What You Need to Know About Walk-In Freezers

A freezer walk (also called a walk-in freezer) is an enclosed refrigerated space that maintains temperatures below 0°F (-18°C) and allows a person to enter for storage and retrieval. Unlike reach-in units, these room-sized freezers provide massive storage capacity for businesses that need to preserve large quantities of temperature-sensitive materials.

Key Features of Walk-In Freezers:

- Size Range: 6'x6' up to 40'x60' or larger

- Temperature: Maintains 0°F to -10°F (-18°C to -23°C)

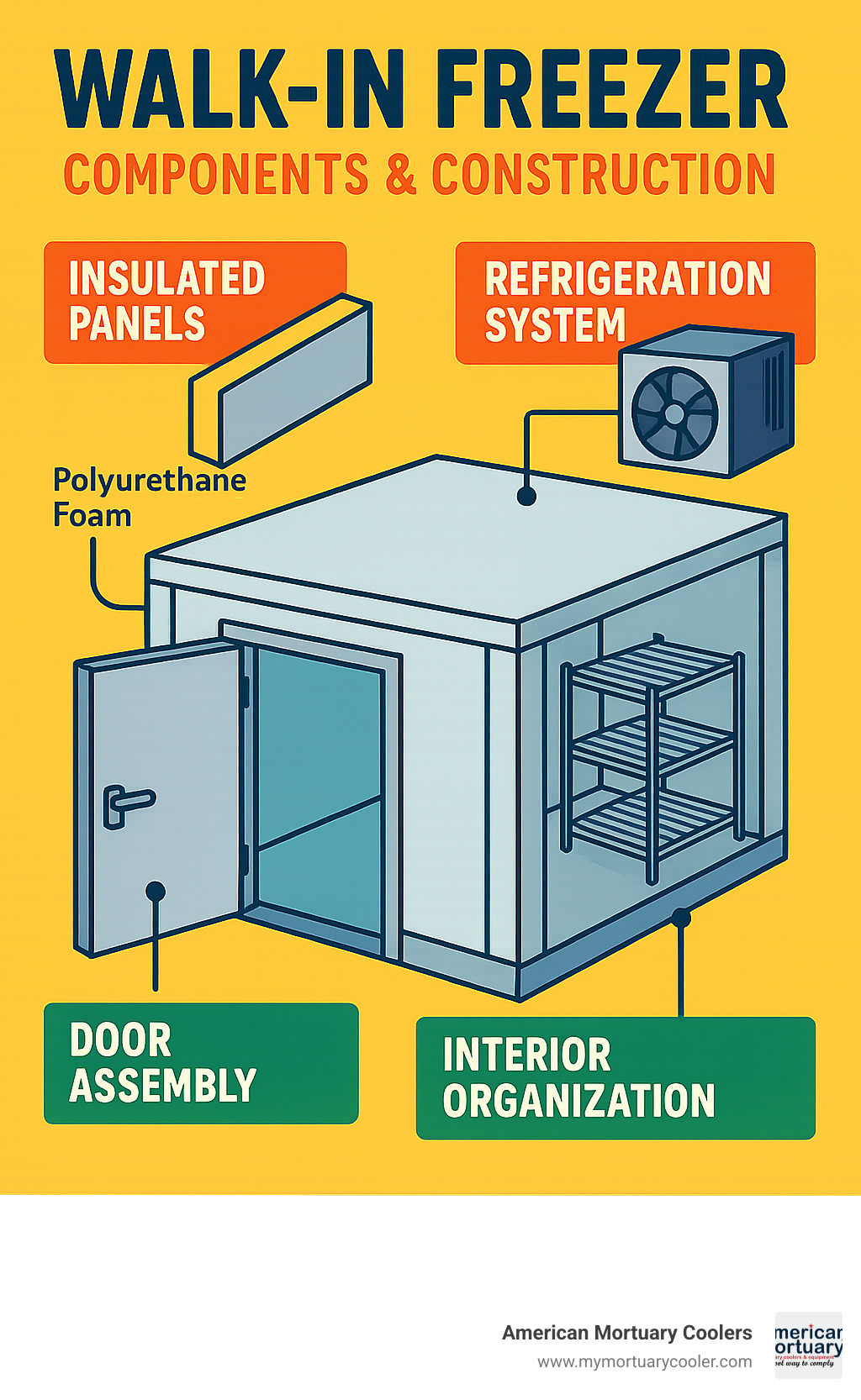

- Construction: Insulated panels with polyurethane foam (R-32+ insulation)

- Access: Full-height doors allowing cart and equipment entry

- Installation: Indoor, outdoor, or thru-wall configurations

- Industries: Food service, medical, mortuary, floral, pharmaceutical

Walk-in freezers use high-density closed cell polyurethane foam insulation within cam-lock panels to maintain consistent temperatures while minimizing energy consumption. The refrigeration system can be self-contained (mounted on top), remote (condenser located elsewhere), or side-mounted depending on your space and ventilation requirements.

These units are built to handle the demands of commercial operations where thousands of dollars worth of inventory depends on reliable temperature control. With proper organization using wire shelving and adequate airflow, a well-maintained walk-in freezer can operate efficiently for decades.

I'm Mortuary Cooler, a national-level mortuary cooler supplier with extensive experience helping funeral homes select the right freezer walk solutions for their specific needs.

Important freezer walk terms:

How a Walk-In Freezer Works & Its Core Components

Your freezer walk operates like a giant, well-insulated box with a powerful cooling system. The compressor acts as the heart, squeezing refrigerant gas under high pressure and pumping it to the condenser outside your freezer where heat gets expelled.

Next, the cooled refrigerant flows through an expansion valve and enters the evaporator coil inside your freezer. This is where the real cooling happens - the refrigerant absorbs heat from your freezer's air, keeping everything at that perfect sub-zero temperature.

What makes a freezer walk special are those insulated panels - 4-inch thick walls filled with high-density closed cell polyurethane foam. This provides incredible R-values that keep the cold in and heat out, translating directly to lower energy bills.

Those panels snap together using cam-lock fasteners - heavy-duty connectors that create an airtight seal. The tongue-and-groove design means no gaps where warm air can sneak in. The exterior gets a 26-gauge white embossed stucco finish that looks professional and resists daily wear.

Floor panels carry hundreds of pounds of product plus foot traffic. Most use galvanized steel with reinforced plywood backing, though you can upgrade to stainless steel for maximum sanitation. Canadian energy standards require these floors to hit at least R-28 thermal resistance.

Vapor-proof lighting is essential since regular fixtures would fail quickly in freezer environments. LED lighting has become the go-to choice because it produces less heat and lasts much longer.

Magnetic gaskets around doors and panels create better seals than old compression styles, meaning better temperature control and less ice buildup.

For refrigeration systems, you have three main options:

| System Type | The Good | The Not-So-Good | Perfect For |

|---|---|---|---|

| Remote | Quiet operation, better cooling, easier to fix | Costs more upfront, needs refrigerant lines | Big units, indoor setups |

| Self-Contained | Cheaper to start, simple setup | Louder, adds heat to your building | Smaller units, outdoor spots |

| Side-Mount | Saves space, easy to reach | Limited power, height limits | Medium units in tight spaces |

Freezer Walk Doors & Panels

Your door is a critical piece of safety equipment. Fire-rated panels meeting CAN/ULC-S138 standards are required by building codes. Every quality door comes with a 36-inch high stainless steel kick plate at the bottom for protection against cart collisions.

Magnetic gaskets are especially important on doors since that's where most air leakage happens. You have options beyond standard hinged doors - sliding doors work in cramped spaces, bi-parting doors handle wide openings, and pallet doors let forklifts roll through.

More info about Walk-In Cooler features and prices

Refrigeration Systems: Picking the Right Fit

Getting BTU sizing right is crucial - too small and your system struggles, too big and you waste money. The calculation factors in heat coming through walls, floors, lighting, people, and warm products being stored.

Ambient conditions can make or break performance. Low-ambient controls become essential for outdoor units in colder climates where temperatures drop below 60°F.

Humidity management prevents excessive ice buildup and extends product life. Modern controllers like the Intelliref controller provide precise monitoring and can send alerts to your phone if problems arise.

Walk-in freezer systems manufactured after July 10, 2020, must meet specific energy efficiency standards under Canadian regulations designed to keep operating costs reasonable.

Scientific research on energy-efficient refrigeration

Designing the Perfect Freezer Walk for Your Business

Getting your freezer walk design right saves you headaches, money, and space. Standard sizes range from compact 6'x6' units up to massive 16'x60' warehouses. Popular mid-range options like 8'x10', 10'x12', and 12'x16' work well for most businesses, but custom sizing maximizes your available space.

Heights typically run from 7'6" to 9'6" for standard applications. With cam-lock panels, you can reach up to 24 feet high, and continuous panels can stretch up to 50 feet for warehouse applications.

For moving large quantities, drive-in options feature oversized doors at least 4 feet wide and 8 feet high that accommodate forklifts and pallet jacks.

Modular cam-lock panels offer flexibility since you can disassemble and reconfigure them. Seamless fiberglass construction eliminates gaps where air and moisture could enter, providing superior performance.

The outdoor vs indoor decision often comes down to space constraints. Outdoor units free up interior space but need weatherproof construction. Indoor units provide convenient access but consume floor space.

Thru-wall installations connect directly to your building, while freestanding units can be moved if needed. Blast freezer upgrades include heated perimeters, improved insulation, and powerful refrigeration for rapid freezing.

More info about an Ultimate Guide to Walk-In Fridge and Freezer Combos

Industry-Specific Customization

Food service operations need NSF-certified components meeting health department standards, plus easy-to-clean surfaces preventing cross-contamination.

Medical applications demand precise temperature control with backup systems and often glass doors for quick inventory location without opening doors.

Industrial operations might need reinforced floors for heavy products, wider doors for equipment access, and specialized coatings resisting harsh chemicals.

At American Mortuary Coolers, we specialize in mortuary applications requiring specific temperature ranges, often with combination cooler/freezer capabilities across the contiguous 48 states.

Floral operations benefit from humidity control systems extending flower life. Pharmaceutical storage may require validation documentation and redundant monitoring for FDA compliance.

"Freezer Walk" Layout Essentials

Smart layout design makes the difference between a freezer walk that works with you versus against you. Aisle width needs 36-48 inches for standard carts, or 8-10 feet for forklifts.

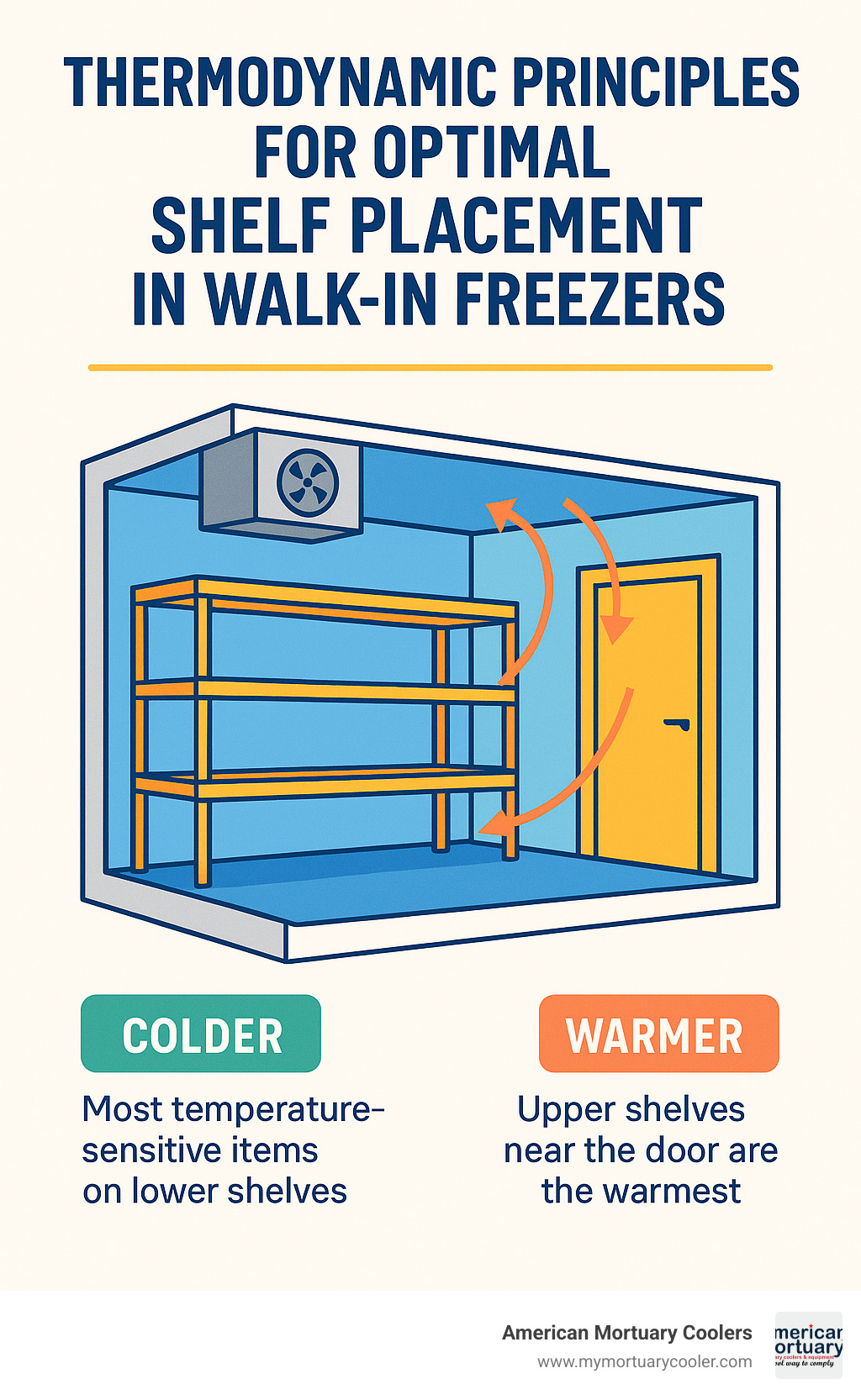

Shelf zoning based on thermodynamics affects product quality and energy bills. Cold air sinks while warm air rises, so place temperature-sensitive items closest to the floor and farthest from doors.

Forklift access requires reinforced floors handling combined weight of forklift, operator, and product load, plus adequate ceiling height. Kick-plates protect doors from cart damage in high-traffic areas.

Vinyl strip curtains dramatically reduce humid air infiltration, especially valuable in hot climates or high-traffic areas where doors open frequently.

Installation, Energy Codes & Safety for Freezer Walk-Ins

Proper freezer walk installation ensures safe, reliable operation for years. Site prep starts with a level foundation within 1/4" over 10 feet. Uneven floors cause door seal problems, air leaks, and structural stress.

Electrical hookup must be done by a licensed electrician. Walk-in freezers need serious power - typically 208-230V single-phase, with larger units requiring three-phase. Every component requires GFCI protection because moisture and electricity don't mix.

Crane delivery is standard for larger units. Your freezer arrives fully assembled and tested, then gets lifted into place. It's pre-wired and ready for electrical connection and startup.

RSI/R-value standards protect against high energy bills. Freezer walls and ceilings need RSI-value ≥5.64 m²·K/W (R-32), while floors require ≥4.93 m²·K/W (R-28). These ensure proper insulation and prevent condensation damage.

Annual energy factor requirements mean refrigeration systems must meet efficiency standards. Indoor units need ≥1.644 W-h/W-h, while outdoor units require ≥2.227 W-h/W-h.

Bilingual nameplates in Canada must show brand name, model number, manufacturing date, and intended use in English and French.

Safety features prevent emergencies. OSHA safety latches and inside release mechanisms prevent entrapment. Every freezer walk must open from inside even if external handles break or ice blocks them.

Alarm systems alert staff about entrapment and temperature problems before inventory loss occurs.

Meeting Energy Efficiency Regulations

Energy regulations save money long-term. EISA and Canadian regulations set minimum efficiency standards preventing energy-wasting equipment. Door assemblies made after June 5, 2017, and refrigeration systems after July 10, 2020, must meet federal requirements.

LED lighting uses less energy and generates less heat than old fixtures. Less heat means refrigeration systems work less, lowering electric bills monthly.

High-density foam insulation provides superior thermal performance while maintaining its properties year after year.

Scientific research on insulation performance

Freezer Walk Safety Checklist

Every freezer walk needs a panic bar for escape without keys. Anti-slip flooring prevents dangerous falls on icy surfaces. Temperature alarms provide audible and visual alerts when temperatures drift.

Staff training might be the most important safety feature. Everyone needs proper procedures for entering, working inside, and exiting safely. Regular drills make procedures second nature.

At American Mortuary Coolers, we ensure every installation includes critical safety features because protecting staff is as important as protecting inventory.

Organizing, Maintaining & Troubleshooting Your Freezer Walk

A well-organized freezer walk protects your investment and keeps operations running smoothly. The FIFO system (First In, First Out) prevents costly waste by ensuring older inventory moves before newer stock.

NSF wire shelving with blue certification labels meets food safety standards. Wire shelving beats solid shelving because it allows proper air circulation, preventing hot and cold spots.

Airflow gaps are crucial - leave at least two inches between shelves and walls, and maintain 6-inch floor clearance under your lowest shelf. This meets health codes, makes cleaning easier, and ensures proper air circulation.

Your cleaning schedule should include daily attention to door handles, weekly shelf cleaning, and monthly deep cleaning of panels and gaskets.

Defrost cycles are automatic in modern systems, but watch for ice buildup. Condenser coil cleaning twice yearly prevents your compressor from working harder and extends equipment life.

Seal inspection using baking soda solution spots cracks or damage in door seals that keep expensive cold air inside.

Preventing Ice Build-Up & Downtime

Ice buildup is like a slow bank account leak. Poor door management is the biggest culprit - every minute doors stay open invites humid air that equals ice problems.

Vinyl strip curtains cut humid air infiltration by up to 80%, meaning less ice and lower energy costs. They pay for themselves quickly in busy environments.

Drain line flush prevents clogged drains causing water backup and ice formation. Schedule professional service annually with monthly visual checks.

Proper defrost timer settings balance ice prevention with energy efficiency. When troubleshooting frost, check defrost controls, drain lines, door seals, and airflow around evaporator coils.

Compressor diagnostics catch problems early. High discharge pressure often indicates dirty condenser coils, while low suction pressure might mean refrigerant leaks.

More info about Walk-In Cooler repair

Extending Equipment Life & Reducing Bills

Energy-saving tips cut operating costs while extending equipment life. Avoid overpacking shelves and ensure adequate spacing for air circulation.

Smart controllers like Intelliref V2 optimize defrost cycles, manage door heaters efficiently, and provide early problem warnings. Maintenance logs document service history and prove regulatory compliance.

A well-maintained freezer walk serves reliably for decades while keeping energy bills reasonable.

Frequently Asked Questions about Freezer Walk-Ins

What distinguishes a freezer walk from reach-in or chest freezers?

The biggest difference is you can actually walk into a freezer walk to access stored items, versus trying to reach items from outside in smaller units.

Storage capacity is where walk-ins shine - 81 to 1,600+ square feet versus just a few cubic feet in smaller units. Organization becomes easy with proper shelving systems, carts, and actual visibility of inventory.

Walk-in freezers use commercial-grade refrigeration systems and insulated panels designed for frequent access and heavy use, built for businesses depending on reliable temperature control.

How do I size a freezer walk for my operation?

Sizing requires thinking beyond today's needs to future growth. Calculate typical inventory storage, then add breathing room. A cramped freezer is inefficient.

Product types matter - bulky items need more space per pound than compact ones. Access requirements affect both size and door configuration - do you need cart access or forklift capability?

Small operations often use 8'x10' units, busy restaurants might need 12'x16' or larger, while distribution centers require massive 20'x40' units. At American Mortuary Coolers, funeral homes need anywhere from 6'x8' to 16'x20' depending on caseload.

Growth planning saves money - it's cheaper to size up initially than replace your entire system later.

What warranties and after-sales services are typical?

Panel warranties often extend 20 years for structural components. Door warranties usually cover 5 years, while compressor warranties typically match that timeframe. Quality manufacturers include 1 year parts and labor coverage.

Top-tier manufacturers offer 12-year complete structural coverage. Look for technical support, professional installation, preventive maintenance programs, and emergency repair services.

At American Mortuary Coolers, we provide comprehensive support across the contiguous 48 states, understanding funeral homes can't afford equipment failures.

Conclusion

Investing in a well-designed freezer walk is one of the smartest decisions for your business. When thousands of dollars of inventory depends on reliable temperature control, choosing the right system becomes critical.

Every detail matters - from proper insulation and door seals to regular maintenance and smart layout design. Modern walk-in freezers offer incredible flexibility, whether you need a compact 6'x6' unit or a massive drive-in freezer.

Energy efficiency benefits both environment and bottom line. With proper maintenance, smart controllers, and efficient organization, many businesses see significant energy bill reductions while extending equipment lifespan.

At American Mortuary Coolers, we understand funeral homes have unique requirements beyond standard commercial applications. Our custom freezer walk solutions are designed specifically for the mortuary industry across the contiguous 48 states.

We combine decades of industry experience with genuine understanding of how critical reliable temperature control is for your business, helping funeral directors design and install systems meeting both operational needs and regulatory requirements.

Ready to take the next step? Whether replacing an aging system, expanding current setup, or installing your first walk-in freezer, we're here to help you steer options and find the perfect solution.

The investment in a quality freezer walk system pays dividends through reduced product loss, improved organization, energy savings, and peace of mind from reliable operation. Don't let inadequate refrigeration put your business at risk.