Why Gurnee Medical Beds Are Essential for Modern Healthcare Transport

A gurnee medical bed is a wheeled stretcher designed for safe patient transport in hospitals, ambulances, and medical facilities. Here's what you need to know:

Key Features:

- Weight capacity: 350-1,000 lbs depending on model

- Adjustable height: Manual or powered systems

- Safety features: Side rails, braking systems, restraint points

- Types: Standard, bariatric, pediatric, and mortuary models

- Price range: $700-$12,000 for new units

Main Benefits:

- Safe patient transport between locations

- Reduced caregiver strain through ergonomic design

- Versatile positioning for medical procedures

- Shock absorption for patient comfort

The healthcare industry relies heavily on these specialized transport beds. As one facility manager noted in our research: "The mortuary stretcher is great! We already used it for [transporting] 450 pounds... was smooth and easy to operate."

Whether you need a basic manual model or a high-capacity powered unit, understanding the different types and features helps you make the right choice for your facility's needs.

We're American Mortuary Coolers, a national-level mortuary cooler supplier with experience in medical transport equipment. Over the years, we've helped countless facilities select the right gurnee medical bed solutions that balance durability, functionality, and budget requirements.

Gurnee Medical Bed Fundamentals: Definition & Main Types

Let's clear up some confusion right away. When you're shopping for medical transport equipment, you'll hear "gurnee medical bed," "stretcher," and "gurney" used almost interchangeably. While they're all in the same family, there are some key differences worth knowing about.

A gurnee medical bed is essentially a wheeled stretcher built specifically for moving patients around. Think of it as the workhorse of medical transport - always ready to roll, literally. The term "gurney" has an interesting backstory too. It comes from the Gurney Cab Company, which was cranking out wheeled stretchers way back in the early 1900s for more history).

Here's where things get interesting. You've got two main camps when it comes to power: manual models that rely on good old-fashioned elbow grease, and powered models that do the heavy lifting for you.

| Feature | Manual Models | Powered Models |

|---|---|---|

| Height Adjustment | Hand crank operation | Electric or hydraulic controls |

| Weight Capacity | 350-600 lbs typically | Up to 1,000+ lbs |

| Price Range | $700-$3,000 | $3,000-$12,000 |

| Power Requirements | None | Battery or AC power |

| Maintenance | Minimal | Regular service needed |

| Best For | Budget-conscious facilities | High-volume operations |

Manual models are the budget-friendly choice. You'll be doing some cranking to adjust heights, but they're reliable and won't leave you stranded when the power goes out. Powered models are the premium option - they handle heavier loads and make life easier for staff who are moving patients all day long.

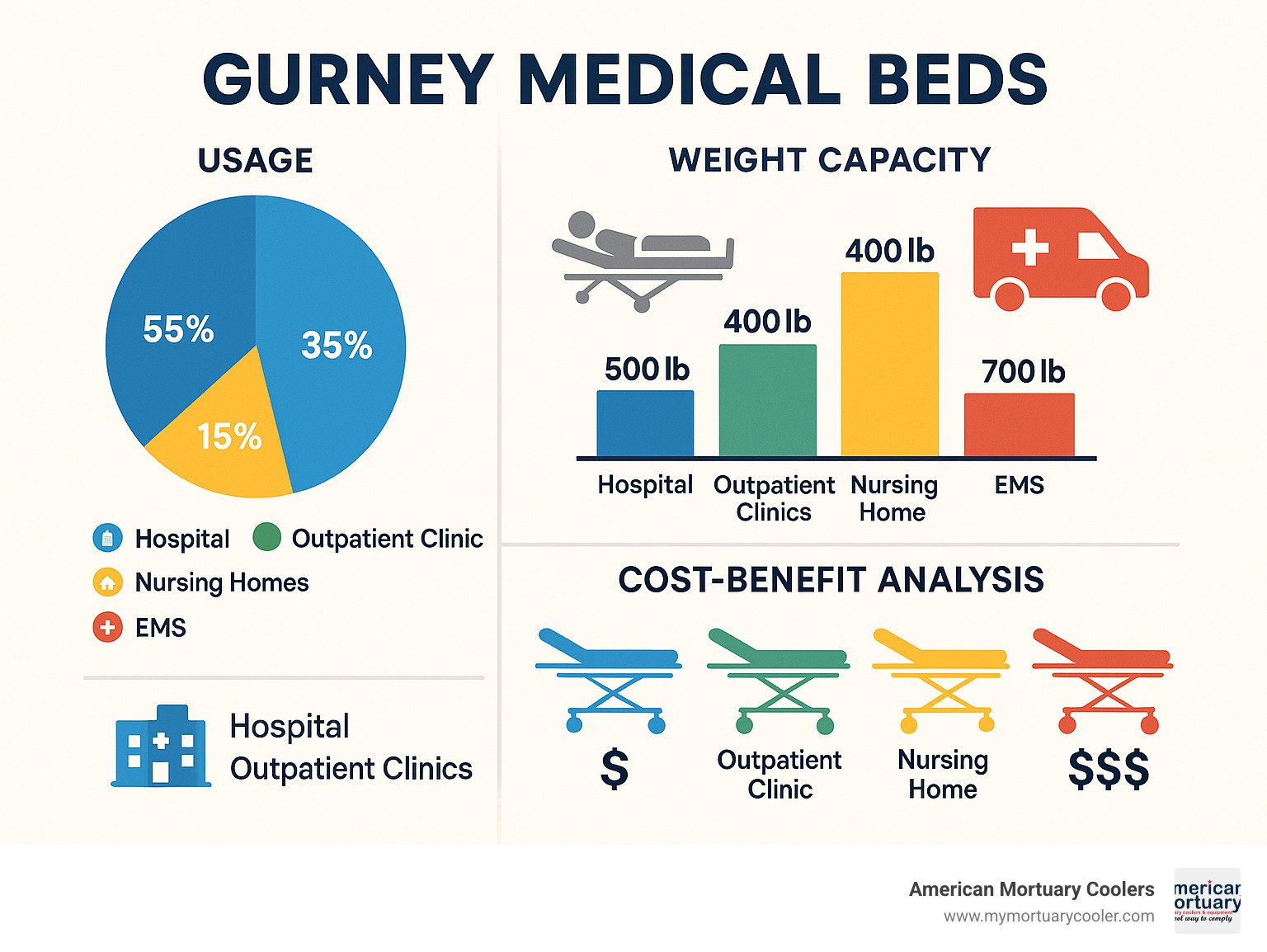

Now, let's talk about the different types you'll encounter. Standard transport models are your everyday heroes, handling most patients with weight capacities between 350-450 lbs. They're straightforward, dependable, and get the job done without breaking the bank.

Bariatric units are the heavy-duty champions, supporting anywhere from 600 to 1,000 lbs. These aren't just beefed-up regular models - they feature reinforced frames and wider surfaces. With about 61 million Americans living with mobility-affecting disabilities, these units are becoming increasingly essential.

Pediatric versions are designed with our smallest patients in mind. They're lower to the ground, smaller overall, and typically support up to 300 lbs. The safety features are specially designed for children, which gives everyone peace of mind.

Mortuary models serve a different but equally important purpose. These units are purpose-built for funeral homes and morgues, designed to handle deceased individuals with dignity and ease of operation. More info about stretcher vs mortuary differences.

How a gurnee medical bed differs from standard hospital beds

Here's the thing about gurnee medical beds versus regular hospital beds - they're built for completely different jobs. Hospital beds are like comfortable recliners designed for long-term stays. They've got all sorts of positioning options, built-in monitoring systems, and they're meant to stay put in one room.

A gurnee medical bed is all about movement. These units live on the road, so to speak. They feature large, smooth-rolling casters - usually about 5 inches in diameter - that glide easily over different floor surfaces. The braking systems are robust because safety can't be an afterthought when you're transporting patients.

Many models have collapsible under-carriages that fold up for storage in ambulances or cramped spaces. The entire design philosophy is transport-first - lightweight but tough, using aluminum or steel frames that can handle constant use.

The side-rails are another key difference. They're designed with quick-release mechanisms so medical staff can access patients rapidly during emergencies. Everything about these beds screams "ready to move."

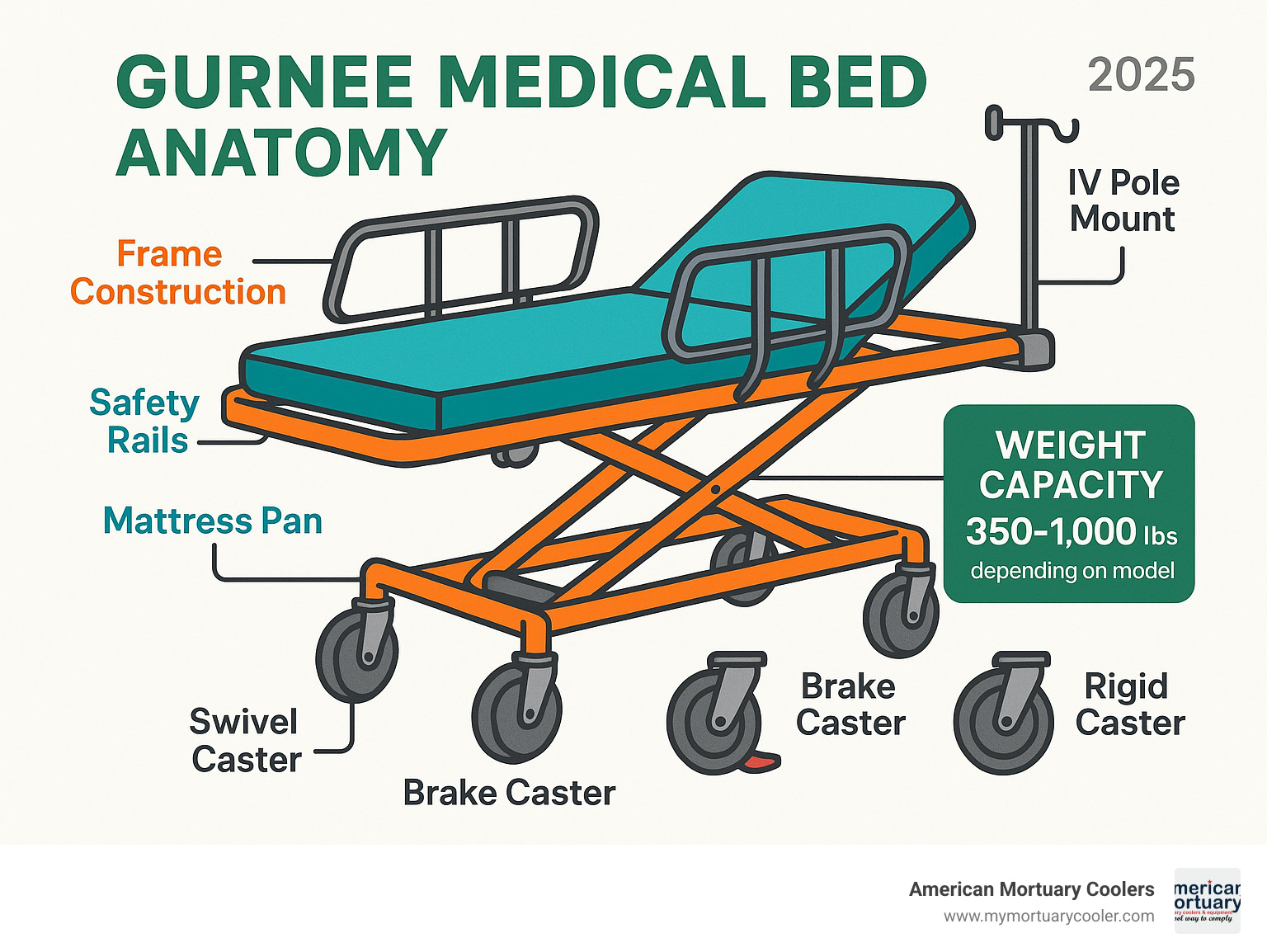

Core components of a gurnee medical bed

Understanding what goes into a quality gurnee medical bed helps you spot the difference between a solid investment and a future headache.

The frame construction is where everything starts. Quality units use TIG-welded steel or aluminum alloy frames. Steel gives you maximum durability - it can handle years of abuse. Aluminum reduces weight, making the unit easier for staff to maneuver. Either way, the frame needs to handle repeated stress from loading patients, transport bumps, and constant height adjustments.

The mattress pan is where your patient actually lies. Most are made from perforated steel or aluminum, and those holes aren't just for looks - they allow for drainage and make cleaning much easier. Some models use mesh slings instead, which is particularly helpful in mortuary applications where thorough decontamination is critical.

Your caster system typically includes four or five wheels, with at least two featuring locks. That fifth wheel, when present, is a game-changer for tight spaces - it lets you pivot and maneuver like you wouldn't believe. Quality casters use sealed bearings and non-marking materials so you won't leave tracks on hospital floors.

Braking systems are absolutely critical for safety. You'll find everything from simple foot pedals to total-lock systems that secure both wheels and swivel mechanisms at once. Trust us, when you're dealing with a 400-pound patient on an incline, you want brakes you can count on.

Don't overlook the IV pole mounts - these integrated attachment points handle medical equipment and are typically rated for 20-30 lbs of accessories. Finally, restraint points provide built-in anchor spots for safety straps, ensuring secure patient transport even in moving ambulances.

Key Features, Safety Improvements & Patient Benefits

The evolution of gurnee medical bed technology over the past decade has been remarkable. What used to be basic wheeled stretchers have transformed into sophisticated patient transport systems that prioritize both safety and comfort.

Shock absorption systems represent one of the most significant advances. Modern units incorporate pneumatic or hydraulic dampening that smooths out every bump and vibration during transport. This isn't just about comfort – it's critical for patients with spinal injuries or those in unstable condition where every jolt could cause complications.

The five-position backrest has become standard on quality models, allowing positioning from completely flat to nearly upright. This flexibility proves invaluable when transporting patients with breathing difficulties. As medical research confirms, elevation of the head section aids fluid removal in conditions like pneumonia or asthma, making transport safer for respiratory patients.

Advanced side-rail systems have evolved far beyond simple barriers. Today's safety rails feature multiple locking positions and intuitive quick-release mechanisms. They effectively prevent patient falls while allowing healthcare workers rapid access during emergencies – a balance that older models struggled to achieve.

Braking technology has seen dramatic improvements too. Modern total-lock systems secure both wheels and swivel mechanisms with a single foot action. This prevents the dangerous rolling that could occur during patient transfers when only some wheels were locked.

Fall prevention features address a growing concern in healthcare facilities. Low-profile models with height ranges of 240-790mm significantly reduce fall risk, particularly valuable for patients with dementia or mobility challenges. Long-term care facilities have reported notable decreases in patient injuries after upgrading to these newer designs.

The integration of pressure-relief mattress compatibility shows how manufacturers think beyond basic transport. Many units now accommodate specialized mattresses with alternating air pressure or low-air-loss systems, preventing pressure ulcers during extended transport periods.

Ergonomic improvements benefit the caregivers who use these beds daily. Strategic handle placement and smooth height adjustability reduce physical strain on healthcare workers. Scientific research on stretcher safety consistently shows that proper ergonomics can significantly cut workplace injuries among medical staff – a win for everyone involved.

Essential accessories that modern facilities should consider include oxygen bottle holders for respiratory support, IV pole attachments for continuous medication delivery, patient chart holders for documentation, personal effects storage for belongings, quality restraint straps and buckles for safety, drain pans for mortuary applications, and protective mattress covers for infection control.

The cumulative impact of these advances is substantial. Healthcare facilities consistently report fewer patient injuries, reduced caregiver strain, and improved operational efficiency when upgrading from older models to modern gurnee medical bed systems. Scientific research on stretcher safety continues to validate these improvements, showing measurable benefits in patient outcomes and staff satisfaction.

These aren't just incremental improvements – they represent a fundamental shift toward viewing patient transport as a critical component of overall care quality rather than simply moving people from point A to point B.

Buying, Sizing & Maintenance Guide

Choosing the right gurnee medical bed doesn't have to be overwhelming. After helping countless facilities over the years, we've learned that success comes down to understanding your specific needs and matching them with the right equipment.

Understanding Weight Capacity

The most important decision you'll make is selecting the proper load capacity. We typically see facilities choosing from three main ranges:

Standard models handle 350-450 lbs and work well for most adult patients. Heavy-duty units support 500-700 lbs and represent the sweet spot for general hospital use. Bariatric models accommodate 800-1,000+ lbs and are essential if you serve patients with higher weight requirements.

Here's something many people miss: that weight capacity includes everything – the patient, medical equipment, blankets, and any accessories. We always recommend choosing a model with 20-30% more capacity than your typical patient weight. It's better to have the extra capacity and not need it than to be caught short.

Getting the Size Right

Most gurnee medical beds measure 75-80 inches long and 25-30 inches wide. Bariatric models can stretch up to 54 inches wide. The height typically adjusts from 20-40 inches, which is crucial for matching different work surfaces and reducing caregiver strain.

Before you buy, grab a tape measure and check your facility's narrowest doorways, elevator dimensions, and storage areas. Nothing's more frustrating than finding your new equipment won't fit where you need it most.

Material Choices: Aluminum vs Stainless Steel

This decision often comes down to priorities. Aluminum construction costs more upfront but offers significant advantages – it's lightweight for easier handling, won't corrode, and works in MRI environments. Stainless steel provides maximum durability at a lower price point, though it's heavier and requires more effort to move around.

We've seen facilities choose aluminum when staff frequently move equipment between locations, while stainless steel works well for high-volume operations where durability trumps weight concerns.

Brand Considerations

In our experience, Stryker represents the premium option with models like the 1020 Trauma Stretcher offering advanced features and excellent reliability. Hill-Rom provides solid hospital-grade equipment with strong service support. Ferno offers good value, especially for emergency services applications.

New vs Refurbished Equipment

Don't overlook refurbished units – they can cost 50% less than new models while delivering excellent performance. When evaluating used equipment, check the warranty coverage, review service history, and inspect frame welds and caster condition carefully. Test all adjustment mechanisms before purchasing.

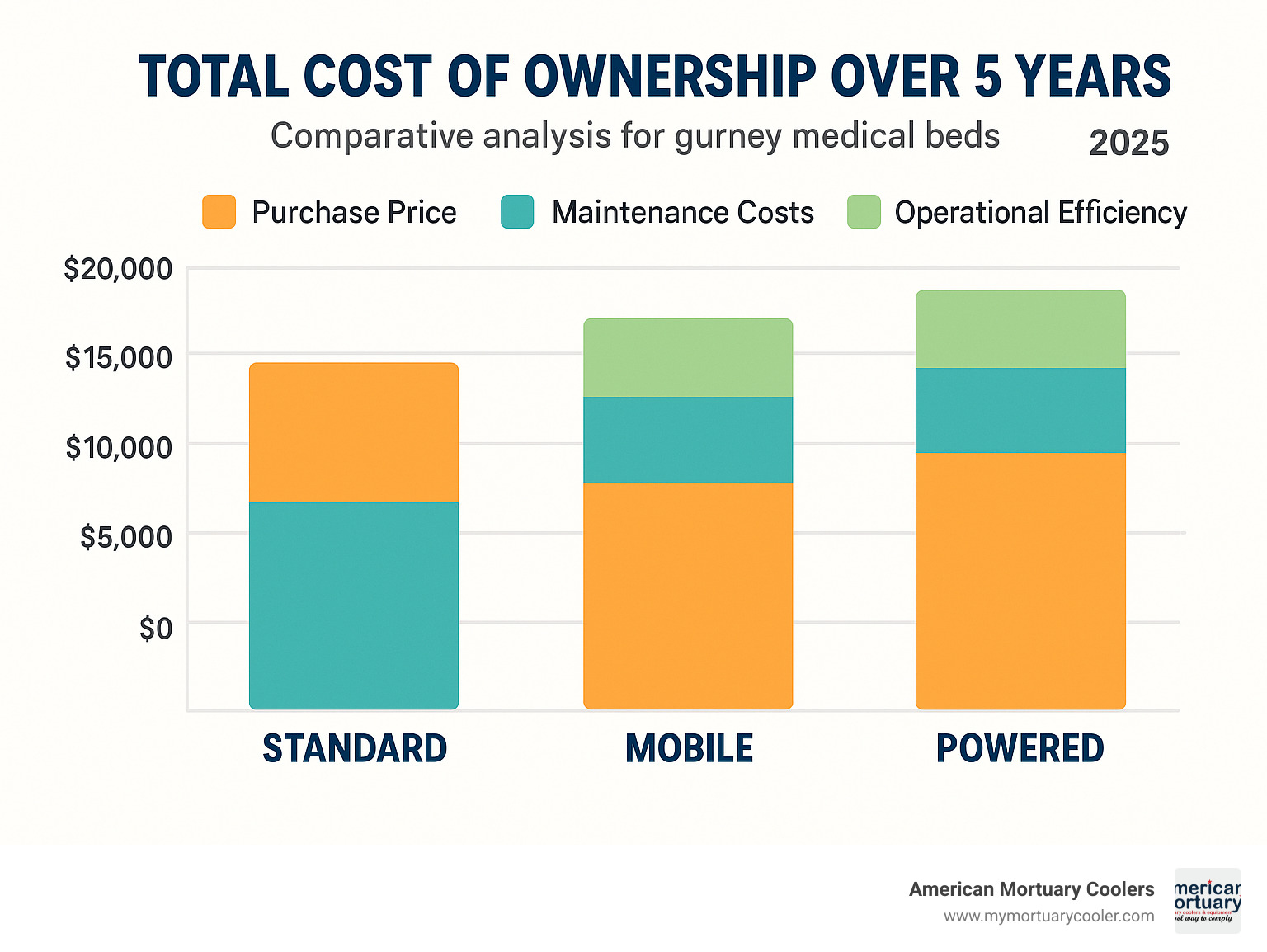

Budget Planning

Pricing varies significantly based on features and capacity. Basic manual models start around $700-$1,500, while standard powered units range from $2,000-$5,000. Bariatric models typically cost $3,000-$8,000, and specialized units can reach $5,000-$12,000 or more.

Many suppliers offer financing programs, particularly for higher-priced models. Leasing makes sense for facilities with limited capital budgets or those wanting to upgrade regularly as technology advances.

More info about finding medical stretchers

Maintenance That Actually Works

Proper maintenance isn't just about following a checklist – it's about keeping your equipment safe and extending its useful life. We recommend a simple three-tier approach.

Daily attention should focus on the basics: test the brakes, check casters for debris, verify safety rails work properly, and confirm battery charge on powered models. These quick checks prevent most problems before they start.

Weekly maintenance involves deeper cleaning with EPA-approved disinfectants, lubricating moving parts, inspecting restraint points, and testing height adjustment mechanisms. Many modern models feature removable, washable components that make thorough sanitization much easier.

Monthly professional service should include brake adjustments, caster replacement when needed, and battery maintenance for powered units. This level of care might seem excessive, but it prevents costly breakdowns and ensures patient safety.

Cleaning Protocols

The increased focus on infection control makes proper cleaning protocols more important than ever. Use only EPA-approved disinfectants designed for medical equipment. Remove all washable components regularly for thorough sanitization – this practice has become standard across the industry.

Scientific research on transport guidelines provides valuable insights into proper equipment maintenance and safety protocols that healthcare facilities should follow.

The right gurnee medical bed represents an investment in both patient care and staff safety. Take time to evaluate your specific needs, and don't hesitate to ask suppliers for demonstrations or trial periods. The few extra days spent on proper selection will pay dividends for years to come.

Frequently Asked Questions about Gurnee Medical Beds

When facilities contact us about gurnee medical bed selection, three questions come up consistently. Let me share what we've learned from years of helping healthcare facilities make the right choices.

What weight capacity should I choose?

Choosing the right weight capacity isn't just about safety—it's about making a smart long-term investment for your facility.

350-lb standard models work well for pediatric facilities and outpatient clinics where you're primarily serving smaller patients. However, we've found that many facilities quickly outgrow these lighter-duty units. Operating near maximum capacity shortens service life and increases your maintenance headaches down the road.

600-lb bariatric models have become our most popular recommendation for general hospital use. Here's why: they handle the vast majority of adult patients while giving you that crucial safety margin for medical equipment, blankets, and accessories. Plus, they're built more robustly, which means fewer repairs over time.

1000-lb heavy-duty units are essential if you're running specialized bariatric care, mortuary services, or serving populations with higher average weights. The Rescue Essentials Quiklitter XL we mentioned earlier shows just how capable these ultra-high-capacity models can be.

One facility manager told us: "We thought we'd save money with the 350-lb models, but we ended up replacing them within two years. The 600-lb units we bought next are still going strong after five years."

How do I keep a gurnee sanitary?

Keeping your gurnee medical bed properly sanitized doesn't have to be complicated, but it does need to be consistent.

EPA-approved disinfectants are your first line of defense. Use hospital-grade solutions that tackle bacteria, viruses, and fungi. The key is following the manufacturer's contact time requirements—don't rush the process.

Modern units make your life easier with removable components. Take advantage of mattress pads, side rail covers, and other parts that pop off for thorough cleaning. This is especially important in mortuary applications where complete decontamination is non-negotiable.

Your daily routine should be straightforward: remove accessories, wipe down the frame with disinfectant, clean those casters (they pick up everything from the floor), sanitize all touch surfaces, and let everything dry properly.

Weekly brake checks deserve special attention. Clean debris from brake mechanisms and verify they're engaging properly. We've seen too many close calls from neglected brake systems. A few minutes of weekly maintenance prevents major safety issues.

For deep cleaning, disassemble what you can, inspect for fluid buildup in crevices, and replace disposable components regularly. Your patients and staff will notice the difference.

Are there motorized gurnee medical beds for self-propelled movement?

Yes, motorized gurnee medical bed options exist, though they're not as common as manual models—and for good reason.

Battery-powered drive systems can reduce caregiver strain significantly. These units typically run 8-12 hours on a charge, which covers most shift requirements. Some include 5th-wheel steering assistance that makes navigating tight hospital corridors much easier.

Hybrid stretcher-chairs represent the most versatile option. They function as transport stretchers and treatment chairs, often with powered positioning features. The MS3C-100S Lightweight Automatic Loading Ambulance Stretcher we discussed earlier shows how sophisticated these systems have become.

But here's the reality check: motorized units cost significantly more ($5,000-$15,000+), require regular battery maintenance, and add complexity that many facilities don't actually need. They're also heavier, which can offset some of the ergonomic benefits.

Most facilities we work with find that well-designed manual models meet their needs effectively while keeping costs and maintenance requirements manageable. However, if you're running high-volume operations or have specialized applications, powered assistance might justify the investment.

The key is honestly evaluating your actual needs versus the marketing appeal of powered features. Sometimes the simpler solution is the smarter choice.

Conclusion

The gurnee medical bed market continues evolving with future-proof designs that emphasize safety, efficiency, and regulatory compliance. Modern units incorporate advanced materials, improved ergonomics, and improved safety features that benefit both patients and caregivers.

The industry is experiencing significant changes driven by new safety standards. Regulatory compliance requirements like IEC 60601-2-52 are pushing manufacturers to improve bed rail design and patient safety features. The Invacare G-Series beds mentioned in our research represent this new generation of compliant equipment that meets these stricter standards.

Material innovation is another key trend shaping the future. Advanced aluminum alloys and corrosion-resistant coatings extend equipment life while reducing maintenance requirements. This means lower total ownership costs for facilities willing to invest in quality equipment upfront.

Healthcare facilities are also placing greater emphasis on ergonomic focus. The recognition that caregiver injuries cost healthcare facilities millions annually is driving better handle design, height adjustment ranges, and mobility features. This isn't just about worker comfort—it's about reducing liability and improving staff retention.

Infection control remains a top priority, especially following recent global health challenges. Improved cleaning capabilities and antimicrobial surfaces address ongoing concerns about healthcare-associated infections. Many newer models feature completely removable components that can be thoroughly sanitized or replaced as needed.

When selecting a gurnee medical bed, consider your facility's specific needs, patient population, and long-term operational goals. The right equipment choice balances initial cost with total ownership expenses, including maintenance, training, and operational efficiency.

At American Mortuary Coolers, we understand that each facility has unique requirements. Our experience across Tennessee, Atlanta, Chicago, and other regions has shown us that successful equipment selection requires careful analysis of your specific operational needs. Whether you need standard transport units or specialized mortuary equipment, we provide custom solutions with direct delivery across the contiguous 48 states.

The investment in quality gurnee medical beds pays dividends through improved patient safety, reduced caregiver injuries, and improved operational efficiency. As the healthcare industry continues evolving, these essential transport tools will remain critical components of effective patient care.

More info about ambulance stretchers and gurneys

For facilities seeking reliable, durable transport solutions, we recommend focusing on proven manufacturers, appropriate weight capacity, and comprehensive service support. The right gurnee medical bed becomes an invaluable tool that serves your facility and patients for many years to come.

Working with a single-source supplier simplifies procurement, service, and warranty issues. This approach ensures consistency across your equipment fleet and streamlines staff training requirements.