Understanding Walk-In Cooler Costs: What You Need to Know

Walk in cooler pricing typically ranges from $5,000 to $40,000 depending on size, features, and installation requirements:

| Walk-In Cooler Type | Price Range | Timeline |

|---|---|---|

| Standard Models | $5,000-$15,000 | 1-6 weeks |

| Quick-Ship Units | $8,000-$30,000 | 1-6 weeks |

| Custom Units | $10,000-$40,000 | 10-12 weeks |

| Installation Costs | $800-$2,500+ | Varies by location |

When looking to invest in refrigeration equipment for your business, understanding walk in cooler pricing is crucial for budgeting and planning. These large, insulated spaces maintain temperatures between 28°F and 55°F and serve as essential equipment for restaurants, breweries, floral shops, medical facilities, and yes—funeral homes.

Unlike residential refrigerators, walk-in coolers represent a significant business investment with multiple cost factors to consider. The price isn't just about the initial purchase—it includes the shell, refrigeration unit, flooring, doors, and ongoing operational expenses.

Many buyers focus solely on the upfront cost, only to be surprised by installation fees, shipping charges, and long-term energy consumption. A strategic approach to walk in cooler pricing requires looking at the complete picture.

I'm Mortuary Cooler, a national-level supplier of mortuary coolers with extensive experience navigating walk in cooler pricing considerations for funeral homes and medical facilities across America. My expertise in US cooler supply has helped countless funeral directors find solutions that balance upfront costs with long-term value.

Simple guide to walk in cooler pricing terms:

2024 Walk In Cooler Pricing Snapshot

The walk-in cooler market has finally found its footing in 2024 after years of roller-coaster supply chain challenges. If you're budgeting for a new unit, you'll want to know that the average walk in cooler pricing now sits around $15,000 – though I've seen plenty sell for much less or considerably more depending on what you need.

Need cooling ASAP? Quick-ship walk-in coolers ($8,000-$30,000) can rescue your business with delivery in just 1-6 weeks. These units strike that sweet spot between "I need it yesterday" and "I want it my way" – making them perfect when time matters but you still need some customization options.

For those who can wait a bit longer, custom walk-in coolers ($10,000-$40,000) give you exactly what you want, down to the inch. The trade-off? You'll typically wait 10-12 weeks while your perfect cooler comes to life.

As one of our specialists at American Mortuary Coolers likes to say, "Shopping for walk-in coolers is a lot like house hunting. You can grab the move-in ready ranch, or you can commission that dream home with the chef's kitchen and three-car garage. Both keep you sheltered, but one is built specifically for your lifestyle."

Timing still matters in 2024. While you can have a standard or quick-ship unit chilling your products within 1-6 weeks, those custom beauties still need 10-12 weeks to come together. And fair warning: during summer rush or in high-demand regions, those timelines can stretch even longer.

Don't forget about delivery costs when calculating your walk in cooler pricing! These fees vary wildly based on distance, cooler size, and whether your delivery location requires special equipment or access. Here at American Mortuary Coolers, we include shipping to all 48 contiguous states in our pricing – no surprise charges when the delivery truck arrives.

Average walk in cooler pricing by size

Size is the heavyweight champion when it comes to influencing costs. Here's what you can expect to pay in today's market:

- 6' x 8' x 8': $7,000 - $16,000

- 8' x 8' x 8': $9,000 - $23,000

- 8' x 10' x 8': $11,000 - $27,000

- 10' x 10' x 8': $14,000 - $33,000

- 10' x 12' x 8': $17,000 - $37,000

These ranges cover basic models with standard features. Quick-ship options typically land somewhere in the middle, while those fully-loaded custom units with all the bells and whistles push toward (or beyond) the upper limits.

To put this in perspective, a standard 6' x 8' Amerikooler might run about $9,500, but add premium finishes, remote refrigeration, and specialized features to that same footprint and you could easily be looking at $16,000+.

Want to dive deeper into features and what they'll cost you? Check out The Complete Guide to Walk-In Cooler Features and Prices.

Regional walk in cooler pricing differences

Your zip code significantly impacts your walk in cooler pricing – sometimes dramatically. Our market research shows some eye-opening price differences for identical units:

A standard 10 sq. ft. unit costs approximately $9,638 in New York City but only $5,880 in Miami. Chicago buyers pay around $8,419, while Los Angeles customers see bills around $7,276.

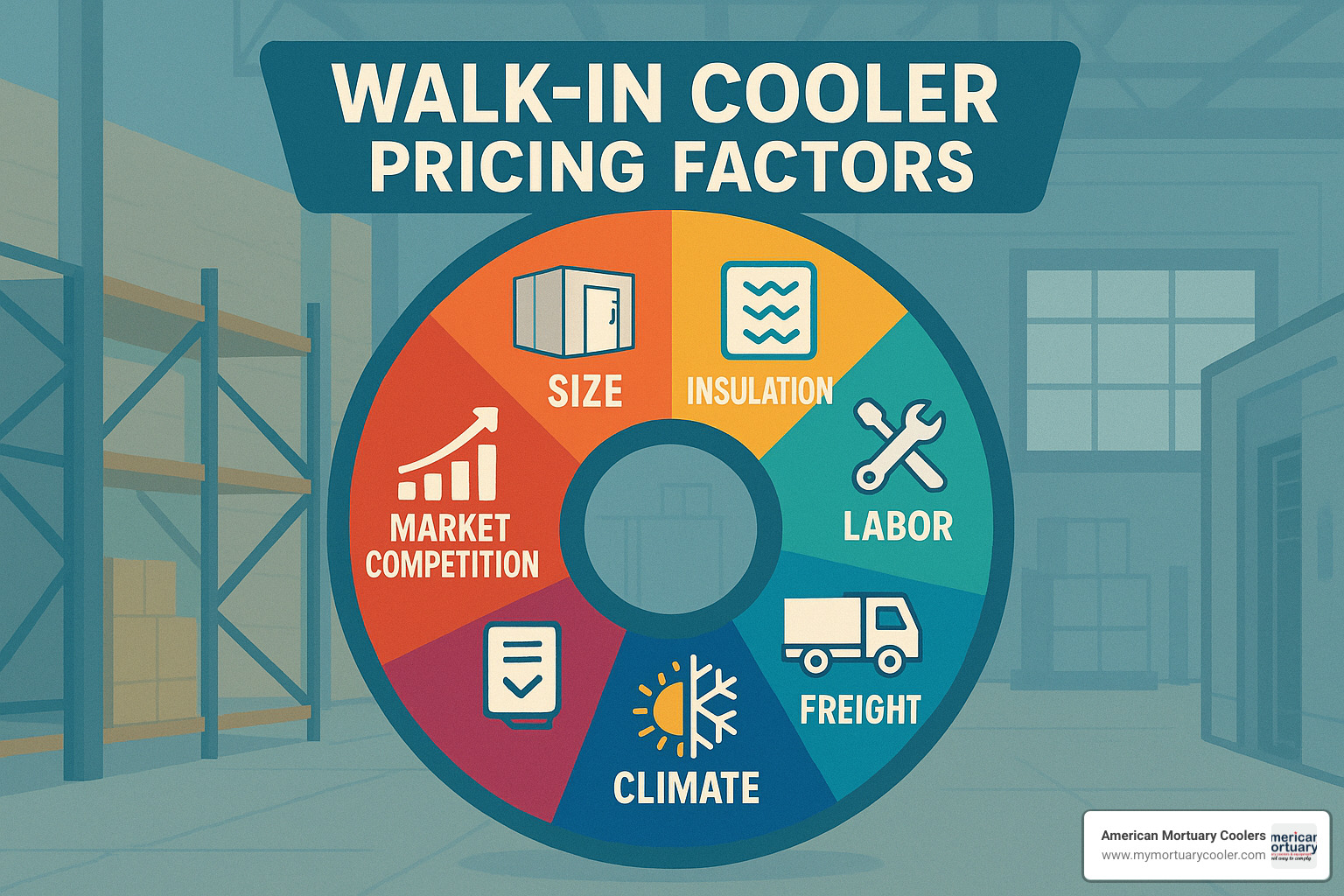

Why such big differences? Several factors come into play:

Labor rates in major metros like NYC can double or triple those in smaller markets. The distance from manufacturing hubs to your location affects shipping costs – that's why coastal and remote locations often pay premium delivery fees. Your local climate matters too; extreme temperatures might require beefier insulation or specialized refrigeration components.

Don't forget about local regulations – some areas have strict energy codes or complex permitting processes that drive up costs. And in regions with fewer suppliers, limited competition can mean higher prices.

To combat these regional differences, we've established distribution points in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA. This network helps us offer more consistent walk in cooler pricing no matter where your business calls home.

Core Factors Influencing Walk-In Cooler Pricing

Understanding what drives walk in cooler pricing helps buyers make informed decisions and avoid unexpected costs. Here are the primary factors that influence the final price tag:

Size and Dimensions

When it comes to walk-in coolers, size matters—and directly impacts your wallet. Square footage is the most obvious price determinant, with larger units requiring more materials and beefier refrigeration systems. You might be surprised to learn that a modest 6' x 8' unit could cost half as much as its 10' x 12' bigger brother, even with similar features. Every additional square foot adds to both the upfront cost and your long-term operating expenses.

Insulation Quality

Think of insulation as your cooler's winter coat—the better it is, the more comfortable (and affordable) things stay inside. Standard walk-in coolers typically use 4" thick panels with R-values between R-29 for coolers and R-32 for freezers.

"The insulation material is critical for long-term performance," our engineering team often explains. "Extruded polystyrene typically retains about 47% of its initial R-value over its lifetime, while polyurethane retains only about 19%. This difference significantly affects energy costs over time."

While better insulation costs more upfront, it's one of those investments that keeps paying you back every month on your utility bill.

Refrigeration System Type

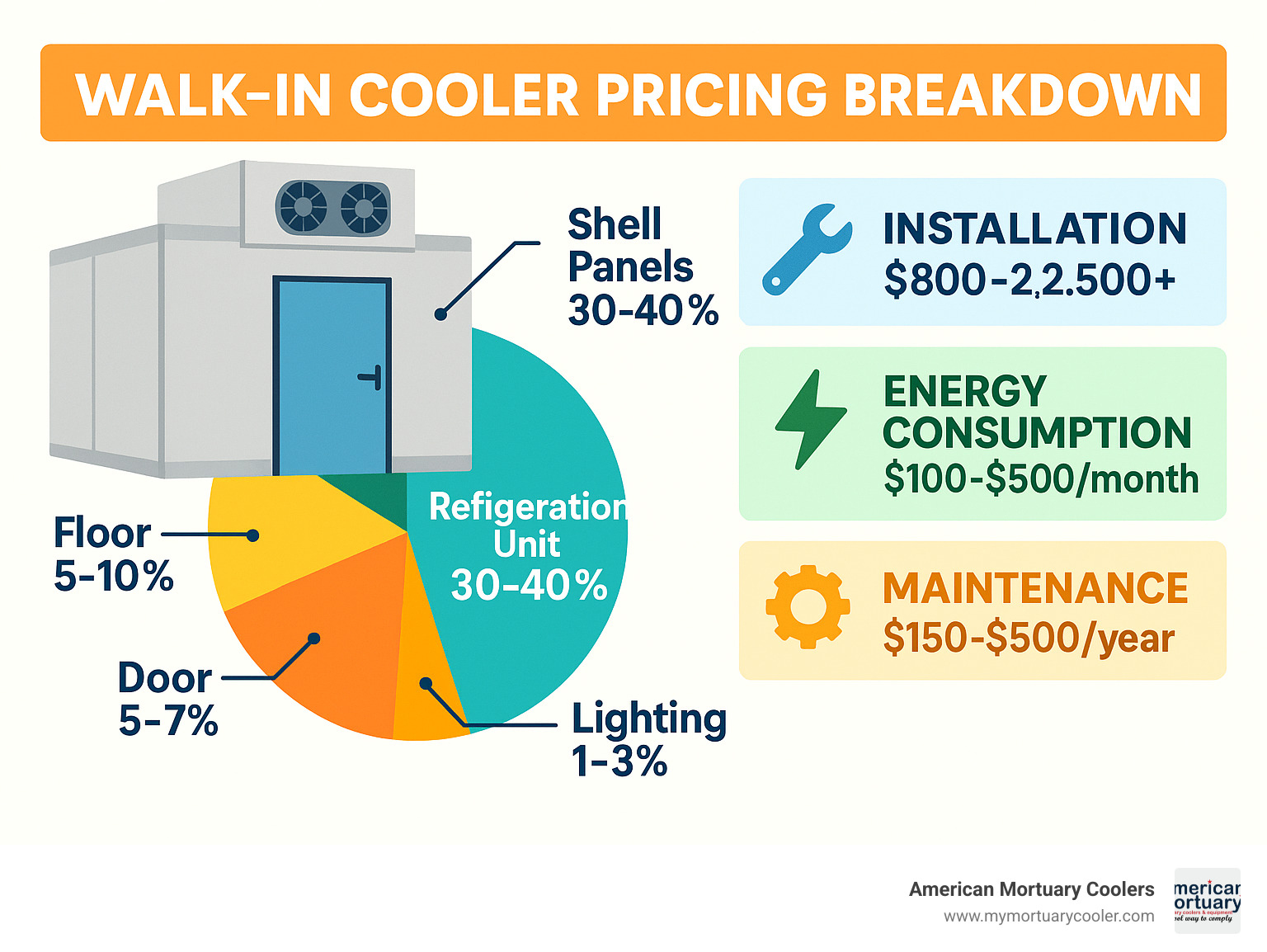

The cooling heart of your walk-in typically accounts for 30-40% of the total walk in cooler pricing. Self-contained reach-in units might run between $1,400 and $4,000, while more sophisticated remote condensing systems can cost anywhere from $5,000 to $11,000 or more. The choice between top-mount or side-mount configurations also affects pricing based on your space constraints and ceiling height.

Indoor vs. Outdoor Installation

Planning to put your cooler outside? Be prepared to spend about 10-15% more than you would for a comparable indoor model. Outdoor units require weather-resistant materials, specialized sealing, rain roofs, and in colder climates, winter kits to keep everything running smoothly through snow and ice.

Flooring Options

The floor beneath your feet represents a significant pricing decision. Walk-in coolers with built-in floors typically cost 10-20% more than floorless models. But before you celebrate those savings, floorless models require properly prepared concrete pads with insulation barriers—costs that might offset your initial savings while adding installation complexity.

Door Configuration

Doors are the gateway to your cold storage—and a major factor in your final bill. Standard hinged doors might run $600 to $2,000+, while those attractive glass display doors add $800 to $2,500+ per door. Need additional or oversized doors to accommodate large items? Plan on spending an extra $1,000 to $3,000+ for each one.

Site Preparation and Installation

Sometimes it's what's beneath and around your cooler that drives unexpected costs. Site preparation can add substantial expenses, especially for outdoor installations requiring concrete pads or indoor setups needing electrical upgrades. The hands that put it all together matter too—installation labor typically ranges from $800 to $2,500 but can climb higher for complex configurations.

Regulatory Compliance

Rules and regulations aren't just red tape—they're important safeguards that affect your bottom line. Energy efficiency regulations from the Department of Energy (DOE) and safety certifications from organizations like NSF and UL add to manufacturing costs but ensure your cooler operates safely and efficiently for years to come.

For more scientific information on cooling systems and their efficiency, check out Scientific research on cooling systems.

Impact of optional upgrades on walk in cooler pricing

Optional features can significantly affect the final walk in cooler pricing, but many provide excellent return on investment through energy savings or improved functionality.

Those standard vapor-proof lights might only cost $30 to $60 per bulb, but upgrading to LEDs for $100 to $300+ could slash your lighting energy costs by 30-50%. Similarly, energy-efficient ECM motors add $300 to $800 but deliver 10-20% energy savings that keep giving year after year.

Weather protection matters too. If you're installing outdoors, rain roofs ($500-$1,200), winter kits for cold climates ($400-$1,000), and wind guards or hurricane anchors ($300-$800) aren't just nice-to-haves—they're essential protections for your investment.

Some upgrades are about looks and durability. Custom exterior finishes can add 10-40% to panel costs, while stainless steel interiors bump prices by 15-30%. Those attractive diamond tread kick plates that protect your walls? They'll set you back $150 to $300.

Modern smart controls offer convenience and peace of mind. Remote temperature monitoring ($300-$1,200), automated alerts ($500-$1,500), and comprehensive energy management systems ($800-$2,500) let you keep tabs on your cooler from anywhere.

"We often recommend investing in quality doors with heavy-duty hinges and proper sealing," our service team at American Mortuary Coolers likes to say. "Door-related issues account for nearly 40% of the service calls we receive, so quality hardware pays for itself quickly."

For more detailed information on pricing factors, read our article on Decoding Walk-In Cooler Pricing Factors.

Component & Lifetime Cost Breakdown

When you're shopping for a walk-in cooler, the sticker price is just the beginning of the story. Think of it like buying a car - there's the purchase price, but then there's everything that comes after. Let's break down both the upfront and long-term costs so you can make a truly informed decision.

Initial Component Costs

Your walk-in cooler is made up of several key components, each contributing a specific percentage to that final price tag.

The insulated panels that form the walls and ceiling typically represent 30-40% of your total investment. These panels range from $8 to $25 per square meter, with prices climbing if you opt for premium insulation or specialized finishes. Many of our funeral home clients choose stainless steel interiors for easier cleaning and sanitizing, which adds about 15-30% to panel costs but provides tremendous long-term value.

Your refrigeration system accounts for another hefty 30-40% of the walk in cooler pricing. Self-contained units run $1,400-$4,000, while remote systems (which place the heat-generating components outside) range from $5,000 to $11,000+. This component is not where you want to cut corners - it's the heart of your cooler.

Flooring makes up a smaller portion at 5-10% of total cost. Standard aluminum floors cost $6-$10 per square foot, while heavy-duty options range from $10-$15. For funeral homes that use transport carts, we often recommend reinforced flooring at $12-$20 per square foot - a small price to pay for avoiding structural issues down the road.

Doors (5-7% of total cost), lighting (1-3%), and various accessories (3-10%) round out the initial investment. A standard hinged door runs $600-$2,000+, while glass display doors can reach $3,500 or more. LED lighting systems cost more upfront at $100-$300+ but pay for themselves quickly in energy savings.

Long-Term Operational Costs

"One of the biggest mistakes we see is tunnel vision on the purchase price," says our sales team at American Mortuary Coolers. "The electricity and maintenance costs often exceed the initial investment within 5-7 years, which makes efficiency and quality absolutely crucial."

Your monthly energy consumption will typically run $100-$500, varying based on unit size, efficiency, and usage patterns. According to the U.S. Energy Information Administration, commercial electricity averages about $0.1071 per kWh. A standard 8' x 10' walk-in cooler uses approximately 1,113.86 kWh/month, which translates to monthly costs around $132.44.

Maintenance isn't optional if you want your cooler to last. Budget $150-$500 annually for preventive maintenance, with additional costs for specific repairs like refrigerant recharges ($200-$800) or compressor replacements ($1,000-$3,000+) if needed. Door gaskets typically need replacement every 2-3 years at $100-$300.

Warranty coverage provides important protection. Standard warranties typically include 20 years on panels, 5 years on doors and compressors, and 1 year on parts and labor. Extended warranties add $500-$2,000+ but can prevent budget-busting surprises.

| Component | 6' x 8' Unit | 8' x 10' Unit | 10' x 12' Unit |

|---|---|---|---|

| Shell Panels | $2,100 - $4,800 | $3,300 - $7,200 | $4,800 - $10,800 |

| Refrigeration | $2,100 - $4,800 | $3,300 - $8,100 | $4,800 - $12,000 |

| Flooring | $350 - $700 | $640 - $1,280 | $960 - $1,920 |

| Door | $600 - $1,400 | $800 - $1,800 | $1,000 - $2,100 |

| Lighting | $70 - $360 | $100 - $450 | $150 - $600 |

| Accessories | $210 - $700 | $330 - $1,080 | $480 - $1,600 |

| Total | $5,430 - $12,760 | $8,470 - $19,910 | $12,190 - $29,020 |

Price impact of floor choices

The floor decision is bigger than many buyers realize. Choosing a floored model provides complete insulation and simplified installation but adds 10-20% to your total walk in cooler pricing. Floorless models reduce upfront costs but require proper site preparation.

For funeral homes and other health-regulated industries, floored models are often mandatory to ensure proper sanitation and prevent contamination. But if you're running a warehouse or brewery, you might save with a floorless model.

The weight capacity of your floor matters tremendously. Standard floors are rated for 600 lbs per square foot, while heavy-duty floors handle 1,000+ lbs (adding 20-40% to floor cost). If you'll be using ramps and carts, you'll need specially reinforced floors.

"A 200-pound cart on two wheels can exert up to 7,200 pounds per square foot in a concentrated area," our engineering team explains. "Standard floors simply aren't designed for this kind of pressure, which is why proper reinforcement is essential when using transport equipment."

Smart upgrades that curb lifetime spend

We've helped countless funeral homes make strategic upgrades that dramatically reduce their long-term costs. Here are the highest-impact improvements:

LED lighting costs $100-$300 more upfront but delivers 30-50% energy savings on lighting while lasting 5 times longer than traditional bulbs. They also generate less heat, reducing strain on your refrigeration system.

ECM motors for evaporator fans add $300-$800 initially but cut overall energy consumption by 10-20% while lasting 2-3 times longer than standard motors. They also maintain more consistent performance across varying conditions.

Quality door gaskets and strip curtains might seem minor, but they're mighty. High-quality magnetic gaskets ($150-$300) and strip curtains ($100-$300) can reduce energy consumption by 5-15% by preventing air infiltration, while also reducing wear on your compressor.

Preventive maintenance plans at $150-$500 annually might feel like an expense, but they're truly an investment. Regular service prevents costly emergency repairs, extends equipment life, and maintains optimal performance.

Smart inventory management costs nothing but delivers real savings. By managing your inventory efficiently, you'll reduce door openings and improve cooling efficiency. Organized shelving maximizes space utilization while strategic product placement reduces retrieval time and cold air loss.

"We've seen funeral homes reduce their operating costs by 20-30% simply by implementing these strategic upgrades," our service department notes. "The payback period is typically just 1-3 years, after which the savings continue for the life of the equipment."

At American Mortuary Coolers, we specialize in helping funeral directors identify the most cost-effective upgrades for their specific needs. We understand that every dollar saved on operations is a dollar that can be invested back into providing exceptional service to families.

Frequently Asked Questions & Buying Tips

When navigating walk in cooler pricing, I've noticed most customers ask similar questions. After helping hundreds of funeral homes find the right cooling solutions, here are the most common questions we receive at American Mortuary Coolers—along with some straight talk to help you make the best decision.

What reputable brands should I consider?

The walk-in cooler world has several manufacturers that have earned solid reputations over the years. Amerikooler builds exceptionally durable units with great energy efficiency (we're particularly fond of their quality control). Nor-Lake offers wonderful customization options if you have unique space requirements. Kolpak has innovative designs and some of the strongest warranties in the business. Mr. Winter specializes in premium custom solutions with high-end features, while U.S. Cooler provides reliable American-made units with responsive customer support.

I always tell my customers that brand reputation matters, but local service support might matter even more. Even the best cooler will eventually need maintenance, so make sure your chosen brand has authorized service providers in your area. Nothing's worse than having a cooling emergency and finding the nearest technician is three states away!

How do I evaluate quotes effectively?

Comparing walk in cooler pricing quotes can feel like comparing apples to oranges if you don't know what to look for. Make sure every quote includes detailed specifications about R-values, the gauge of metal used, and refrigeration capacity. Some vendors exclude floors, refrigeration, or installation to make their prices look more attractive.

Watch for hidden costs like freight, delivery, or setup fees that can add thousands to your bottom line. Double-check warranty terms and coverage periods—they vary dramatically between manufacturers. And don't forget to ask about lead times and delivery schedules, especially if you're working with tight deadlines.

One of our funeral director clients in Florida once told me he received three quotes that differed by over $5,000. When we helped him analyze them, it turned out the lowest quote didn't include the floor or delivery fees!

What about used walk-in coolers?

Used units typically cost 40-60% less than new ones, which can be tempting when you're on a tight budget. The savings can be substantial, they're often available immediately, and reusing equipment reduces environmental impact.

But there are serious tradeoffs. Most used coolers come with limited or no warranty, and you can't be certain about the remaining lifespan. Older units are typically less energy efficient, which means higher monthly bills. They might not comply with current regulations, and installation can be challenging if the unit wasn't properly disassembled.

If you're considering a used unit, I strongly recommend having it inspected by a qualified refrigeration technician before purchase. One of our customers nearly purchased a used cooler for $6,000, only to find it would need $7,500 in repairs and upgrades to meet current health department standards.

What financing options are available?

Several approaches can help manage walk in cooler pricing if you're not able to make a lump-sum purchase:

Equipment leasing offers monthly payments with potential tax advantages. SBA loans provide government-backed financing with favorable terms for small businesses. Some manufacturers offer their own payment plans, though terms vary widely. Don't forget to check for energy-efficiency rebates—many utility companies offer incentives for efficient units that can offset your costs.

For more comprehensive information on purchasing considerations, our resource on Everything You Need to Know About Walk-In Coolers for Sale covers financing in more detail.

What is the typical walk in cooler pricing for installation?

Installation costs often surprise buyers who focused only on the unit price. For a basic 10 sq. ft. unit, expect equipment costs of $1,000-$5,000 and labor costs between $2,000-$4,000. All told, standard installation typically runs $3,000-$9,000, but complex sites can cost considerably more.

Don't forget about site preparation! Electrical upgrades might add $500-$2,000 if your existing circuits aren't sufficient. Need a new concrete pad? That's another $1,000-$3,000. Plumbing modifications for condensate drainage can add $500-$1,500, and permits and inspections range from $200-$800 depending on your location.

I always advise customers to factor in site preparation when budgeting. Just last month, a funeral home in Texas called me, frustrated that their project was $4,000 over budget because they hadn't accounted for the electrical work and concrete pad their site needed.

Is DIY walk in cooler pricing really cheaper?

DIY options like CoolBot systems (starting around $4,625) can be tempting with their significant upfront savings. They're easier to install and offer flexibility for non-commercial applications.

However, I have to be honest about their limitations. These systems typically aren't compliant with commercial food safety codes or regulations governing funeral homes. They have limited capacity and temperature range, consume more energy over time, generally have shorter lifespans, and offer limited warranty coverage.

CoolBot systems work beautifully for small farms or temporary applications, but they're rarely suitable for regulated environments like funeral homes, where reliable performance and code compliance are non-negotiable. One funeral director I know tried this route to save money, only to have their health inspector require a complete replacement within six months.

How can I secure the best walk in cooler pricing from vendors?

After helping hundreds of customers find the right cooling solution at the right price, I've learned a few insider tips:

Always request itemized quotes from multiple vendors so you can see exactly what you're paying for. Make sure you're specifying identical requirements to each vendor for truly comparable pricing. Verify certifications like NSF and UL compliance—cutting corners here can cause regulatory headaches later.

Try to negotiate freight costs or find vendors (like us!) who include shipping in their pricing. Ask about bundle discounts for accessories purchased with your main unit. If your timeline is flexible, consider timing your purchase during slower seasons when vendors might offer promotions. And always ask about floor models or overstock units that might be available at reduced prices.

At American Mortuary Coolers, we often provide discounts when customers purchase multiple accessories with their main unit. We can also sometimes offer preferential pricing on quick-ship models that align with our production schedule. Just ask—the worst we can say is no!

Conclusion

Navigating walk in cooler pricing can feel like a complex journey, but when you break it down, it's about balancing initial costs with long-term value. Throughout this guide, we've seen that prices typically range from $5,000 for standard units to $40,000+ for custom solutions with all the bells and whistles. Size, insulation quality, refrigeration type, and those tempting optional features all play significant roles in what you'll ultimately pay.

I'd like to share some key takeaways that my customers have found most valuable:

First, look beyond the sticker price. I've seen too many business owners focus solely on upfront costs, only to call me later about their sky-high energy bills. A quality unit might cost more initially but can save thousands in operating costs over its lifetime.

Second, size your cooler appropriately for your needs. It's like buying shoes—too big wastes money and energy, too small creates painful problems. One restaurant owner told me recently, "I wish I'd listened when you suggested going one size larger. Now we're struggling during busy weekends."

Third, don't skimp on quality components. Those doors, gaskets, and refrigeration systems take a beating with daily use. One funeral director shared, "The extra $800 I spent on premium doors was the best decision I made—seven years later, they're still working perfectly."

Fourth, regional factors matter. Installation costs in Manhattan are vastly different from those in rural Tennessee. Climate requirements in humid Miami demand different specifications than dry Arizona. Your local regulations might also impact what features are mandatory versus optional.

Finally, plan for the future of your business. That small cooler might meet your needs today, but what about three years from now? The most satisfied customers I work with think long-term, investing in energy-efficient features and quality construction that pays dividends through lower bills and fewer headaches.

At American Mortuary Coolers, we understand that walk-in coolers represent a significant investment, especially for funeral homes and medical facilities where reliability isn't just convenient—it's essential. Our nationwide presence with locations in Johnson City TN, Atlanta GA, Chicago IL, Columbia SC, Dallas TX, Los Angeles, New York NY, and Pittsburgh PA means we can provide consistent pricing, reliable delivery, and ongoing support virtually anywhere you are in the continental US.

We've built our reputation by crafting durable, custom solutions specifically designed for the funeral industry, where performance simply cannot be compromised. Our team includes experts who've spent decades in the field, and we're always available to help you steer the complexities of walk in cooler pricing to find that sweet spot between affordability now and value over time.

For more information about our specialized mortuary coolers and related equipment, I invite you to visit American Mortuary Coolers—your one-stop shop for custom cold storage.

A walk-in cooler isn't just another purchase—it's an investment in your business's efficiency, compliance, and operational capability for years to come. Choose wisely, with both your immediate budget and long-term operations in mind, and the returns will follow. That's something I've seen proven time and again with hundreds of satisfied customers across the country.