.

Many manufacturers build panels in specific increments – often 1' or 2' – so your custom dimensions may need to work within these constraints.

Don't forget to plan for space around your cooler – you'll need clearance for the condensing unit, door swing, and regular maintenance access.

For our mortuary clients, we often recommend custom dimensions to create the most respectful and efficient environment. For many commercial applications, though, standard sizes offer excellent value and faster delivery.

Certifications & Regulatory Must-Haves

A trustworthy walk in cooler quote should always include information about certifications and compliance. These aren't just bureaucratic hoops – they ensure your cooler is safe, efficient, and legal.

The Department of Energy (DOE) has set efficiency standards since the Energy Independence and Security Act of 2007. Today's walk-in coolers must meet minimum insulation values: R-29 for coolers and R-32 for freezers. These standards aren't just good for the planet – they're good for your utility bills too.

If you're in food service, look for NSF/ANSI Standard #7 certification. This ensures all surfaces are cleanable and safe for food storage environments. Your health inspector will definitely check for this!

UL listings from Underwriters Laboratory certify that electrical components and panel systems meet fire safety standards – critical for insurance purposes and local code compliance.

Quality panels should meet ASTM E84 and C-518 standards for flame spread and smoke development. Look for ratings like 5/190 and 15/250 in your documentation.

Some locations have additional requirements. For example, if you're installing an outdoor unit in Miami-Dade County, Florida, you'll need certification for 170 mph wind resistance. Hurricane zones don't mess around!

According to our research, properly certified units not only keep you compliant but save serious money over time. A detailed operating cost analysis shows that DOE-compliant coolers can save thousands in energy costs compared to older, less efficient models.

Want to learn more about how these factors affect pricing? Check out our guide to Walk-In Cooler Pricing 101: Compare Walk-In Cooler Prices for a deeper dive into how these specifications influence your bottom line.

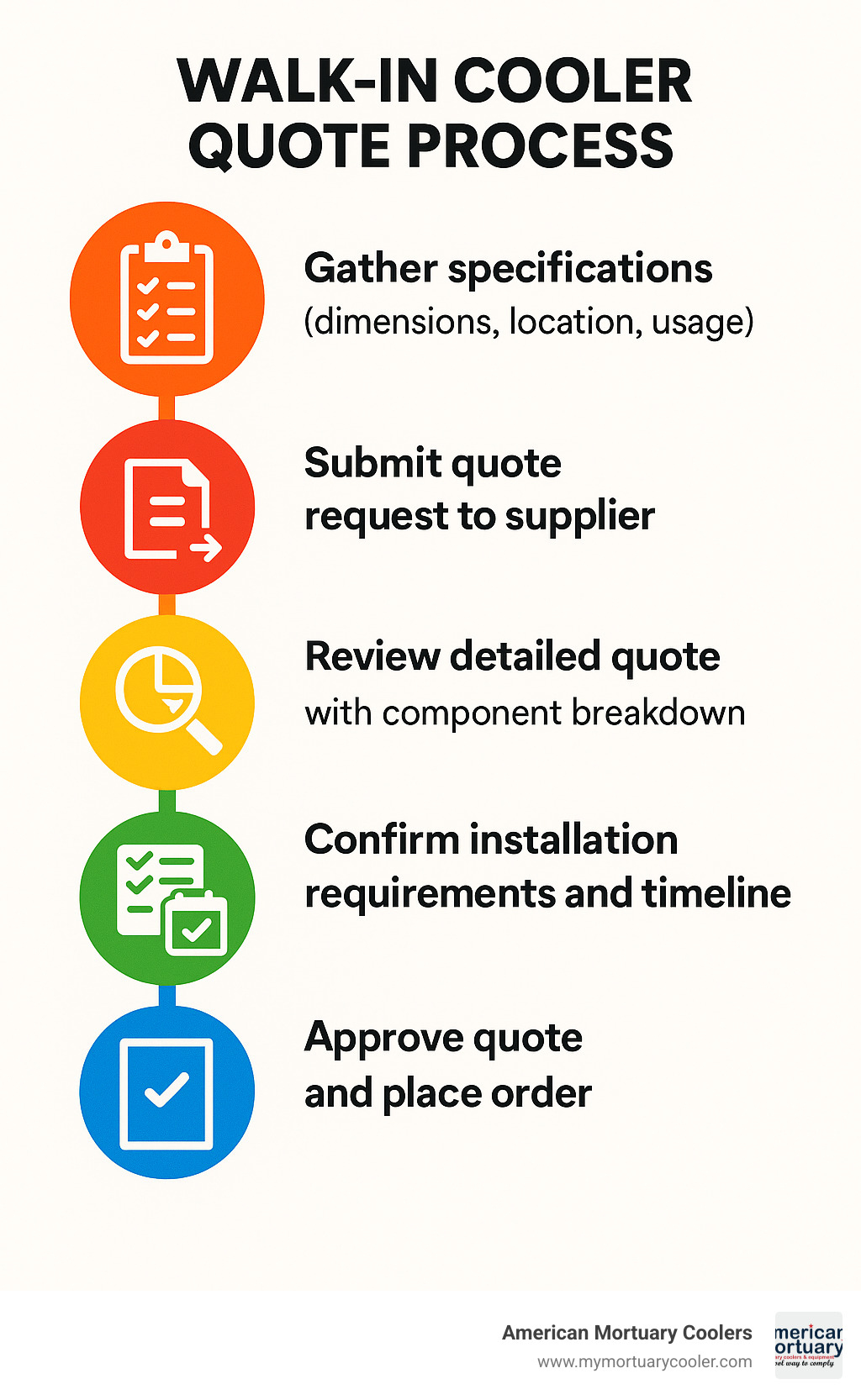

Getting an Accurate Walk-In Cooler Quote: Step-by-Step

Let's face it – getting a precise walk in cooler quote shouldn't feel like solving a puzzle. After helping countless businesses from coast to coast find their perfect cooling solution, I've developed a straightforward approach that takes the guesswork out of the process.

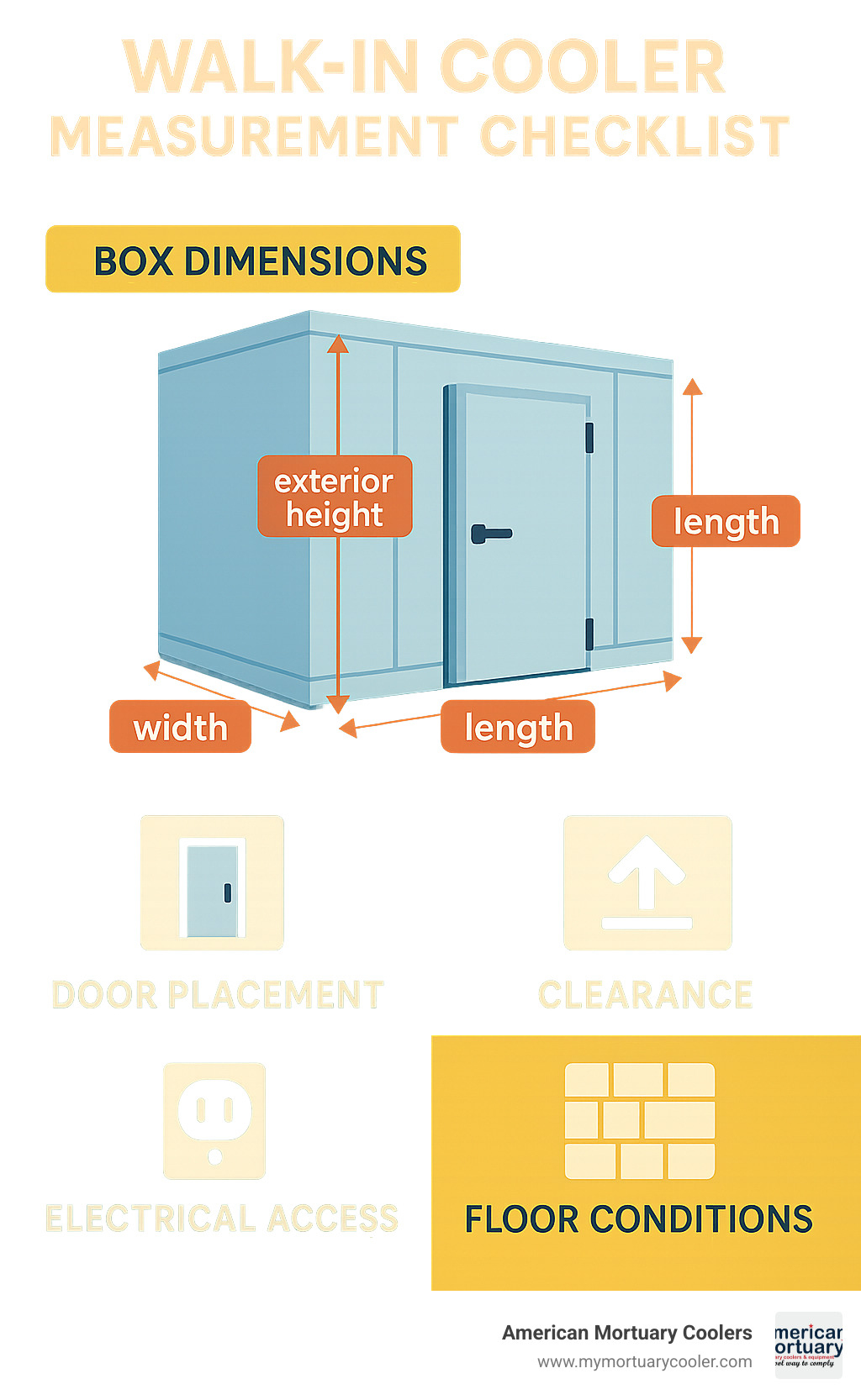

Start by nailing down your fundamental needs. What size cooler do you need? Are you looking for refrigeration temperatures or freezer-level cold? Will it live indoors or brave the elements outside? Do you need a floor, or will you use an existing concrete slab? These basics form the foundation of any accurate quote.

Next, take a good look at your installation site. Measure the available space carefully – and I mean carefully! I've seen too many projects hit snags because someone rounded up or down an inch or two. Note your door access measurements (nothing worse than a cooler that won't fit through the delivery entrance), check your electrical service specs, and if you're skipping the insulated floor, evaluate your existing floor condition.

Your usage patterns matter tremendously when sizing refrigeration. What are you storing? How warm is it when it arrives? How cold does it need to stay? And be honest about those door openings – we all tend to underestimate how often we'll pop in and out of the cooler during busy periods.

Once you've covered the essentials, it's time to think about the extras that make your cooler work for your specific needs. Door type and placement, interior fixtures like shelving or hooks, monitoring systems, and any backup requirements all influence both functionality and final price.

With all this information gathered, you're ready to submit your request. Most manufacturers (including us at American Mortuary Coolers) offer dedicated quote forms that guide you through providing all necessary details. Our form specifically asks about metal finishes, insulation types, door configurations, and refrigeration specifications to ensure your walk in cooler quote covers everything you need.

Information You Must Gather Before Requesting a Walk In Cooler Quote

When clients call me for a walk in cooler quote, I always walk them through a thorough pre-planning checklist. Whether you're a mortuary in Miami or a restaurant in Reno, these details make all the difference.

First, know your dimensions. Exact length, width, and height requirements are non-negotiable for an accurate quote. If you're flexible, mention if a standard size might work – it could save you money and delivery time.

Your installation location dramatically affects design requirements. Indoor units need proper ventilation and consideration of ambient conditions, while outdoor installations require weather protection, security features, and proper drainage planning. A cooler facing the Texas sun needs different considerations than one in Minnesota's winter.

Be specific about what you'll store. The type of products, their maximum weight, incoming temperature, and required holding temperature all influence refrigeration sizing. A cooler full of pre-chilled beverages needs less cooling power than one loaded with hot food items needing rapid temperature reduction.

Electrical specifications matter enormously. Know your available voltage (typically 115V or 208-230V), whether you have single or three-phase power, and the distance from your electrical panel to the cooler location. This seemingly mundane detail can save you from costly electrical upgrades later.

For insulation, standard 4" urethane (R-29 for coolers, R-32 for freezers) works for most applications, but specialized needs might require different solutions. Panel finish preferences – from standard galvalume to premium stainless steel – affect both appearance and durability.

Door configuration deserves careful thought. Beyond the standard 34"×76" size, consider whether you need hinged doors, sliding doors, or glass display doors. Their placement on the unit affects workflow and efficiency. Additional features like kickplates, windows, or strip curtains improve functionality but impact your bottom line.

Floor requirements can't be overlooked. Will you need an insulated floor, or are you using an existing slab? What's your floor load capacity requirement? Do you need ramps for cart access? These decisions affect both price and performance.

For refrigeration, decide between self-contained or remote systems, note any brand preferences, and consider special controls like winter packages or alarm systems.

Don't forget accessories that make daily operation smoother – shelving systems, lighting packages, monitoring systems, and digital thermometers.

Finally, be clear about your timeline. When do you need the cooler operational? Are there scheduling constraints for delivery and installation? Rush orders are possible but often come at a premium.

Common Mistakes People Make With a Walk In Cooler Quote

After helping businesses from New York to Los Angeles with their cooling needs, I've seen the same pitfalls trip up buyers time and again. Avoiding these common mistakes will save you headaches and unexpected costs.

Underestimating door usage is perhaps the most frequent oversight. I remember a deli owner who insisted his staff would access the cooler "just a few times a day." After installation, we finded they were opening that door 75+ times during lunch rush alone! Be realistic about frequency – each opening introduces warm air that your system must remove.

Many buyers forget about freight costs until the final bill arrives. Shipping can add 5-15% to your total, especially for delivery to remote locations or sites requiring specialized handling. Always confirm if shipping is included in your walk in cooler quote or will be added later.

Permit requirements catch many buyers off guard. Local building codes may demand permits and inspections, adding time and expense to your project. Some jurisdictions have specific requirements for refrigeration systems, electrical connections, or floor drains. Check with your local authorities before finalizing your purchase.

I once visited a client whose new floor was cracking under the weight of their loaded shelving units. They'd overlooked proper floor load analysis. Standard floors support about 600 pounds per square foot when evenly distributed, but point loads from wheels can be dramatically higher. A seemingly modest 200-pound cart can create point loads up to 7,200 pounds per square foot!

Condensate drainage seems minor until you're mopping up water or dealing with health code violations. Every cooler produces condensate that must go somewhere – planning this drainage from the start prevents headaches later.

Many installations are compromised by insufficient clearance for refrigeration. Those remote condensing units need adequate airflow and service access. I recommend at least 36 inches of clearance for maintenance and proper operation.

Incomplete electrical information leads to painful surprises. Your walk in cooler quote should specify required electrical service, but verify your available service matches these requirements before ordering. Electrical upgrades can be surprisingly expensive and time-consuming.

Don't make the mistake of assuming all insulation is equal. The difference between published and actual aged R-values can be dramatic. Polyurethane might start at R-32 but can degrade significantly over time, while extruded polystyrene maintains its values better long-term.

Ambient conditions matter more than you might think. An outdoor cooler in humid Florida faces different challenges than one in arid Arizona. Your location affects refrigeration sizing, insulation needs, and weather protection requirements.

Finally, I caution against focusing solely on initial price. The lowest walk in cooler quote might lead to higher long-term costs through increased energy consumption, maintenance issues, or shorter equipment life. Consider the total cost of ownership, not just the purchase price.

Price Drivers, Suppliers, Financing & Warranty

When you're looking at a walk in cooler quote, understanding what drives the price helps you make smarter decisions about where to invest your money. Think of it like buying a car – knowing which features matter most helps you get the best value.

Size matters, of course. Larger units cost more upfront, but there's good news – the price per cubic foot actually drops as the cooler gets bigger. It's like buying in bulk at the grocery store!

The panel system is a major part of your investment. Standard panels are 4" thick with R-29/R-32 insulation values, but you can upgrade to 5" or 6" panels for better efficiency. Material choices make a big difference too – galvalume is the standard finish, but upgrading to stainless steel adds 30-40% to your panel costs. Worth it? Often yes, especially in environments where cleanliness is critical.

Your refrigeration system typically accounts for 30-40% of the total cost. Self-contained systems are more budget-friendly upfront but might cost more to operate over time. Remote systems cost more initially but offer better efficiency and usually last longer. It's the classic "pay now or pay later" scenario.

Doors are another area where choices impact your bottom line. Standard hinged doors are the most economical option, while glass display doors add 15-25% to door costs. They look great for retail applications but remember they'll increase your energy consumption too.

Many buyers don't realize they can save 10-20% by choosing a floorless installation – assuming your existing floor is suitable. On the flip side, if you need a reinforced floor for heavy loads, expect to add 5-15% to your floor costs.

Location matters too. Outdoor installations add 10-15% for weather protection, and if you're in a coastal region needing hurricane ratings, that jumps to 15-25% more.

One of the biggest decisions is whether to go with a quick-ship model or custom unit. Here's how they compare:

| Feature | Quick-Ship | Custom | Used |

|---|---|---|---|

| Cost Range | $8,000-$30,000 | $10,000-$40,000 | $5,000-$20,000 |

| Lead Time | 1-6 weeks | 10-12 weeks | Immediate-2 weeks |

| Customization | Limited | Extensive | None |

| Warranty | Full (10-20 years panels) | Full (10-20 years panels) | Limited/None |

| Energy Efficiency | Current standards | Current standards | Varies/Older standards |

| Financing Options | Available | Available | Limited |

Here at American Mortuary Coolers, we understand that a walk-in cooler is a significant investment. That's why we offer several financing and leasing options to make it more manageable:

- Equipment financing with fixed monthly payments that might offer tax benefits

- Operating leases with lower monthly payments and end-of-term options

- 100% financing packages that cover everything from the unit itself to installation and accessories

Our warranty coverage is designed to give you peace of mind, typically including a 20-year limited warranty on panels, 5-year warranty on doors and compressors, 1-year warranty on parts, and optional extended labor warranties up to 3 years.

How Insulation, Finish & Door Impact Cost

The choices you make about insulation, finish, and doors affect both your initial walk in cooler quote and what you'll spend operating the unit over its lifetime.

Insulation comes in two main flavors. Foamed-in-place urethane offers a higher initial R-value (R-32) and costs 5-10% more than extruded polystyrene. It's excellent for freezer applications but may degrade faster in humid environments. Extruded polystyrene (EPS) maintains a more stable R-value over time and handles moisture better, making it a good standard choice for many cooler applications.

Here's something many suppliers won't tell you: after five years, urethane might drop to just R-8 while extruded polystyrene stays closer to R-24. That difference significantly impacts your operating costs and might offset the higher initial investment in EPS.

When it comes to finishes, galvalume (embossed) is the standard, economical option with good corrosion resistance. It works well for most applications. Stainless steel adds 30-40% to panel costs but offers superior sanitation and durability – it's required in some health-regulated environments and is our standard for mortuary applications. Aluminum sits in the middle price-wise and works well in high-humidity environments.

Door options greatly impact both cost and functionality. Standard hinged doors (typically 34"×76" or 36"×78") are the most economical and come with self-closing cam-lift hinges. Glass display doors add 15-25% to door costs and increase energy consumption by 5-15%, but they're essential for retail applications where product visibility matters. Sliding doors cost more upfront but save valuable space in tight areas, though they may need more maintenance over time.

Don't forget door accessories – strip curtains can reduce energy loss by up to 25%, kick plates extend door life in high-traffic areas, and view windows add convenience but slightly reduce efficiency.

For our mortuary clients, we typically recommend stainless steel interiors for sanitation and durability, paired with standard hinged doors for reliability. Restaurant and retail clients often benefit from glass display doors despite the higher energy costs – the improved product visibility usually justifies the expense.

Choosing the Right Refrigeration System

Your refrigeration system typically accounts for 30-40% of your total walk in cooler quote, making it one of the most important components to understand.

Remote systems place the condensing unit away from the evaporator, resulting in less noise and heat near the cooler area. They offer better efficiency and longer life but come with higher initial costs and more complex installation. They're ideal for larger installations and environments where noise or heat could be problematic.

Self-contained systems package all components together, making installation easier and initial costs lower. The trade-offs are higher noise and heat output near the cooler and typically lower long-term efficiency. They're perfect for smaller installations with space constraints.

Getting the sizing right is crucial. A properly sized system should run approximately 16-18 hours per day (about 80% of the time). Undersized systems can't maintain proper temperatures, while oversized systems cycle too frequently, reducing efficiency and component life. Proper sizing depends on box dimensions, insulation values, product load, turnover rate, ambient temperature, door opening frequency, and desired pull-down time.

When reviewing your walk in cooler quote, pay attention to these key refrigeration components:

- The evaporator (or "air handler") located inside the cooler that removes heat from the space

- The condensing unit located remotely that releases heat outside

- The expansion valve that controls refrigerant flow

- Controls and safeties that maintain proper operation and protect the system

Consider optional features that might be worth the extra investment: winter controls (essential for outdoor units in colder climates, adding 5-10% to refrigeration costs), electronic controllers for precise temperature control, proper defrost systems (critical for freezers), and eco-friendly refrigerants that meet current regulations.

For more details about refrigeration options, check out our guide on everything you need to know about walk-in refrigeration units.

At American Mortuary Coolers, we help clients across all regions—from the Southeast to the Pacific—select the right refrigeration system based on their specific needs and local climate conditions.

Comparing Suppliers & Lead Times

The supplier you choose for your walk in cooler quote significantly impacts both product quality and your overall experience.

Quality manufacturers use rigorous quality assurance processes. Look for suppliers that pre-assemble units at the factory before shipping, conduct third-party inspections, and offer quality certification. Some even provide live webcam viewing of assembly. At American Mortuary Coolers, we partner with manufacturers that test-assemble every unit before shipping, ensuring your installation goes smoothly.

Lead times vary significantly by product type. Quick-ship standard units (sizes from 6×6 to 10×10 with standard options) typically take 1-6 weeks from order to delivery. Custom units with specialized dimensions, finishes, or complex refrigeration requirements usually need 10-12 weeks. Used equipment might be available immediately or within 2 weeks, but selection is limited and warranty coverage minimal or nonexistent.

Warranty coverage is another area where suppliers differ. Industry-standard warranties typically include 10-20 years limited coverage on panels, 5 years on doors and compressors, and 1 year on parts and refrigeration labor. Premium suppliers might offer extended labor warranties up to 3 years, performance guarantees, or energy consumption warranties.

The service network is something many buyers overlook until they need help. National coverage ensures support regardless of location, local partners provide faster response for urgent issues, and factory-trained technicians ensure proper maintenance and repair. With service locations across the United States—including Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA—we provide responsive support throughout the contiguous 48 states.

When comparing walk in cooler quotes, evaluate customer support by noting responsiveness during the quote process, technical knowledge and assistance, availability of design consultation, and post-sale support reputation. Our clients consistently rate our customer support as "best," citing our technical expertise and ongoing assistance years after installation.

Frequently Asked Questions about Walk-In Cooler Quotes

How long does it take to receive my cooler after I approve the quote?

Once you've given the green light on your walk in cooler quote, the countdown to delivery begins—but how long will you actually wait? The timeline varies based on what you've ordered:

For standard quick-ship units, you'll typically see delivery within 1-6 weeks. If you've chosen a custom configuration (which many of our funeral home clients prefer for their specific needs), plan for 10-12 weeks from approval to delivery. For highly specialized applications with unique requirements, the timeline might stretch to 12-16 weeks.

Your cooler's journey to you follows a predictable path. First comes order processing and engineering review, which typically takes 3-5 business days as our team ensures everything is properly specified. Then the manufacturing and quality testing phase begins—this is where the real time variable comes in, depending on whether you've chosen standard or custom options.

Before shipping, we spend 2-3 days on careful preparation and logistics coordination. Finally, transit time varies by your location, but typically ranges from 1-7 days within the continental US.

Here at American Mortuary Coolers, we don't leave you wondering. We provide detailed timeline estimates with every quote, and when time is of the essence, we'll work with you to explore expedited options for urgent projects.

What warranty coverage should I expect on panels and refrigeration?

A solid walk in cooler quote should leave no mystery about warranty coverage. You're making a significant investment, and you deserve to know exactly how it's protected.

Industry-standard coverage typically includes a 10-20 year limited warranty on panels (covering materials and workmanship), a 5-year warranty on door components, and a 5-year warranty on compressors from the date of installation. Most companies also offer a 1-year warranty on miscellaneous parts and components, plus a 1-year warranty on refrigeration labor.

At American Mortuary Coolers, we believe in going beyond the basics. We offer improved warranty options including extended labor coverage for up to 3 years, comprehensive maintenance packages to keep your system running smoothly, and emergency service agreements for peace of mind.

When you're reviewing your walk in cooler quote, take a moment to verify that all warranty terms are clearly stated. Also, make sure you understand any maintenance requirements that might affect your coverage—like regular filter changes or annual inspections. A few minutes of attention now can save significant headaches down the road.

Are financing or leasing programs available for my project?

Yes! We understand that a walk-in cooler represents a substantial investment for your business, whether you're running a funeral home in Tennessee or a mortuary in California. That's why most reputable suppliers, including American Mortuary Coolers, offer several financing paths to help make your purchase more manageable.

Equipment financing provides fixed monthly payments, typically over 2-7 year terms. Many of our clients appreciate the predictability this option offers for budgeting, along with potential tax benefits (though we always recommend consulting your tax advisor about your specific situation). This option often includes installation costs, giving you a complete solution with one payment.

If you prefer lower monthly payments and the flexibility to upgrade at the end of your term, operating leases might be your best bet. These can sometimes offer off-balance-sheet treatment and occasionally include maintenance as part of the package.

For businesses looking to preserve working capital and credit lines, 100% financing options require no down payment and cover everything—equipment, installation, and accessories.

When you request a walk in cooler quote from American Mortuary Coolers, we'll review financing options custom to your business needs. We've helped funeral directors and mortuary owners across all our service regions find the most advantageous approach for their specific situations.

The financing process is straightforward, typically requiring business financial statements, tax returns, bank statements, and some basic business history information. For qualified businesses, we can often secure approval within 24-48 hours, allowing your project to move forward without unnecessary delays.

Financing isn't just about affording the equipment—it's about making a smart business decision that preserves your capital for other needs while still getting the quality cooler your operation requires.

Conclusion

Securing an accurate walk in cooler quote is more than just a price check—it's a crucial step in making sure your refrigeration investment truly meets your needs while respecting your budget constraints. Throughout this guide, we've walked through the many factors that influence both the cost and performance of your walk-in cooler.

From the size of your unit to the type of insulation, from door configurations to refrigeration systems, each choice affects not just what you'll pay now, but how your cooler will perform for years to come. Whether you're deciding between indoor or outdoor installation, weighing quick-ship versus custom options, or comparing warranty coverage, these decisions matter.

Here at American Mortuary Coolers, we've worked with clients across countless industries—restaurants in Chicago needing food storage, mortuaries in Dallas requiring dignified body storage, and floral shops in New York preserving delicate blooms. Our deep experience in the specialized world of mortuary refrigeration has given us unique insights into creating cooling solutions that stand up to even the most demanding environments.

When you choose American Mortuary Coolers for your walk in cooler quote, you're getting several distinct advantages:

First, you'll work with a single dedicated representative who handles your entire project from start to finish—no getting passed around from department to department. Second, we offer direct delivery across all 48 contiguous states, simplifying logistics and reducing potential complications. Third, you'll benefit from our industry-specific expertise that helps us recommend the right solutions for your unique needs. And finally, we provide truly comprehensive support that extends from your initial quote through installation and beyond.

Ready to request your walk in cooler quote? We suggest gathering all the information we've outlined in this guide to ensure you receive the most accurate pricing and specifications. Our friendly team is standing by to help you steer the options and make informed decisions that balance what you pay today with how your system performs tomorrow.

For personalized help with your walk-in cooler project, reach out to our team at any of our regional offices across the United States. We're real people committed to providing clear, detailed quotes and exceptional support throughout your purchasing journey.